Preparation method of mixed-phase titanium dioxide visible-light-induced photocatalyst derived from MOF

A titanium dioxide, visible light technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, physical/chemical process catalyst, etc., can solve the problems of limited application, visible light electron hole excitation, etc., achieve good photocatalytic degradation activity, and simple preparation method The effect of easy operation and easy preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

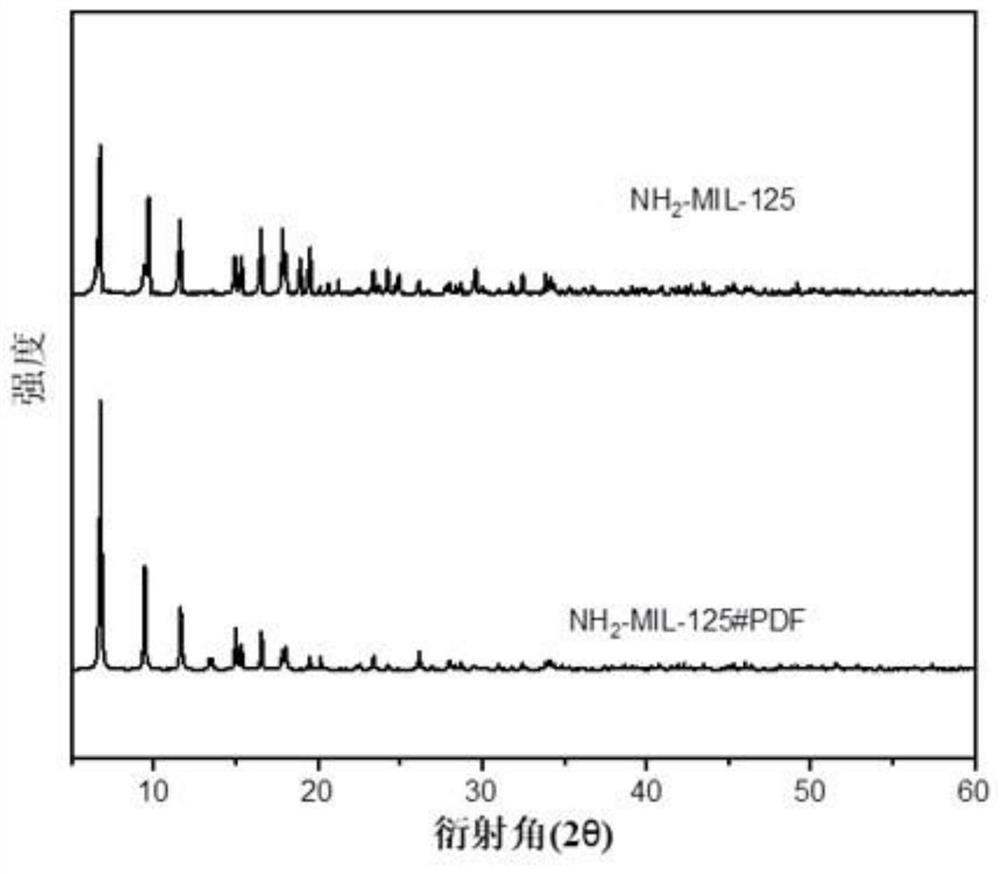

[0026] (1) NH 2 -Preparation of MIL-125: 1.2681g of 2-aminoterephthalic acid, 1.0618ml of titanium isopropoxide were dissolved in a mixed solvent of 50ml of DMF (N-N dimethylformamide) and 50ml of anhydrous methanol, and the mixture was stirred for 30 minutes to obtain a homogeneous mixture. The mixture was transferred to a polytetrafluoroethylene stainless steel autoclave and kept at 150 °C for 48 h. After the mixture was cooled to room temperature, the yellow NH 2 - MIL-125, rinsed several times with anhydrous methanol and DMF, dried overnight in an oven at 60°C for 12 hours.

