Alkali-modified high specific surface area alumina material and its preparation method and application

A technology with high specific surface area and specific surface area, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of small pore size, large specific surface area of alumina, and channel blockage, etc., to achieve Excellent performance, high specific surface area, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

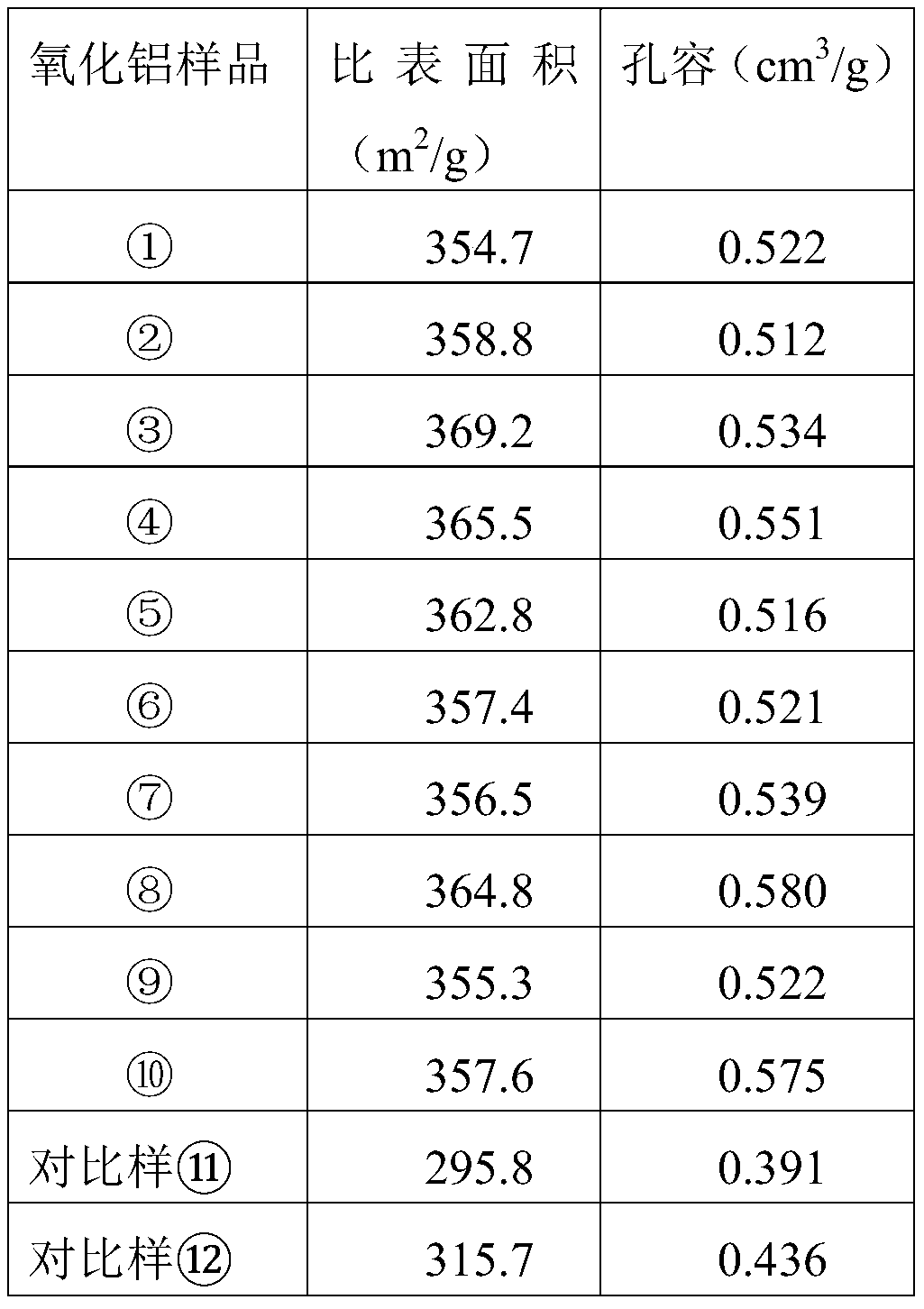

Embodiment 1

[0030] Weigh activated alumina powder and pseudoboehmite dry rubber powder according to 90:10 mass percentage, and mix them evenly; configure 2% EDTA aqueous solution, use sodium hydroxide to adjust the pH value of the aqueous solution to 11, so that EDTA is completely dissolved ; Spray the prepared aqueous solution into the uniformly mixed powder, and granulate through discs to obtain 2.0-3.0mm granule moldings. Introduce water vapor at 105°C, keep for 1 hour, dry at 80°C, and roast at 350°C to prepare alumina material ①.

Embodiment 2

[0032] Weigh activated alumina powder and pseudoboehmite dry rubber powder according to 40:60 mass percentage, and mix them evenly; configure 5% EDTA disodium aqueous solution, use sodium carbonate to adjust the pH value of the aqueous solution to 9, and make EDTA di The sodium is completely dissolved; the prepared aqueous solution is sprayed into the uniformly mixed powder, and granulated by a drum to obtain a granule shaped product of 4.0-6.0 mm. Introduce water vapor at 125°C, keep for 5 hours, dry at 150°C, and roast at 600°C to prepare alumina material②.

Embodiment 3

[0034] Weigh activated alumina powder and pseudoboehmite dry rubber powder according to the mass percentage of 50:50, and mix them evenly; configure 20% tetrasodium EDTA aqueous solution, use sodium bicarbonate to adjust the pH value of the aqueous solution to 9, and make EDTA The tetrasodium is completely dissolved; the prepared aqueous solution is sprayed into the uniformly mixed powder, and granulated by a sugar coating machine to obtain 3.0-5.0mm granule moldings. Introduce water vapor at 110°C, keep for 5 hours, dry at 110°C, and bake at 400°C to prepare the alumina material③.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com