Method for preparing bismuth oxyhalide nanosheets by electrochemical method

A nanosheet, electrochemical technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of poor sample dispersion, troublesome control of template method conditions, uneven size, etc., to achieve crystallization Good performance, good photocatalytic degradation activity, and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 50mL of 0.5mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaI solution;

[0039] (2) Take the size as 5mm 3 1. The metal Bi block with a purity of 99.99% is used as the cathode, and the Pt sheet electrode is used as the anode. The DC regulated power supply provides a voltage of 20V, and the cathode electrolytic cell is magnetically stirred under the electrified condition;

[0040] (3) After energizing for 5 hours, centrifuge the solution in the cathode electrolytic cell at 7500r for 5 minutes, wash the obtained precipitate with ultrapure water for 5 times, collect the product and dry it in an electric blast drying oven at 80°C for 4 hours to obtain Bi 5 o 7 I nanosheets.

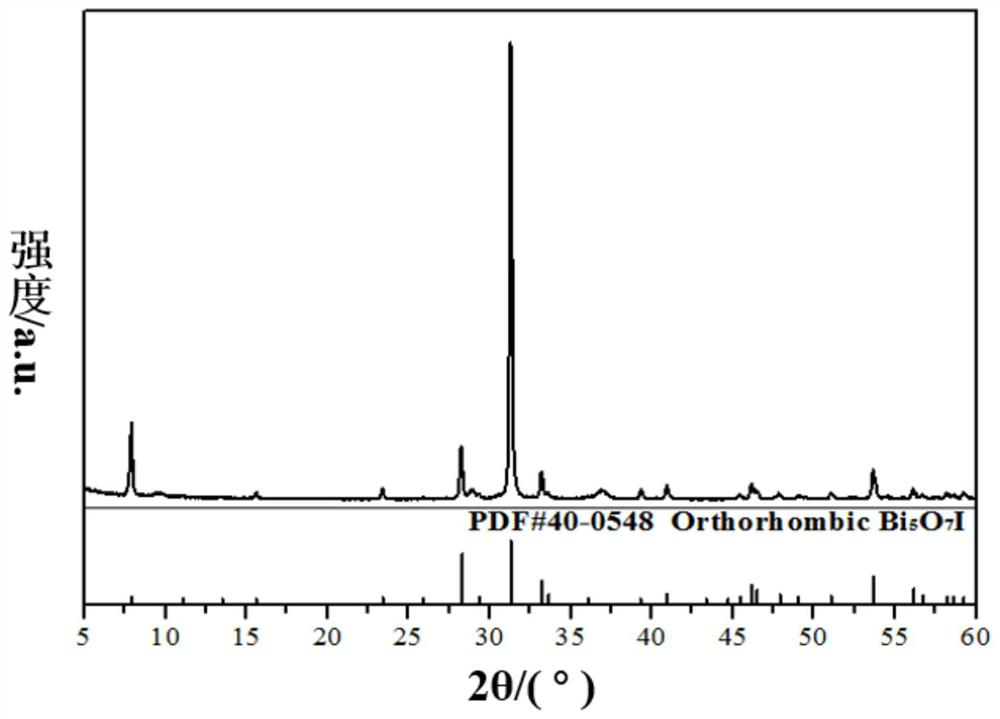

[0041] To the Bi prepared in this embodiment 5 o 7 I nanosheets were tested by XRD, figure 1 For the XRD spectrum of the bismuth oxyiodide nanocrystals prepared in this example, it is proved that the prepared product is an orthorhombic phase Bi 5 o ...

Embodiment 2

[0044] (1) Add 50mL of 0.5mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaCl solution;

[0045] (2) Take the size as 5mm 3 1. The metal Bi block with a purity of 99.99% is used as the cathode, the Pt sheet electrode is used as the anode, and the DC regulated power supply provides a voltage of 15V. During the electrification process, the cathode electrolytic cell needs to be magnetically stirred;

[0046] (3) After energizing for 5 hours, the solution in the cathode electrolytic cell was centrifuged at 7500r for 5 minutes, the obtained precipitate was washed 4 times with ultrapure water, and the collected product was dried in an electric blast drying oven at 60°C for 6 hours to obtain Bi 4 o 5 Cl 2 Nanosheets.

