A method for preparing bismuth oxyhalide nanosheets by electrochemical method

A nanosheet, electrochemical technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of template method condition control, uneven size, poor sample dispersion, etc., to achieve good Photocatalytic degradation activity, good crystallinity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 50mL of 0.5mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaI solution;

[0039] (2) Take the size as 5mm 3 1. The metal Bi block with a purity of 99.99% is used as the cathode, and the Pt sheet electrode is used as the anode. The DC regulated power supply provides a voltage of 20V, and the cathode electrolytic cell is magnetically stirred under the electrified condition;

[0040] (3) After energizing for 5 hours, centrifuge the solution in the cathode electrolytic cell at 7500r for 5 minutes, wash the obtained precipitate with ultrapure water for 5 times, collect the product and dry it in an electric blast drying oven at 80°C for 4 hours to obtain Bi 5 o 7 I nanosheets.

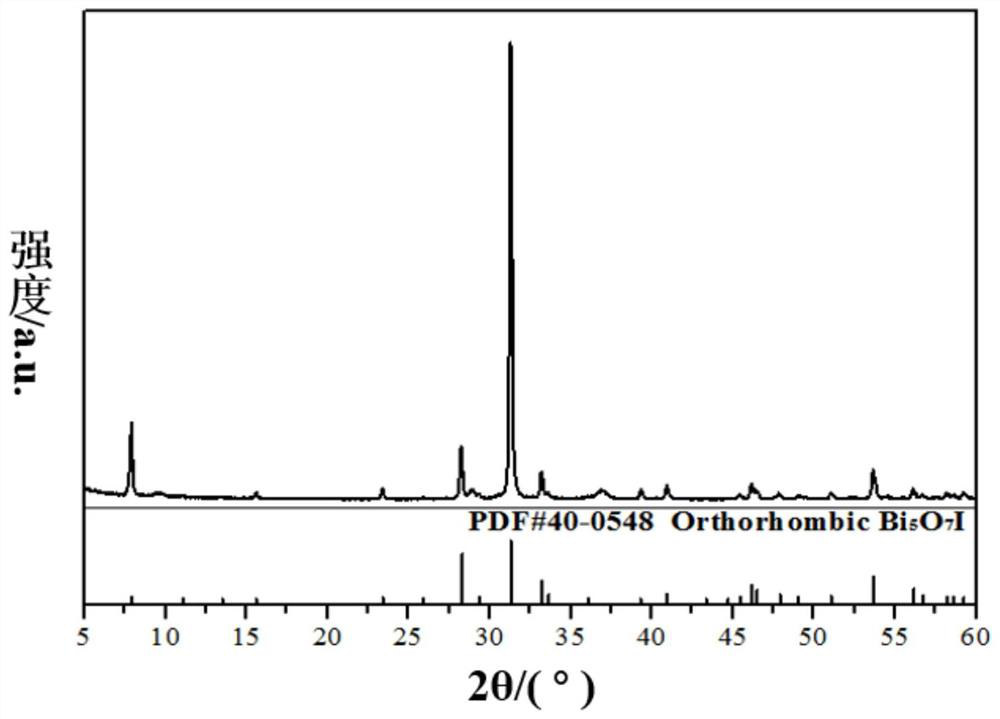

[0041] To the Bi prepared in this embodiment 5 o 7 I nanosheets were tested by XRD, figure 1 For the XRD spectrum of the bismuth oxyiodide nanocrystals prepared in this example, it is proved that the prepared product is an orthorhombic phase Bi 5 o ...

Embodiment 2

[0044] (1) Add 50mL of 0.5mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaCl solution;

[0045] (2) Take the size as 5mm 3 1. The metal Bi block with a purity of 99.99% is used as the cathode, the Pt sheet electrode is used as the anode, and the DC regulated power supply provides a voltage of 15V. During the electrification process, the cathode electrolytic cell needs to be magnetically stirred;

[0046] (3) After energizing for 5 hours, the solution in the cathode electrolytic cell was centrifuged at 7500r for 5 minutes, the obtained precipitate was washed 4 times with ultrapure water, and the collected product was dried in an electric blast drying oven at 60°C for 6 hours to obtain Bi 4 o 5 Cl 2 Nanosheets.

