Carbon nitride/titanium dioxide nanosheet array heterojunction photocatalyst and preparation method

A nanosheet array and titanium dioxide technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of easy recombination of photogenerated electrons/holes, uneven recombination of composite materials, and solar energy utilization. Low-level problems, to achieve the effect of improving photocatalytic hydrogen production activity, good commercial application prospects, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) g-C 3 N 4 preparation of

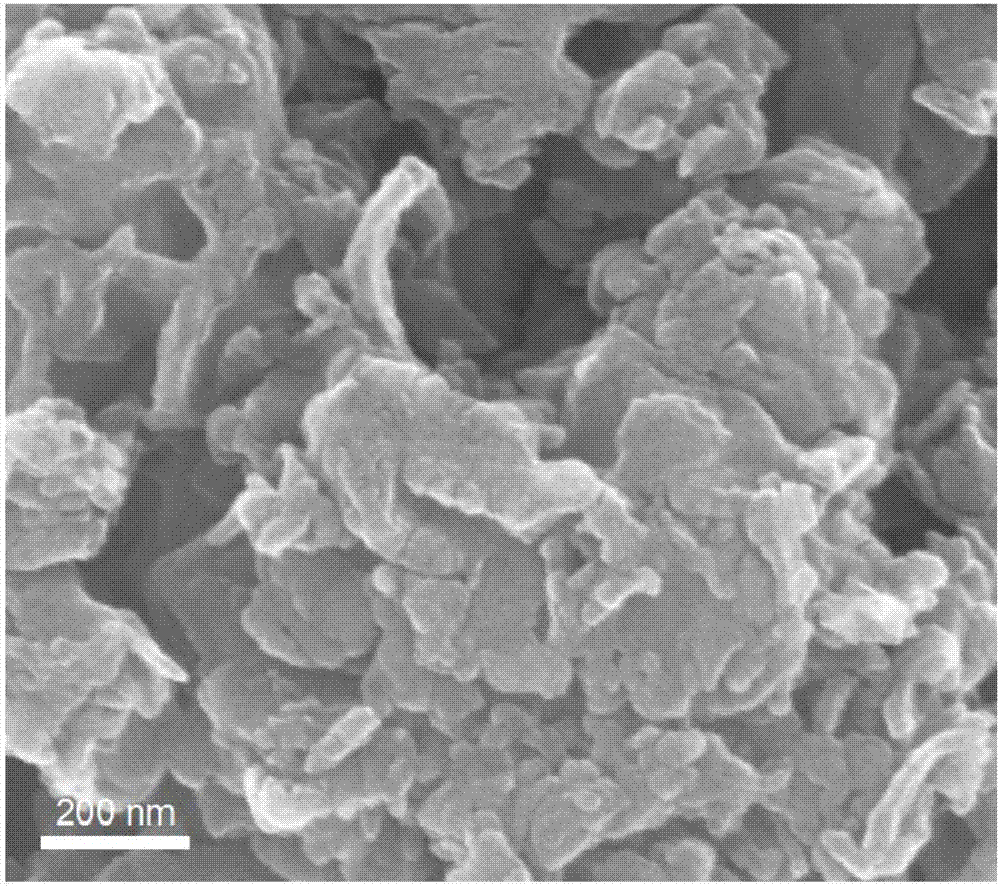

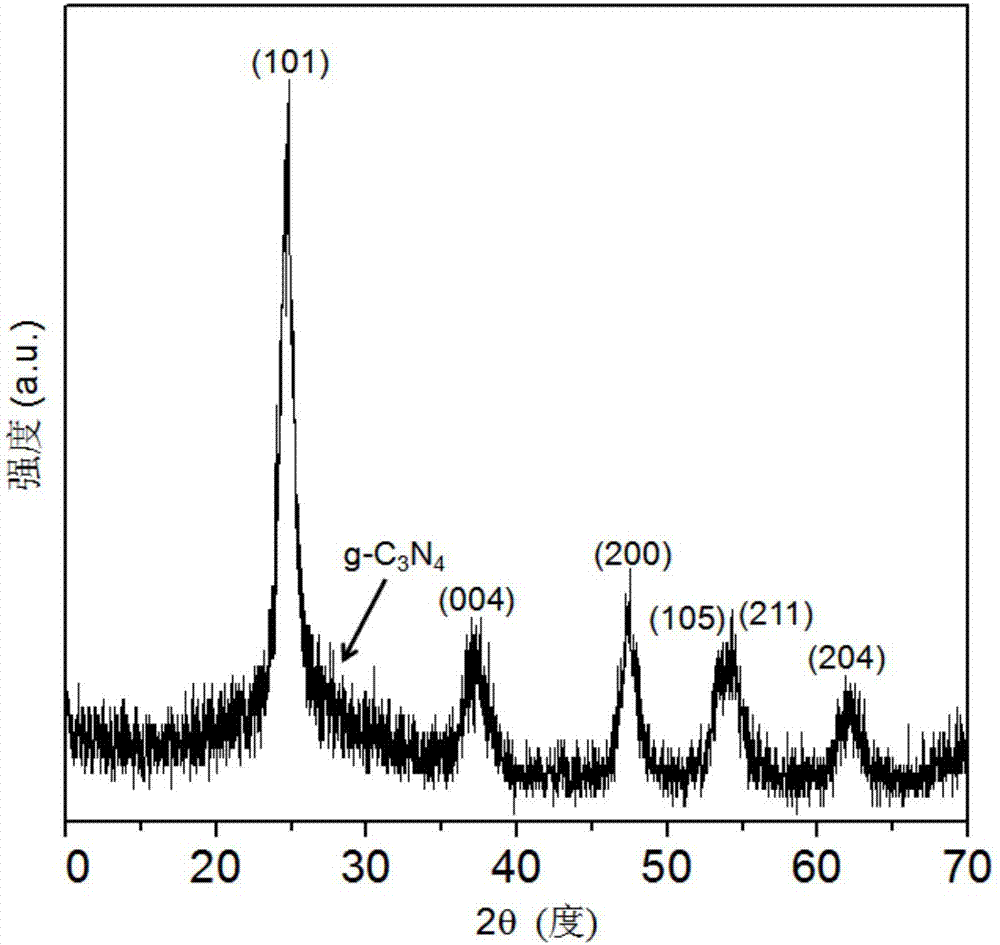

[0026] Accurately weigh 10g of urea and transfer it into an alumina crucible, put the crucible into a muffle furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep it for 3h to obtain a light yellow powder g-C 3 N 4 The crude product was ground, washed successively with deionized water, 0.4% HCl solution, 1% NaOH solution, and finally washed with deionized water until neutral, and dried at 60°C for 12 hours to obtain pure yellow powder g-C 3 N 4 . Then, accurately measure 50mL of isopropanol and transfer it into a beaker, add 150mg of the obtained pure g-C 3 N 4 , ultrasonic dispersion for 30min to obtain pure g-C 3 N 4 exfoliation dispersion. (2)g-C 3 N 4 / TiO 2 Precursor preparation

[0027] Replace the above g-C 3 N 4 Transfer the exfoliation dispersion liquid into a hydrothermal kettle, add 21mL isopropanol, then add 0.09mL diethylenetriamine and 4.5mL isopropyl titanate in sequence, mix the solution ev...

Embodiment 2

[0033] (1) g-C 3 N 4 preparation of

[0034] Accurately weigh 10g of urea and transfer it into an alumina crucible, put the crucible into a muffle furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep it for 3h to obtain a light yellow powder g-C 3 N 4 The crude product was ground, washed successively with deionized water, 0.4% HCl solution, 1% NaOH solution, and finally washed with deionized water until neutral, and dried at 60°C for 12 hours to obtain pure yellow powder g-C 3 N 4 . Then, accurately measure 50mL of isopropanol and transfer it into a beaker, add 50mg of the obtained pure g-C 3 N 4 , ultrasonic dispersion for 30min to obtain pure g-C 3 N 4 exfoliation dispersion. (3) g-C 3 N 4 / TiO 2 Precursor preparation