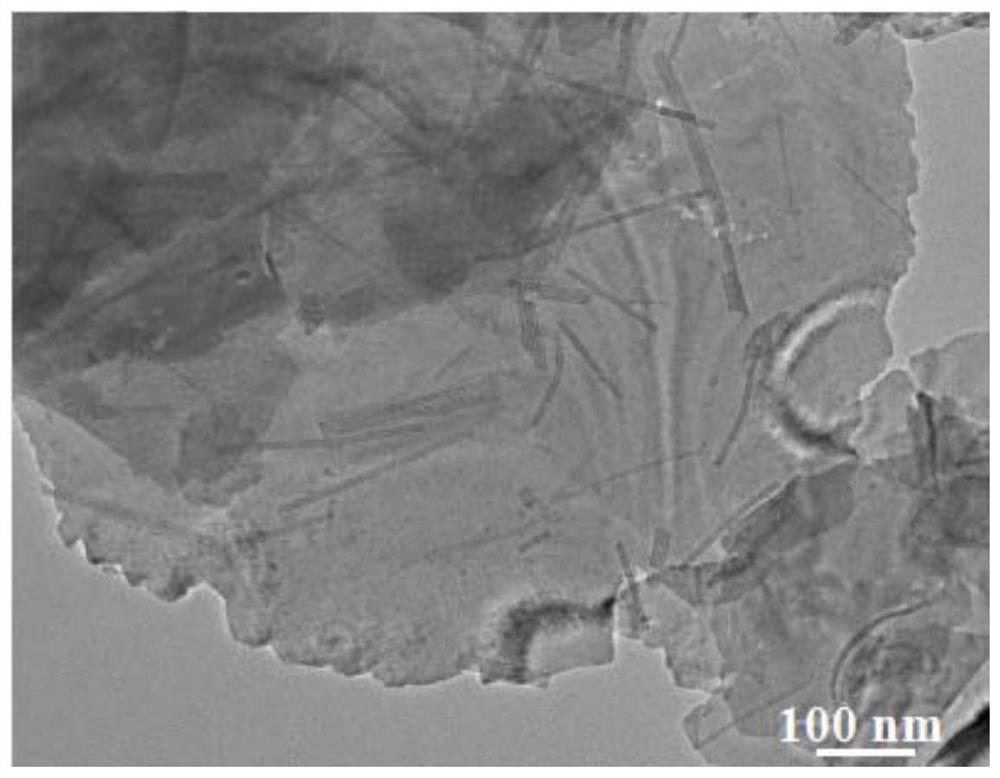

[0047] To the Bi prepared in this embodiment 4 o 5 Cl 2 Nanosheets take transmission electron microscope pictures, image 3 Bi prepared for this embodiment 4 o 5 Cl 2 The TEM photo of the nanosheets was taken at 40,000 t...

Embodiment 3

[0049] (1) Add 50mL of 0.7mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaBr solution;

[0050] (2) Take the size as 5mm 3 1. The metal Bi block with a purity of 99.99% is used as the cathode, and the Pt sheet electrode is used as the anode. The DC regulated power supply provides a voltage of 20V, and the cathode electrolytic cell is magnetically stirred under the electrified condition;

[0051] (3) After 4 hours of electrification, the solution in the cathode electrolytic cell was centrifuged at 7500r for 5 minutes, the obtained precipitate was washed 5 times with ultrapure water, and the collected product was dried in an electric blast drying oven at 70°C for 5 hours to obtain Bi 4 o 5 Br 2 Nanosheets.

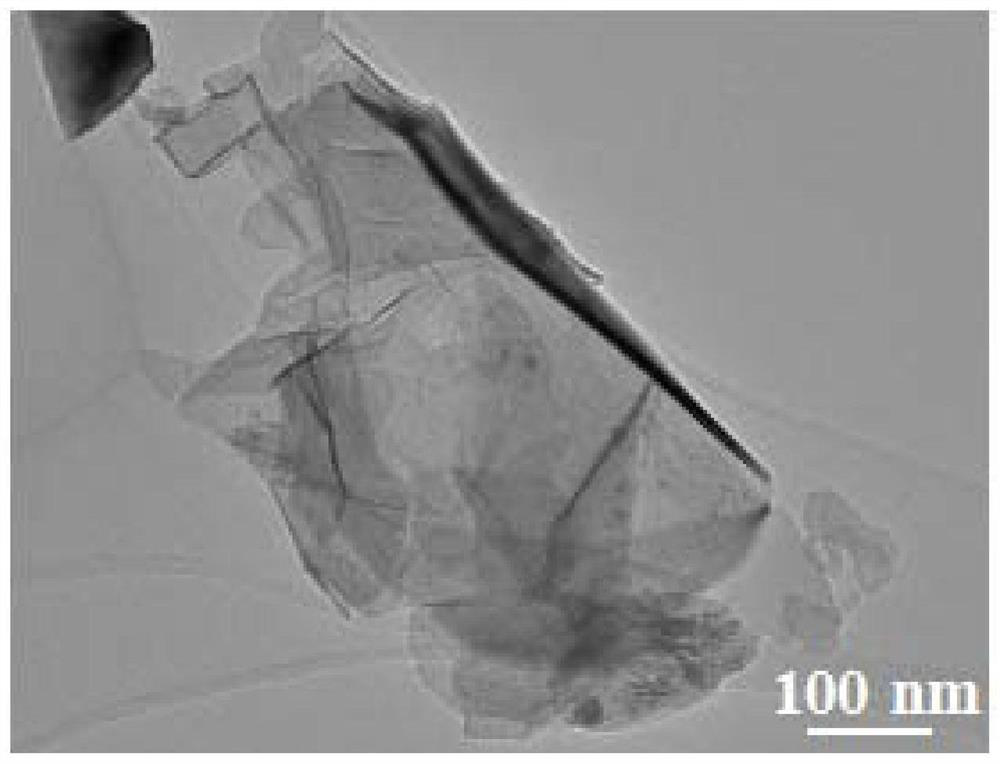

[0052] To the Bi prepared in this embodiment 4 o 5 Br 2 Nanosheets take transmission electron microscope pictures, Figure 4 Bi prepared for this embodiment 4 o 5 Br 2 The TEM photo of the nanosheets was taken at a magnificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com