Patents

Literature

41results about How to "Many active centers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for producing propylene by catalytic pyrolysis and preparation method thereof

ActiveCN101462071AConducive to diffusionLess side effectsMolecular sieve catalystsBulk chemical productionCrystalliteMolecular sieve

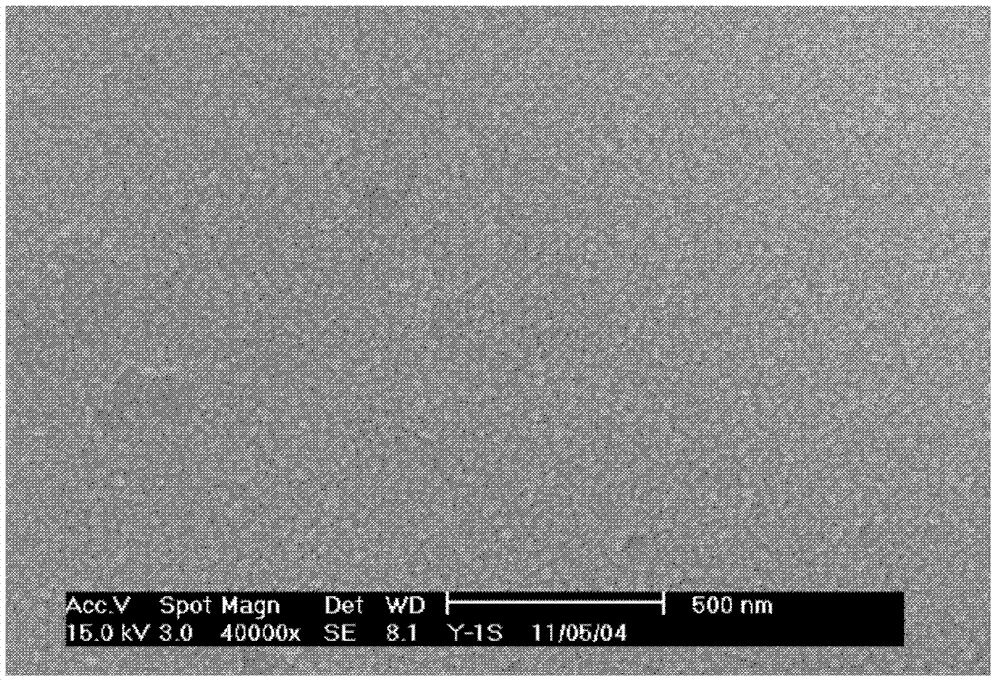

The invention discloses a catalyst for producing propylene by catalytic pyrolysis and a preparation method thereof. Calculated as the total weight of the catalyst, the catalyst comprises 20 to 40 weight percent of element-modified molecular sieve and 60 to 80 weight percent of heat-resistant inorganic oxide, wherein the content of a modified element is between 1 and 10 weight percent calculated as the total weight of the molecular sieve, the average grain diameter of crystal grains of the molecular sieve is between 10 and 100nm, and the modified element is one or a mixture of more of family IB metals and / or phosphorus. The catalyst is used for reactions that low carbon olefin, particularly the propylene is produced by C6-C12 olefins through catalytic pyrolysis, and has higher conversion rate of the C6-C12 olefins and yield of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

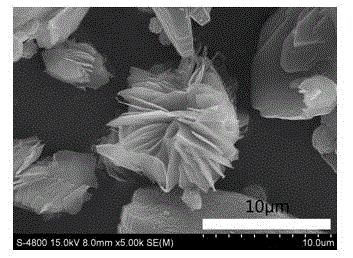

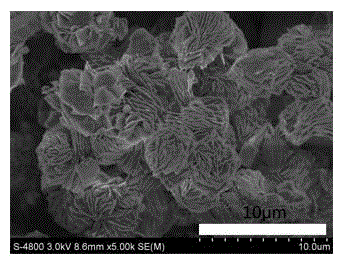

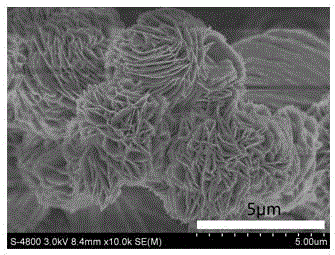

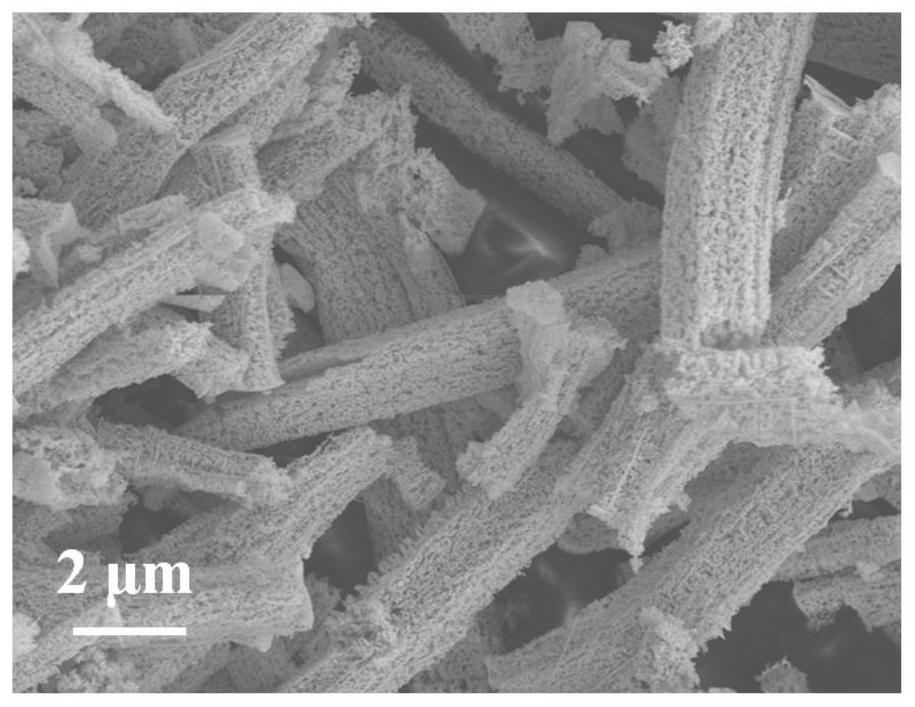

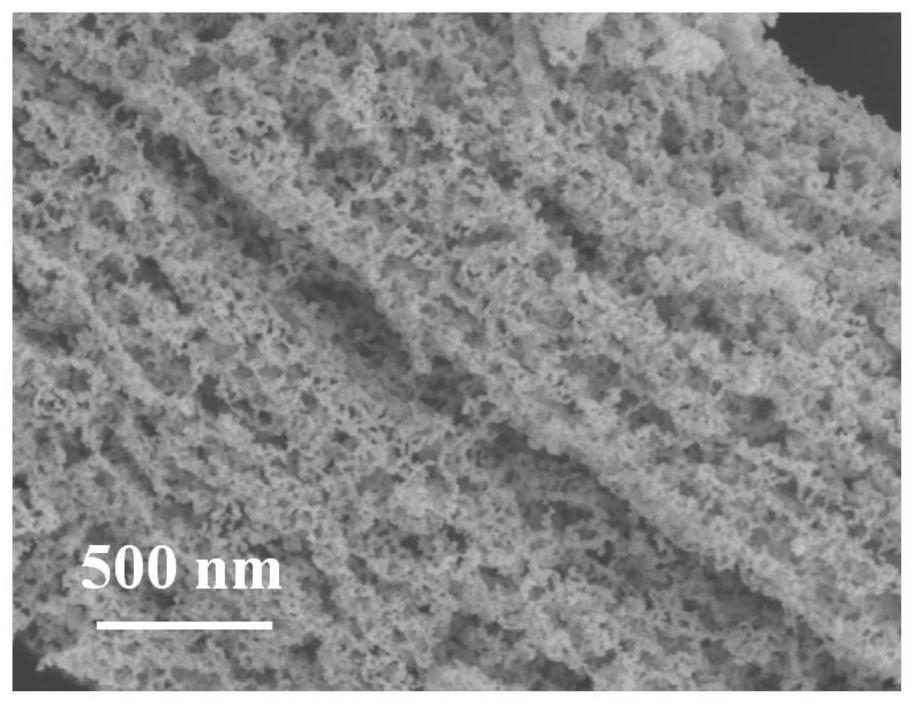

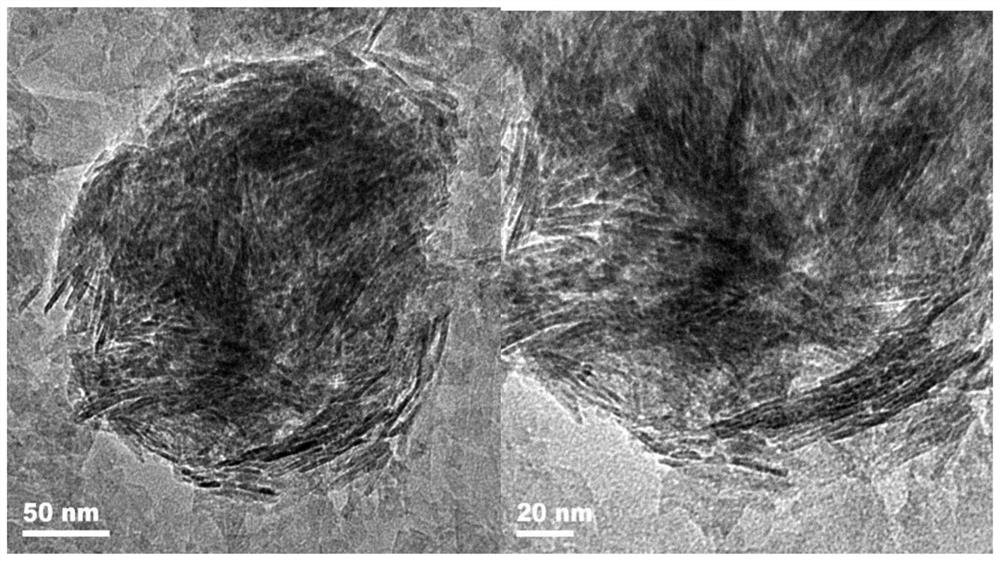

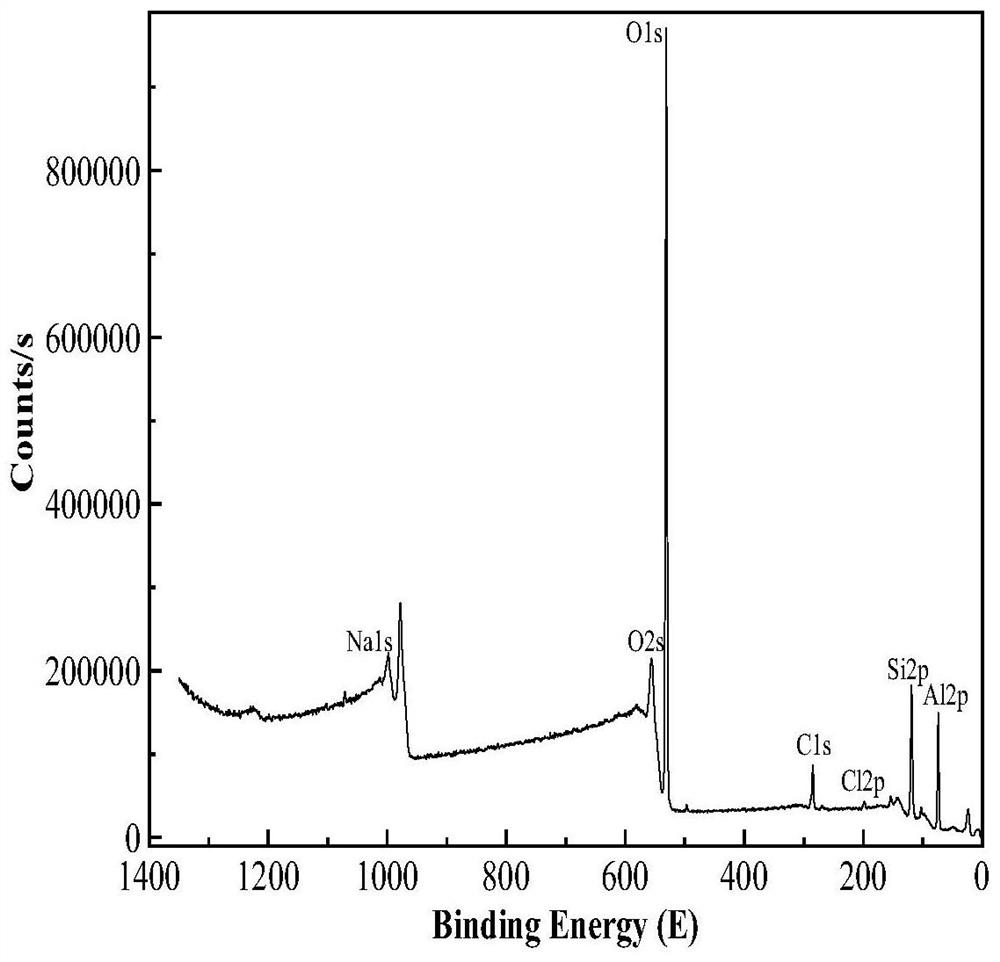

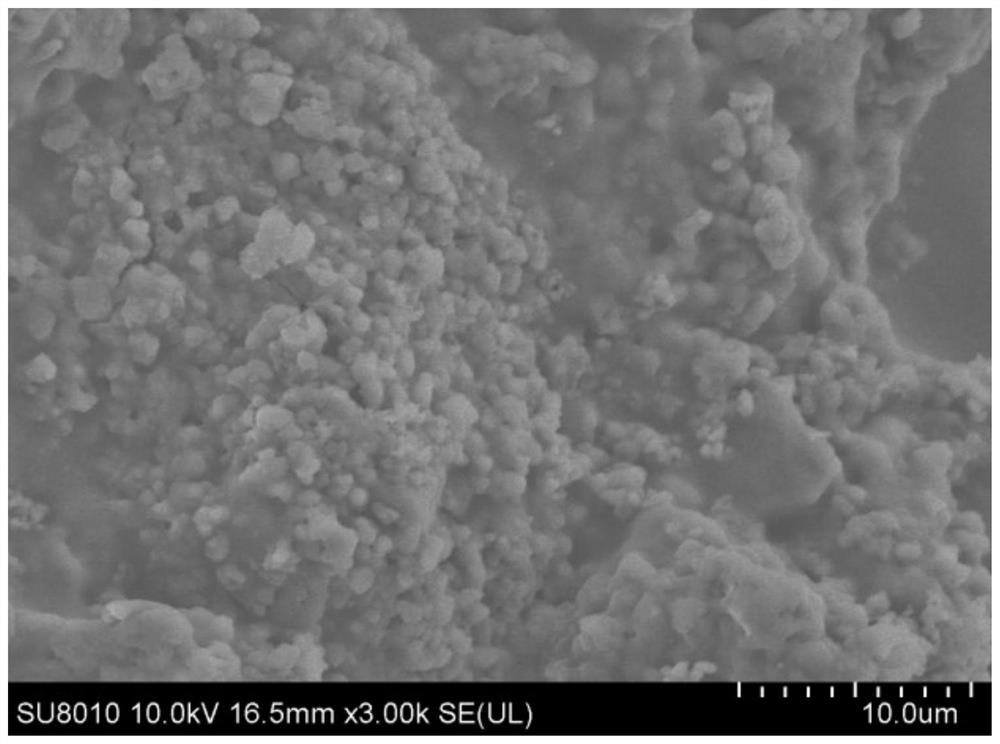

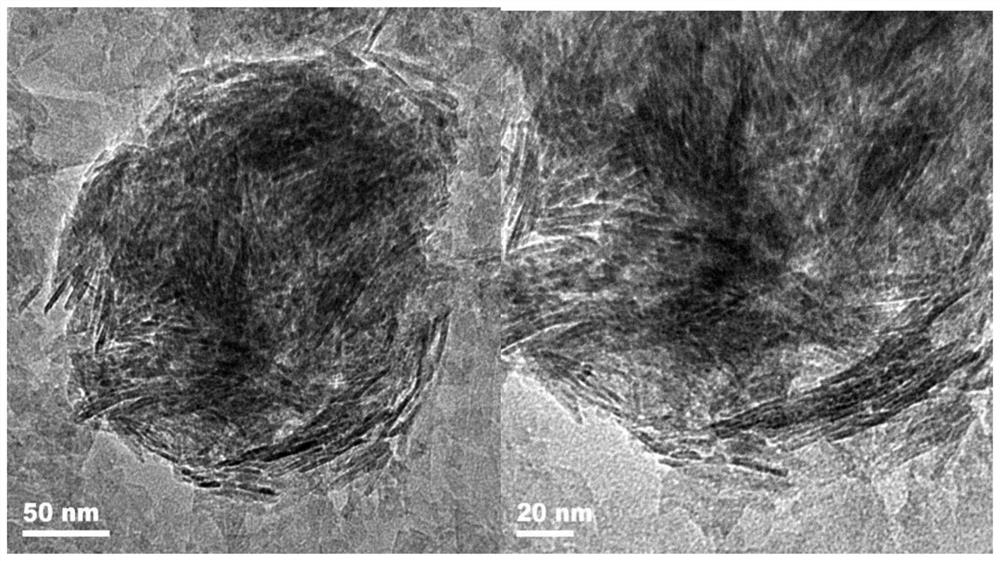

Preparation method for low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve

InactiveCN103601213AWide variety of sourcesReduce the ratio of silicon to aluminumMaterial nanotechnologyMordenite aluminosilicate zeoliteIsomerizationReaction rate

The invention discloses a preparation method for a low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve. The preparation process of the mordenite molecular sieve includes: dissolving an aluminum source and an alkali source in deionized water, adding silica sol into the obtained clarified solution to obtain a uniform white colloid, transferring the white colloid into a reaction kettle to undergo hydrothermal reaction, thus obtaining the low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve. The mordenite molecular sieve prepared by the invention has the advantages of wide silicon source and aluminum source, low silicon-aluminum ratio, multiple active centers, no adding of any surfactant, low preparation cost, less environmental pollution and large specific surface area, and is conducive to spread of the reactants and product and acceleration of the reaction rate, thus being widely applicable in adsorption, separation, catalytic cracking, isomerization and other fields.

