Photocatalytic hydrogen production catalyst as well as preparation method and application thereof

A catalyst and photocatalysis technology, applied in the field of materials, can solve problems such as low catalytic yield, achieve the effect of small change in hydrogen evolution rate, promote separation and isolation of photogenerated charge carriers, and improve photocatalytic hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

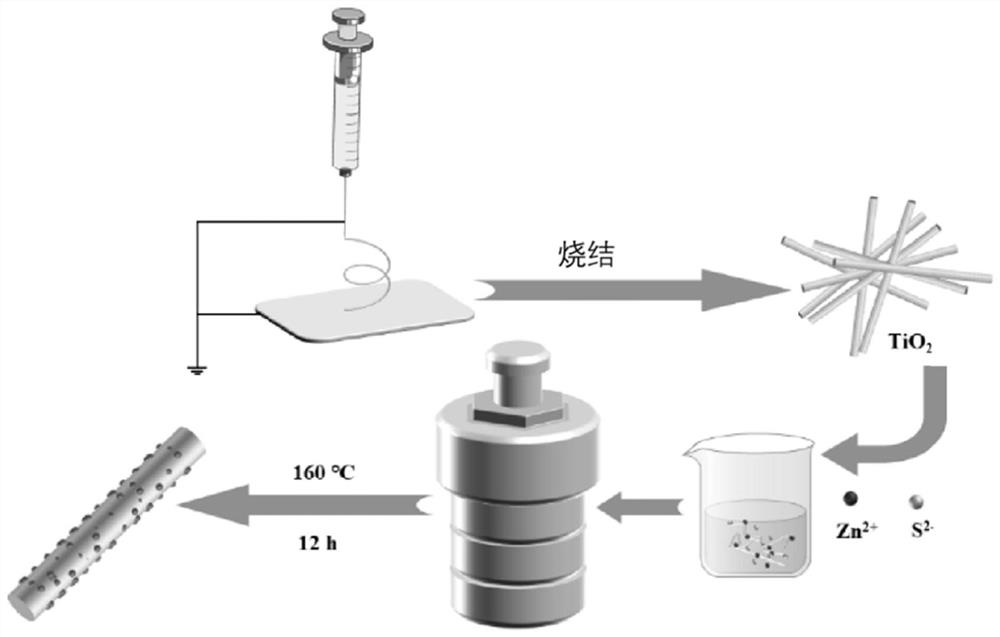

[0066] The preparation method of the photocatalytic hydrogen production catalyst in this example is as follows:

[0067] (1) TiO 2 preparation:

