Patents

Literature

130 results about "Iso butanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

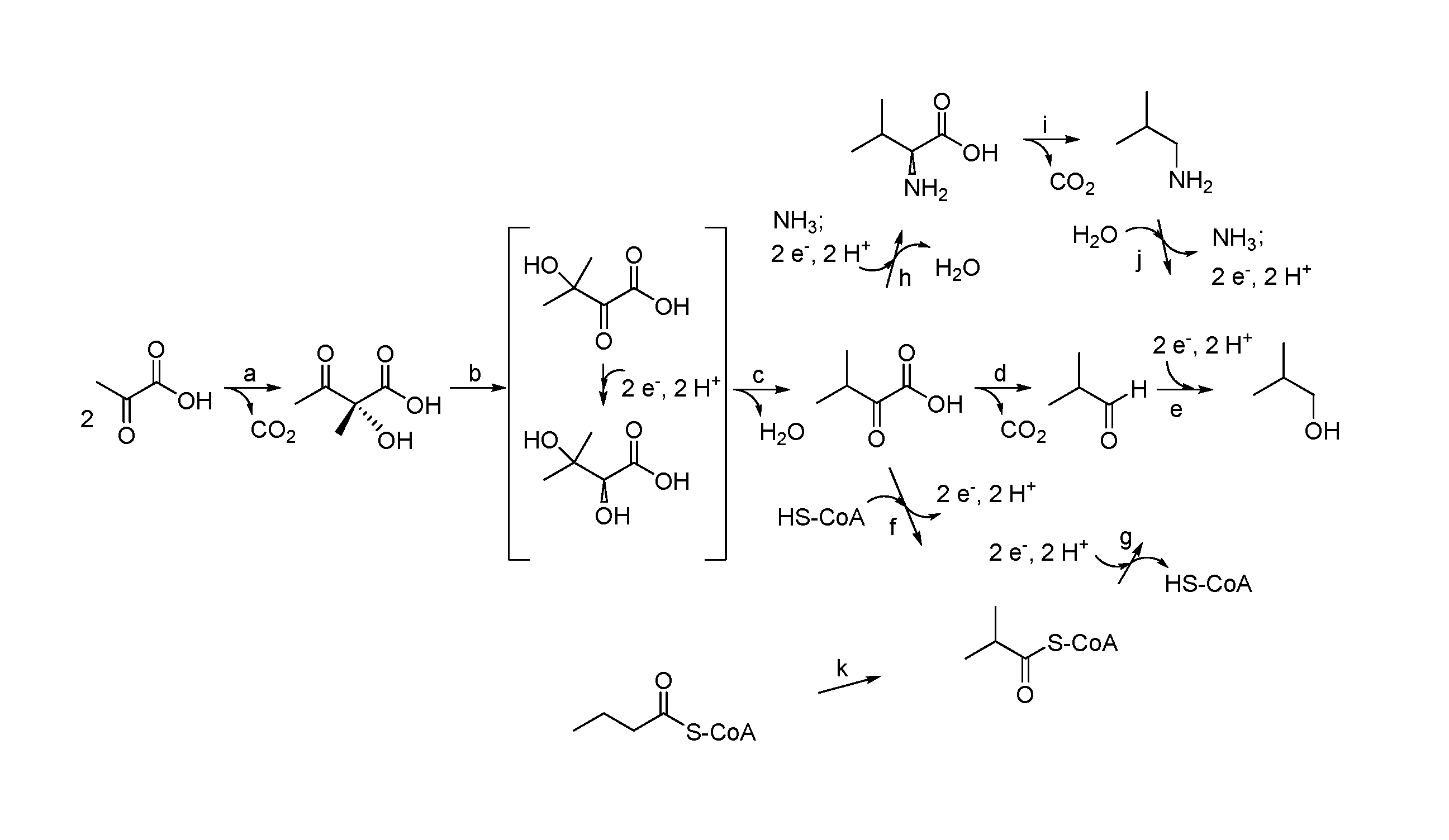

Isobutanol is an organic compound, a form of lightweight alcohol, that is produced from natural and petrochemical sources and has many common solvent and some potential fuel uses.