Owner:TIANJIN UNIV

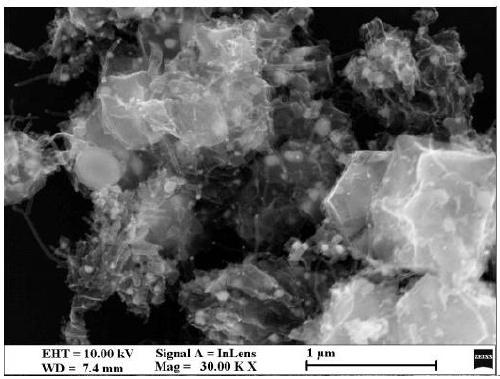

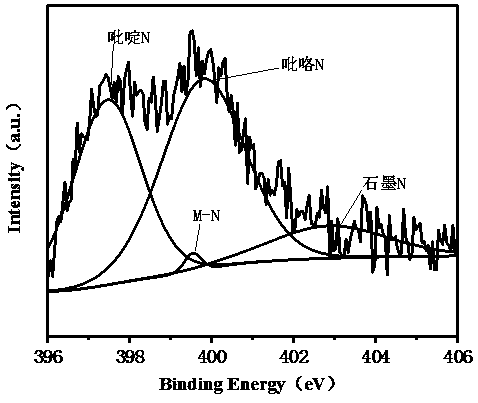

Heteroatom doped cobalt metal catalyst and preparation method thereof

PendingCN111558391AWide variety of sourcesLow priceCell electrodesCatalyst activation/preparationBio moleculesPtru catalyst

The invention discloses a heteroatom doped cobalt metal catalyst and a preparation method thereof, and belongs to the field of catalyst synthesis technology and application. The method for preparing the cobalt metal catalyst by heteroatom doping comprises the following steps: dispersing and dissolving biomolecules in a solution, sequentially adding a cobalt salt and an organic ligand, stirring, drying, and directly carbonizing at a high temperature to prepare the heteroatom (nitrogen, phosphorus and sulfur) doped cobalt metal catalyst in one step. According to the catalyst disclosed by the invention, the complete morphology is kept; meanwhile, the catalyst has a high specific surface area, a hierarchical porous structure and good methanol resistance and stability; and the preparation method is simple, the raw materials are easy to obtain, the price is low, the obtained catalyst shows remarkable fuel cell cathode oxygen reduction reaction (ORR) activity in an alkaline medium, the good method is provided for exploring the new non-noble metal catalyst material, and a basis is provided for further experimental optimization and industrial production.

Owner:FUZHOU UNIV

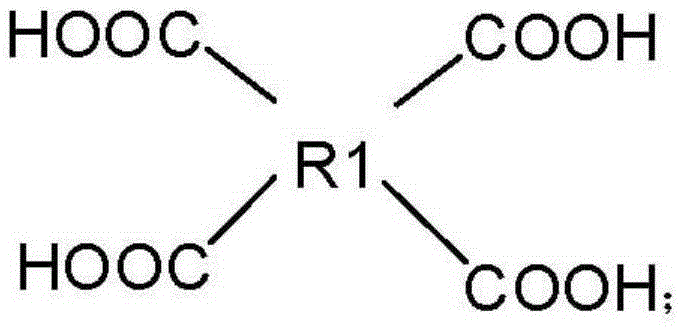

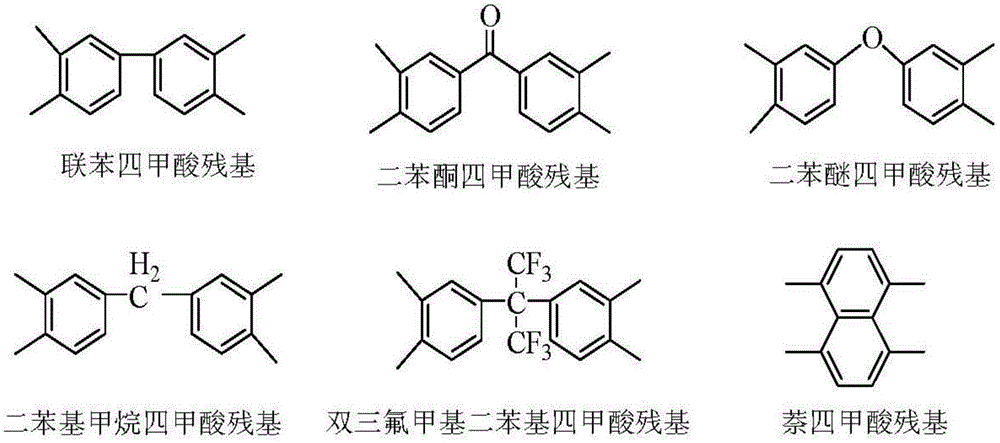

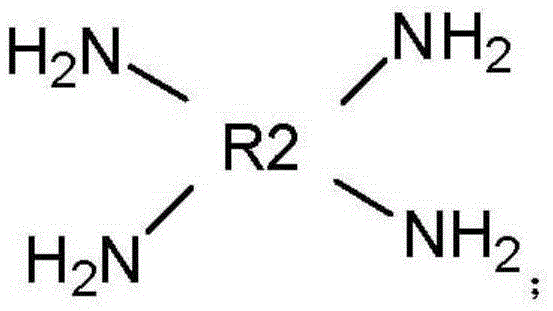

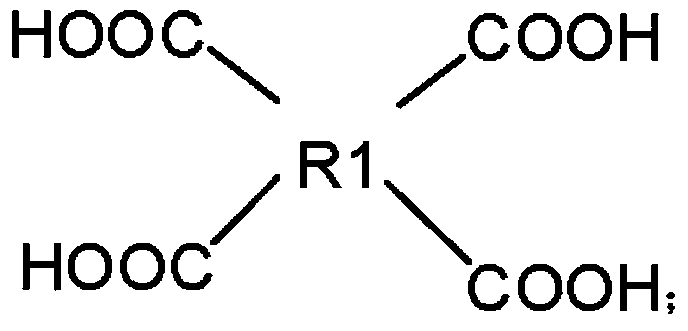

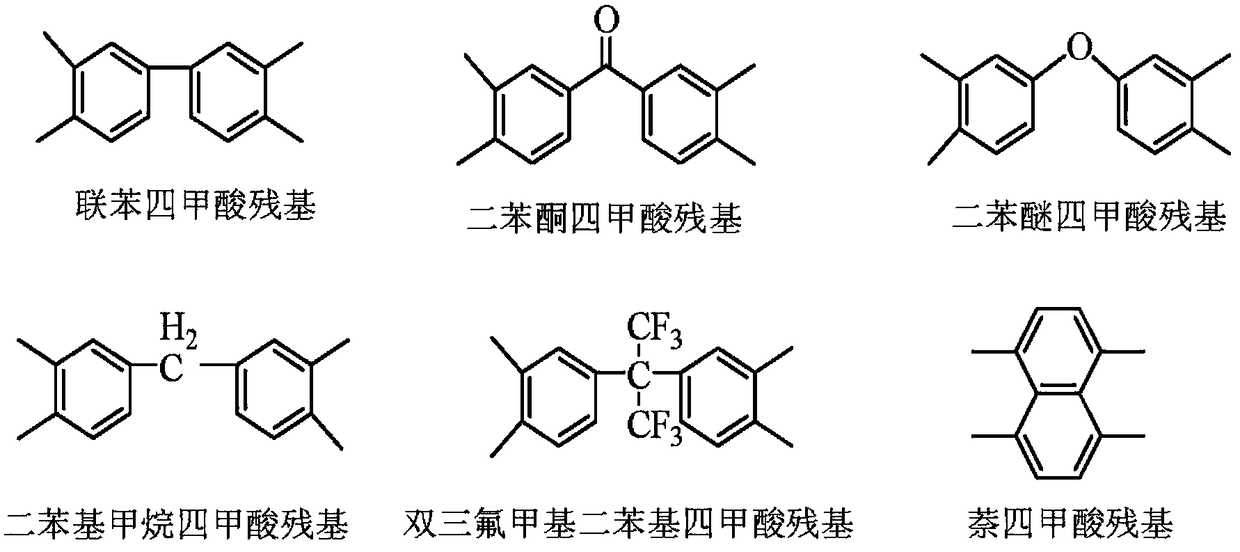

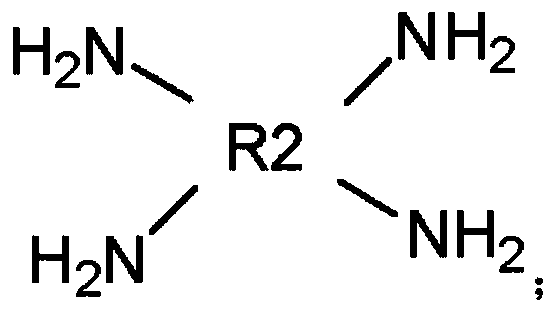

Polypyrrolone/polyimide composite porous catalytic film and preparation method thereof

ActiveCN105709611AMany active centersImprove mechanical propertiesSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsFiberPetroleum

The invention discloses a polypyrrolone / polyimide composite porous catalytic film and a preparation method thereof. The preparation method includes following steps: 1), dissolving tetracid monomer and tetramine monomer in a solvent to obtain a polypyrrolone prepolymer solution; 2), sequentially adding a polyamic acid solution, metal components and pore former into the polypyrrolone prepolymer solution to obtain a mixed spinning solution, and forming a composite nano fiber precursor through electrostatic spinning; 3), subjecting the composite nano fiber precursor to vacuum drying and thermal treatment to obtain the polypyrrolone / polyimide composite porous catalytic film. The polypyrrolone / polyimide composite porous catalytic film obtained by the method has high heat resistance and mechanical performance when being applied in the field of petroleum catalysis, and expense needed for separating reaction liquid from a catalyst is reduced.

Owner:JIANGXI NORMAL UNIV

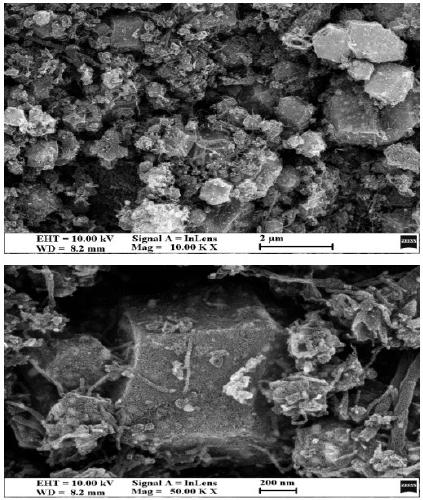

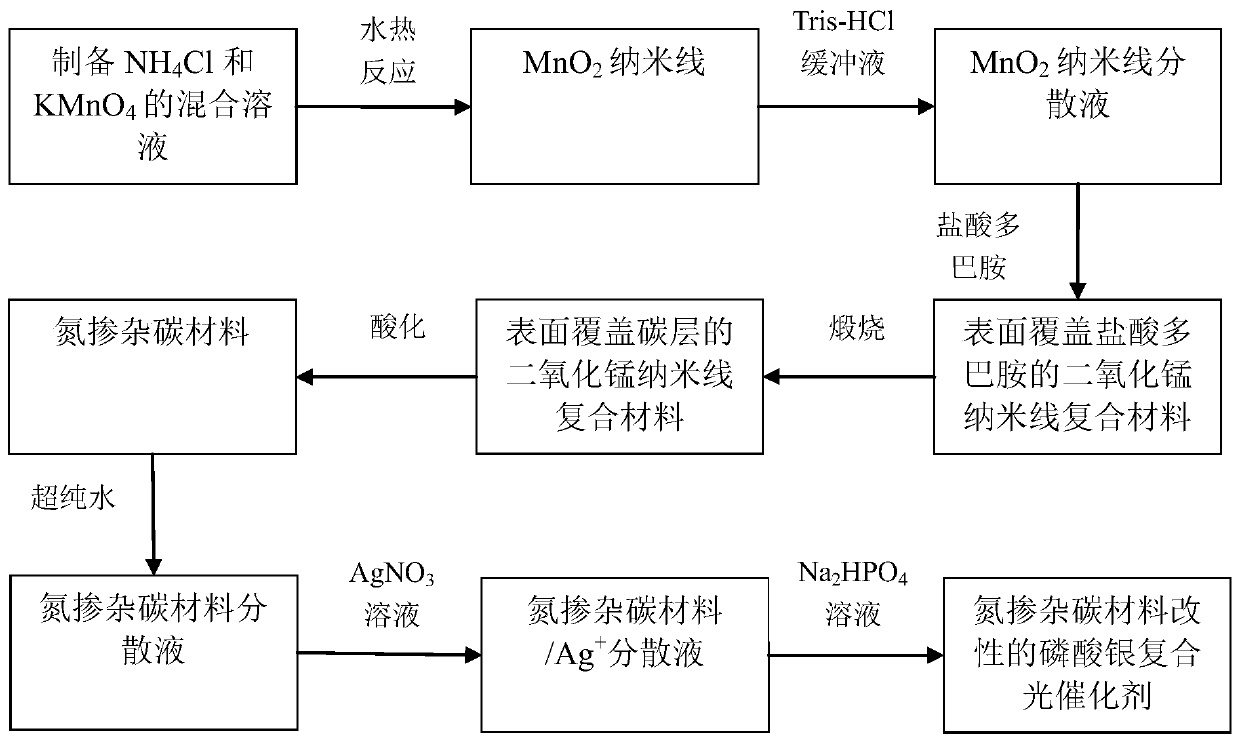

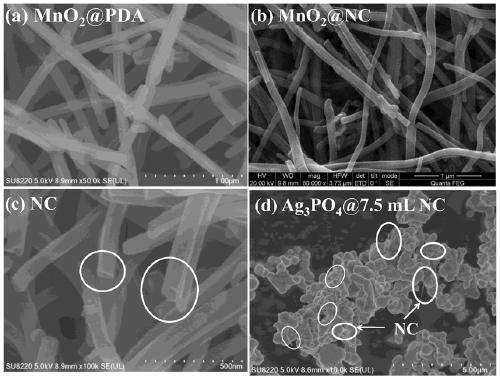

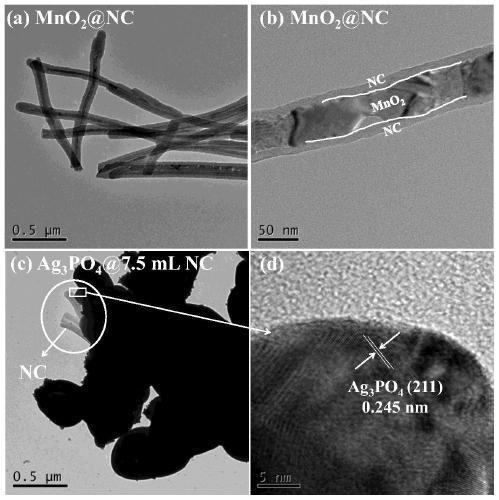

Nitrogen-doped carbon material modified silver phosphate composite photocatalyst, preparation method and application thereof

ActiveCN111389449AImprove conductivityImprove photocatalytic efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationSilver phosphateVisible light photocatalytic

The invention discloses a nitrogen-doped carbon material modified silver phosphate composite photocatalyst, a preparation method and application thereof. The silver phosphate composite photocatalyst comprises a nitrogen-doped carbon material, and silver phosphate particles are loaded on the nitrogen-doped carbon material. The preparation method comprises the following steps: preparing the nitrogen-doped carbon material into a nitrogen-doped carbon material dispersion liquid, adding an Ag<+> solution to prepare a nitrogen-doped carbon material / Ag<+> dispersion liquid, and adding an HPO4<2-> solution to prepare the silver phosphate composite photocatalyst. The silver phosphate composite photocatalyst disclosed by the invention has the advantages of high photo-induced electron-hole pair separation efficiency, strong light corrosion resistance, strong photocatalytic activity and the like, is a novel efficient visible light photocatalyst, can be widely applied to removal of organic pollutants in the environment, and has very high use value and very good application prospect. The preparation method of the silver phosphate composite photocatalyst has the advantages of simple process, operation method, low cost, greenness, no pollution and the like, is suitable for large-scale preparation, and is beneficial to industrial application.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Forsterite bio-filter material for sewage treatment and preparation method of forsterite bio-filter material

InactiveCN104071891AStrong oxidation abilityImprove flocculation abilitySustainable biological treatmentBiological water/sewage treatmentBiofilmPolystyrene

The invention particularly relates to a forsterite bio-filter material for sewage treatment and a preparation method of the forsterite bio-filter material. The technical scheme is as follows: the preparation method comprises the following step: uniformly mixing 45-55wt% of forsterite raw ore fine powder, 20-30wt% of talc fine powder, 15-25wt% of magnesium oxide fine powder and 2-6wt% of dravite micropowder as raw materials with additional 2-6wt% of starch to prepare a mixed material; then, putting the mixed material and polystyrene balls in a pelletizer in a volume ratio of the polystyrene balls and the mixed material of (1.5-2.0) to 1; then, adding 10-20wt% of water to prepare particles with the grain size being 5-13mm; and then, roasting the prepared particles for 16-24 hours at 110-150 DEG C, and sintering for 2-4 hours at 1300-1500 DEG C to prepare the forsterite bio-filter material for sewage treatment. The forsterite bio-filter material for sewage treatment is simple in process and wide in source of raw materials and the prepared forsterite bio-filter material for sewage treatment has the characteristics of good flora biofilm culturing effect, high flora survival rate, good decoloring effect and high strength.

