Application of solid-solution type sodium zirconate titanate micro/nanobelt powdery material

A technology of sodium titanate zirconate and nanobelt, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of inability to obtain powdery materials, difficulty in mass production, and high cost, and improve the The effect of material utilization rate, production cost reduction and activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

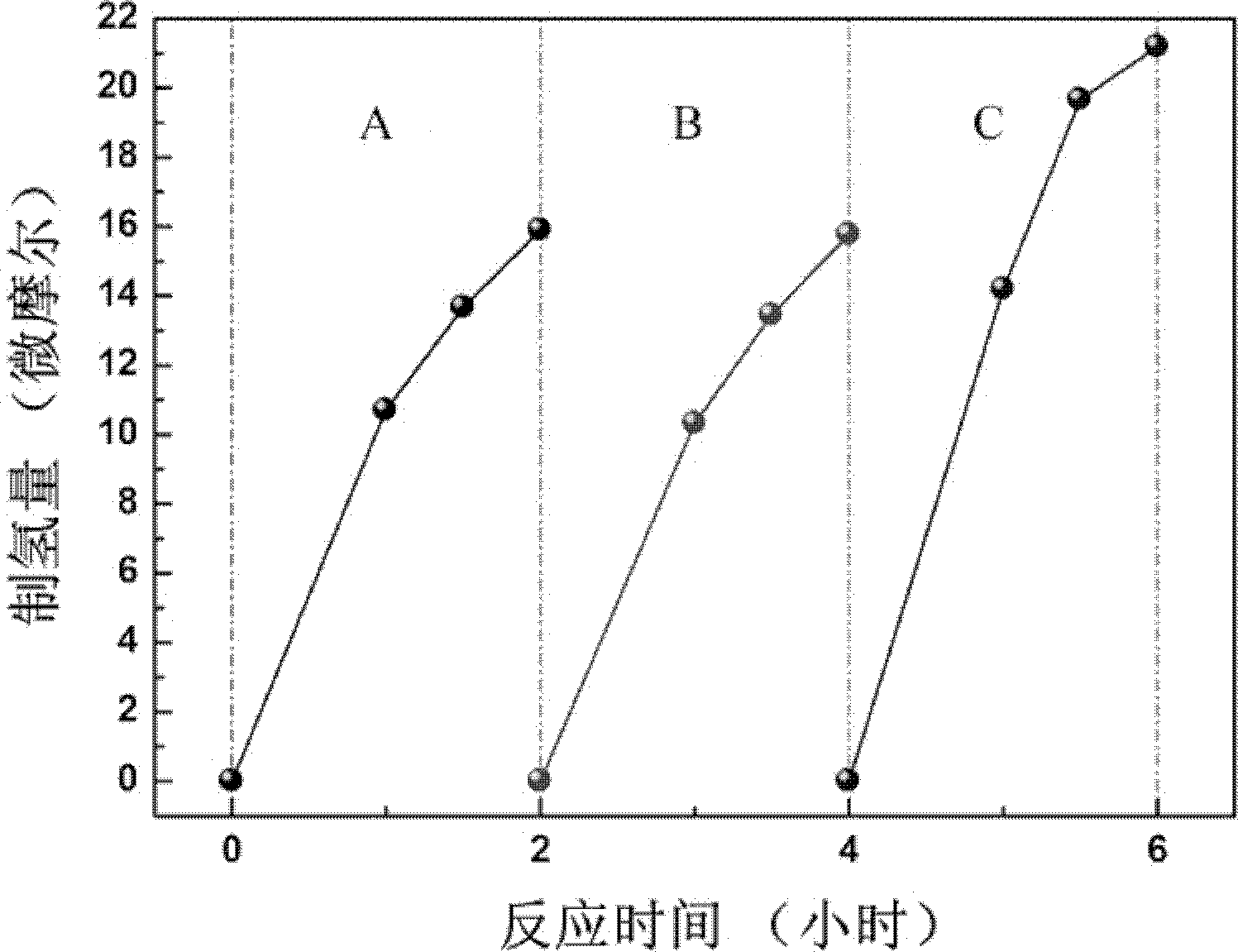

[0008] Specific embodiment one: this embodiment is a kind of preparation method of solid-solution sodium titania zirconate micro / nano belt powder material, specifically is finished according to the following steps:

[0009] 1. Put sodium hydroxide and deionized water into a closed reaction vessel, then add titanium-zirconium-based alloy powder with a diameter of 5-150 μm, and react at a temperature of 110°C-190°C and a pressure of 1MPa-40MPa for 3- 200 hours, then naturally cooled to room temperature to obtain a reaction product mixed system; 2, add deionized water to the reaction product mixed system prepared in step 1, adjust the pH value of the reaction product mixed system prepared in step 1 to neutrality, and then Separate the precipitate at the bottom of the closed reaction vessel, and dry the separated precipitate at a temperature of 50°C to 90°C to a constant weight to obtain titanium-zirconium with solid-solution sodium titanium zirconate micro / nano ribbons grown on th...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium-zirconium-based alloy powder described in Step 1 is prepared from industrially pure raw materials by industrial gas atomization. Others are the same as in the first embodiment.

[0040] In this embodiment, the preparation of titanium-zirconium-based alloy powder by using an industrial gas atomization method and industrially pure raw materials has the advantages of no pollution and low cost.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of titanium to zirconium in the titanium-zirconium-based alloy powder described in step 1 is (0.2-30):1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com