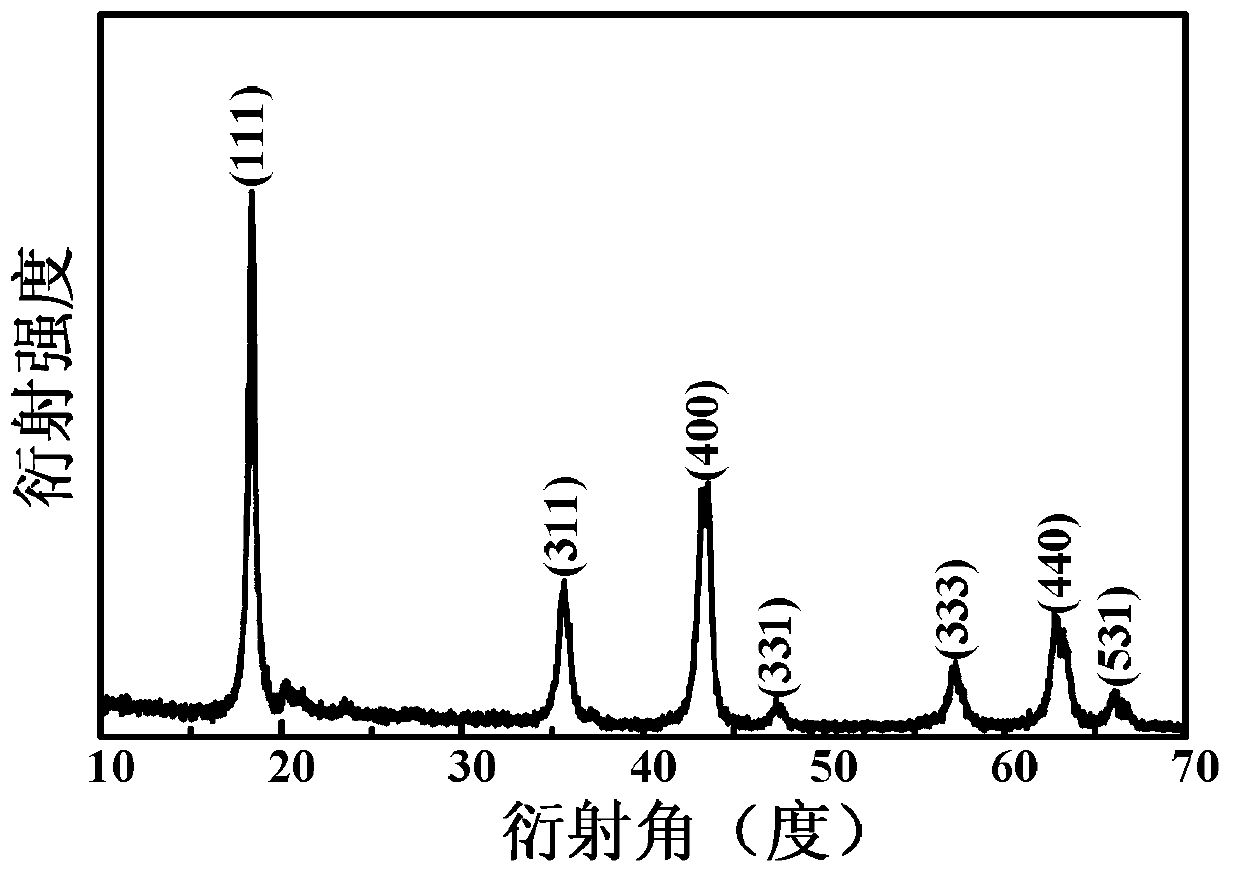

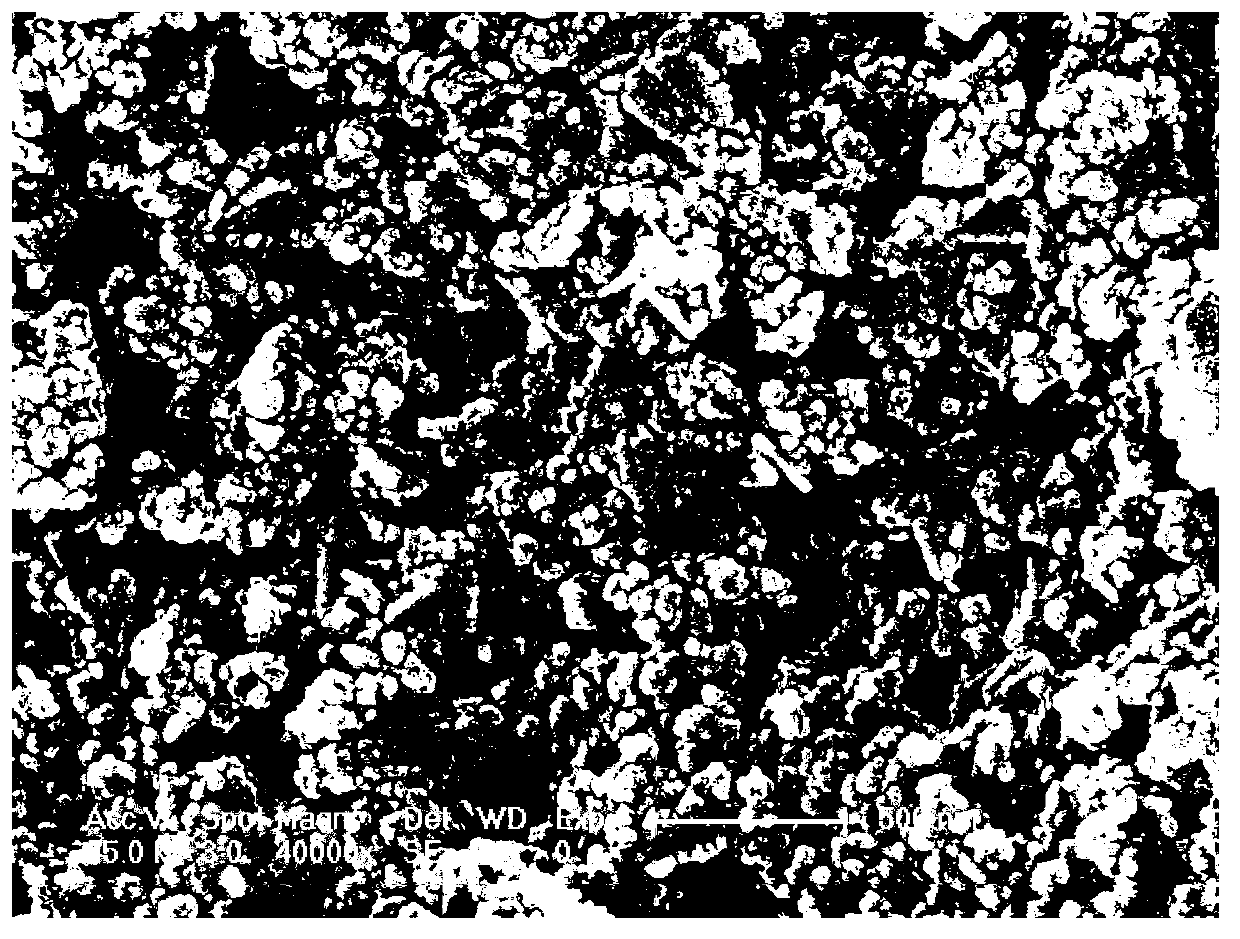

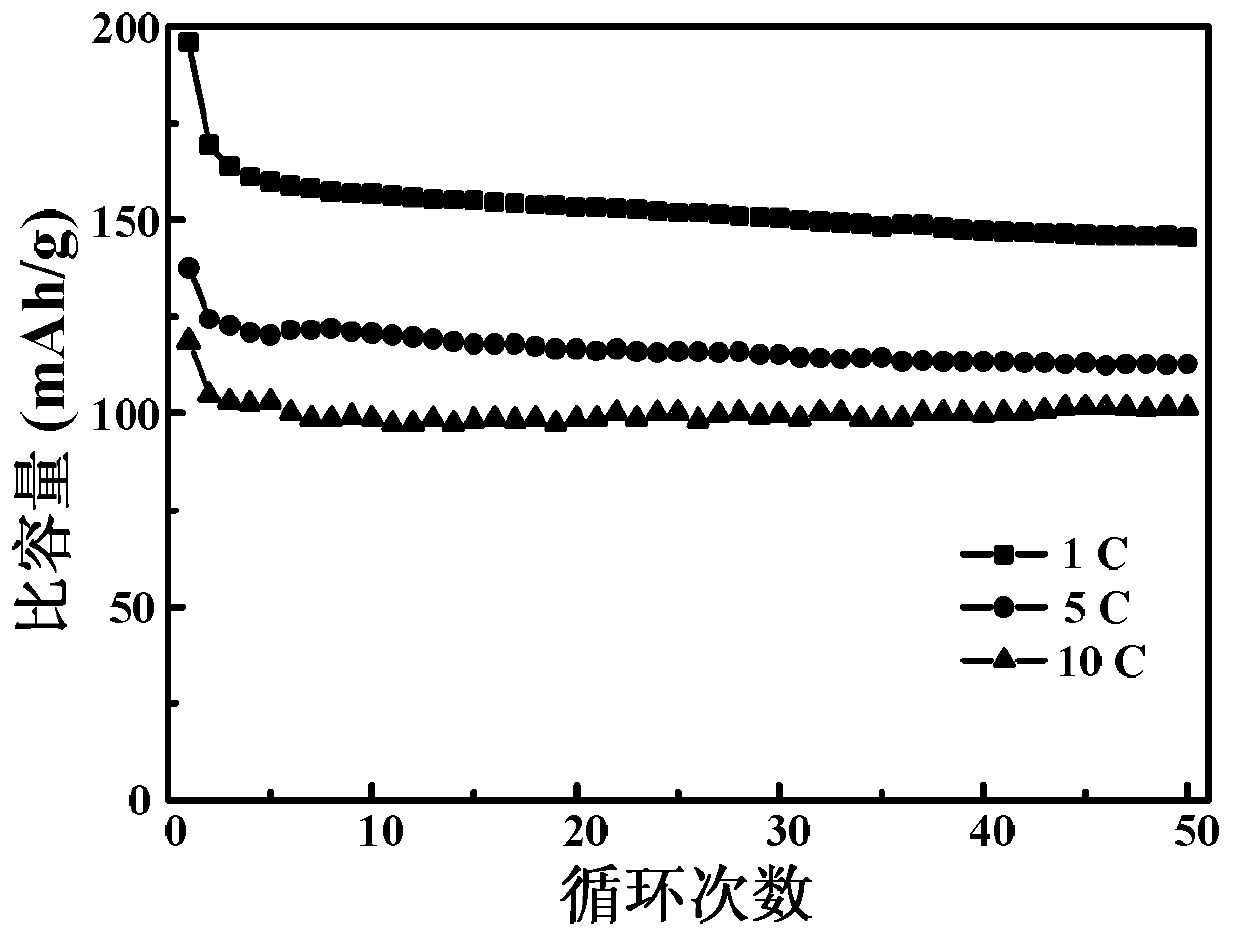

Hydrothermal synthesis method of micro-emulsion of nano lithium titanate

A nano-lithium titanate, hydrothermal synthesis technology, applied in the direction of titanium compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex synthesis route, poor sample dispersibility, high synthesis cost, and achieve simple process, low cost, The effect of increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix the raw materials cetyltrimethylammonium bromide, n-hexanol, cyclohexane and deionized water to prepare two identical microemulsions. Wherein the concentration of cetyltrimethylammonium bromide is 0.01-1.2 mol / liter, the concentration of cyclohexane is 3-7 mol / liter, and the amount of deionized water is the same as that of cetyltrimethylammonium bromide. The ratio of the amount of substance of ammonium bromide is: 10-80, the ratio of the amount of substance of n-hexanol to the amount of substance of cetyltrimethylammonium bromide is: 2-30;