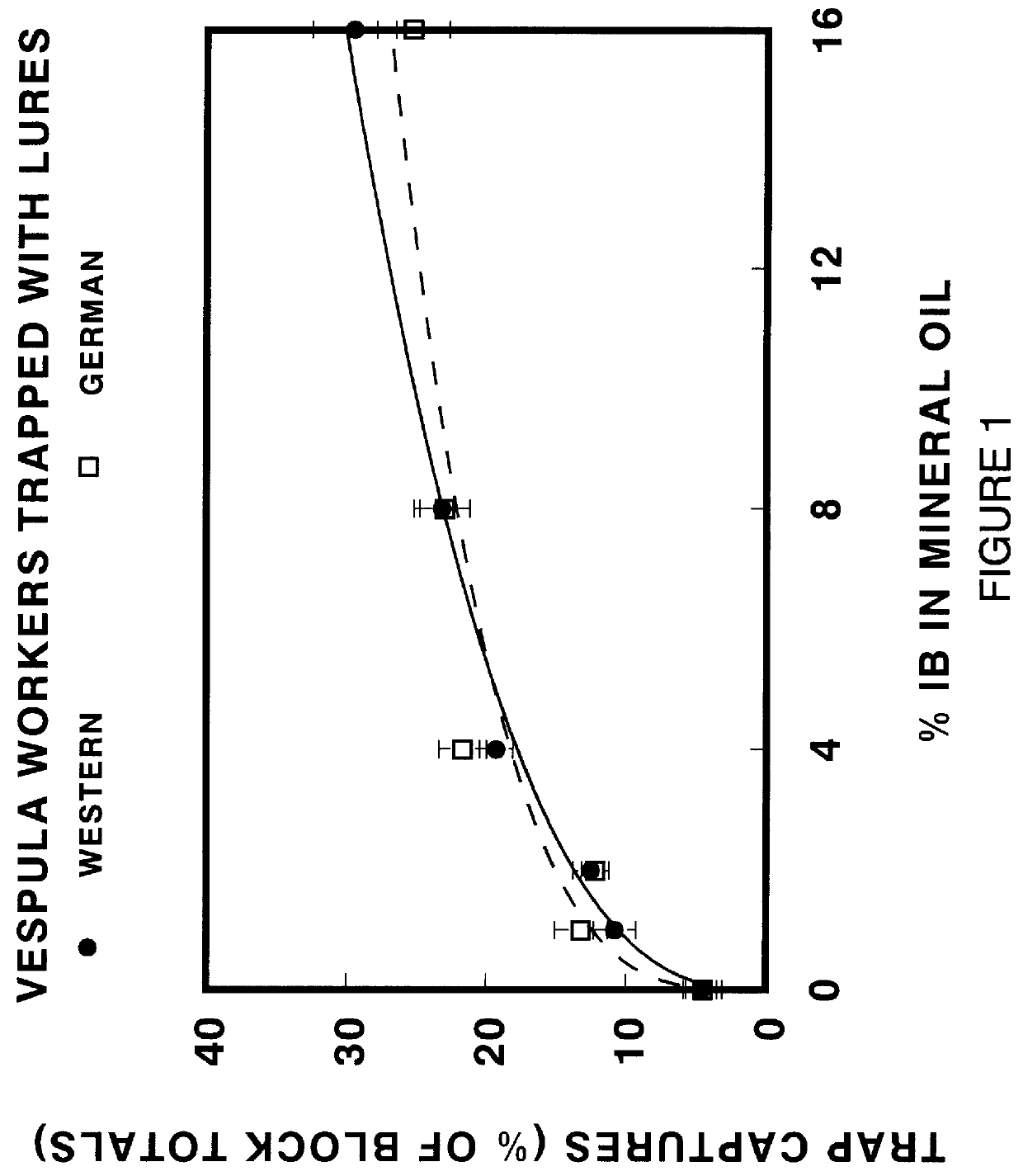

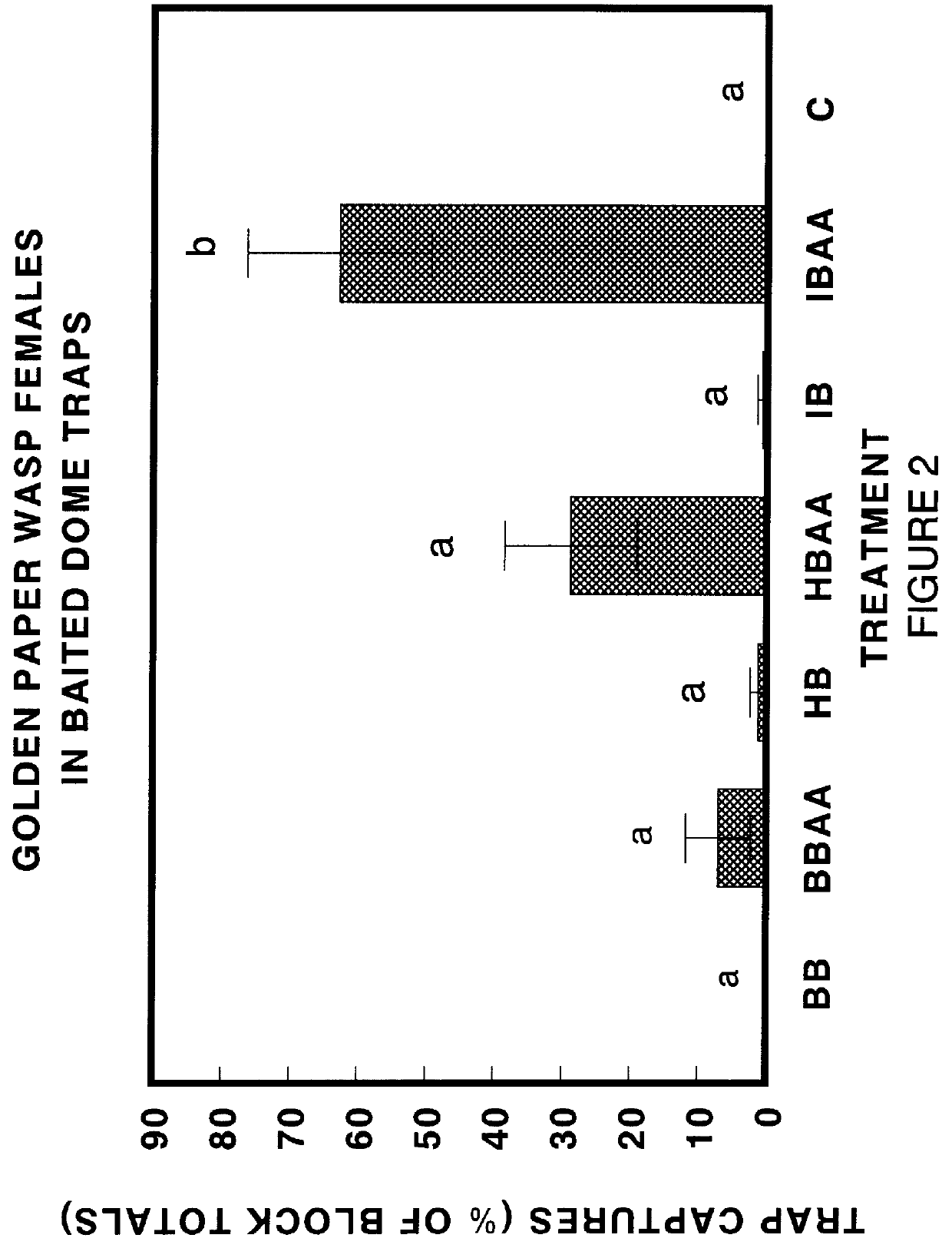

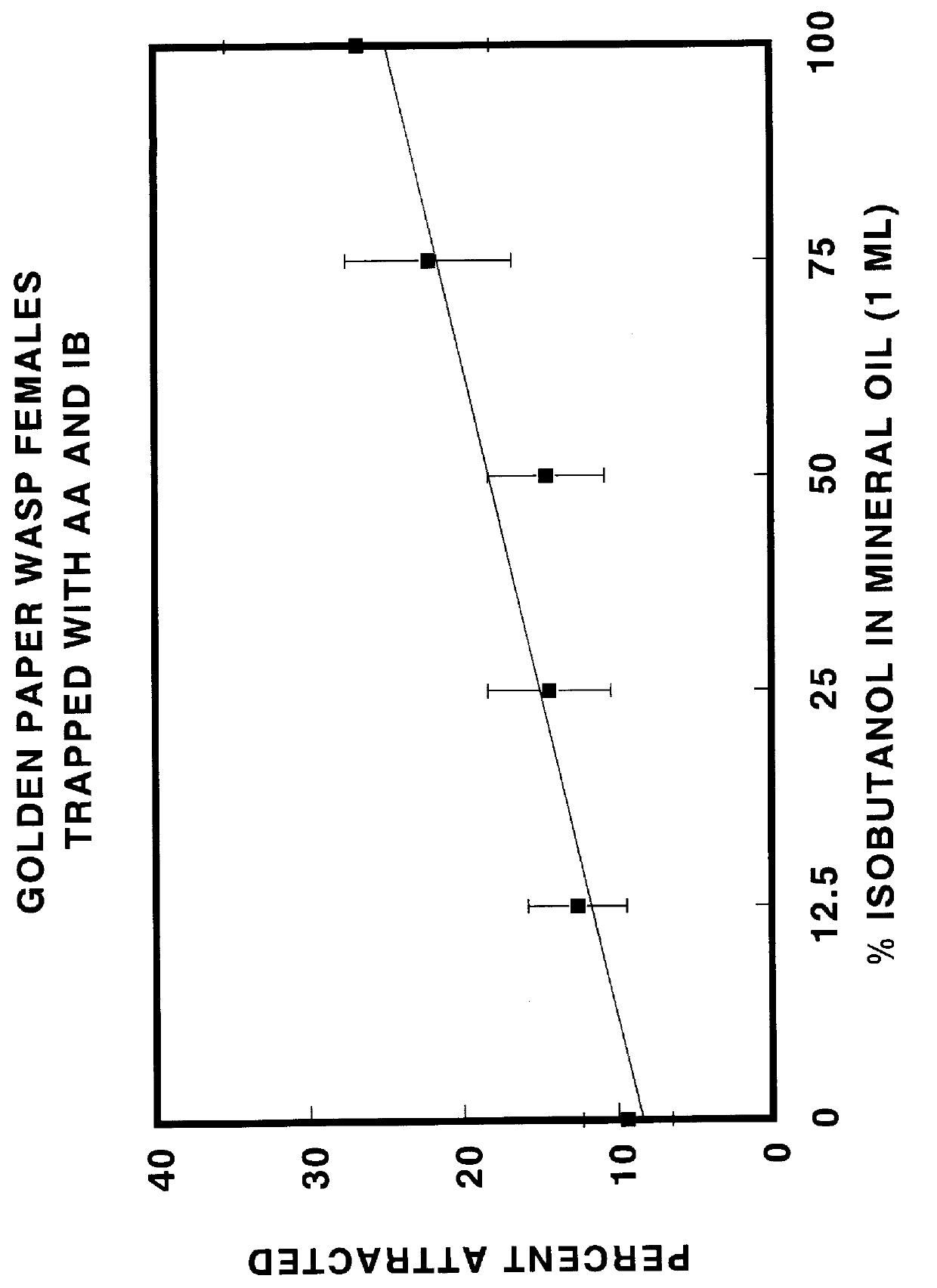

Chemical attractants for yellowjackets and paper wasps

InactiveUS6083498AEnhanced informationEfficient methodBiocidePeptide/protein ingredientsIsobutanolPropanol

Compositions and lures are described which provide vapor blends of acetic acid and one or more compounds selected from the group consisting of isobutanol, racemic 2-methyl-1-butanol, S-(-)-2-methyl-1-butanol, 2-methyl-2-propanol, heptyl butyrate, and butyl butyrate which function as highly effective attractants for yellowjacket wasps and paper wasps. By attracting wasps to traps or baits, the chemical attractants provide a means for detecting, surveying, monitoring, and controlling the wasps.