Owner:XIXIA HONGTAI FORSTERITE +1

Method for producing ethylene and propylene by catalytic cracking

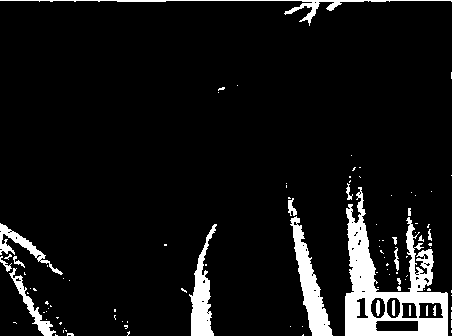

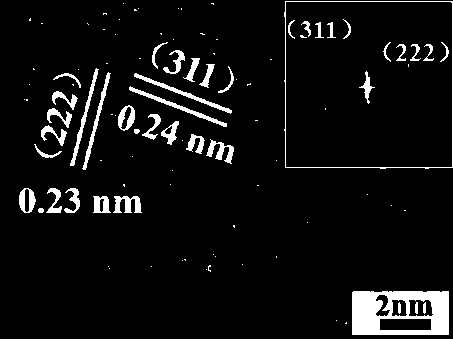

ActiveCN101619011AIncrease surface areaMany active centersMolecular sieve catalystsBulk chemical productionHydrocarbon mixturesFixed bed

The invention provides a method for producing ethylene and propylene by catalytic cracking. The method comprises the steps: introducing an alkene raw material into a fixed bed reactor to contact the alkene raw material with a catalyst to perform a catalytic cracking reaction under the conditions of a temperature of between 500 and 680 DEG C, a pressure of between 0 and 0.5MPa, a weight space velocity of between 10 and 50h<-1> and a water-oil weight ratio of between 0 and 1.0; and separating resulting the hydrocarbon mixture obtained after the reaction to obtain the ethylene and the propylene, wherein based on the total weight of the catalyst, the catalyst contains 20 to 40 percent by weight of modified molecular sieve and 60 to 80 percent by weight of heat resisting inorganic oxide, the average grain size of the modified molecular sieve is between 10 and 100nm and the modified element is one of phosphorus and metals in the IB group or the modified elements are a mixture of elements selected from phosphorus and metals in the IB group; and based on the total weight of the molecular sieve, the content of the modified element is between 1 to 10 percent. The method provided by the invention has higher alkene conversion rate and once-through yield of the ethylene and the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

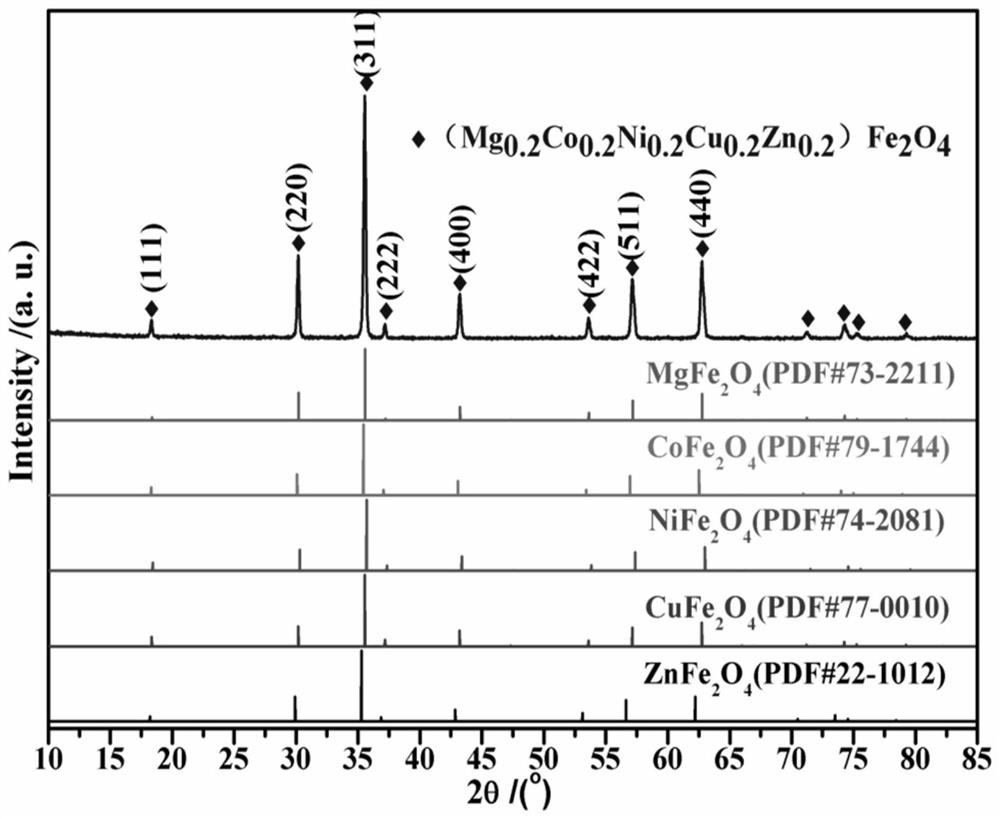

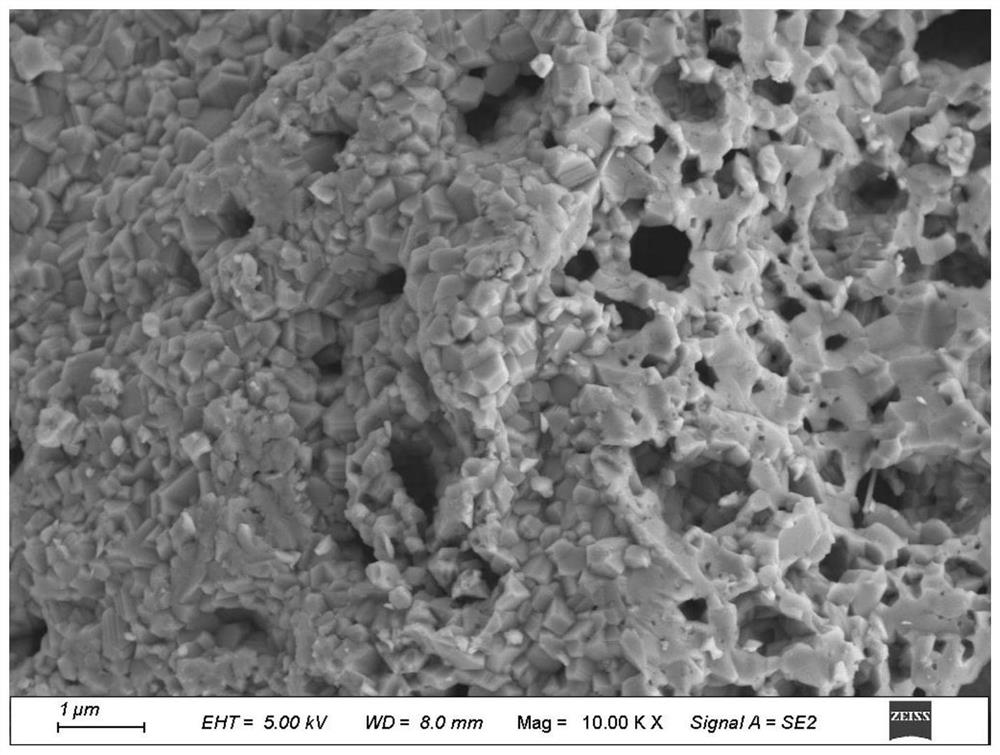

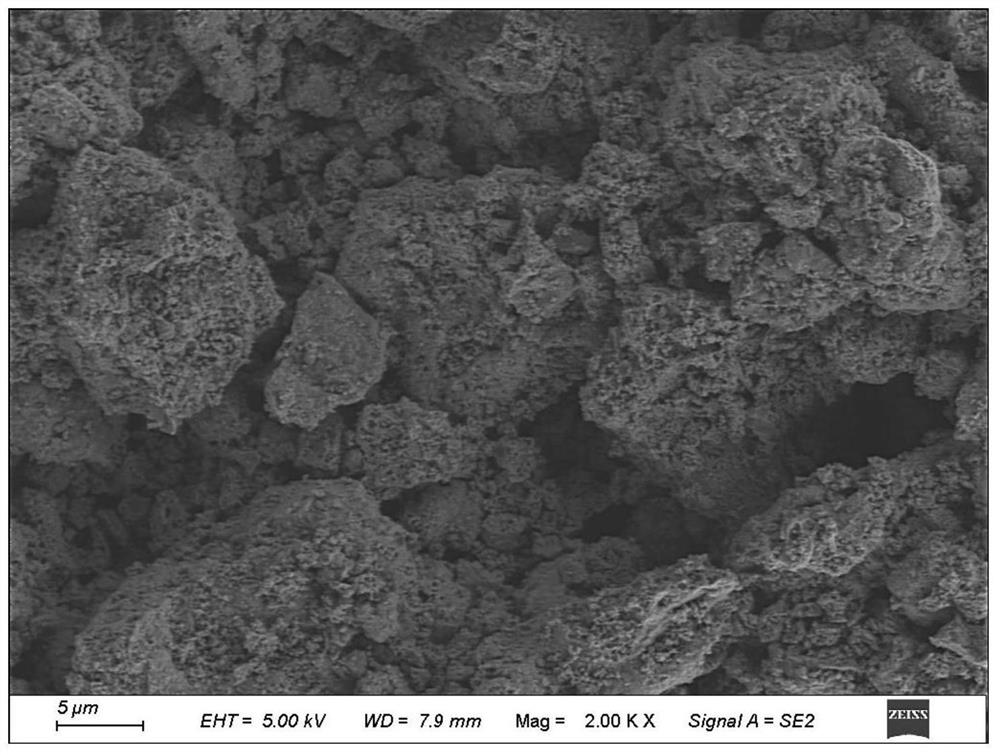

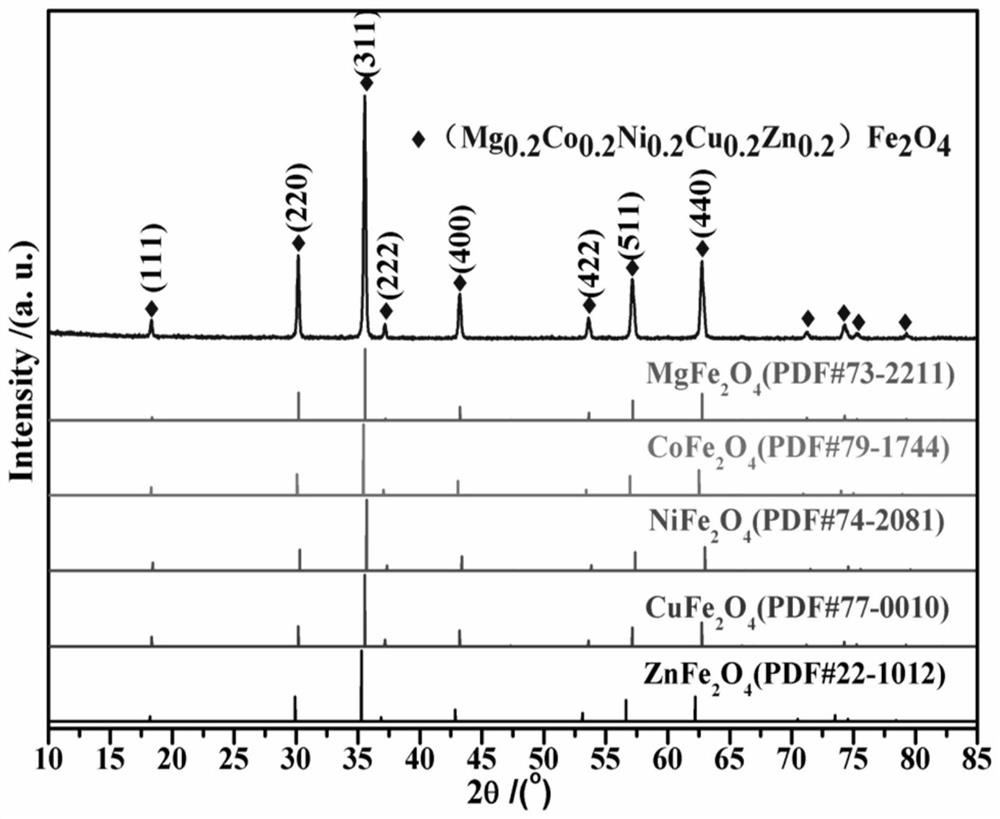

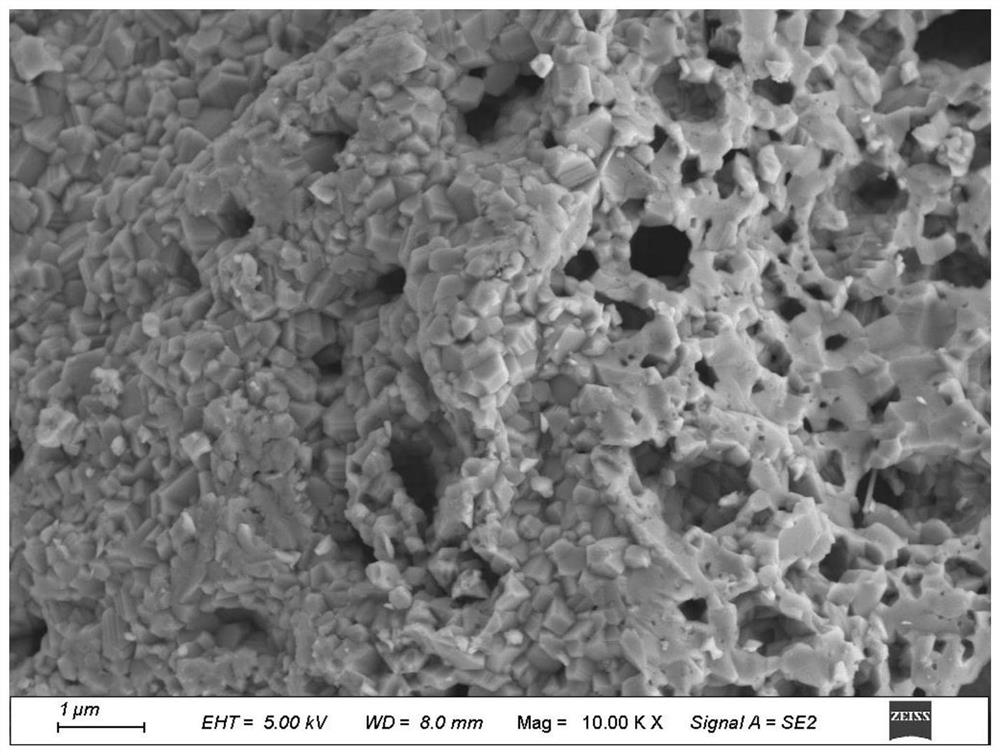

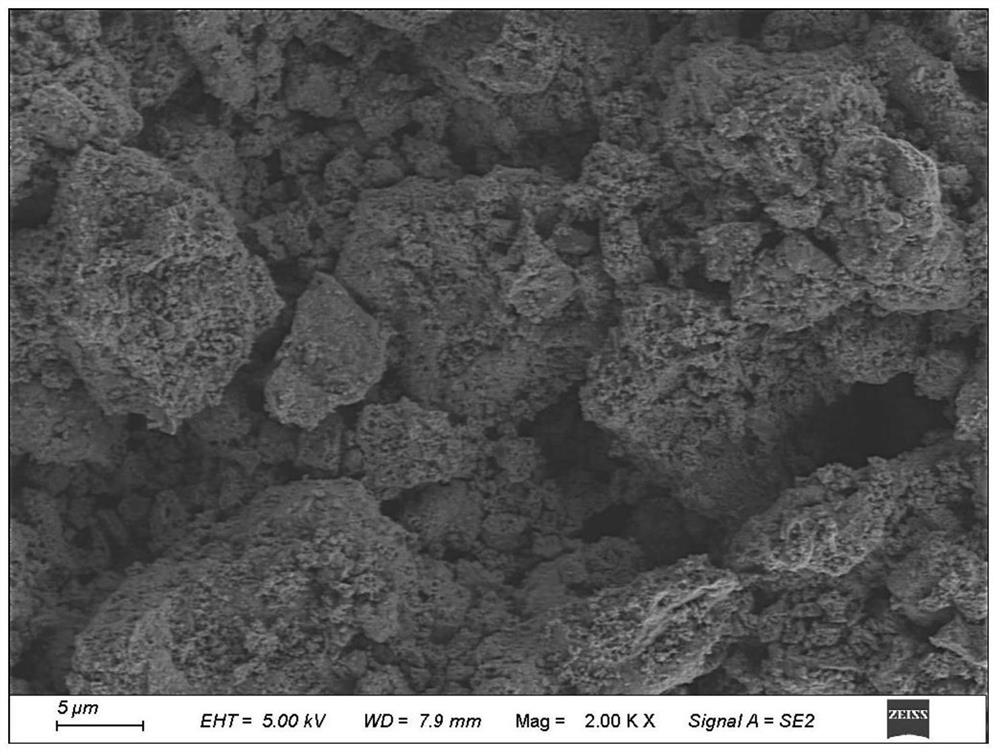

High-entropy ferrite porous ceramic material as well as preparation method and application thereof

ActiveCN113860911ALarge specific surface areaSelf-supportingCatalyst carriersGas treatmentChemical compositionCopper nitrate

The invention discloses a high-entropy ferrite porous ceramic material as well as a preparation method and application thereof, and belongs to the field of inorganic functional materials. The chemical composition of the high-entropy ferrite porous ceramic material is (Mg<0.4-x>Co<x>Ni<0.2>Zn<0.2>Cu<0.2>)Fe<2>O<4>, wherein x is more than 0 and less than or equal to 0.2. The preparation method comprises the following steps: dissolving glycine, magnesium nitrate, cobalt nitrate, nickel nitrate, zinc nitrate, copper nitrate and ferric nitrate in water to obtain a mixed solution; adjusting the pH value of the obtained mixed solution, and conducting heating until the solution is subjected to combustion reaction to obtain precursor powder; and carrying out heat treatment, molding and sintering on the obtained precursor powder to obtain the high-entropy ferrite porous ceramic material. The high-entropy ferrite porous ceramic material disclosed by the invention integrates the advantages of a high-entropy effect and a foam structure synergistic effect, has a self-supporting capability and a high specific surface area, is convenient to transport, store and recycle, and has a good application prospect.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Cobaltosic oxide catalyst, preparation method and application thereof

PendingCN110787822ARaw materials are easy to obtainLow costCatalyst activation/preparationIncinerator apparatusNitrogen plasmaPtru catalyst

The invention discloses a cobaltosic oxide catalyst, a preparation method and application thereof. The preparation method includes: (a) preparing a cobaltosic oxide nanorod Co3O4-110 with an exposed crystal surface (110); and (b) doping N atom to the surface of Co3O4-110 to obtain the cobaltosic oxide catalyst N-Co3O4-110. The preparation method of the cobaltosic oxide catalyst provided by the invention has easily controllable reaction conditions, can be operated at room temperature, and by changing the nitrogen plasma treatment time, different nitrogen doping amounts and oxygen vacancy content can be obtained. The cobaltosic oxide catalyst obtained by the preparation method disclosed by the invention has the advantages of simple and easily available raw materials, and lower cost than platinum, palladium and the like, and simple operation method, and is suitable for industrial application. The cobaltosic oxide catalyst has more surface defects, higher surface oxygen content and highercharge transfer efficiency, and can be used for catalyzing various oxidation reactions.

