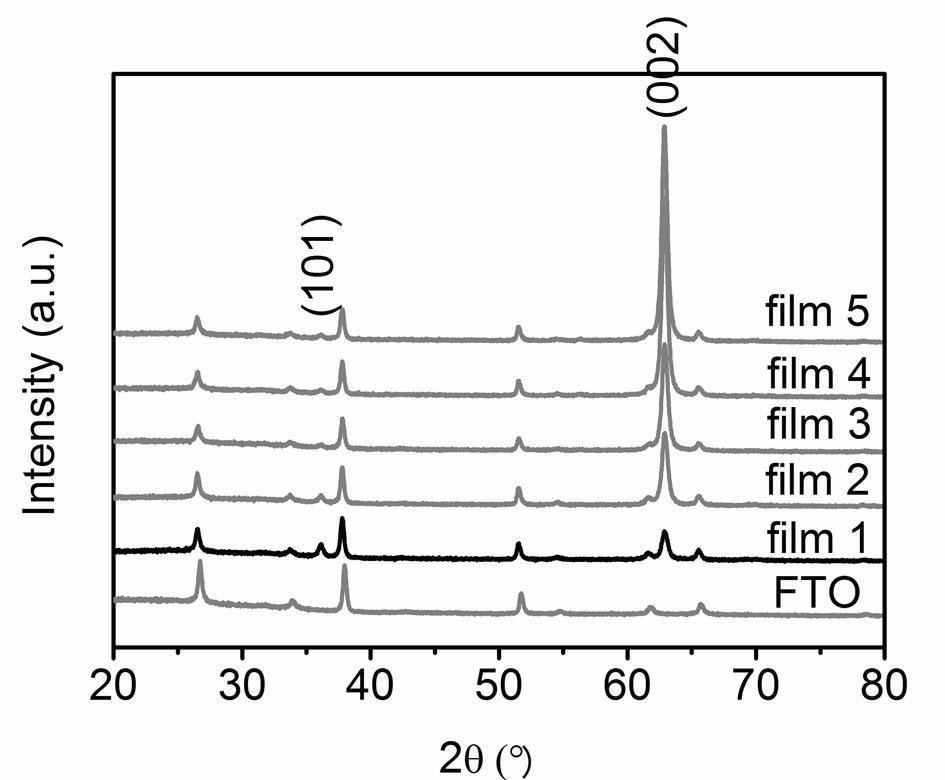

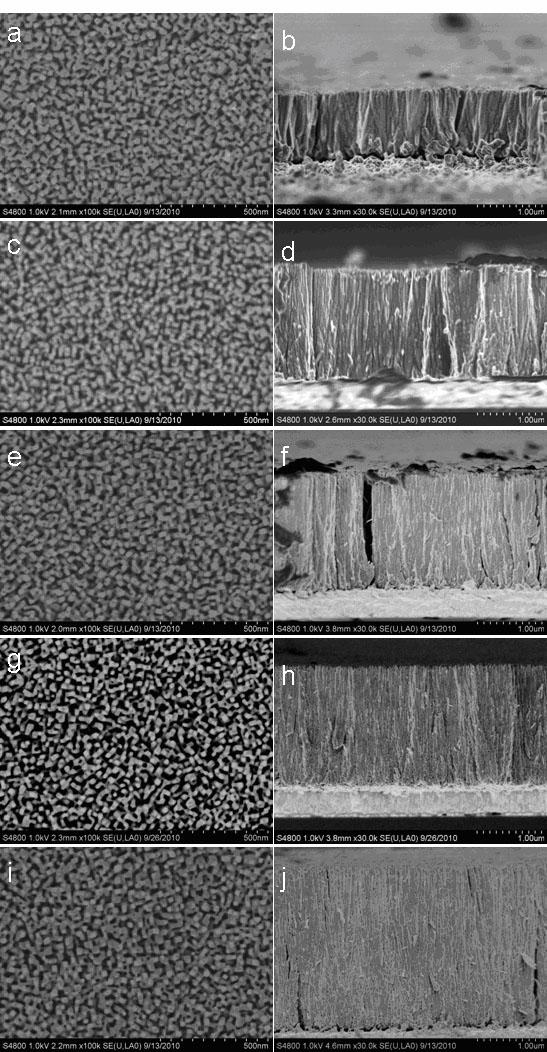

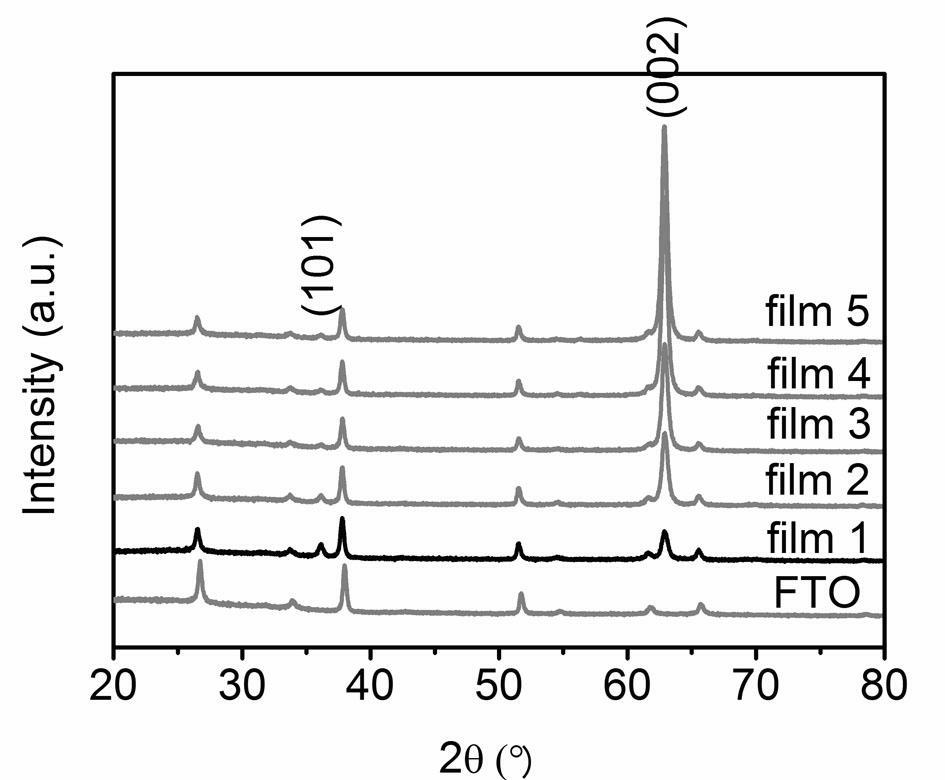

Titanium dioxide (TiO2) nano-rod single-crystal array thin film as well as preparation method and application thereof

A technology of titanium dioxide and nanorods, applied in the field of solar cells, can solve problems such as hindering electron transmission, reducing battery performance, and increasing electronic recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of the growth liquid that the volume ratio of titanium tetraisopropoxide, hydrochloric acid, acetic acid and deionized water is 0.2 / 4 / 8 / 8

[0019] The growth solution is prepared by the following process: measure 0.8 mL titanium tetraisopropoxide with a graduated cylinder, and add 16 mL hydrochloric acid, 32 mL acetic acid, and 32 mL deionized water to it successively, and place on a magnetic stirrer at room temperature Stir fully to make the reactants mix evenly, and obtain the growth solution with the volume ratio of titanium tetraisopropoxide, hydrochloric acid, acetic acid and deionized water being 0.2 / 4 / 8 / 8, and the solution is colorless and transparent.

Embodiment 2

[0020] Embodiment 2: the preparation of the growth liquid that the volume ratio of titanium tetraisopropoxide, hydrochloric acid, acetic acid and deionized water is 0.4 / 4 / 8 / 8

[0021] The growth solution was prepared by the following process: Measure 1.6 mL of titanium tetraisopropoxide with a graduated cylinder, and add 16 mL of hydrochloric acid, 32 mL of acetic acid, and 32 mL of deionized water successively, and place on a magnetic stirrer at room temperature Stir fully to make the reactants mix evenly, and then obtain the growth liquid whose volume ratio of tetraisopropoxytitanium, hydrochloric acid, acetic acid and deionized water is 0.4 / 4 / 8 / 8, and the solution is colorless and transparent.

Embodiment 3

[0022] Embodiment 3: the preparation of the growth liquid that the volume ratio of titanium tetraisopropoxide, hydrochloric acid, acetic acid and deionized water is 0.6 / 4 / 8 / 8

[0023] The growth solution was prepared by the following process: Measure 2.4 mL of titanium tetraisopropoxide with a graduated cylinder, and add 16 mL of hydrochloric acid, 32 mL of acetic acid, and 32 mL of deionized water successively, and place on a magnetic stirrer at room temperature Stir fully to make the reactants mix evenly, and then obtain the growth solution with the volume ratio of titanium tetraisopropoxide, hydrochloric acid, acetic acid and deionized water being 0.6 / 4 / 8 / 8, and the solution is colorless and transparent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com