Owner:US SEC AGRI

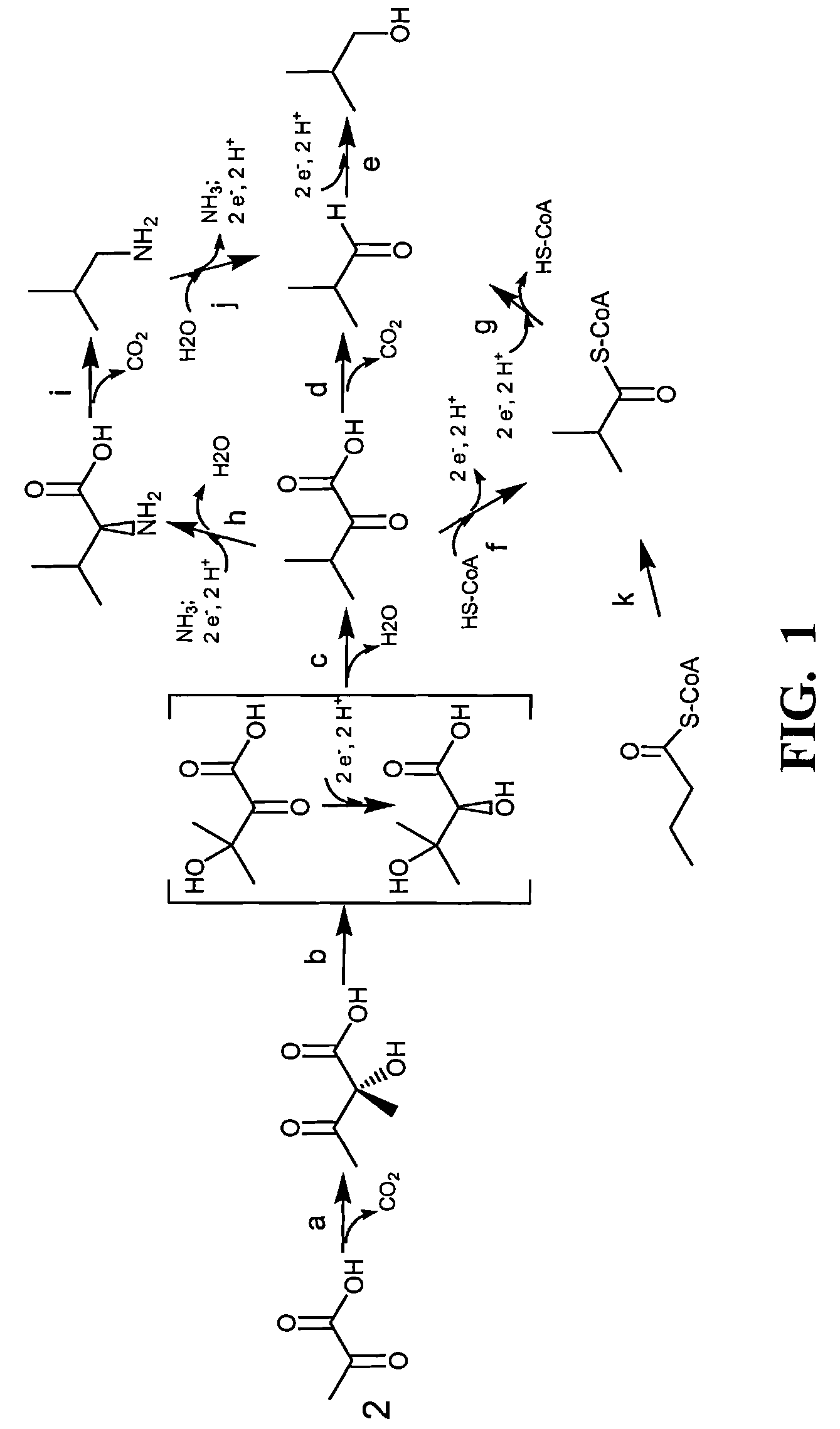

Yeast with increased butanol tolerance involving cell wall integrity pathway

Increasing tolerance to butanol in yeast has been accomplished by increasing activity of the cell wall integrity pathway. Yeast with increased expression of SLT2p, a mitogen activated protein kinase of the MAPK module of the cell wall integrity pathway had increased tolerance to isobutanol. These yeast may be used for improved butanol production.

