Antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and preparation method thereof

An antiferroelectric and pyroelectric technology, applied in the direction of electric radiation detectors, layered products, etc., can solve the problems of antiferroelectric thin film pyroelectric research, research and development, etc., and achieve large pyroelectricity. The effect of electric coefficient, broad market prospect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

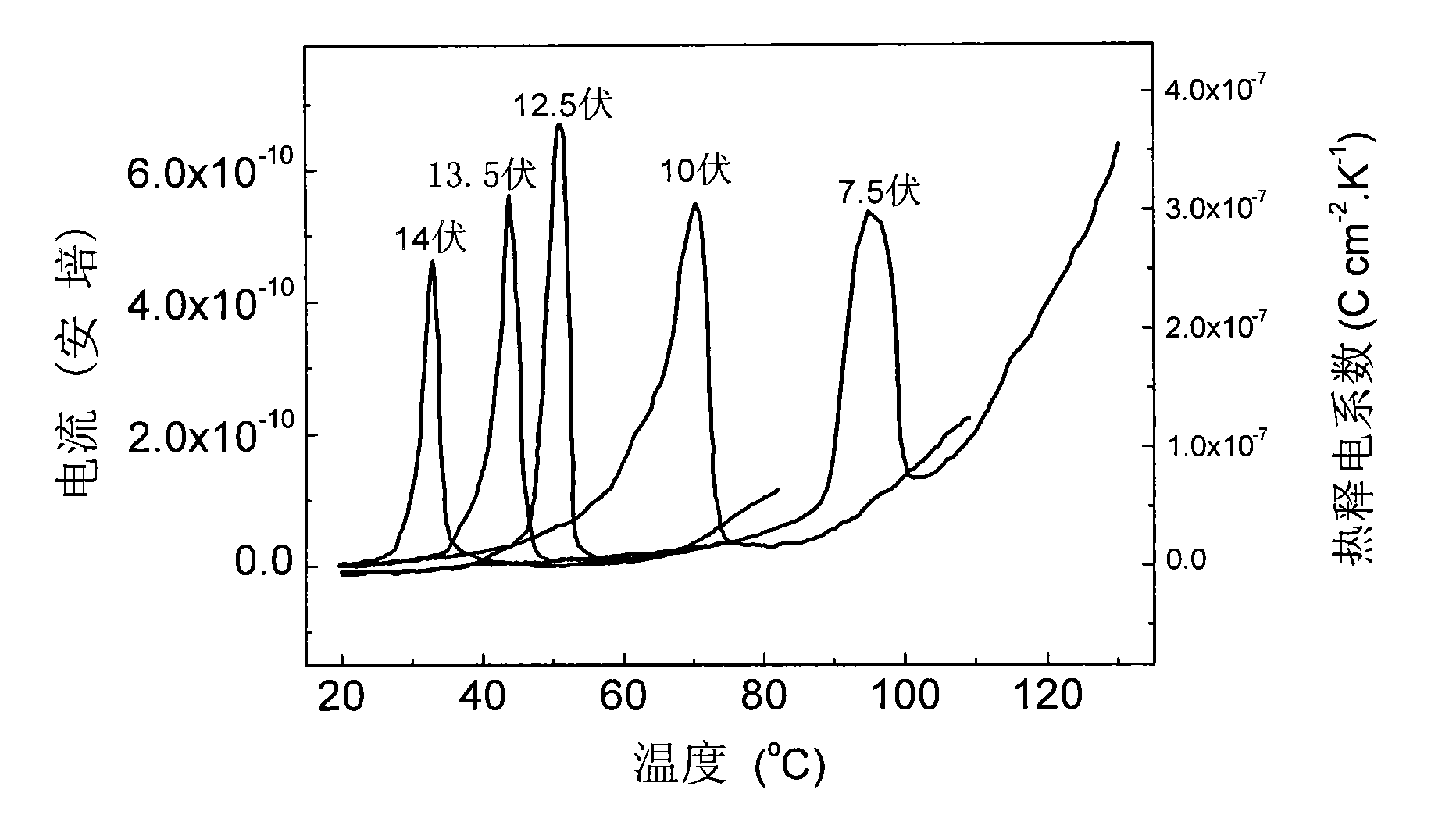

[0026] p (Pb,Nb)(Zr,Sn,Ti)O 3 system, select Pb 0.99 Nb 0.02 (Zr 0.85 sn 0.13 Ti 0.02 ) 0.98 o 3 (PNZST) is in the region of the antiferroelectric orthorhombic system.

[0027] The chemical raw material used is lead acetate Pb(CH 3 COO) 2 ·3H 2 O, niobium ethanol Nb(OC 2 h 5 ) 5 , tin acetate Sn(CH 3 COO) 4 , zirconium isopropoxide Zr (OC 3 h 7 ) 4 and titanium isopropoxide Ti(OC 3 h 7 ) 4 , the solvent is glacial acetic acid, ethylene glycol ether and deionized water. First lead acetate Pb(CH 3 COO) 2 ·3H 2 O was weighed according to the stoichiometric ratio, a certain amount of glacial acetic acid was added, the molar ratio of Pb to glacial acetic acid was 1:10, heated to 110°C and refluxed for 1 hour; after cooling to room temperature, tin acetate Sn(CH 3 COO) 4 And continue to reflux for 1 hour; After cooling to room temperature, add ethylene glycol ether, niobium ethoxide Nb(OC 2 h 5 ) 5 , zirconium isopropoxide Zr (OC 3 h 7 ) 4 and titanium...