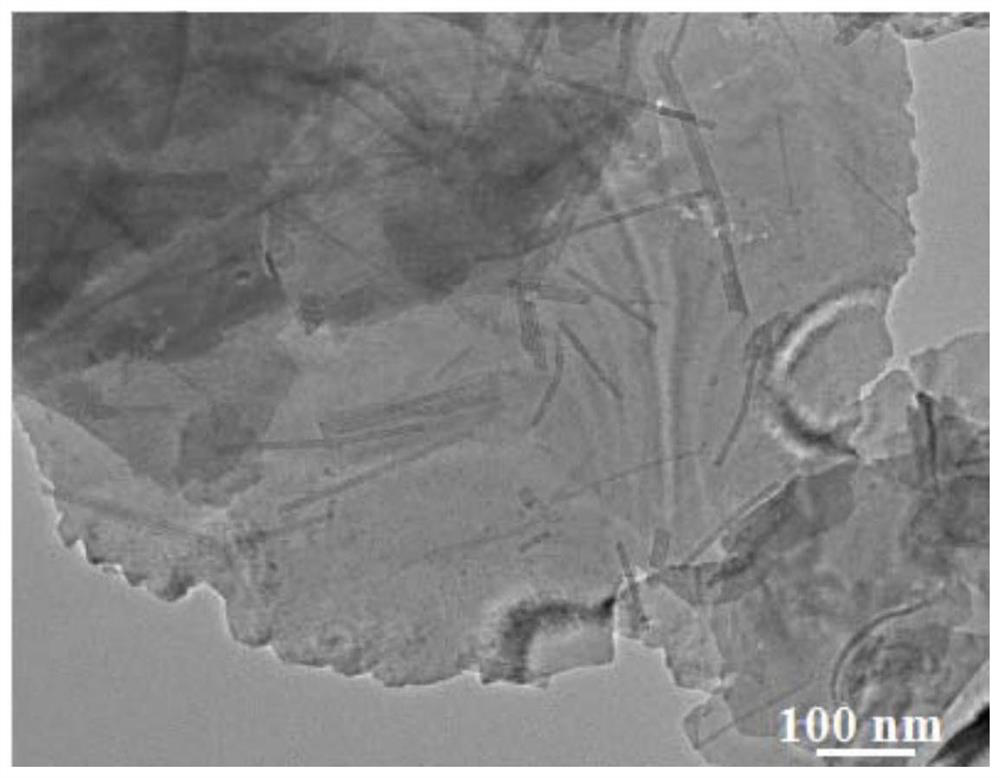

[0047] To the Bi prepared in this embodiment 4 o 5 Cl 2 Nanosheets take transmission electron microscope pictures, image 3 Bi prepared for this embodiment 4 o 5 Cl 2 The TEM photo of the nanosheets was taken at 40,000 t...

Embodiment 3

[0049] (1) Add 50mL of 0.7mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaBr solution;

[0050] (2) Take the size as 5mm 3 1. The metal Bi block with a purity of 99.99% is used as the cathode, and the Pt sheet electrode is used as the anode. The DC regulated power supply provides a voltage of 20V, and the cathode electrolytic cell is magnetically stirred under the electrified condition;

[0051] (3) After 4 hours of electrification, the solution in the cathode electrolytic cell was centrifuged at 7500r for 5 minutes, the obtained precipitate was washed 5 times with ultrapure water, and the collected product was dried in an electric blast drying oven at 70°C for 5 hours to obtain Bi 4 o 5 Br 2 Nanosheets.

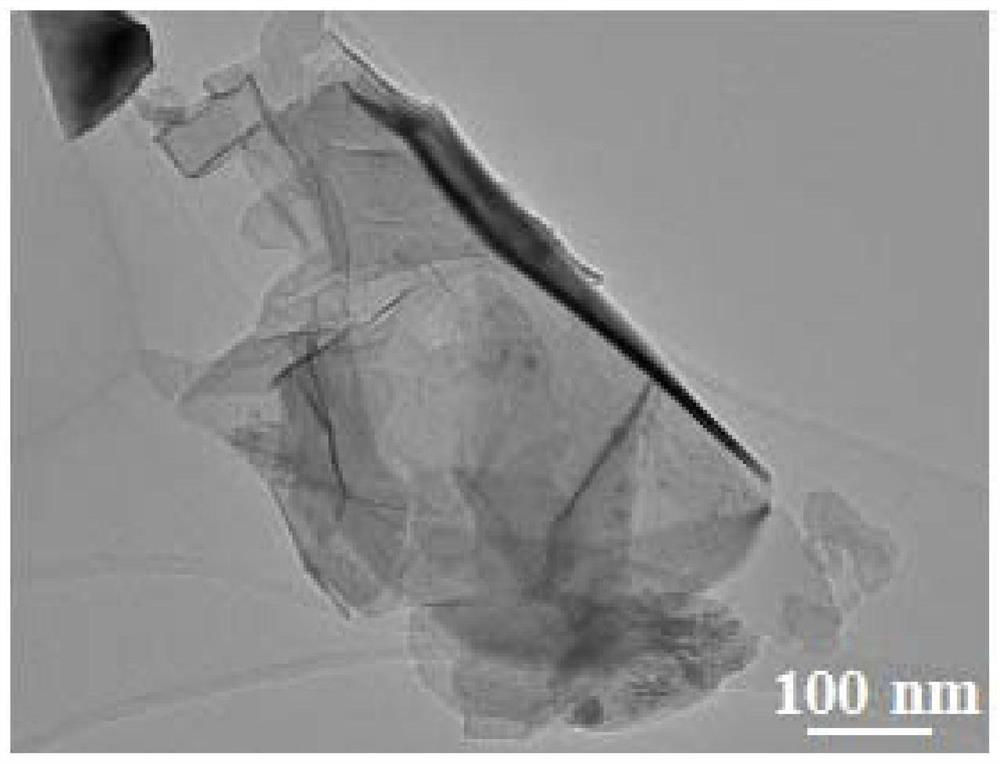

[0052] To the Bi prepared in this embodiment 4 o 5 Br 2 Nanosheets take transmission electron microscope pictures, Figure 4 Bi prepared for this embodiment 4 o 5 Br 2 The TEM photo of the nanosheets was taken at a magnificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com