Owner:QINGDAO UNIV

Production method and application for organic yeast protein selenium product with life combined state

InactiveCN103756922ASmall particle sizeLarge specific surface areaFungiAnimal feeding stuffBiotechnologyYeast Proteins

The invention relates to a production method and an application for an organic yeast protein selenium product with a life combined state. According to the production method and the application disclosed by the invention, a selenium source used during a fermentation process is nano-selenium; nano-selenium has the advantages of being low in toxicity, large in specific surface area, high in bioactivity, and the like, and is capable of increasing the tolerance dose of yeasts to selenium and the bioavailability; protease is added in a yeast fermentation culture medium to increase the utilization rate of fermentation materials and reduce cost. Compared with the previous method of converting inorganic selenium to organic selenium by yeasts, the selenium source used in the production method and the application disclosed by the invention is nano-selenium, and has the advantages of being low in toxicity, high in conversion rate, high in absorption rate, good in product safety performance, high in bioactivity, convenient for large-scale production and collection, and the like.

Owner:广州市博仕奥生物科技有限公司 +1

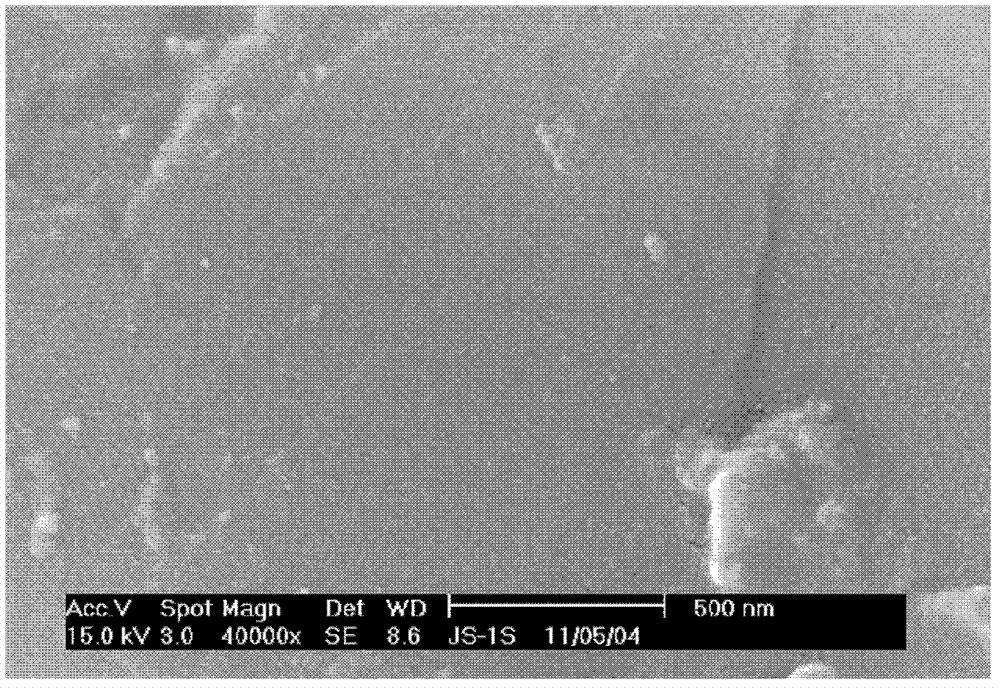

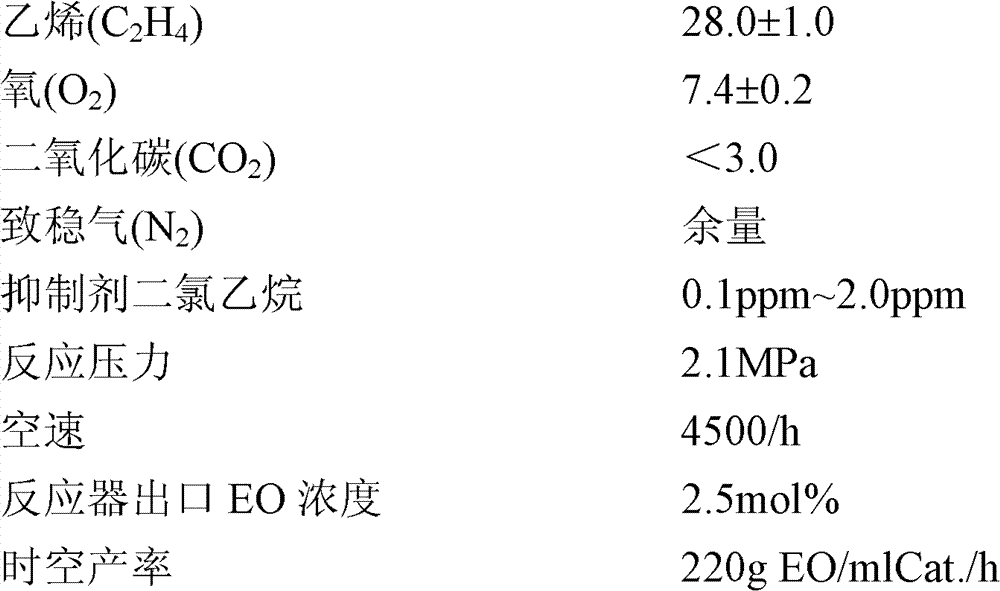

Modification method of alumina carrier as well as preparation method and application of silver catalyst supported by alumina carrier

ActiveCN103357440ALarge specific surface areaMany active centersCatalyst carriersOrganic chemistryEthyleneSilver catalyst

The invention relates to a modification method for forming an alpha-alumina carrier of a silver catalyst used for producing ethylene oxide through ethylene oxidation. The method has the beneficial effect of increasing the pore canal and specific surface area of the carrier by carrying out acid-alkali combined treatment on the formed alpha-alumina carrier. The silver catalyst prepared from and supported by the alpha-alumina carrier prepared by the method is beneficial to increase of reaction centers and diffusion of products. The modified alpha-alumina carrier shows good selectivity when applied to the reaction process of producing ethylene oxide through ethylene oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of aniline hydrogenating amorphous nickel-aluminum catalyst

InactiveCN103302257AImprove hydrogenation activityMagneticMetal/metal-oxides/metal-hydroxide catalystsAlloy catalystAlloy

The invention discloses a preparation method of an aniline hydrogenating amorphous nickel-aluminum catalyst. The preparation method of the aniline hydrogenating amorphous nickel-aluminum catalyst comprises the following steps: pretreating an alloy to crush the alloy; and putting the crushed alloy into a melting furnace for melting the alloy, pressing the melted alloy onto a copper roll from a spray nozzle on the lower part of the melting furnace through inert gas, quickly cooling, and throwing out from a tangent line of the copper roll to obtain an amorphous alloy. According to the preparation method, under the same condition, the amorphous alloy catalyst has high hydrogenating activity, relatively high magnetism and thermal stability, more active centers and better catalyzing effect in aniline hydrogenation.

Owner:SUZHOU TAILIDA TECH

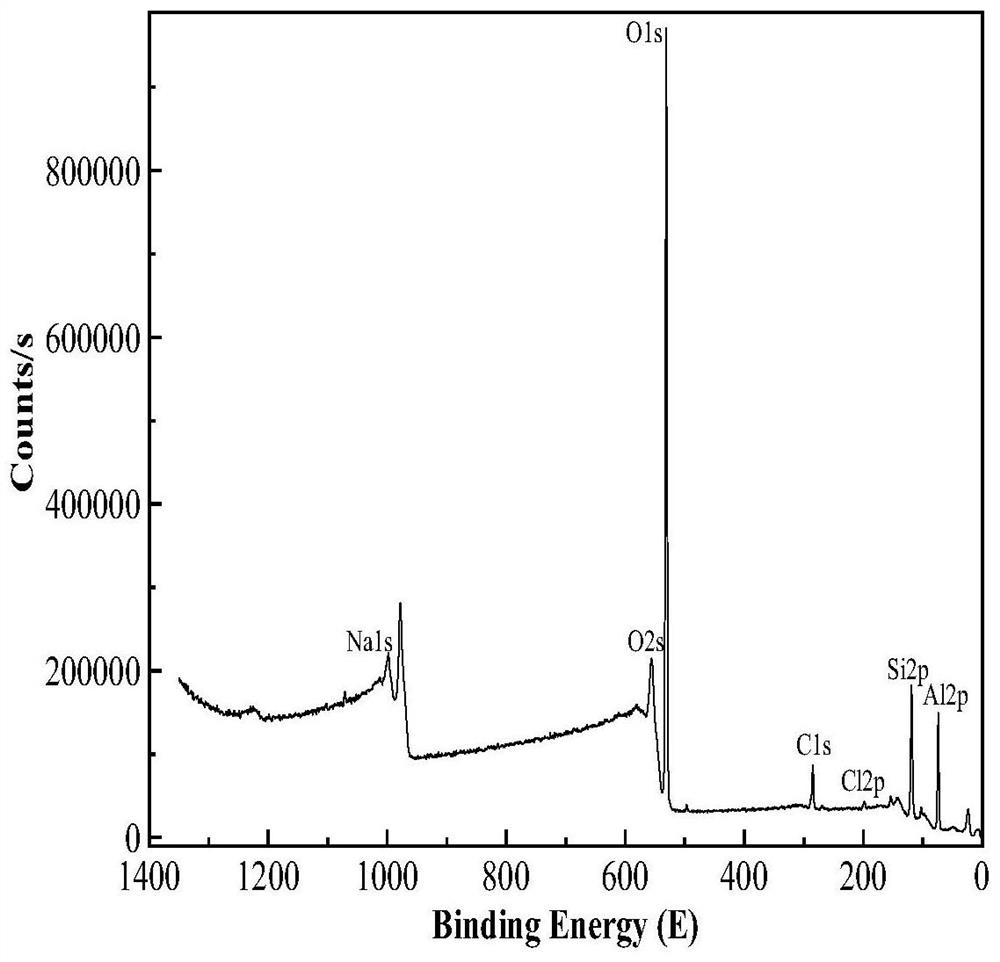

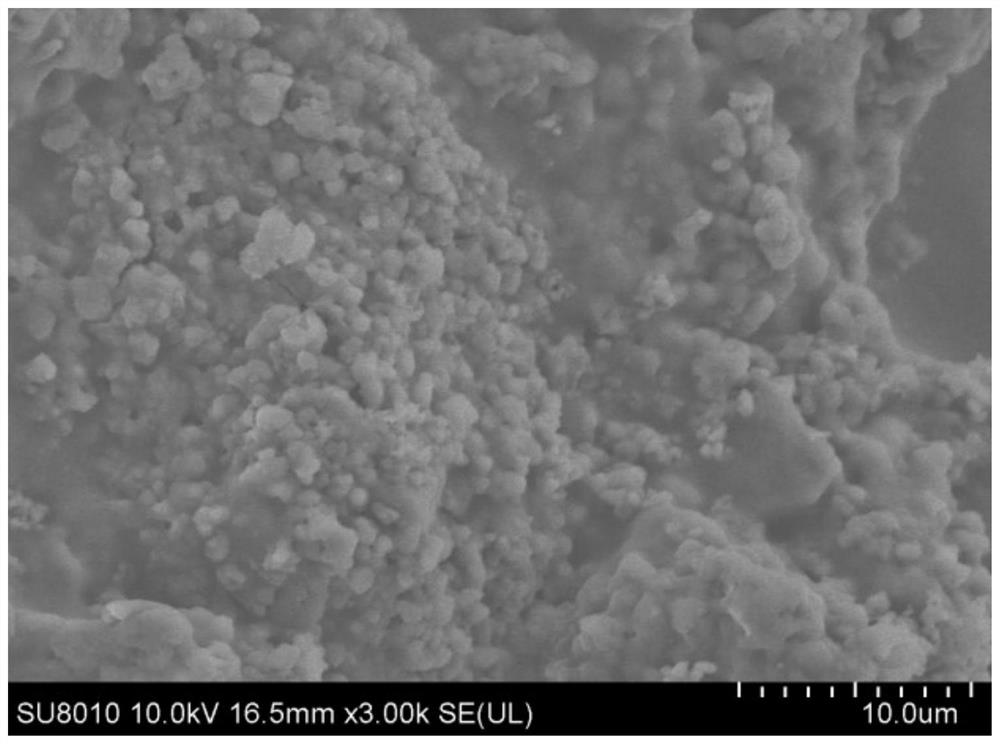

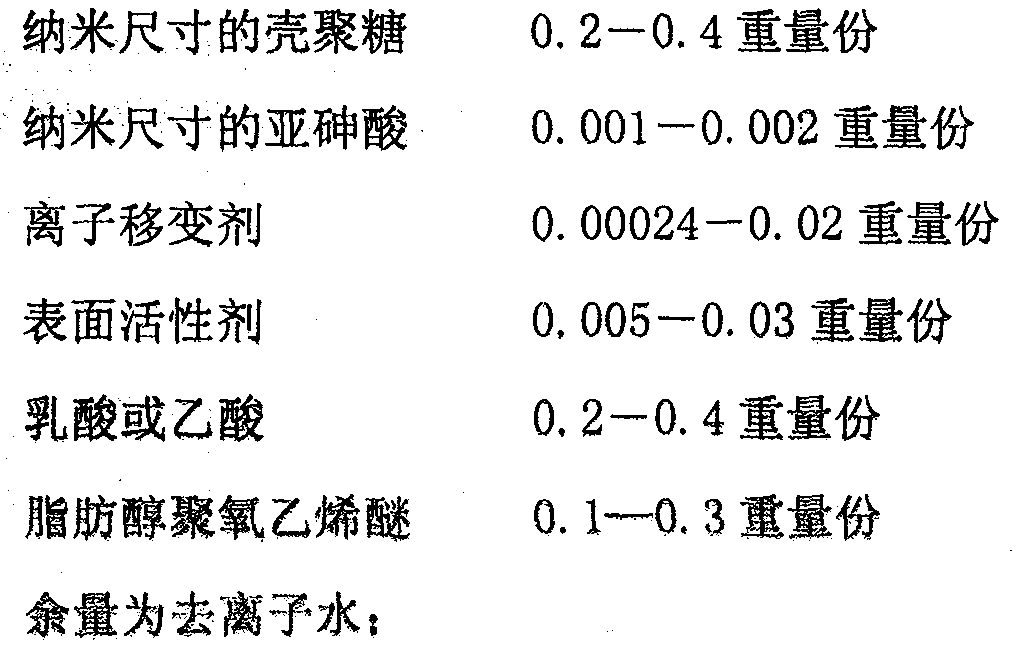

Chitosan entrapment body of nano-scale arsenous acid and manufacturing method thereof

InactiveCN101695501ASmall particlesImprove surface reactivityPowder deliveryInorganic active ingredientsChemistrySurface-active agents

The invention provides a chitosan entrapment body of nano-scale arsenous acid, which comprises the following components in part by weight: 0.2 to 0.4 part of nano chitosan, 0.001 to 0.002 part of nano arsenous acid, 0.00024 to 0.02 part of ion shift variant agent, 0.005 to 0.03 part of surface active agent, 0.2 to 0.4 part of lactic acid or acetic acid, 0.1 to 0.3 part of fatty alcohol polyethenoxy ether, and the balance of deionized water. An integration process of three highly difficult reactions including the preparation of an arsenous acid pre-dispersed intermediate, the preparation of an active nano chitosan three-dimensional network colloid and the entrapment to the nano arsenous acid by the active nano chitosan three-dimensional network colloid is achieved by a 'one-step method', and nano arsenous acid particles in the manufactured chitosan entrapment body have the main area particle size distribution of between 20 and 50 nanometers and show the characteristics of the arsenous acid. The chitosan entrapment body of the nano-scale arsenous acid has the advantages of high bioavailability, enhanced slow-release property, reduced dosage, low toxic or side effect and enhanced anti-cancer curative effect, and provides a selection path with high-tech synthesis for arsenic medicaments.