Embodiment 2

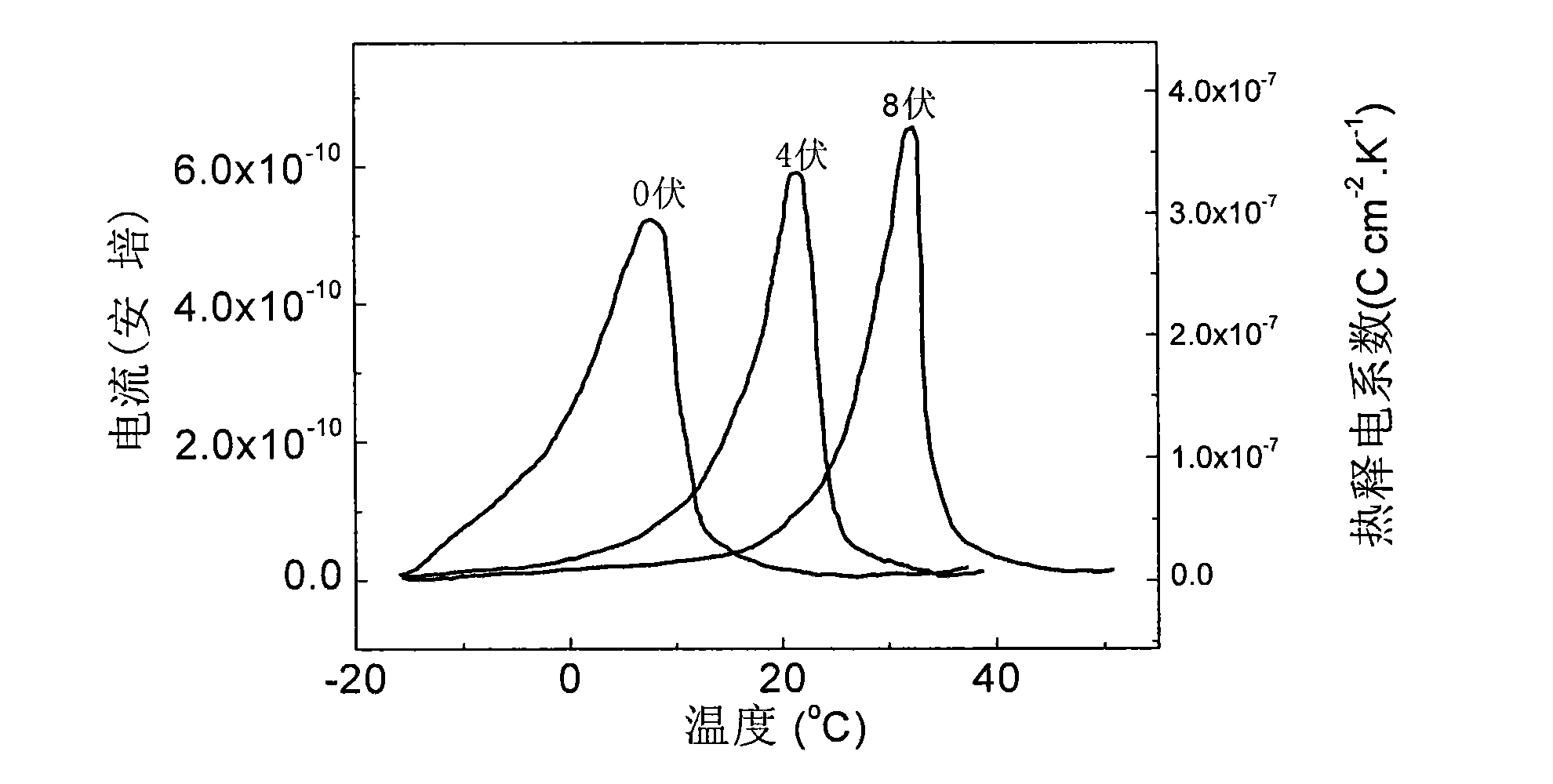

[0034] p (Pb,La)(Zr,Sn,Ti)O 3 system, select Pb 0.97 La 0.02 (Zr 0.75 sn 0.16 Ti 0.09 )O 3 (PLZST) is close to the antiferroelectric and ferroelectric phase boundary but in the antiferroelectric tetragonal phase region.

[0035] The chemical raw material used is lead acetate Pb(CH 3 COO) 2 ·3H 2 O, lanthanum acetate La(CH 3 COO) 3 ·H 2 O, tin acetate Sn(CH 3 COO) 4 , zirconium isopropoxide Zr (OC 3 h 7 ) 4 and titanium isopropoxide Ti(OC 3 h 7 ) 4 , the solvent is glacial acetic acid, ethylene glycol ether and deionized water.

[0036] First lead acetate Pb(CH 3 COO) 2 ·3H 2 O and lanthanum acetate La(CH 3 COO) 3 ·H 2 O was weighed according to the stoichiometric ratio, a certain amount of glacial acetic acid was added, the molar ratio of (Pb+La) to glacial acetic acid was 1:10, heated to 110°C and refluxed for 1 hour; after cooling to room temperature, tin acetate Sn(CH 3 COO) 4 And continue to reflux for 1 hour; After cooling to room temperature, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com