Solvent-free asphalt waterproofing material for cold applications modified silicon polymer and method for the same

A technology of waterproof material and asphalt coating film, which is applied in asphalt coatings, building insulation materials, chemical instruments and methods, etc., can solve the problem of difficulty in actively responding to changes in the surrounding environment, chemical resistance, ozone resistance, UV resistance, and waterproof performance. Weakening and other problems to achieve the effect of preventing rapid oxidation and aging, inhibiting the generation of harmful gases, and minimizing harmful gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

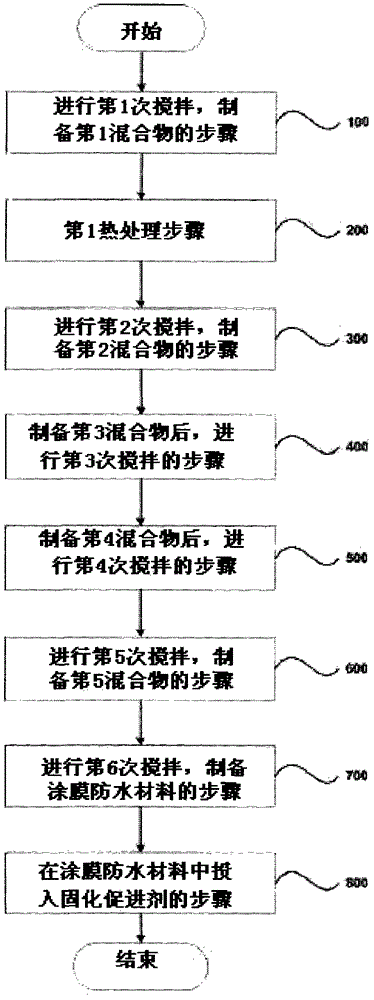

Method used

Image

Examples

Embodiment 1

[0082] After heating 20 parts by weight of straight-run asphalt to 180° C., 5 parts by weight of thermoplastic rubber were mixed in the heated straight-run asphalt, and mixed in a high-shear mixer at a stirring speed of 4000 rpm for 60 minutes. Next, after heat-treating the mixture to 150°C, 5 parts by weight of a C9-based aromatic petroleum resin was mixed, and stirred in a low-shear mixer at a stirring rate of 150 rpm for 30 minutes at a temperature of 150°C. Then, 8 parts by weight of paraffin-based white oil was mixed, and naturally cooled while stirring until it reached 80°C.

[0083] Then, 18 parts by weight of the modified silicone-based polymer and 15 parts by weight of petroleum-based hydrocarbon oil were mixed while stirring until the temperature reached 60°C. Then, 50 parts by weight of heavy calcium carbonate and precipitated calcium carbonate were added, and after stirring at a low speed for 30 minutes, vinyl silane and amino silane were added to produce a coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com