Owner:广汉恒宇新材料有限公司

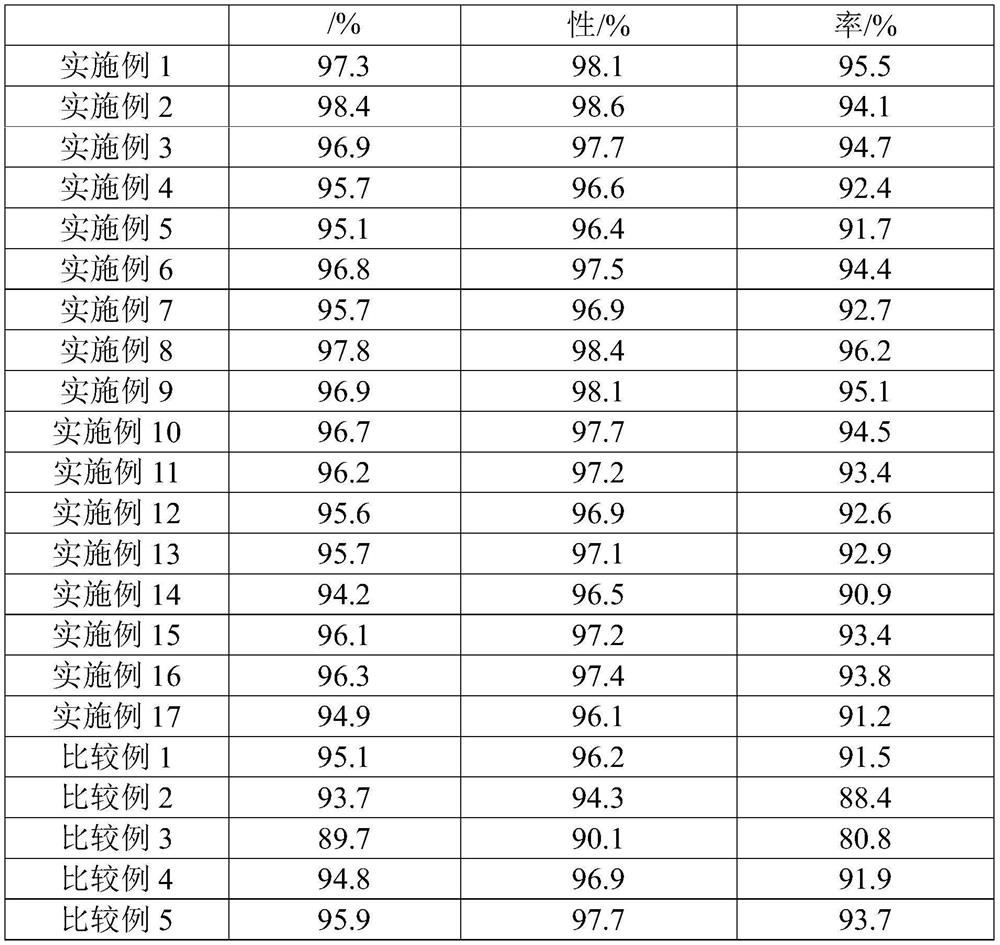

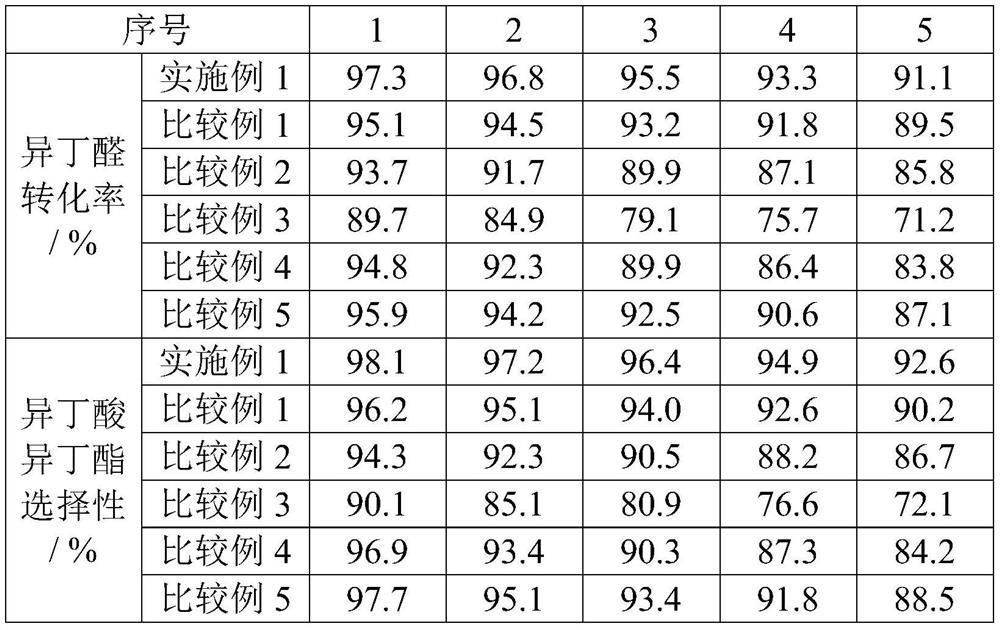

Composite metal oxide catalyst for one-step preparation of isobutyl isobutyrate from isobutyraldehyde, and preparation method of composite metal oxide catalyst

ActiveCN112206820AStrong adsorption and mass transfer capacityIncreased stability and longevityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by aldehyde oxidation-reductionIso butanolMaterials science

The invention belongs to the technical field of catalysts, and particularly relates to a composite metal oxide catalyst for one-step preparation of isobutyl isobutyrate from isobutyraldehyde, and a preparation method of the composite metal oxide catalyst. According to the invention, carbon black is used as an inert matrix, a nanometer CuO-MxOy (wherein M is Ce, Cr or Ti) carrier with a mesoporousstructure is synthesized by combining a space synthesis method with a hydrothermal microwave method, and then aluminum isobutoxide is loaded on the surface of the carrier by utilizing a supercriticalfluid impregnation method to prepare the catalyst. The preparation method is simple; the catalyst has a good structure and a good surface distribution state; a mesoporous structure significantly improves the stability of the catalyst and prolongs the service life of the catalyst, so the catalyst has a higher specific surface area and can be used in a reaction for preparing isobutyl isobutyrate from isobutyraldehyde in one step; and the reaction activity of the catalyst and the selectivity of isobutyl isobutyrate are obviously improved.

Owner:RUNTAI CHEM TAIXING CO LTD

Environmentally-friendly wood-plastic integrated wallboard and production method thereof

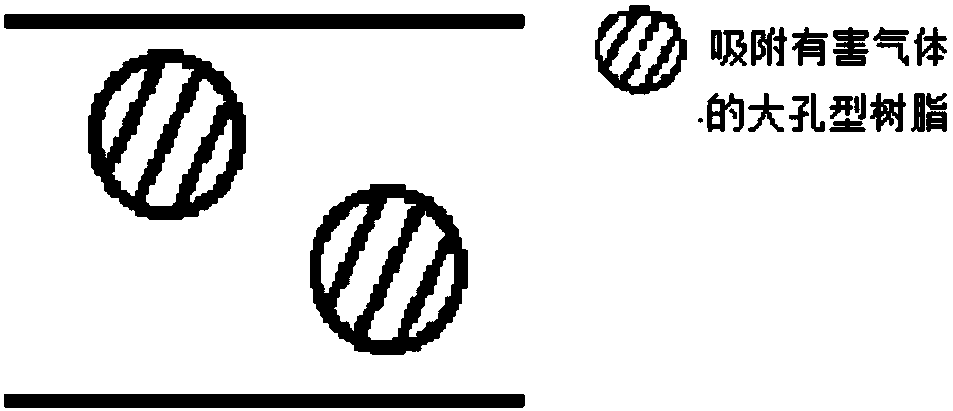

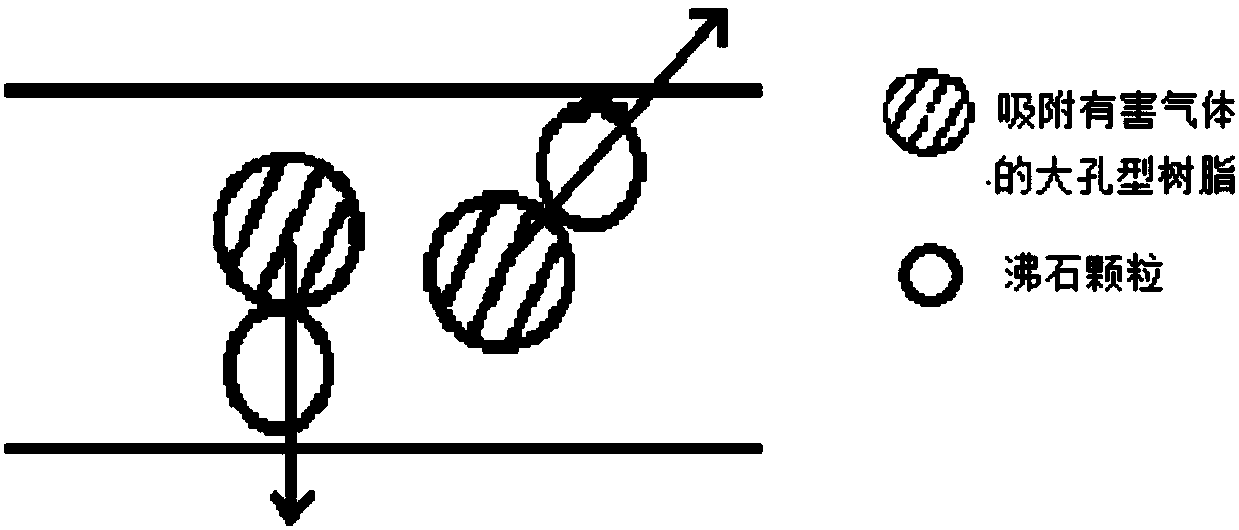

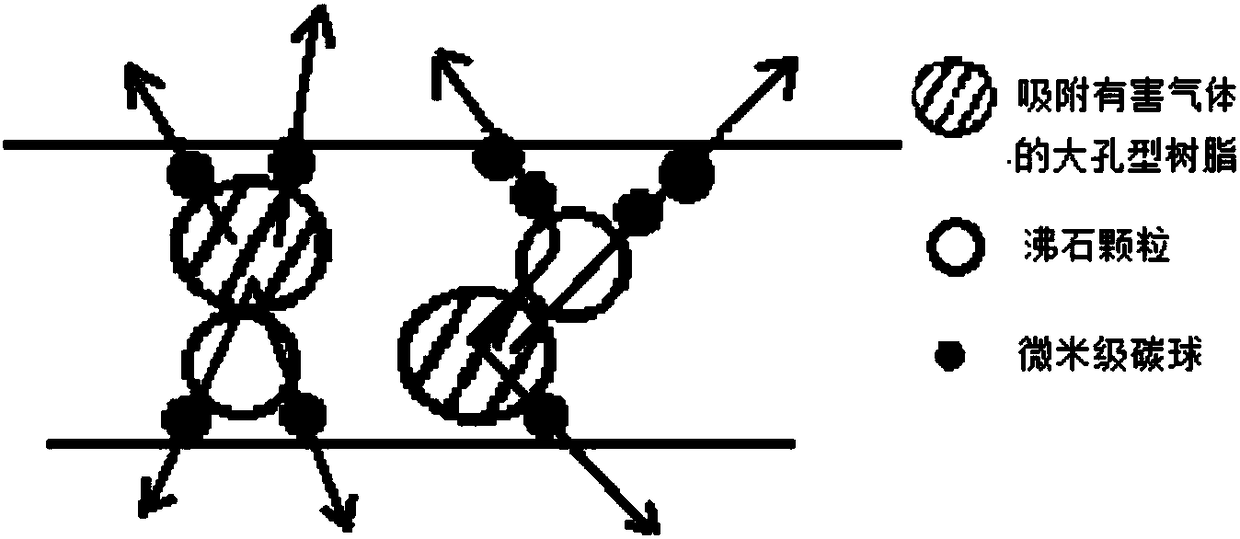

The invention discloses an environmentally-friendly wood-plastic integrated wallboard and a production method thereof, belonging to the field of environmentally-friendly high-molecular materials. According to the invention, polyvinyl chloride resin and polychlorohexene resin are used as substrates; wood powder and calcium carbonate powder are used as fillers; polyethylene wax is used as a lubricant; stearic acid is used as a stabilizer; chlorinated polyethylene 135A is used as a toughness and impact modifier; foaming AC-02 is used as a foaming regulator; and macroporous resin, micron-sized carbon spheres and zeolite particles are compounded to form an adsorption purifying agent, so adsorption and desorption discharge channels for harmful gases are formed inside the integrated wallboard. According to the invention, zeolite particles, macroporous resin and micron-sized carbon spheres are added into the integrated wallboard to form the adsorption purifying agent, so the adsorption and desorption channels are formed inside the integrated wallboard; and thus, the internal structure of the wallboard is more abundant, the combination of macro-holes, small holes and micropores makes the porosity of the formed adsorbent larger, the channels for desorption and discharge of harmful gases from the integrated wallboard are increased, and the adsorption and discharge of harmful gases are more thorough and environment-friendlier.

