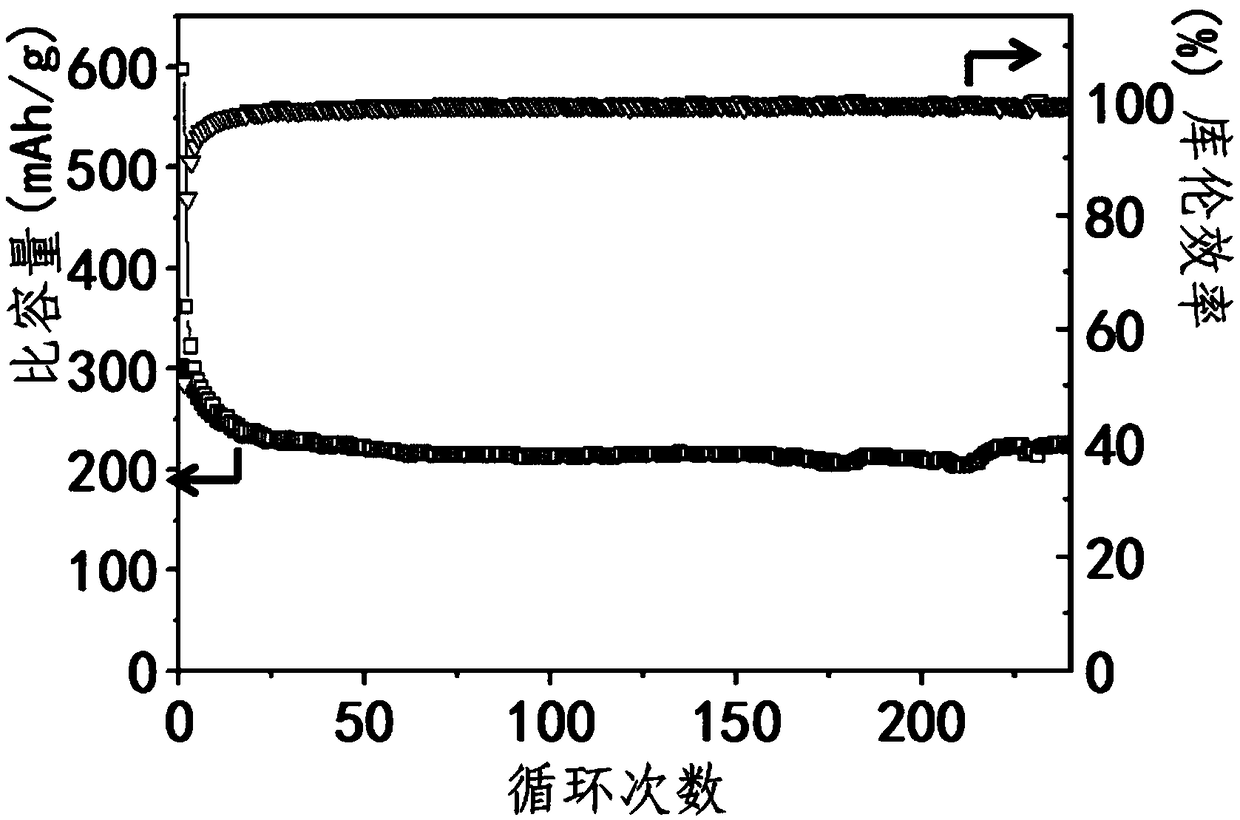

Preparation method of hollow porous TiO2 nanocubic material and application thereof

A nano-cube, hollow and porous technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the difficulty of forming a coating layer for high-curved nano-templates, reduce battery storage capacity, and form templates. In order to improve the electrochemical active sites, improve the capacity and reduce the powdering effect of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The hollow porous TiO of this embodiment 2 The preparation method of nano cube material comprises the following steps:

[0036] Step 1. Mix 0.5 g of 2-aminoterephthalic acid and 20 mL of N,N-dimethylformamide and stir evenly to obtain a clear mixed solution A;

[0037] Step 2: Mix 0.4g of titanium isopropoxide and 16mL of methanol and stir evenly to obtain a mixed solution B;

[0038] Step 3. Add the mixed solution B obtained in step 2 to the mixed solution A obtained in step 1, stir for 2 hours to obtain a bright yellow mixed solution C, and then transfer the mixed solution C to a hydrothermal reaction kettle and heat to 160 ℃ reaction 10h;

[0039] Step 4. Centrifuge the mixed solution C after the heating reaction in step 3, and wash the centrifuged precipitate with equal volumes of N,N-dimethylformamide and anhydrous methanol three times in sequence, and then place it in a vacuum drying oven Dry in vacuum at 40°C to obtain amino-modified Ti-MIL-125 nanocube materi...

Embodiment 2

[0048] The hollow porous TiO of this embodiment 2 The preparation method of nano cube material comprises the following steps:

[0049] Step 1. Mix 2g of 2-aminoterephthalic acid and 120mL of N,N-dimethylformamide and stir evenly to obtain a clear mixed solution A;

[0050] Step 2: Mix 3g of titanium isopropoxide and 180mL of methanol and stir evenly to obtain a mixed solution B;

[0051] Step 3. Add the mixed solution B obtained in step 2 to the mixed solution A obtained in step 1. After stirring for 1 h, a bright yellow mixed solution C is obtained, and then transfer the mixed solution C to a hydrothermal reaction kettle and heat to 170 ℃ reaction 20h;

[0052] Step 4. Centrifuge the mixed solution C after heating and reacting in step 3. The centrifuged precipitate obtained is washed three times with N,N-dimethylformamide and anhydrous methanol successively, and then placed in a vacuum drying oven at 90 ℃ drying, to obtain the amino-modified Ti-MIL-125 nano-cube material; ...

Embodiment 3

[0061] The hollow porous TiO of this embodiment 2 The preparation method of nano cube material comprises the following steps:

[0062] Step 1. Mix 1 g of 2-aminoterephthalic acid and 50 mL of N,N-dimethylformamide and stir evenly to obtain a clear mixed solution A;

[0063] Step 2: Mix 1 g of titanium isopropoxide and 50 mL of methanol and stir evenly to obtain a mixed solution B;

[0064] Step 3: Add the mixed solution B obtained in step 2 to the mixed solution A obtained in step 1, stir for 1 hour to obtain a bright yellow mixed solution C, then transfer the mixed solution C to a hydrothermal reaction kettle and heat to 165 ℃ reaction 15h;

[0065] Step 4. Centrifuge the mixed solution C after heating and reacting in step 3. The centrifuged precipitate obtained is washed three times with N,N-dimethylformamide and anhydrous methanol successively, and then placed in a vacuum drying oven at 60 ℃ drying, to obtain the amino-modified Ti-MIL-125 nano-cube material;

[0066] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com