Scraping-resistant polypropylene combination with good appearance and manufacturing method and application thereof

A polypropylene composition and scratch-resistant technology, applied in the field of polymer modification, can solve problems such as scratches and scratches on injection molded parts, achieve good surface effect, good application prospects, and improve flow marks and tiger skin problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

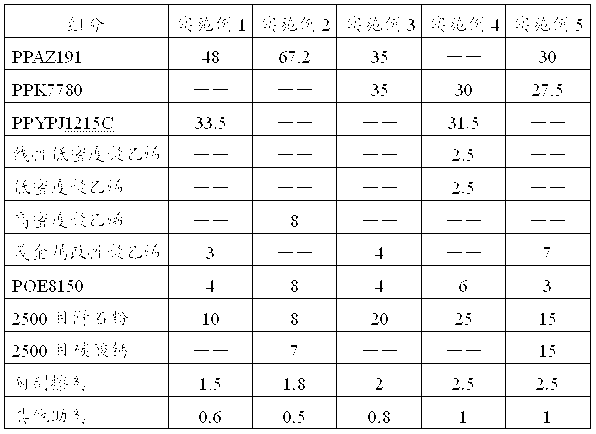

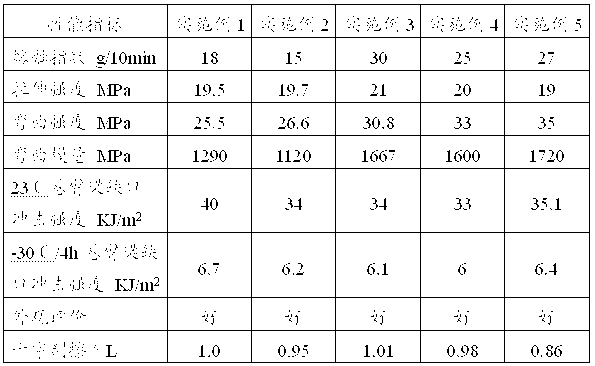

Embodiment 1

[0028] (1) Add 10 parts by weight of talc powder of 2500 mesh, 0.1 parts by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168, 0.2 parts by weight of UV531, and 0.2 parts by weight of calcium stearate into a high-speed mixer for pre-mixing for 3 minutes , then 48 parts by weight of copolymerized polypropylene PPZA191, 33.5 parts by weight of copolymerized polypropylene PPYPJ1215C, 3 parts by weight of metallocene modified polyethylene, 4 parts by weight of toughening agent ethylene-octene copolymer POE8150, 1.5 parts by weight of vinyl-terminated Linear reactive siloxane anti-scratch agent, added to a high-speed mixer and mixed for 3 minutes;

[0029] (2) Then put this mixture into the lower hopper of the extruder, extrude and granulate. ); obtaining a scratch-resistant polypropylene composition with good appearance.

[0030] The scratch-resistant polypropylene composition with good appearance in this embodiment can be successfully applied to automobile parts ...

Embodiment 2

[0032] (1) Add 8 parts by weight of 2500 mesh talcum powder, 7 parts by weight of calcium carbonate of 2500 mesh, 0.1 part by weight of antioxidant 1010, 0.1 part by weight of antioxidant 168, 0.1 part by weight of UV531, and 0.2 parts by weight of liquid paraffin, and mix them at high speed Pre-mixed in the machine for 3 minutes, then 67.2 parts by weight of copolymerized polypropylene PPZA191, 8 parts by weight of high-density polyethylene, 8 parts by weight of toughening agent ethylene-octene copolymer POE8150, 1.8 parts by weight of ultra-high molecular weight silicone polymer resistant Scraping agent, add to the high-speed mixer and mix for 3 minutes;

[0033] (2) Then put this mixture into the lower hopper of the extruder, extrude and granulate. ); obtaining a scratch-resistant polypropylene composition with good appearance.

Embodiment 3

[0035] (1) Add 20 parts by weight of 2500 mesh talcum powder, 0.1 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant 168, 0.2 parts by weight of UV531, and 0.3 parts by weight of calcium stearate into a high-speed mixer for pre-mixing for 3 minutes , then 35 parts by weight of copolymerized polypropylene PPZA191, 35 parts by weight of copolymerized polypropylene PPK7780, 4 parts by weight of metallocene modified polyethylene, 4 parts by weight of toughening agent ethylene-octene copolymer POE8150, 2 parts by weight of organic modified silicon Ketone anti-scratch agent, add to high-speed mixer and mix for 3 minutes;

[0036] (2) Then put this mixture into the lower hopper of the extruder, extrude and granulate. ); obtaining a scratch-resistant polypropylene composition with good appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com