Owner:辽宁新世界科技股份有限公司

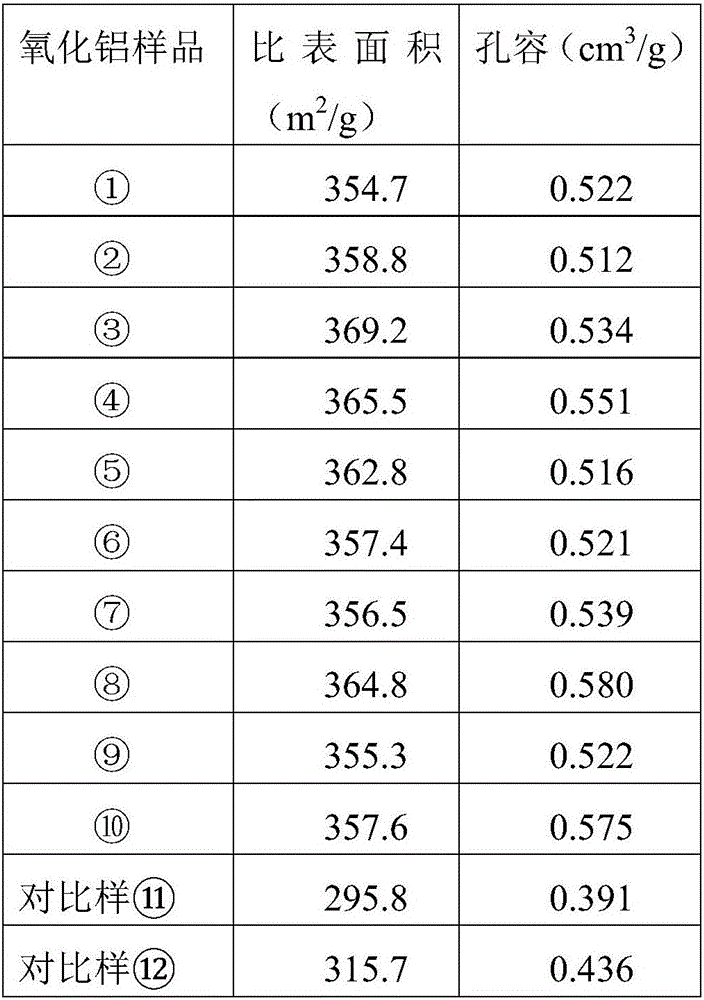

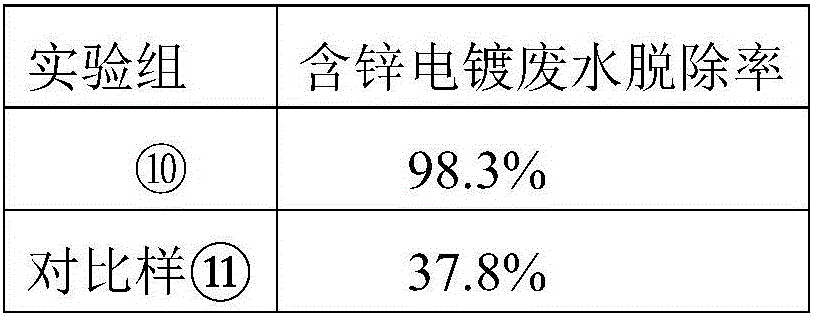

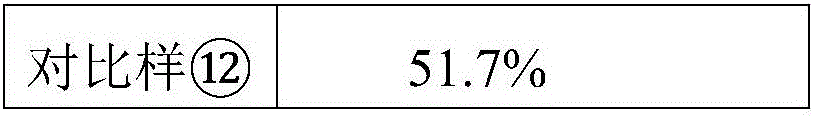

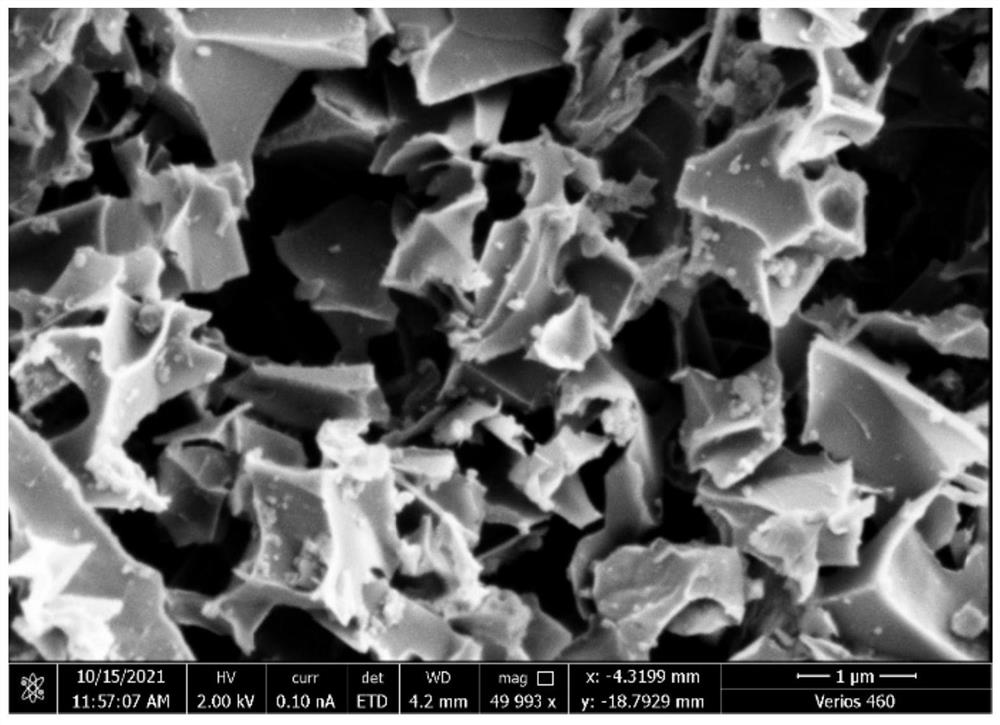

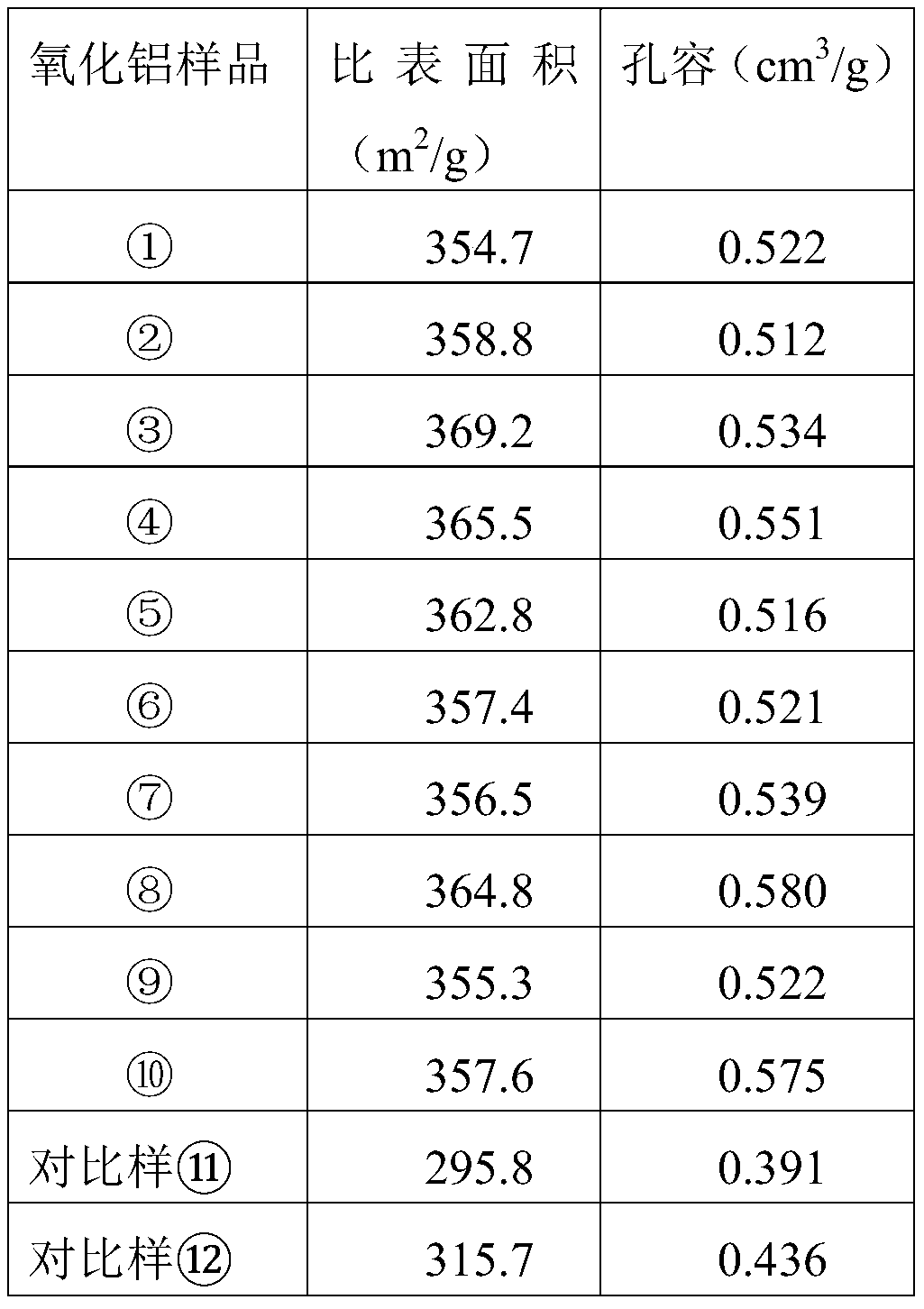

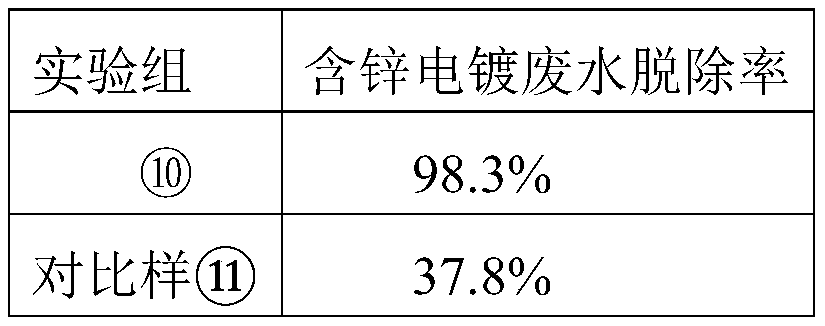

An alkali-modified alumina material having a high specific surface area, a preparing method thereof and applications of the material

ActiveCN106512918ALarge specific surface areaAppropriate pore size distributionOther chemical processesWater contaminantsAdhesiveSorbent

The invention relates to an alkali-modified alumina material having a high specific surface area, a preparing method thereof and applications of the material. The specific surface area of the alumina material is not less than 350 m<2> / g and the pore volume of the alumina material is not less than 0.5 cm<3> / g. The method includes (1) weighing active alumina powder and pseudoboehmite dry gel powder according to preset mass percentages and fully mixing the active alumina powder and the pseudoboehmite dry gel powder, (2) preparing an aqueous solution of EDTA or a sodium salt of EDTA, adjusting the pH value of the aqueous solution by using an alkali metal salt to achieve full dissolution, and performing particle molding through adopting the aqueous solution as an adhesive, and (3) subjected molded particles to hydration curing, drying and calcination to obtain the alumina material. Compared with the prior art, the prepared alumina material has the high specific surface area, a specific pore structure and surface properties, can be adopted as an adsorbent for a plurality of fields, especially the environment protection field, and can be used for treatment of complexing metal waste water.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Nitrogen-doped porous nano biochar, preparation method and application thereof

PendingCN114570331ASelf-dopingHigh porosityOther chemical processesWater contaminantsPorous sheetBiochar

The invention provides nitrogen-doped porous nano biochar as well as a preparation method and application thereof, and the method comprises the following steps: step 1, carrying out heat preservation treatment on a mixture of apple leaf powder and (KOH or NaOH and the like) under the protection of inert gas or N2 atmosphere at 500-700 DEG C to obtain a reactant; and step 2, removing by-products and impurities in the reactants, and drying to obtain the nitrogen-doped porous nano biochar. The waste apple leaves are used as a carbon source, the process is simple, the cost is low, and the obtained biochar has a large specific surface area, rich surface functional groups and a nanoscale 3D porous lamellar structure, can adsorb and activate PDS to synergistically remove organic pollutant tetracycline in water as a pollution-free carbon functional material, and has potential practical application value.

Owner:SHAANXI UNIV OF SCI & TECH

Composite scavenging agent for scavenging methyl blue and preparation method thereof

InactiveCN102688743AFully contactedRich pore structureOther chemical processesWater bathsHigh absorption

The invention discloses a composite scavenging agent for scavenging methyl blue and a preparation method thereof, wherein the composite scavenging agent comprises attapulgite and nano yttrium oxide, wherein the nano yttrium oxide is loaded on the attapulgite, and occupies 3-15% of the attapulgite in mass. The preparation method comprises the following steps of: firstly dissolving yttrium salt in water by adopting a mixed immersing method; adding modified attapulgite powder, regulating pH as 5-8, stirring for 4-12 hours through water bath of 80 DEG C, filtering and washing by deionized water; drying overnight in a baking oven of 80 DEG C; and finally forging, thereby obtaining the composite scavenging agent. According to the invention, firstly, the attapulgite with great specific surface area and high absorption performance is combined with yttrium oxide with favorable hydration performance (a rich active center can be generated by hydration), and the preparation method has the characteristics of high methyl blue decoloration rate, rapid effectiveness, simple process and the like; and the composite scavenging agent can reach 90% maximally for cationic dye decoloration rate under the natural environment within 10 minutes.

Owner:CENT SOUTH UNIV

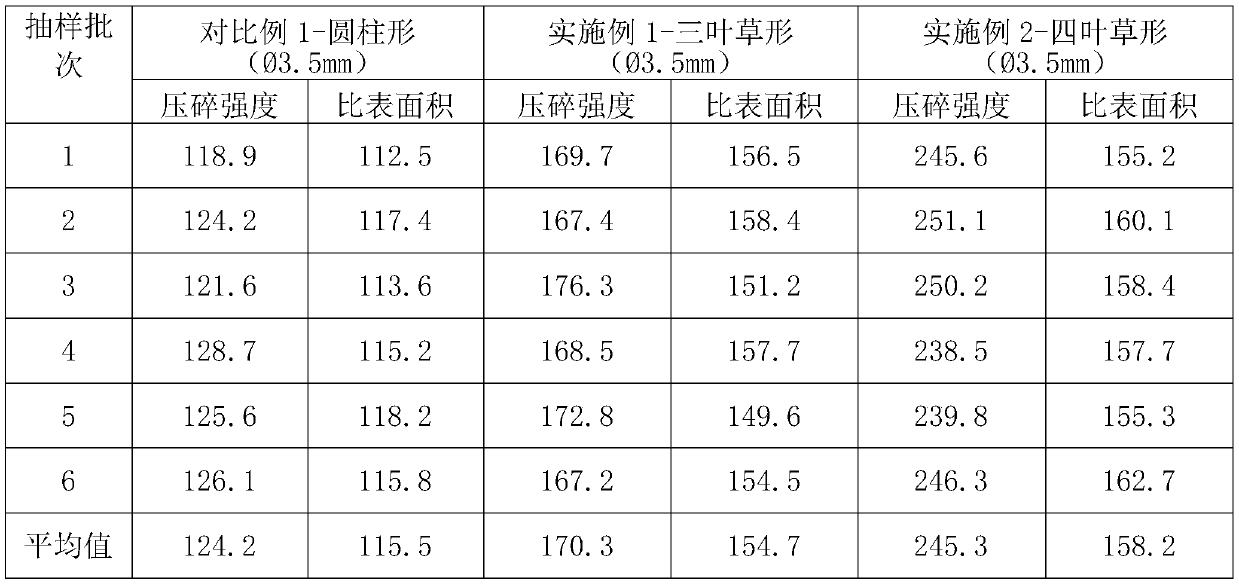

Titanium dioxide catalyst with high strength and large specific surface area for sulfur recovery and preparation method thereof

InactiveCN111282561AIncreased crush strengthLarge specific surface areaPhysical/chemical process catalystsSulfur preparation/purificationOrganic acidPtru catalyst

The invention discloses a high-strength large-specific-surface-area titanium dioxide catalyst for sulfur recovery and a preparation method thereof, and belongs to the technical field of catalysts andpreparation thereof. The preparation method comprises the following steps: firstly, mixing wet metatitanic acid serving as a raw material with alumina dry glue powder and sesbania powder in proportion, rolling for a period of time, adding a certain amount of mixed solution of water, organic acid and nitric acid into the rolled materials, continuously rolling, preserving moisture and ageing; and adding the material obtained by moisturizing and aging into an automatic pressing and banded extruder, selecting a clover template / four-leaf clover template for band extrusion, drying the extrudate through a drying oven to remove water, and roasting through a muffle furnace to obtain the product. The wet metatitanic acid is selected as a raw material of the catalyst, and compared with a dry raw material, the wet metatitanic acid is stable in chemical property and large in number of active centers; the catalyst is in a clover / clover shape, and compared with a cylinder in the prior art, the crushing strength and the specific surface area of the catalyst are both improved.

