Method for performing surface modification on polytetrafluoroethylene separation membrane

A polytetrafluoroethylene and surface modification technology, used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of poor hydrophilicity of PTFE separation membrane, easy pollution of modification process, and low flux. , to improve the anti-pollution ability, the method is simple and practical, and the retention rate is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: respectively adopt trimethyl aluminum (TMA), deionized water (H 2 O) as the precursor, high-purity nitrogen (N 2 ) as carrier and sweep gas. The pulse time of both precursors is 0.015s, the precursor exposure time is 10s, the cleaning time is 20s, and the carrier gas flow rate is 10sccm. Heat the temperature of the reaction chamber to 180°C, keep the membrane at the set temperature of the reaction chamber for 20 minutes, and prepare modified membranes with 10, 20, 50, 100, 200, 300, and 500 cycles respectively.

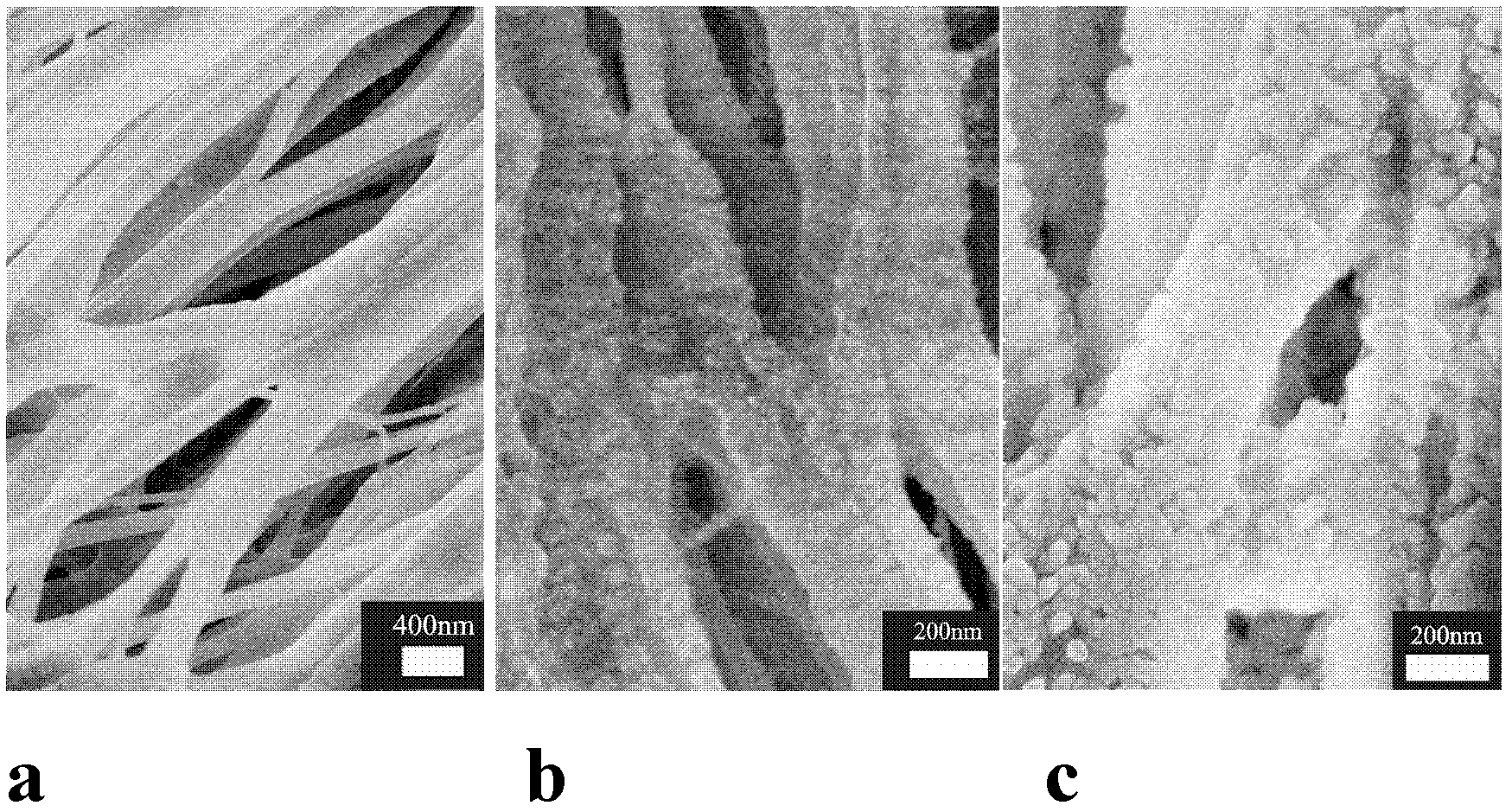

[0028] Depend on figure 1 It can be seen that with the increase of the deposition times, the alumina particles in the membrane pores and on the surface gradually become larger, and the pore diameter of the membrane gradually decreases regularly, realizing the continuous adjustment of the pore diameter.

