Preparation method of upconversion material of core shell structure and application of conversion material in perovskite solar cell

A technology of solar cells and conversion materials, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of urgency of perovskite cells and limit the efficiency of perovskite solar cells, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1, preparation of core-shell structure up-conversion materials

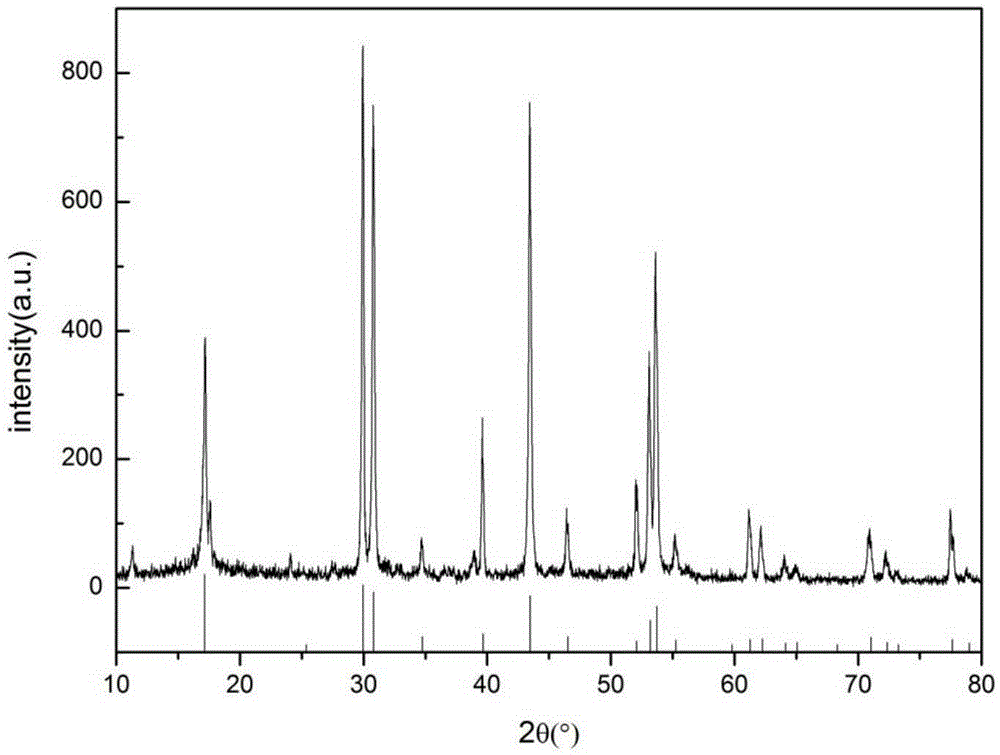

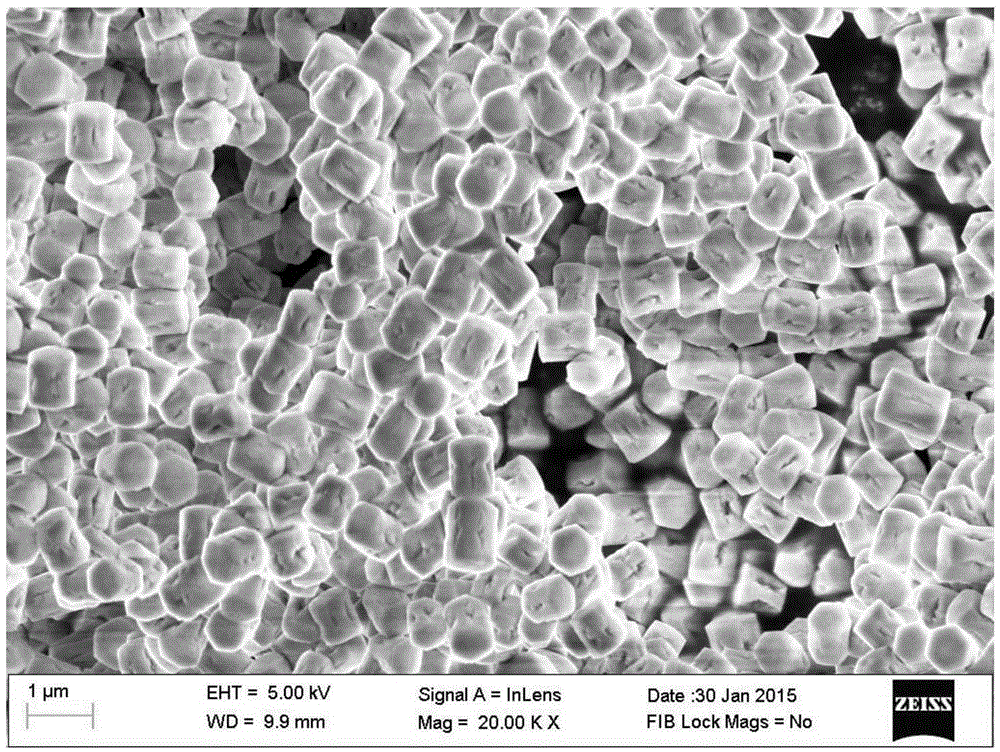

[0043] Step 1.1, 4mmolYCl 3 , 0.9 mmol YbCl 3 , 0.1mmolErCl 3 Mix the solution with 5mmol sodium citrate and stir for 1h, add 50mmolNaF and stir for 30min, adjust the pH of the solution to 8, then conduct a hydrothermal reaction at 200°C for 3h, wash with deionized water and ethanol after cooling, and dry at 80°C for 12h to generate the up-conversion material NaYF 4 :Yb 3+ ,Er 3+ powder, figure 1 For the preparation of NaYF 4 :Yb 3+ ,Er 3+ The X-ray diffraction pattern, it can be seen that NaYF 4 :Yb 3+ ,Er 3+ for pure phase, figure 2 For the preparation of NaYF 4 :Yb 3+ ,Er 3+ It can be seen from the scanning electron microscope that it is hexagonal columnar.

[0044] Step 1.2, add 0.1gNaYF 4 : Yb 3+ , Er 3+ Disperse into 40mL of isopropanol, sonicate for 30min, add 5mL of deionized water and 0.5mL of ammonia water to the above solution, stir for 10min to obtain mixed solution 1; a...

Embodiment 2

[0062] According to Example 1, only the amount of the up-conversion material taken is changed to 0 mmol. Test its electrochemical performance according to the method of embodiment 1, the short-circuit current density of gained battery is 11.74mA cm -2 , the open circuit voltage is 0.63V, the fill factor is 0.57, and the photoelectric conversion efficiency is 4.22%.

Embodiment 3

[0064] According to Example 1, only the process of preparing the prepared up-conversion material is changed, the process is as follows: 4mmolYCl 3 , 0.9 mmol YbCl 3 , 0.1mmolErCl 3 Mix the solution with 10mmol sodium citrate and stir for 1h, add 50mmol NaF and stir for 30min, adjust the pH of the solution to 11, heat the mixed solution at 200°C for 3h, wash with deionized water and ethanol after cooling, and dry at 80°C for 12h to generate the up-conversion material NaYF 4 :Yb 3+ ,Er 3+ powder. Test its electrochemical performance according to the method of embodiment 1, the short-circuit current density of gained battery is 11.73mA cm -2 , the open circuit voltage is 0.76V, the fill factor is 0.68, and the photoelectric conversion efficiency is 6.06%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com