Owner:山东骏飞环保科技有限公司

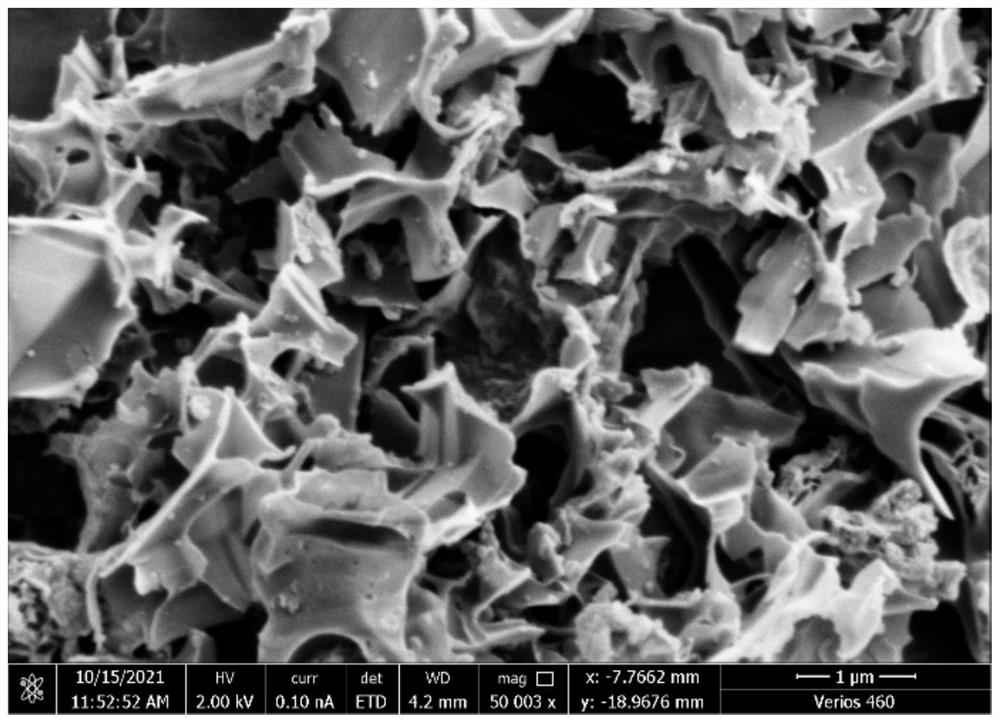

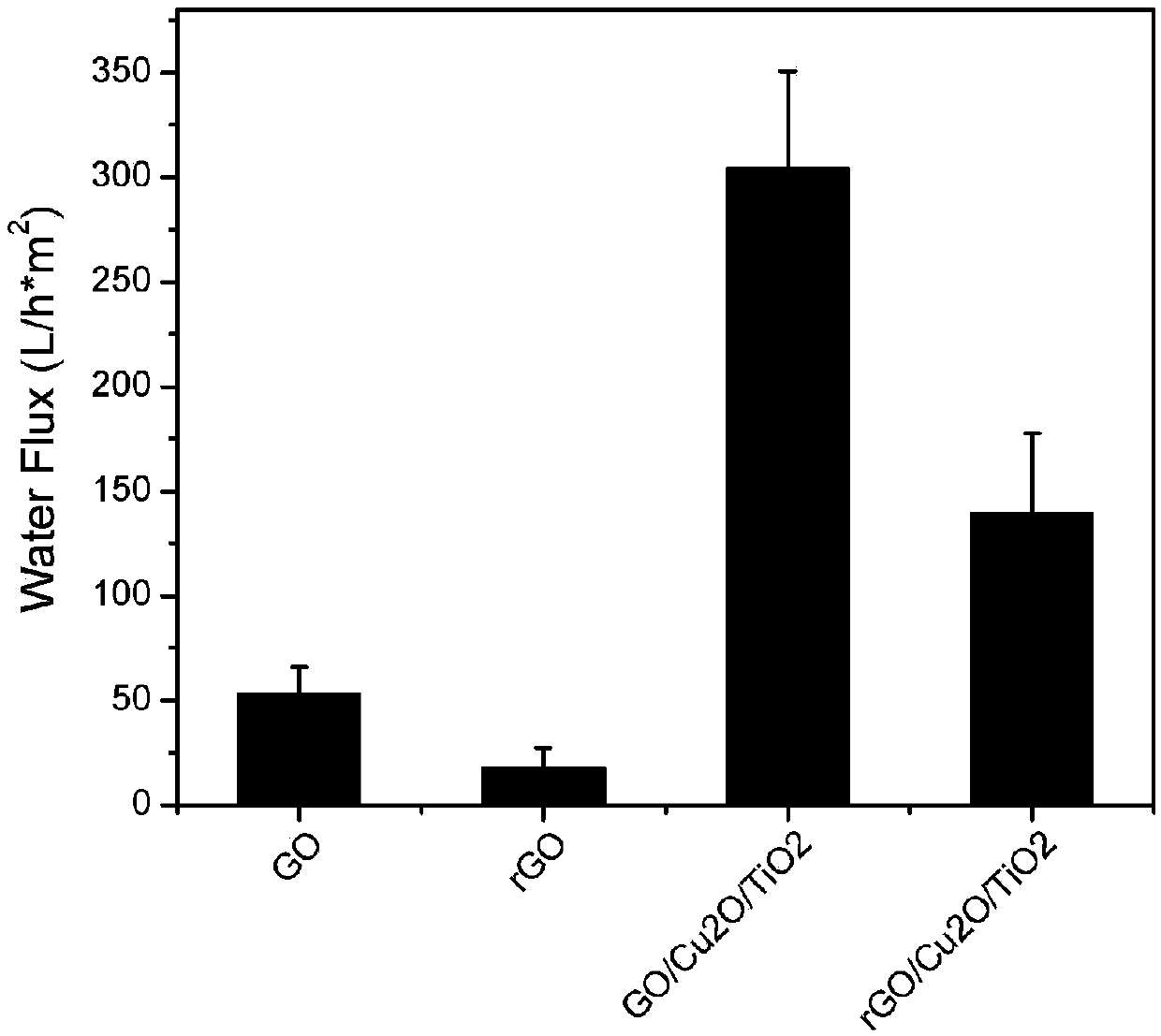

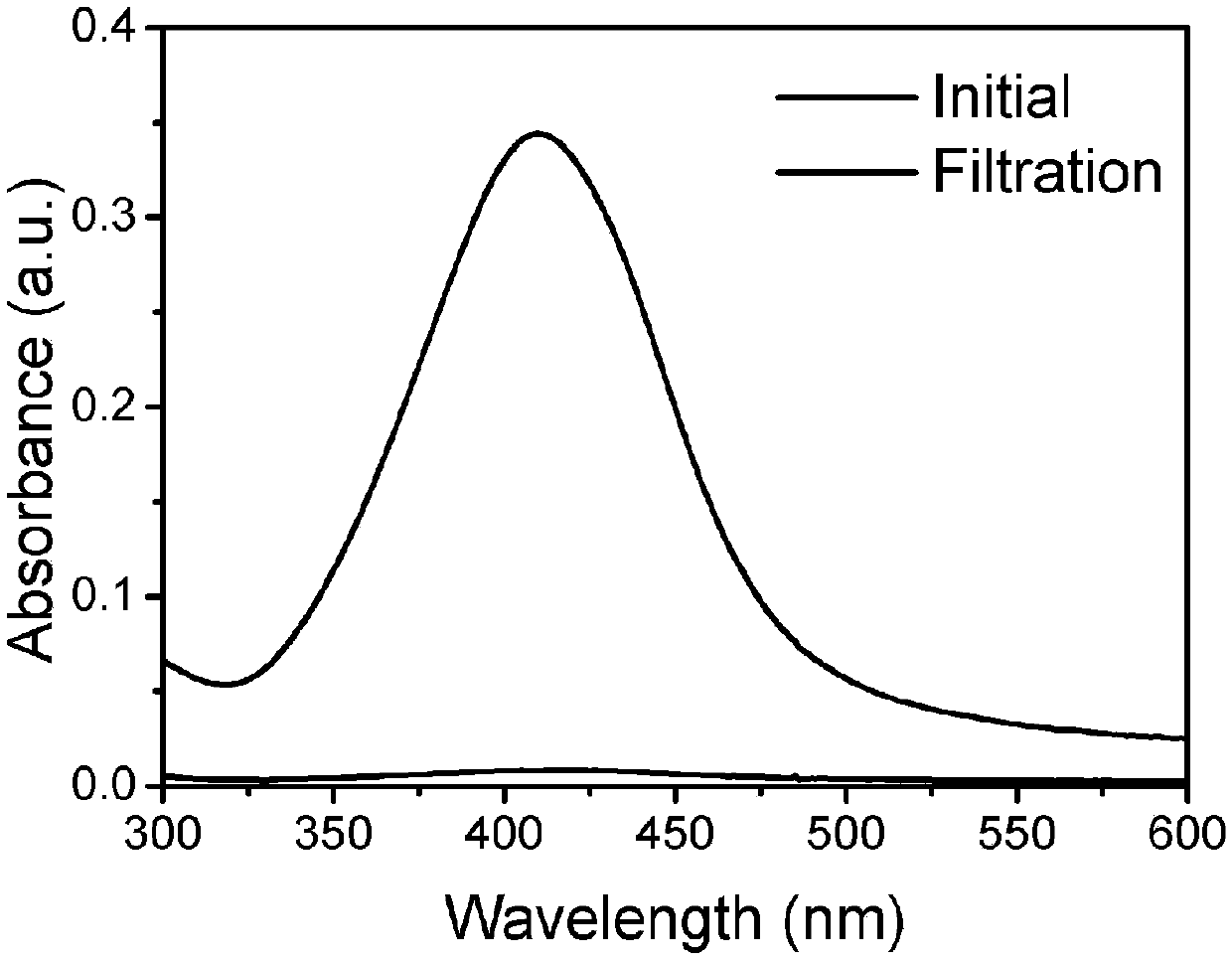

Novel graphene three-dimensional skeleton porous photocatalysis film preparation method

InactiveCN108043402AImprove conductivityLarge specific surface areaSemi-permeable membranesMembranesChemical structureFiltration

The invention discloses a novel graphene three-dimensional skeleton porous photocatalysis film preparation method, which comprises: embedding different types of semiconductor nanometer materials (p-type and n-type) with photocatalytic ability in graphene oxide, and carrying out bulking and reducing treatment to obtain the graphene three-dimensional skeleton porous photocatalysis film. The specificsteps comprise: 1, preparing semiconductor nanometer materials required by a photocatalysis film, wherein the semiconductor nanometer materials comprise Cu2O, Cu2O-CuO, TiO2 nano-wires, and the like;2, assembling a nano-wire / graphene oxide three-dimensional skeleton porous film material, wherein nano-wires are assembled into a graphene oxide film by using a vacuum suction filtration method, andthe nano-wire / graphene oxide is treated by using a fast freezing vacuum drying method or a bulking process to construct a three-dimensional skeleton porous structure; and 3, reducing the nano-wire / graphene oxide three-dimensional skeleton porous film, wherein the chemical structure of the nano-wire photocatalyst is maintained while the reducing of the graphene oxide film is achieved by using hydrogen iodide as a reducing agent.

Owner:OCEAN UNIV OF CHINA

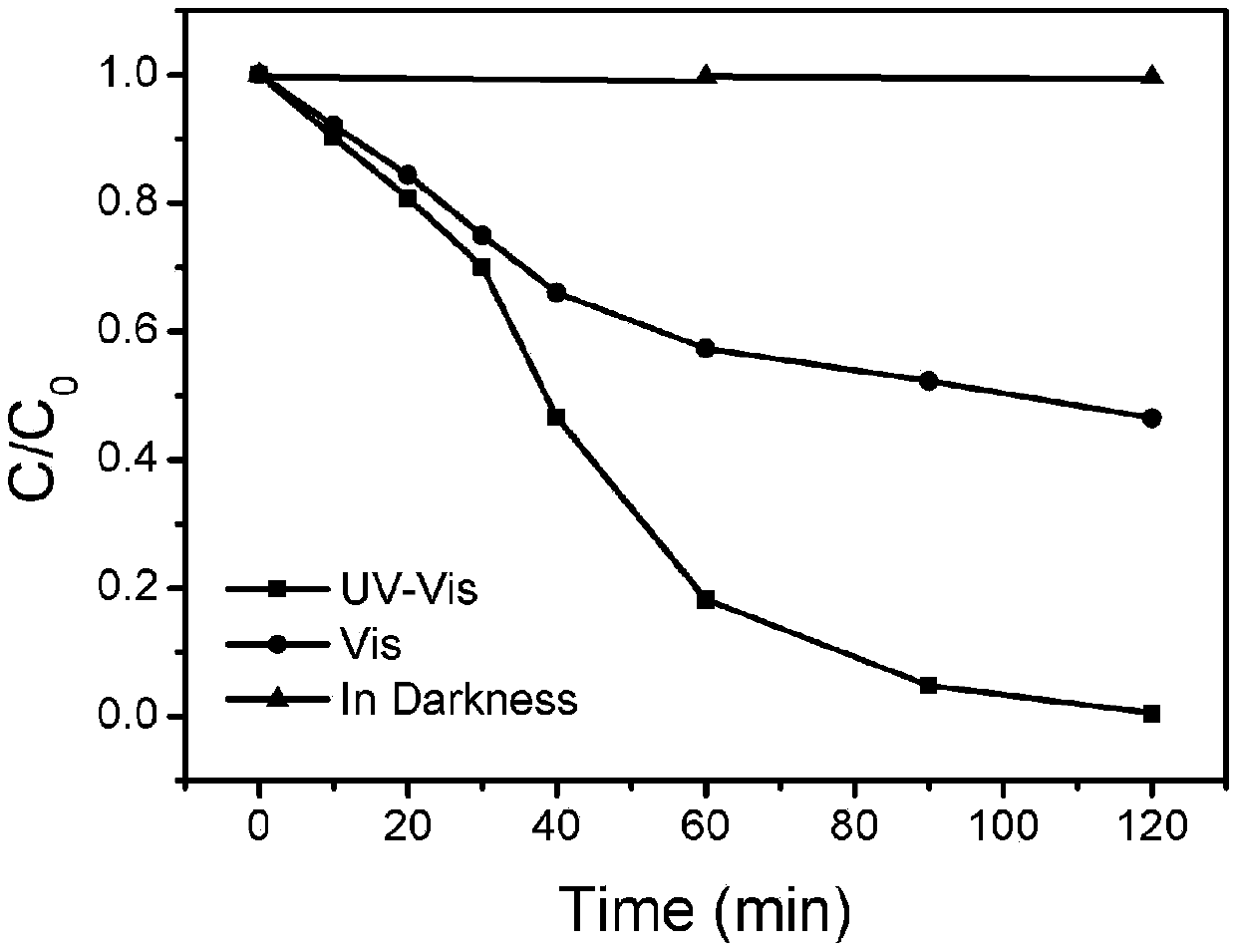

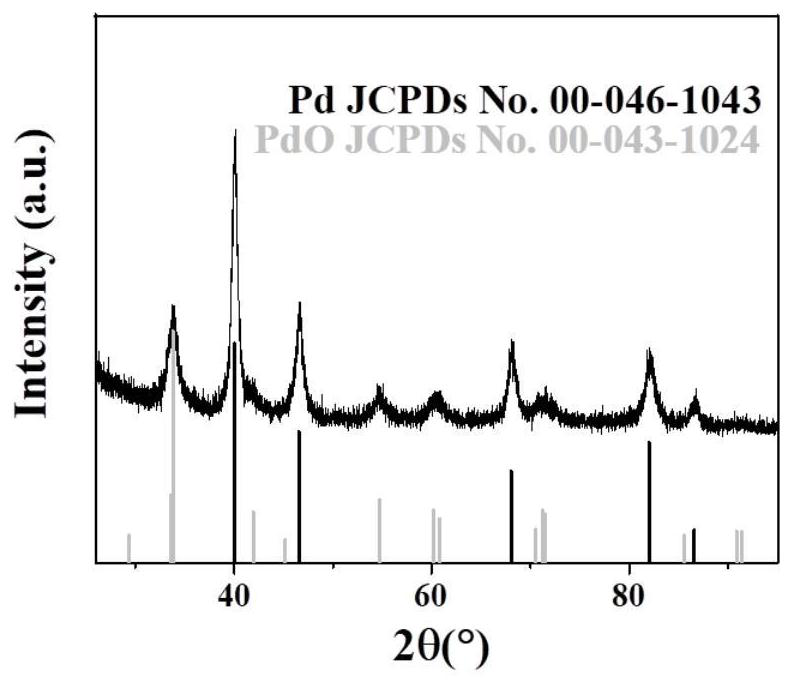

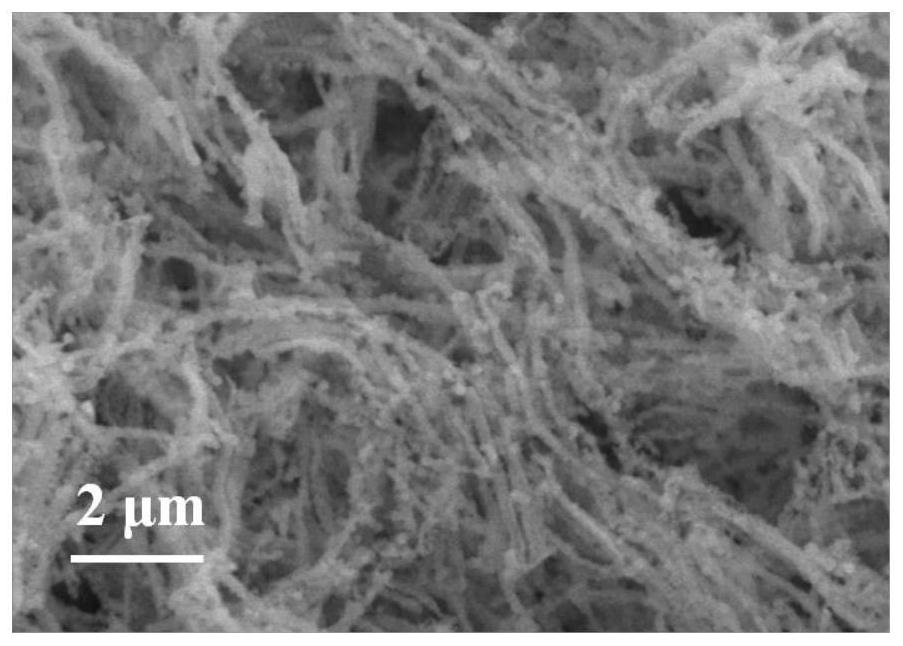

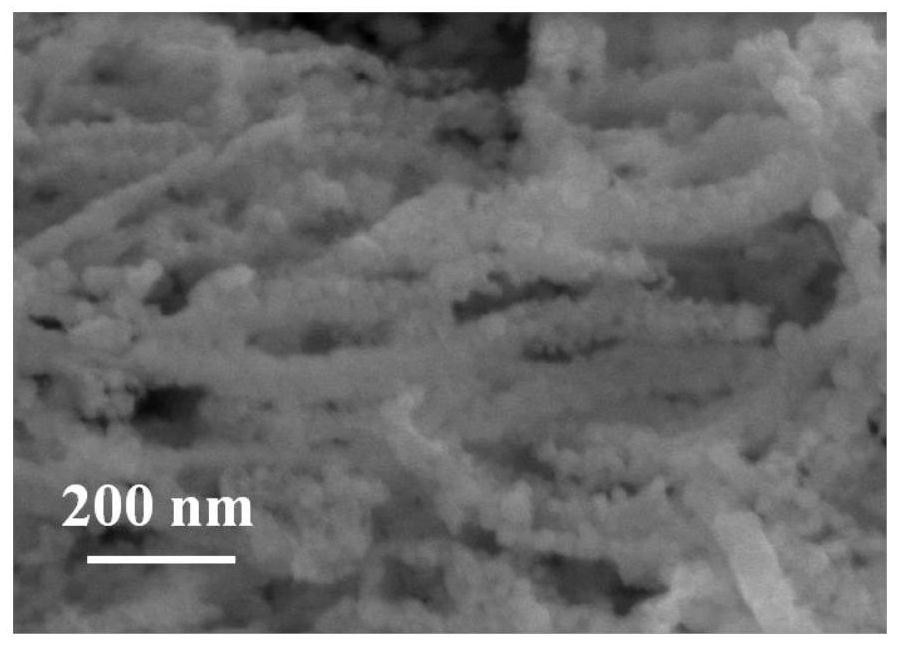

Preparation method and application of porous Pd-PdO nanorod

PendingCN113903934AHelp formPreparation method simple greenCell electrodesFuel cellsPhysical chemistry

The invention belongs to the technical field of fuel cells, and relates to a preparation method and application of a porous Pd-PdO nanorod. The preparation method comprises the following steps of: mixing 1, 10-phenanthroline serving as a complexing agent, potassium chloropalladite serving as a palladium source and ethanol and water serving as solvents at normal temperature to obtain a 1, 10-phenanthroline-palladium complex precursor; and calcining the 1, 10-phenanthroline-palladium complex precursor at high temperature under an air condition to obtain the porous Pd-PdO nanorod. The porous Pd-PdO nanorod obtained by the preparation method shows enhanced methanol oxidation reaction activity.