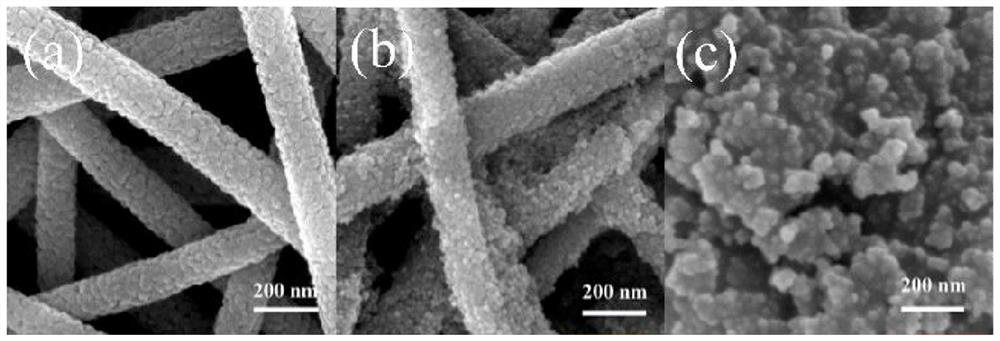

[0068] Dissolve 0.45g of polyvinylpyrrolidone (PVP), 3mL of glacial acetic acid and 1.5g of tetrabutyl titanate in 3mL of methanol to form a mixed solution, and stir the mixed solution at room temperature (25°C) for 12 hours to obtain a clear solution; transfer the solution In the injection device, electrospinning is carried out afterwards. The voltage of electrospinning is 18kV, the feed rate is 0.5ml / h, and the height of the electrospinning needle nozzle from the collector is 14cm; the nanofibers formed after electrospinning Transfer to a crucible and sinter in a muffle furnace to remove excess polyvinylpyrrolidone and other organic components. The sintering temperature in the muffle furnace was 550°C for 2 hours, and the heating rate of the muffle furnace was 1°C / min; after 2 hours, the crucible was quickly taken out and cooled ...

Embodiment 2

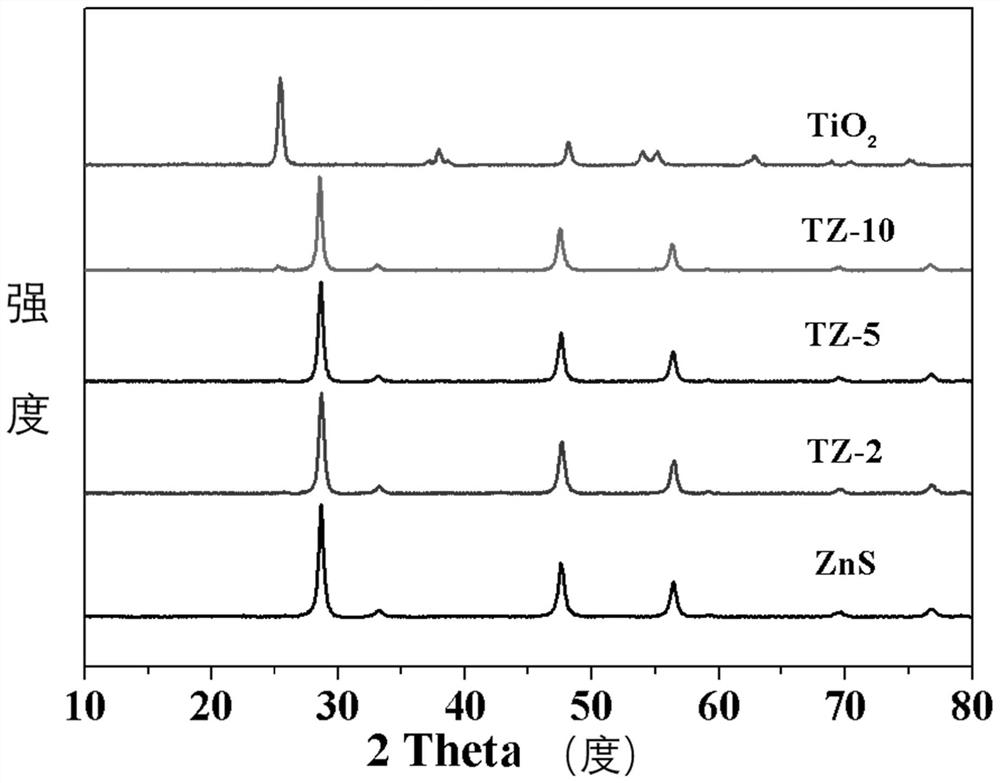

[0074] The photocatalytic hydrogen production catalyst in this example is prepared with reference to the photocatalytic preparation method in Example 1, and the TiO in the photocatalytic hydrogen production catalyst in this example 2 The mass ratio to ZnS is 2:1, which is recorded as TZ-2.

Embodiment 3

[0076] The photocatalytic hydrogen production catalyst in this example is prepared with reference to the photocatalytic preparation method in Example 1, and the TiO in the photocatalytic hydrogen production catalyst in this example 2 The mass ratio to ZnS is 10:1, which is recorded as TZ-10.

[0077] The preparation roadmap of the photocatalytic hydrogen production catalyst in Examples 1 to 3 is shown in figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com