Owner:GEVO INC

Co-solvent composition for compounding methanol gasoline

InactiveCN1740283APromote mutual solubilityHigh calorific valueLiquid carbonaceous fuelsAntioxidantMethyl carbonate

The co-solvent composition for compounding methanol gasoline consists of methyl tert-amyl ether 0-61 weight portions, dimethyl carbonate 0-52 weight portions, methyl tert-butyl ether 0-47 weight portions, allcyl polyoxyethylene ether 0.1-10 weight portions, isopropyl ether 0-10 weight portions, ethyl ether 0-30 wt%, tert-butanol 0-45 weight portions, iso-butanol 0-25 weight portions, isopropanol 0-15 weight portions, antioxidant í‹501íŒ 0-8 weight portions, xylene 0-20 weight portions, urotropin 0-7 weight portions, butanone 0-36 weight portions and acetone 0-20 weight portions. It is added while compounding methanol gasoline to raise the intersolubility between methanol and gasoline and raise the relevant physical and chemical performances of methanol gasoline.

Owner:翟雁萍

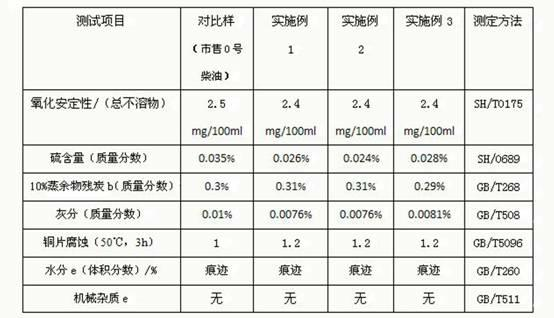

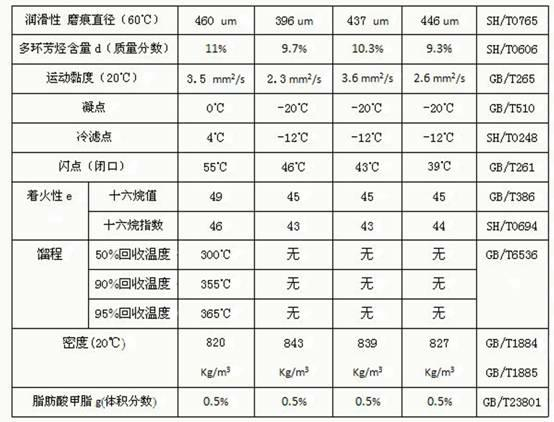

Methanol diesel oil additive and methanol diesel oil

InactiveCN102161922AImprove powerHigh calorific valueLiquid carbonaceous fuelsIsobutanolOil additive

The invention discloses a methanol diesel oil additive and simultaneously discloses methanol diesel oil with the methanol diesel oil additive. The methanol diesel oil prepared by the invention is prepared by mixing 0.04-0.07 part of ferrocene, 2-5 parts of acetone, 4 parts of diemethyl carbonate, 2-3 parts of isobutanol, 2-3 parts of toluene, 70 parts of diesel oil and 20-25 parts of methanol. The methanol diesel oil has the advantages of low corrosion, good intersolubility and swelling property, uniform texture, high flash point, low condensation point and high cetane number, is safe to use and meets all indexes of automobile diesel oil GB19147-2009. The methanol diesel oil can be applied to internal-combustion engines, general engines, power plant fuels, burner substances and the like, thus the applicable range of the methanol diesel oil is wide.

Owner:SUIPING CHEM FACTORY OF CHINA PINGMEI SHENMA GRP LANTIAN CHEM

Low-carbon fuel oil and preparation method thereof

InactiveCN103484172APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsIsobutanolAntioxidant

The invention discloses a low-carbon fuel oil and a preparation method thereof. The low-carbon fuel oil comprises methanol or a modified complex thereof, and an additive, and the additive is prepared through a certain process of an oleic acid-Span series-Tween series (or OP-10) compounded three-in-one emulsifier, a sodium petroleum sulfonate and barium petroleum sulfonate combined pH buffer pair, isobutanol, tritolyl phosphate, an organic solvent, isooctyl nitrate, an emulsification dispersion aid and an antioxidant. The low-carbon fuel oil prepared through the method has the advantages of high cetane number, high flash point, low corrosivity, low emission and low cost, can be compounded with or dissolved in routine diesel oil for use, can be used in the fields of boilers, cars and boats by substituting the routine diesel oil, and has substantial energy saving and emission reduction effects.

Owner:东莞恒量新能源科技有限公司 +1

Yeast with increased butanol tolerance involving filamentous growth response

Increasing tolerance to butanol in yeast has been accomplished by increasing activity of the filamentous growth response. Yeast with increased expression of MSS11p, a transcriptional activator of the filamentous growth response pathway had increased tolerance to isobutanol. These yeast may be used for improved butanol production.

Owner:GEVO INC

Combustible Mixed Butanol Fuels

InactiveUS20110023355A1Increase ratingsEmission reductionLiquid carbonaceous fuelsFuel additivesHeating oilSec-Butanol

A fuel composition including mixed butanols, such as for example, 2-butanol, iso-butanol and tert-butanol, preferably 2-butanol and tert-butanol is provided. Methods of preparing and using the mixed butanols composition as combustible neat fuels and / or oxygenate fuel constituents in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, and the like are also provided.

Owner:SAUDI ARABIAN OIL CO

Yeast with increased butanol tolerance involving cell wall integrity pathway

Increasing tolerance to butanol in yeast has been accomplished by increasing activity of the cell wall integrity pathway. Yeast with increased expression of SLT2p, a mitogen activated protein kinase of the MAPK module of the cell wall integrity pathway had increased tolerance to isobutanol. These yeast may be used for improved butanol production.