Owner:先进能源产业研究院(广州)有限公司

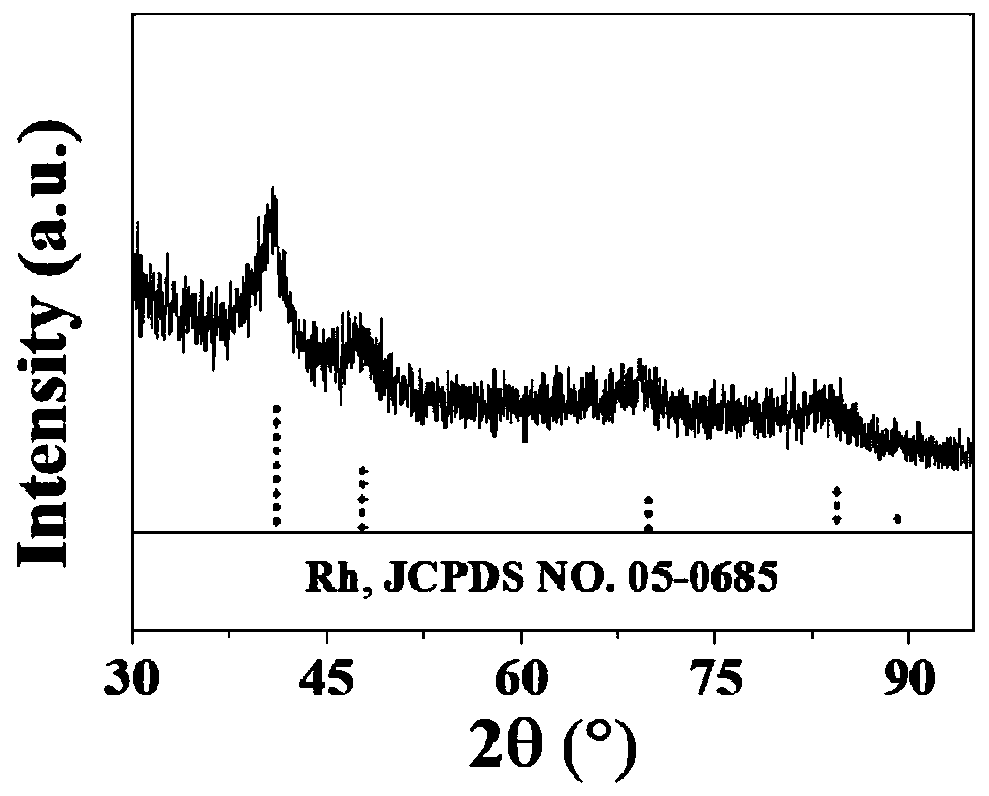

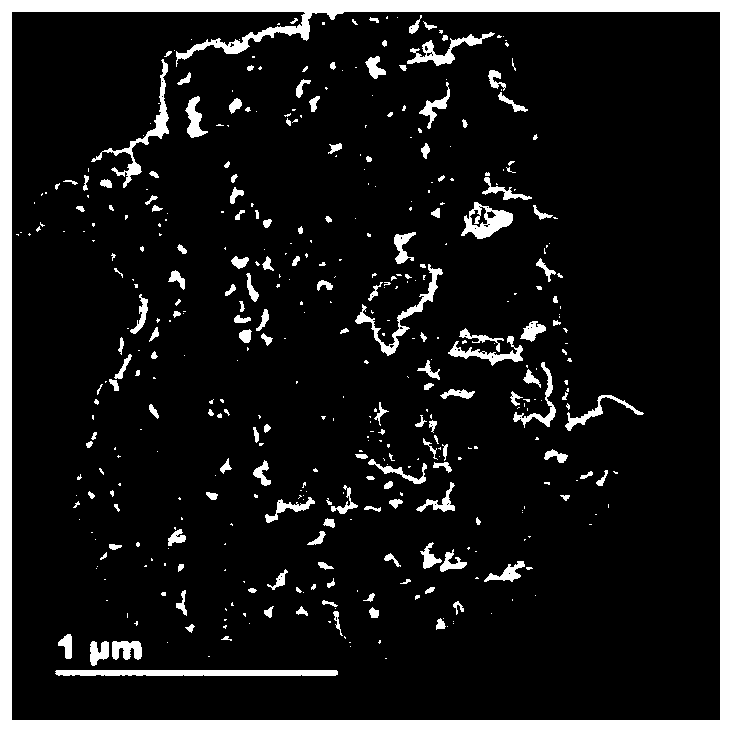

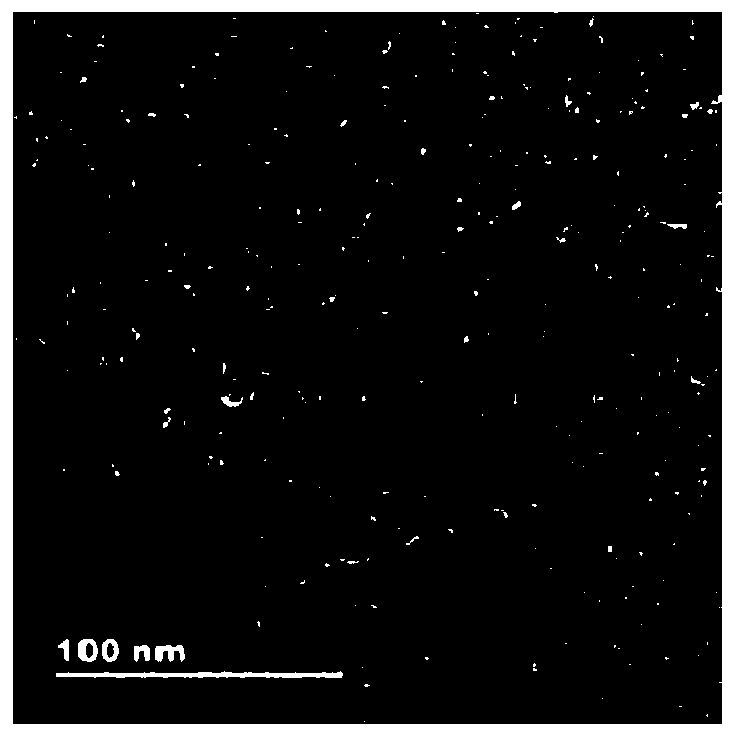

Preparation method of multistage porous Rh nanosheet

ActiveCN110676473AHas an ultra-thin structureEnhanced Methanol Oxidation KineticsMaterial nanotechnologyCell electrodesActive centerGlycol synthesis

The invention discloses a preparation method of a multistage porous Rh nanosheet. The method takes 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP) as a complexing agent, water and ethyl alcohol as solvents and ethylene glycol as a reducing agent, and reduces Rh<3+> into the multistage porous Rh nanosheet through hydrothermal reaction by adopting a simple HEDP-mediated wet chemistry method. The preparation method is environmentally friendly, simple, economical and suitable for industrial large-scale production. The Rh nanosheet prepared by the method has an ultrathin structure, rich pores (edge atoms) and grain boundary atoms, shows rich active centers, has high methanol adsorption energy and low reaction barrier, can be used as a catalyst for methanol electrooxidation reaction, and is a fuel cell catalyst with a great development prospect.

Owner:SHAANXI NORMAL UNIV

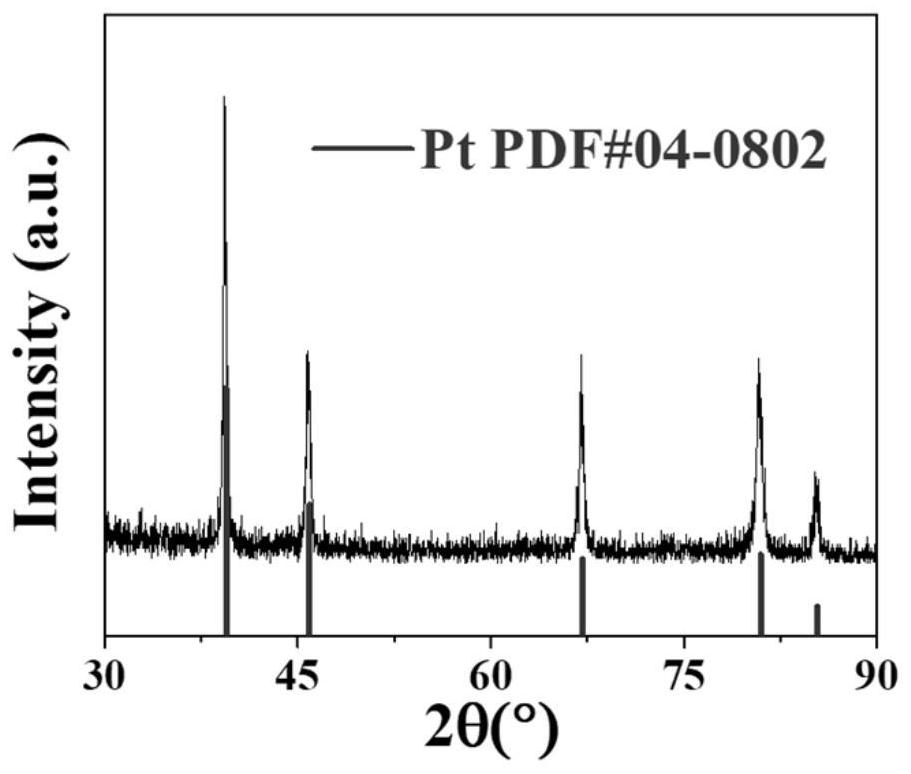

Oxygen reduction reaction catalyst and preparation method thereof

PendingCN114464823AHelp formUniform and smooth surface rod-like structureMaterial nanotechnologyCell electrodesPtru catalystPotassium tetrachloroplatinate

The invention belongs to the technical field of electrochemistry, and particularly relates to an oxygen reduction reaction catalyst and a preparation method thereof. According to the preparation method, phenanthroline is taken as a complexing agent, potassium chloroplatinite is taken as a platinum source, ethanol and water are taken as solvents, strong complexation of Pt < 2 + > and phenanthroline is utilized, the mixture is mixed at normal temperature to obtain a brown phenanthroline-Pt (II) complex precursor, the precursor has a uniform rod-like structure with a smooth surface, the precursor is taken as a template and is reduced in a hydrogen atmosphere, and the complex is prepared. The porous Pt nanorod is obtained. The porous Pt nanorod, as a catalyst, shows relatively high catalytic activity in the aspect of catalyzing oxygen reduction reaction in an acidic medium.

Owner:先进能源产业研究院(广州)有限公司

Alkali-modified high specific surface area alumina material and its preparation method and application

ActiveCN106512918BLarge specific surface areaAppropriate pore size distributionOther chemical processesWater contaminantsSorbentAdhesive

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

A kind of high entropy ferrite porous ceramic material and its preparation method and application

ActiveCN113860911BLarge specific surface areaSelf-supportingCatalyst carriersGas treatmentChemical compositionZinc

The invention discloses a high-entropy ferrite porous ceramic material, a preparation method and application thereof, and belongs to the field of inorganic functional materials. The chemical composition of the high-entropy ferrite porous ceramic material is (Mg 0.4‑x Co x Ni 0.2 Zn 0.2 Cu 0.2 )Fe 2 O 4 , where the value range of x is 0

Owner:JIANGXI SCI & TECH NORMAL UNIV

Hollow microsphere core-shell catalyst as well as preparation method and application thereof

ActiveCN113457726AHigh saturationIncrease speedGroup 4/14 element organic compoundsMolecular sieve catalystsChemistryOrganic chemicals

The invention discloses a hollow microsphere core-shell catalyst and a preparation method and an application thereof, and belongs to the field of organic chemical synthesis, and the preparation method comprises the following steps: preparing ZSM-5 hollow microspheres, and preparing ZSM-5 hollow microspheres, pseudo-boehmite and sesbania powder to obtain a ZSM-5 / gamma-Al2O3 hollow microsphere carrier; and respectively dipping the ZSM-5 / Al2O3 hollow microsphere core-shell catalyst in a NaCl solution and an AlCl3 solution, and carrying out a crystallization reaction so as to obtain the NaAlCl4 / ZSM-5 / gamma-Al2O3 hollow microsphere core-shell catalyst. The catalyst provided by the invention has a good catalytic effect on preparation of dimethyl dichlorosilane from disproportionated methyl trichlorosilane and trimethyl chlorosilane, and the yield of dimethyl dichlorosilane at 200 DEG C can reach 73% or above.

Owner:EAST CHINA JIAOTONG UNIVERSITY

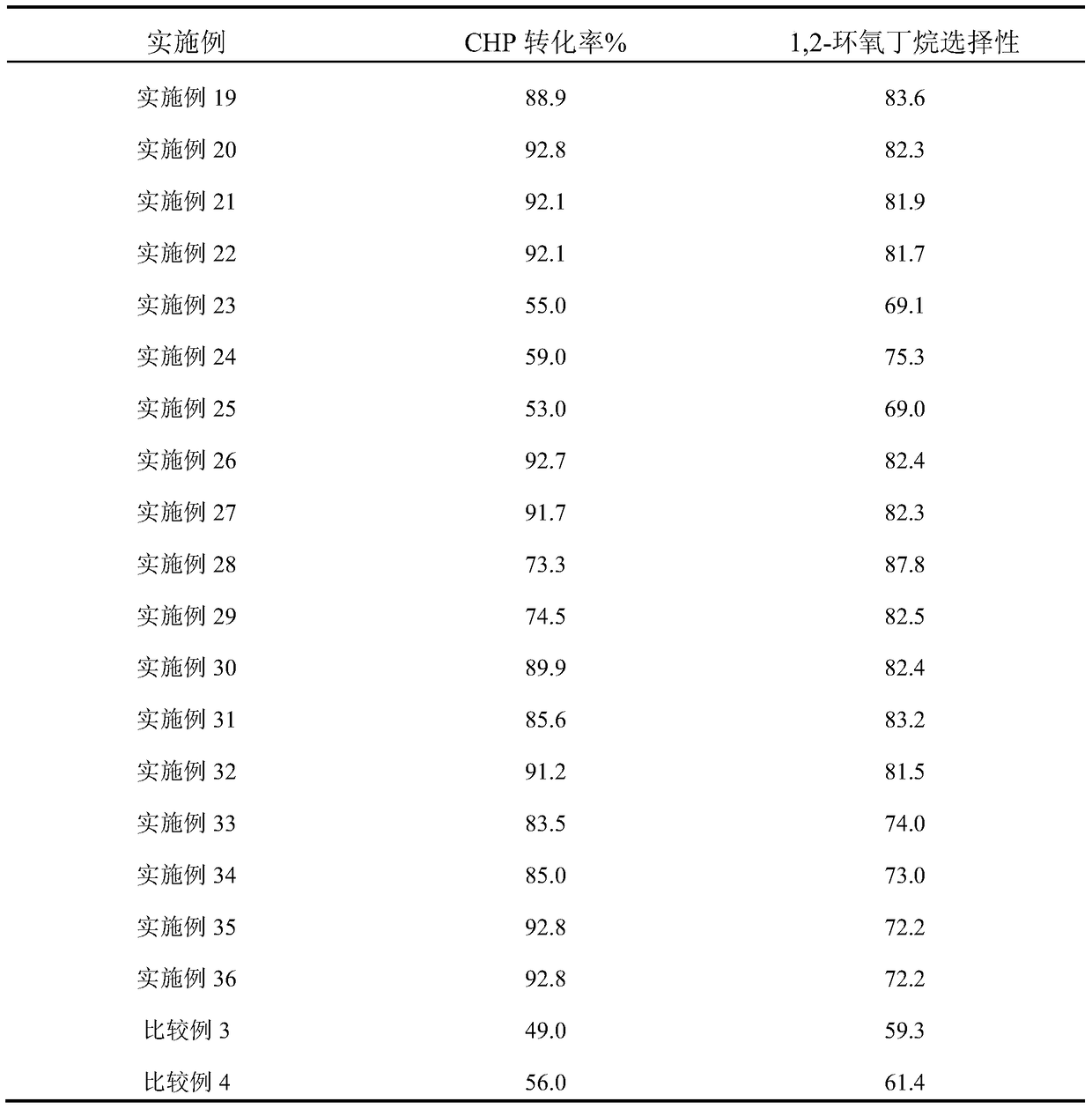

Preparation method of catalyst for epoxidation of 1-butene to prepare 1,2-epoxybutane

ActiveCN105498832BHigh yieldGood effectOrganic chemistryMolecular sieve catalystsMolecular sieveTitanium

The invention relates to a preparation method for a catalyst used for preparing 1,2-epoxybutane through epoxidation of 1-butene. The preparation method comprises adding a template into a solvent, stirring at 20-100 DEG C, and adding proper amount of an acid to adjust pH to 2-9; mixing a silicon source and a titanium source according to a prescribed ratio, adding into the above solution, and crystallizing the solution with stirring, so as to obtain a gel mixed solution; standing the gel mixed solution at 40-100 DEG C for 12 h-48 h; and separating the gel product to obtain a white solid precipitate, performing washing and drying to obtain a catalyst raw powder, then roasting in muffle furnace, so as to obtain the catalyst applied to epoxidation of 1-butene. The method solves the disadvantages that a conventional butene epoxidation catalyst is relatively low in activity, low in titanium-source utilization rate, low in selectivity and not high in epoxybutane product yield. The method avoids the disadvantage that active compositions in the formed silicon-titanium molecular sieve lose due to hydrolysis of the titanium source, and is effectively applied to prepare 1,2-epoxybutane through epoxidation of 1-butene.

Owner:CHINA PETROLEUM & CHEM CORP

Hollow microsphere core-shell catalyst and preparation method and application thereof

ActiveCN113457726BHigh saturationIncrease speedGroup 4/14 element organic compoundsMolecular sieve catalystsPtru catalystMeth-

Owner:EAST CHINA JIAOTONG UNIVERSITY

Chitosan entrapment body of nano-scale arsenous acid and manufacturing method thereof

InactiveCN101695501BExpanded indicationsSmall particlesPowder deliveryInorganic active ingredientsSurface-active agentsFatty alcohol

The invention provides a chitosan entrapment body of nano-scale arsenous acid, which comprises the following components in part by weight: 0.2 to 0.4 part of nano chitosan, 0.001 to 0.002 part of nano arsenous acid, 0.00024 to 0.02 part of ion shift variant agent, 0.005 to 0.03 part of surface active agent, 0.2 to 0.4 part of lactic acid or acetic acid, 0.1 to 0.3 part of fatty alcohol polyethenoxy ether, and the balance of deionized water. An integration process of three highly difficult reactions including the preparation of an arsenous acid pre-dispersed intermediate, the preparation of an active nano chitosan three-dimensional network colloid and the entrapment to the nano arsenous acid by the active nano chitosan three-dimensional network colloid is achieved by a 'one-step method', and nano arsenous acid particles in the manufactured chitosan entrapment body have the main area particle size distribution of between 20 and 50 nanometers and show the characteristics of the arsenous acid. The chitosan entrapment body of the nano-scale arsenous acid has the advantages of high bioavailability, enhanced slow-release property, reduced dosage, low toxic or side effect and enhanced anti-cancer curative effect, and provides a selection path with high-tech synthesis for arsenic medicaments.

Owner:广汉恒宇新材料有限公司

A polypyrrole/polyimide composite porous catalytic membrane and its preparation method

ActiveCN105709611BMany active centersImprove mechanical propertiesSemi-permeable membranesOrganic-compounds/hydrides/coordination-complexes catalystsFiberPolypyrrole

The invention discloses a polypyrrolone / polyimide composite porous catalytic film and a preparation method thereof. The preparation method includes following steps: 1), dissolving tetracid monomer and tetramine monomer in a solvent to obtain a polypyrrolone prepolymer solution; 2), sequentially adding a polyamic acid solution, metal components and pore former into the polypyrrolone prepolymer solution to obtain a mixed spinning solution, and forming a composite nano fiber precursor through electrostatic spinning; 3), subjecting the composite nano fiber precursor to vacuum drying and thermal treatment to obtain the polypyrrolone / polyimide composite porous catalytic film. The polypyrrolone / polyimide composite porous catalytic film obtained by the method has high heat resistance and mechanical performance when being applied in the field of petroleum catalysis, and expense needed for separating reaction liquid from a catalyst is reduced.

Owner:JIANGXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com