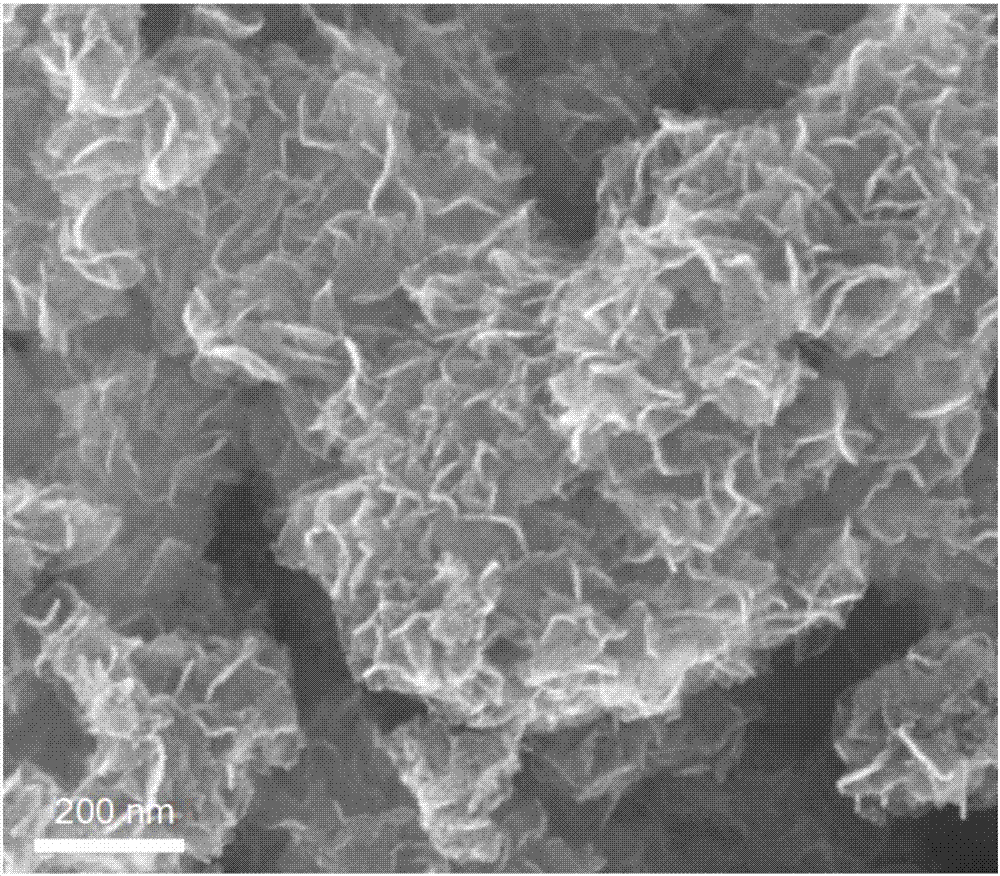

[0035] Replace the above g-C 3 N 4 Transfer the exfoliation dispersion liquid into a hydrothermal kettle, add 21mL isopropanol, then add 0.09mL diethylenetriamine and 4.5mL isopropyl titanate in sequence, mix the solution ev...

Embodiment 3

[0039] (1) g-C 3 N 4 preparation of

[0040] Accurately weigh 10g of urea and transfer it into an alumina crucible, put the crucible into a muffle furnace, raise the temperature to 550°C at a rate of 10°C / min, and keep it for 3h to obtain a light yellow powder g-C 3 N 4 The crude product was ground, washed successively with deionized water, 0.4% HCl solution, 1% NaOH solution, and finally washed with deionized water until neutral, and dried at 60°C for 12 hours to obtain pure yellow powder g-C 3 N 4 . Then, accurately measure 50mL of isopropanol into a beaker, add 100mg of the obtained pure g-C 3 N 4 , ultrasonic dispersion for 30min to obtain pure g-C 3 N 4 exfoliation dispersion. (2)g-C 3 N 4 / TiO 2 Precursor preparation

[0041]Replace the above g-C 3 N 4 Transfer the exfoliation dispersion liquid into a hydrothermal kettle, add 21mL isopropanol, then add 0.09mL diethylenetriamine and 4.5mL isopropyl titanate in sequence, mix the solution evenly, react at 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com