Owner:GEVO INC

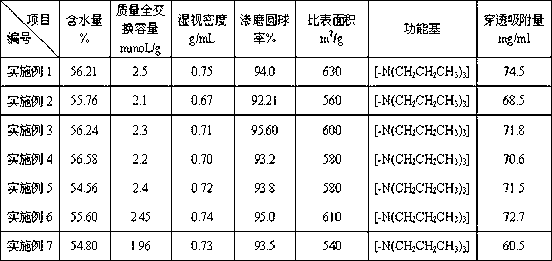

Preparation technology of selective resin for removing trace nitrate ion in water

InactiveCN102702412AImprove pore structureHigh selectivityWater/sewage treatment by ion-exchangeDivinylbenzenePhysisorption

The invention discloses a preparation technology of selective resin for removing trace nitrate ion in water and belongs to the field of preparation of organic high-molecular compound. The technology comprises the steps of respectively adding a water phase including purified water, a dispersing agent and a auxiliary dispersing agent and an oil phase including styrene, divinylbenzene, porogen and initiator to a polymerization reactor, carrying out suspension polymerization, and preparing the selective resin by chloromethylation and amination, wherein the porogen is mixed porogen prepared from 65-75 parts of toluene or benzene and 60-70 parts of white oil or isobutanol. By adopting the resin prepared from the mixed porogen, a hole structure inside the resin is improved, and the resin not only has proper specific surface area, but also has larger exchange capacity, and can remove the nitrate ion in the water by physical adsorption and chemical exchange methods at the same time, so that the selectivity on the nitrate ion is larger and trace nitrate ion in the water can be effectively removed.

Owner:ZIBO DONGDA HONGFANG CHEM

Production technology of hexabromo cyclododecane

The present invention discloses a hexabromocyclododecane production process capable of effectively improving product quality. Said process includes the following procedures: bromization procedure, filter and centrifugal drying procedure, washing procedure, boiling procedure, drying procedure, powder-sieving procedure and solvent recovery procedure. It is characterized by that it adopts chloroform and isobutanol as medium, so that it can raise thermal stability of product. Said product is a good fire retarding agent, therefore it has extensive application.

Owner:HUALUN CHEM SUZHOU CITY

Novel attractants for vespid wasps

This invention relates to novel methods and compositions, wherein chopped dried apple or apple pomace can be used as supplementary lures for trapping wasps in the family Vespidae in combination with volatile chemical attractants, including (but not limited to) heptyl butyrate, acetic acid and isobutanol. Said vespid wasps may be in the genera Vespa, Vespula, Dolichovespula or Polistes. When formulated in a porous bag immersed in a water-detergent capture medium at the bottom of the interior chamber of an Oak Stump trap, either chopped dried apple or apple pomace can increase the capture of said vespid wasps several fold.

Owner:PHEROTECH INT

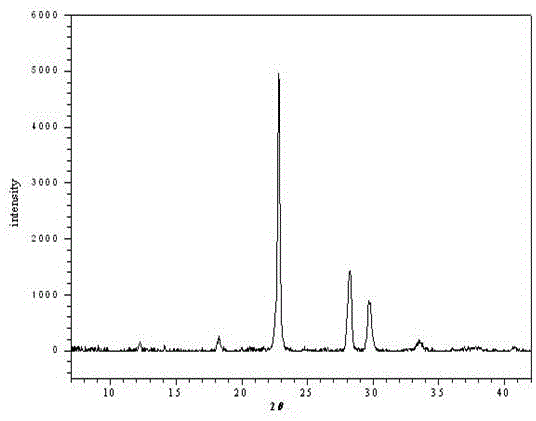

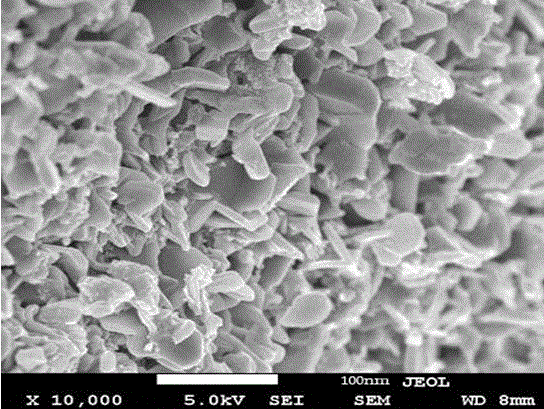

Vanadium-phosphorus oxide catalyst and preparation method thereof

ActiveCN104549394AStable structureDispersedOrganic chemistryPhysical/chemical process catalystsO-Phosphoric AcidPtru catalyst

The invention discloses a vanadium-phosphorus oxide catalyst and a preparation method thereof. The vanadium-phosphorus oxide catalyst has the specific surface area of 120 to 220 m<2> / g, and the grain size of less than 120 nm. The preparation method comprises the following steps: adding a mixture of isobutanol and benzyl alcohol, vanadium pentoxide and an additive into a fluidized bed reactor, introducing a fluid into the reactor, so that the materials in a boiling rolling state; heating the reactor to a reaction temperature for reacting; introducing a certain amount of concentrated phosphoric acid into the reactor, and keeping the boiling state to obtain a blue or light blue slurry reaction liquid; filtering the reaction liquid to obtain a filtrate; washing, drying and roasting the filtrate to obtain a precursor of the vanadium-phosphorus oxide catalyst; activating the precursor to obtain the vanadium-phosphorus oxide catalyst. The catalyst is small in grain size, large in specific surface area, high in strength and low in abrasion; when the catalyst is used for a catalytic reaction for preparing maleic anhydride by oxidizing n-butane, the conversion rate of n-butane is high, and the maleic anhydride selectivity is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly paint and preparation method thereof

