A color filter substrate, a liquid crystal display panel, and a liquid crystal display device

A liquid crystal display panel, color filter substrate technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of display influence, display screen lag, response time prolongation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

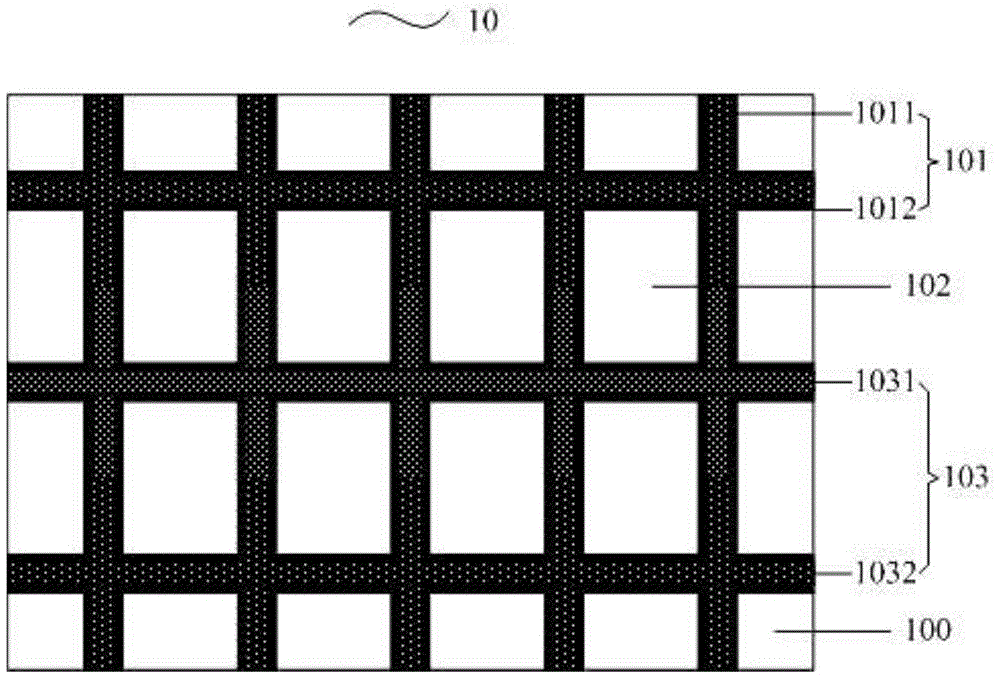

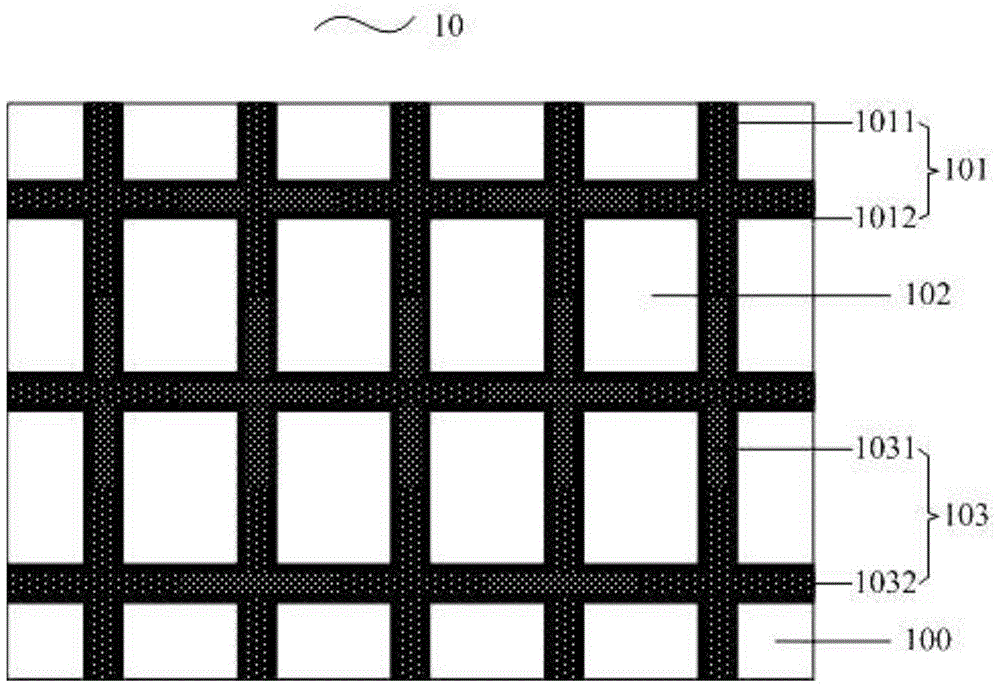

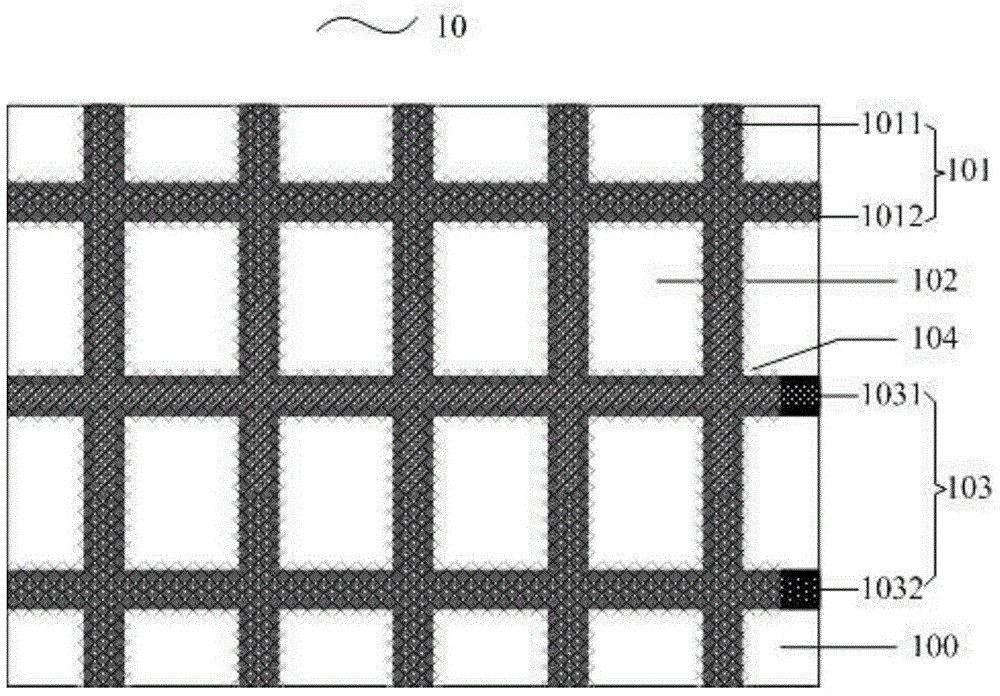

[0060] An embodiment of the present invention provides a method for preparing a color filter substrate 10, the method may include: forming a black matrix 101, a color filter layer 102, and a heating layer 103 on the substrate; the heating layer 103 The formation position corresponds to the formation position of the black matrix 101 ; wherein, the heating layer 103 may include a P-type semiconductor thermoelectric material region 1031 and an N-type semiconductor thermoelectric material region 1032 in contact with each other.

[0061] Here, there is no specific limitation on the sequence of forming the black matrix 101 , the color filter layer 102 and the heating layer 103 .

[0062] On this basis, the method may further include: forming an electromagnetic shielding layer 104 on the substrate on which the heating layer 103 is formed; wherein, the material of the electromagnetic shielding layer 104 may be a transparent conductive material, and the electromagnetic The shielding la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com