CoS graded nano-bubble composite sulfur positive electrode material of lithium sulfur battery and preparation method of positive electrode material

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, nanotechnology, etc., can solve the problems of low sulfur utilization rate of lithium-sulfur batteries, obstacles to popularization and application, short cycle life, etc., to achieve large commercial application prospects, The effect of no pollution to the environment and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

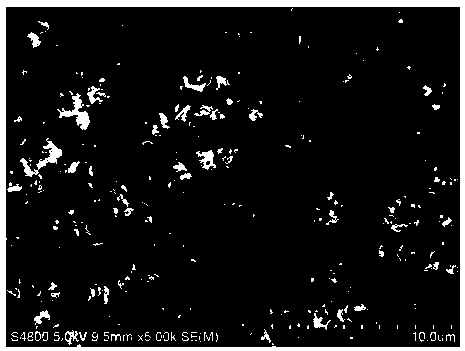

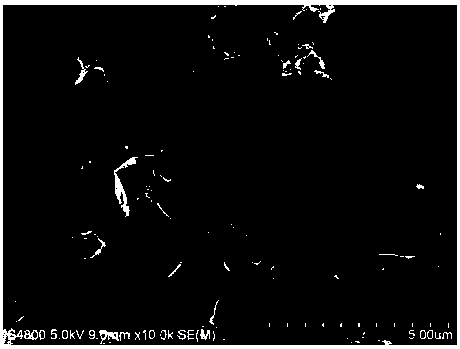

Image

Examples

Embodiment 1

[0029] Synthetic TiO 2 @ Hexadecylamine composite nanoparticles: ultrasonically disperse 0.1 g of hexadecylamine in 10 mL of absolute ethanol, then add 0.2 mL of ammonia water under stirring, continue stirring for 5 min, then add 0.1 mL of titanium under vigorous stirring Acetate isopropyl ester (TIP), centrifuged after stirring for 10 min, washed 3 times with absolute ethanol.

[0030] TiO with jujube cake structure 2 Composite nanoparticles embedded with ZIF-67: Dissolve 0.5 g PVP in 10 mL absolute ethanol, and then clean TiO 2 @ Hexadecylamine composite nanoparticles were dispersed in the PVP ethanol solution, stirred at room temperature for 24 h, washed with absolute ethanol for 3 times, and then dispersed in 2.5 mL of methanol solution again. Take 1.3 mL of TiO2 Add the methanol solution of @hexadecylamine dropwise into the methanol solution of cobalt nitrate with a volume of 50 mL and a concentration of 20 mM, stir for 3 min, then quickly add a methanol solution of 80 ...

Embodiment 2

[0041] Synthetic TiO 2 Nanoparticles: Add 0.2 mL of ammonia water to 10 mL of absolute ethanol, stir for 5 min, then add 0.1 mL of isopropyl titanate (TIP) under vigorous stirring, centrifuge after stirring for 10 min, wash with absolute ethanol for 3 Second-rate.

[0042] TiO with jujube cake structure 2 Composite nanoparticles embedded with ZIF-67: Dissolve 0.5 g PVP in 10 mL absolute ethanol, and then clean TiO 2 @ Hexadecylamine composite nanoparticles were dispersed in the PVP ethanol solution, stirred at room temperature for 24 h, washed with absolute ethanol for 3 times, and then dispersed in 2.5 mL of methanol solution. Take 0.5 mL of TiO 2 The methanol solution was dropped into the methanol solution of cobalt nitrate with a volume of 50 mL and a concentration of 20 mM. After stirring for 3 min, a methanol solution of 2-methylimidazole with a volume of 80 mL and a concentration of 80 mM was quickly added, and after stirring for 3 min, After standing for 12 h, the p...

Embodiment 3

[0048] Synthetic TiO 2 Nanoparticles: Add 0.2 mL of ammonia water to 10 mL of absolute ethanol, stir for 5 min, then add 0.1 mL of isopropyl titanate (TIP) under vigorous stirring, centrifuge after stirring for 10 min, wash with absolute ethanol for 3 Second-rate.

[0049] TiO with jujube cake structure 2 Composite nanoparticles embedded with ZIF-67: Dissolve 0.5 g PVP in 10 mL absolute ethanol, and then clean TiO 2 @ Hexadecylamine composite nanoparticles were dispersed in the PVP ethanol solution, stirred at room temperature for 24 h, washed with absolute ethanol for 3 times, and then dispersed in 2.5 mL of methanol solution. Take 1.3 mL of TiO 2 The methanol solution was dropped into the methanol solution of cobalt nitrate with a volume of 50 mL and a concentration of 10 mM. After stirring for 3 min, a methanol solution of 2-methylimidazole with a volume of 80 mL and a concentration of 40 mM was quickly added. After stirring for 3 min, After standing for 12 h, the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com