PendingCN105462492AAvoid pollutionReduce pollutionAntifouling/underwater paintsRosin coatingsRosinChemistry

The invention provides an environment-friendly paint and a preparation method thereof. The environment-friendly paint is prepared from the following components in parts by weight: 50-70 parts of Jatropha Curcas biodiesel, 35-46 parts of rosin, 5-9 parts of sodium carboxymethyl cellulose, 3-12 parts of sodium silicoaluminate, 5-8 parts of isobutanol, 0.1-0.7 part of essential oil, 0.5-1.2 parts of zinc naphthenate, 10-16 parts of color paste, 3-8 parts of ethyl acetate and 0.1-0.3 part of dibutyltin dilaurate. The raw materials are free of formaldehyde, trimethylbenzene and other harmful substances, thereby avoiding the air pollution in the past paint drying process; and thus, the paint is safe to use and basically harmless to the operating personnel, thereby implementing clean production. All the indexes of the environment-friendly paint developed by using the nontoxic natural pigment and assistants satisfy the requirements. The environment-friendly paint has the advantages of flexible coated film, favorable permeability, favorable wear resistance, favorable high temperature resistance, high safety, no toxicity, wide applicability and excellent properties.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

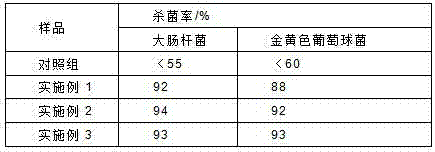

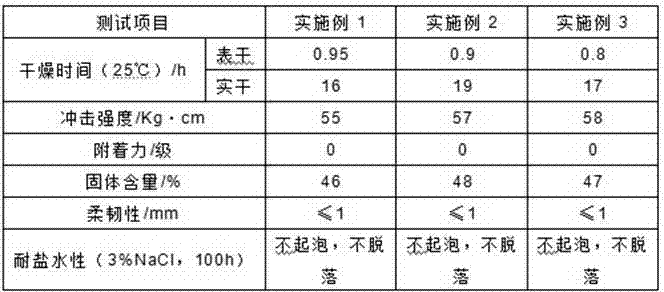

Mouldproof and moth-proof bactericidal paint and preparation method thereof

ActiveCN103788845AStrong adhesionFast drying at low temperatureAntifouling/underwater paintsPaints with biocidesKaolin clayEthyl acetate

The invention relates to a mouldproof and moth-proof bactericidal paint and a preparation method of the bactericidal paint, belonging to the technical field of paint. The mouldproof and moth-proof bactericidal paint comprises the following components in parts by weight: 50-70 parts of rosin modified glyptal resin, 8-15 parts of alpha-bromocinnamaldehyde, 1-3 parts of nano titanium dioxide, 0.2-0.5 part of tagetes essential oil, 10-20 parts of medical stone, 15-24 parts of kaoline, 0.5-1 part of thickening agent, 0.5-2 parts of defoaming agent, 50-65 parts of ethyl acetate and 10-18 parts of isobutanol. The preparation method of the product is simple; the prepared mouldproof and moth-proof bactericidal paint is high in adhesive force and high in low-temperature drying speed, has good mouldproof, moth-proof and bactericidal functions, and is convenient in construction and easy to popularize and apply.

Owner:NANTONG HAIOU LIFE SAVING & PROTECTION EQUIP

Isobutanol tolerance in yeast with an altered lipid profile

InactiveUS20160326551A1Improved production of butanolImprove toleranceTransferasesBiofuelsButanolYeast

Provided herein are recombinant yeast host cells and methods for their use for production of fermentation products from an engineered pyruvate utilizing pathway. The yeast host cells provided herein comprise an altered lipid profile, which confers resistance to butanol.