[0028] (2) Lithium hydroxide and titanium tetraisopropoxide were added to the above two microemulsions respectively, stirred at room temperature for 5-30 minutes, and microemulsions containing lithium hydroxide and titanium tetraisopropoxide were prepared respectively. Wherein the concentration of lithium hydroxide is 0.1-1.2 mol / liter, and the concentration of titanium tetraisopropoxide is 0.15-1.5 mol / liter;

[0029] (3) ...

Embodiment 2

[0032] (1) Mix the raw materials cetyltrimethylammonium bromide, n-hexanol, cyclohexane and deionized water to prepare two identical microemulsions. Wherein the concentration of cetyltrimethylammonium bromide is 0.05-1.0 mol / liter, the concentration of cyclohexane is 3-6 mol / liter, and the amount of deionized water is the same as that of cetyltrimethylammonium bromide. The ratio of the amount of substance of ammonium bromide is: 12-75, and the ratio of the amount of substance of n-hexanol to the amount of substance of cetyltrimethylammonium bromide is: 3-60;

[0033] (2) Lithium acetate and titanium tetraisopropoxide were added to the above two microemulsions respectively, stirred at room temperature for 10-30 minutes, and microemulsions containing lithium acetate and titanium tetraisopropoxide were prepared respectively. Wherein the concentration of lithium hydroxide is 0.2-0.7 mol / liter, and the concentration of titanium tetraisopropoxide is 0.25-0.9 mol / liter;

[0034] (3)...

Embodiment 3

[0037] (1) Mix raw materials sodium lauryl sulfate, n-hexanol, cyclohexane and deionized water to prepare two identical microemulsions. Wherein the concentration of sodium lauryl sulfate is 0.06-0.8 mole / liter, the concentration of cyclohexane is 3.5-6 mole / liter, and the amount of substance of deionized water is equal to the amount of substance of sodium lauryl sulfate The ratio is: 15-70, the ratio of the amount of substance of n-hexanol to the amount of substance of sodium lauryl sulfate is: 2-70;

[0038] (2) Lithium nitrate and tetrabutyl titanate were added to the above two microemulsions respectively, stirred at room temperature for 5-30 minutes, and microemulsions containing lithium nitrate and tetrabutyl titanate were prepared respectively. Wherein the concentration of lithium hydroxide is 0.1-1.0 mol / liter, the concentration of tetrabutyl titanate is 0.12-1.3 mol / liter;

[0039] (3) After mixing the above two microemulsions, continue to stir for 10-30 minutes, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com