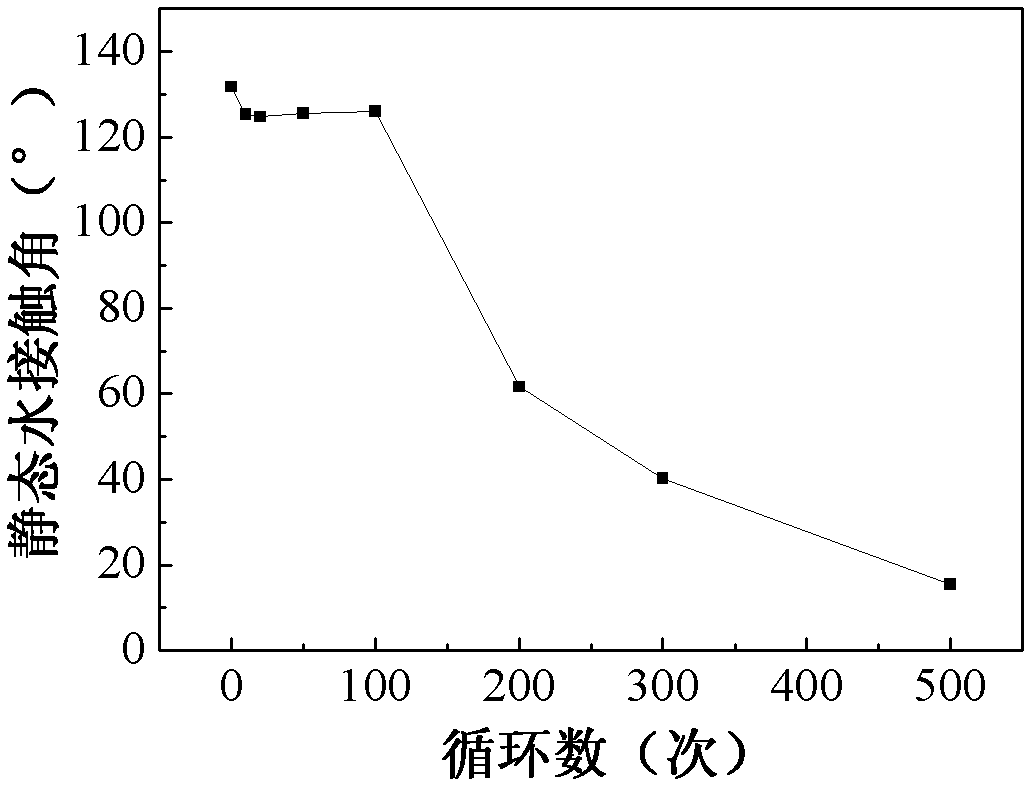

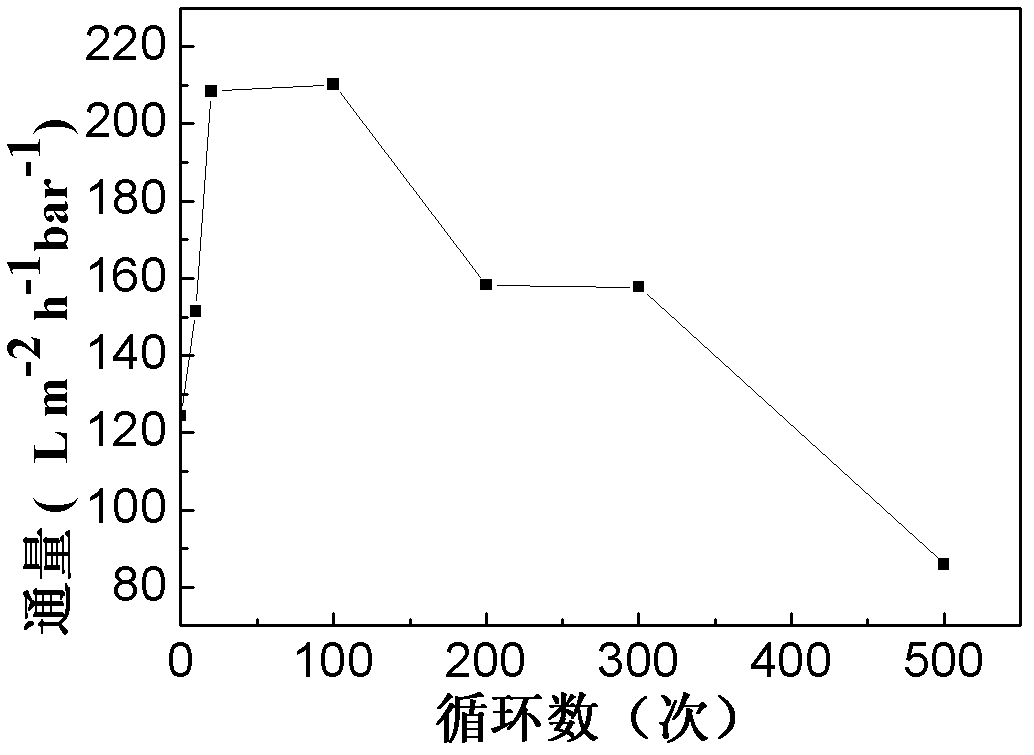

[0029] Depend on figure 2 It can be seen that from 10 cycles to 100 cycles, the contact angle does not change much and is basically about 13...

Embodiment 2

[0032] Embodiment 2: respectively adopt titanium tetrachloride (TiCl 4 ), deionized water (H 2 O) is the precursor, and high-purity argon (Ar) is used as the carrier gas and sweep gas. TiCl 4 The pulse time is 0.3s, H 2 The O pulse time is 0.015s, the precursor exposure time is 0s, the cleaning time is 5s, and the carrier gas flow rate is 20 sccm. Heat the temperature of the reaction chamber to 150°C, keep the membrane at the set temperature of the reaction chamber for 50 minutes, and prepare modified membranes with 200, 400, 800, 850, 900, 950, 1000, and 1300 cycles respectively.

[0033] Depend on Figure 5 It can be seen that the deposition of TiO on the PTFE film 2After that, the hydrophilicity changed significantly. From 0 cycles to 400 cycles, the contact angle does not change much, basically between 130° and 120°; when the deposition reaches 800 times, the contact angle becomes smaller to 112°; then as the deposition progresses, the contact angle changes Suddenly...

Embodiment 3

[0036] Embodiment 3: respectively adopt trimethyl aluminum (TMA), deionized water (H 2 O) as the precursor, high-purity nitrogen (N 2 ) as carrier and sweep gas. TMA pulse time is 0.5s, H 2 The O pulse time is 0.8s, the precursor exposure time is 50s, the cleaning time is 60s, and the carrier gas flow rate is 10sccm. Heat the temperature of the reaction chamber to 70°C, keep the membrane at the set temperature of the reaction chamber for 20 minutes, and prepare modified membranes with 50, 100, 150, and 200 cycles respectively.

[0037] The surface-modified membranes in this example were observed and analyzed by scanning electron microscopy. The membrane pore size decreased with the increase of deposition times, and the hydrophilic angles changed from the original 131° to 125.1°, 120.2°, 63.5°, and 30.4° respectively. °, the tested pure water flux increased by 15.0%, 81.8%, 69.6%, and 57.6% respectively, and the rejection rate of monodisperse PS microspheres (average particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com