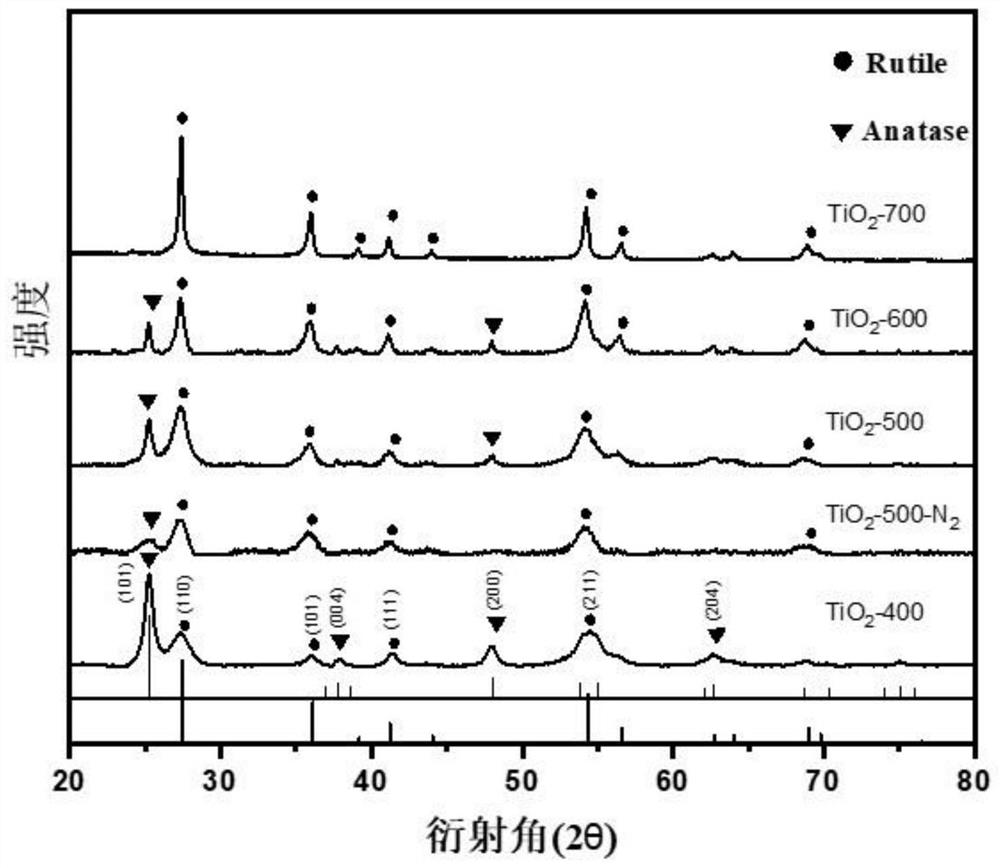

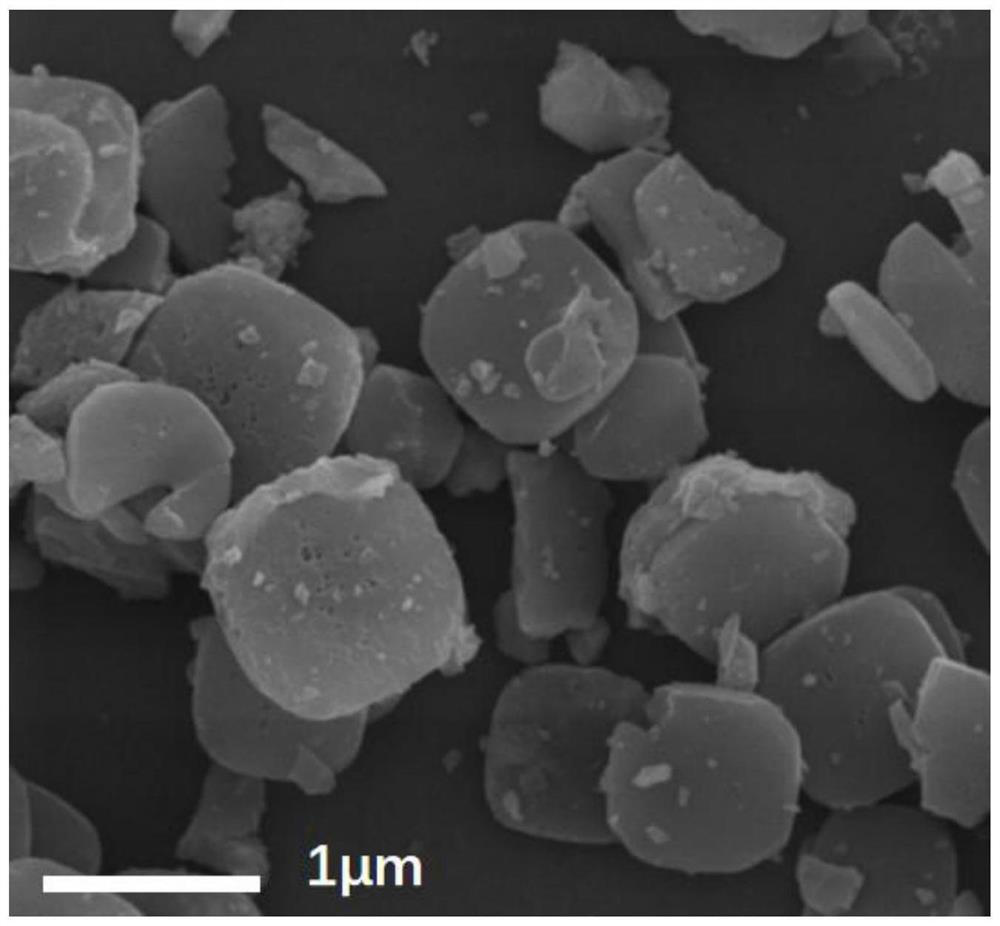

[0027] (2) Mixed phase TiO 2 Preparation: the prepared NH 2 -Weigh 0.5g of MIL-125 into a small porcelain boat, place it in a tube furnace, set the heating rate at 1°C / min, and calcinate at 500°C for 4h under the protection of nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com