Owner:BUTAMAXTM ADVANCED BIOFUELS

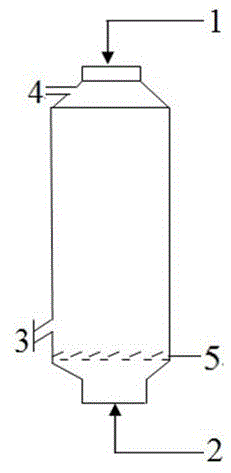

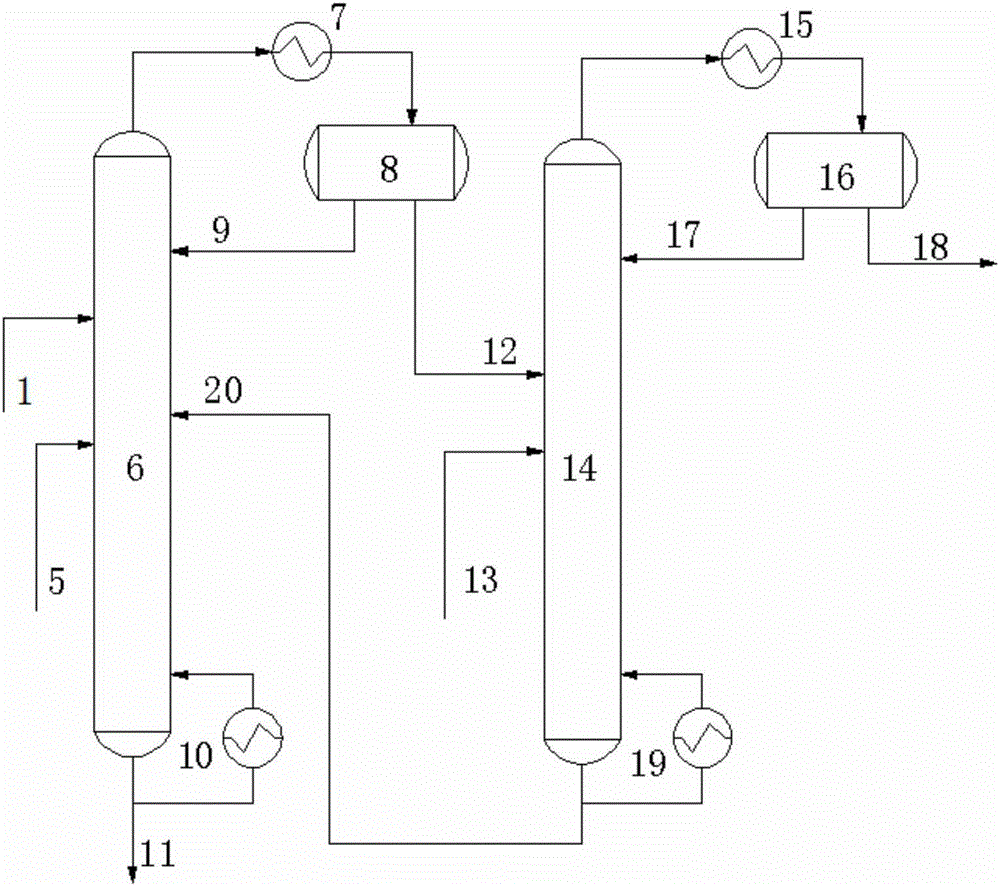

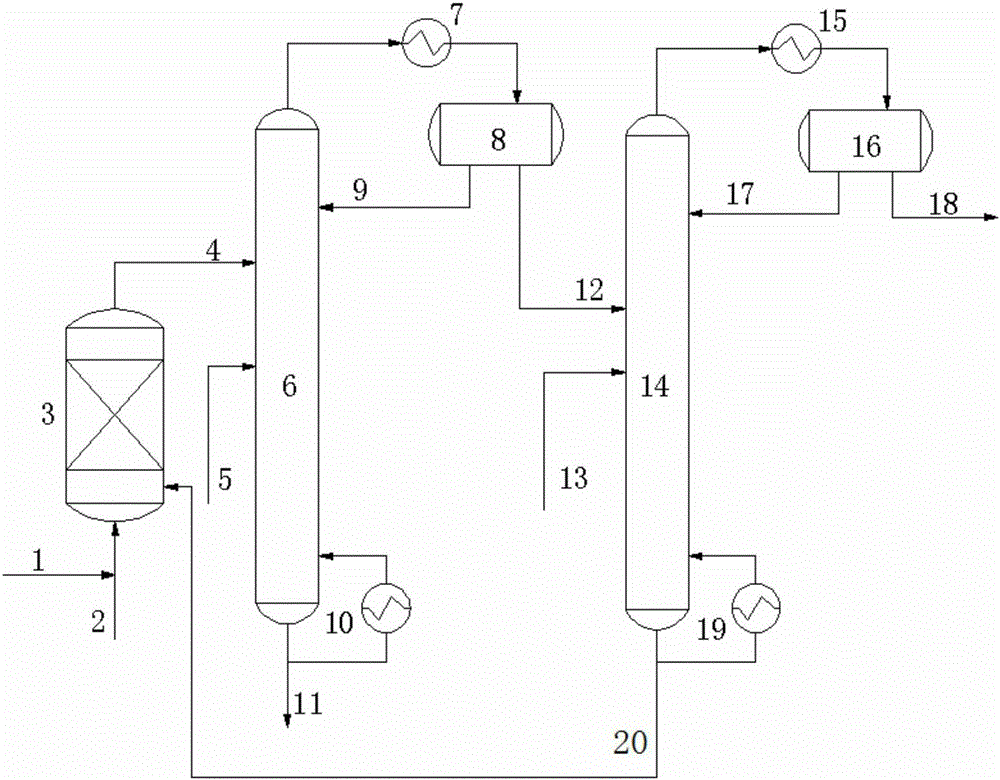

Reactive distillation method and reactive distillation device for producing butanol by hydrogenating butyraldehyde

InactiveCN104557457ALess investmentLow operating costOrganic compound preparationChemical industrySec-ButanolReboiler

The invention relates to a reactive distillation method and a reactive distillation device for producing butanol by hydrogenating butyraldehyde. The device comprises an evaporator, a reactive distillation tower, a butanol distillation tower, an n-butanol and iso-butanol separation tower, a condenser, a reboiler, a compressor, a pump, relevant feeding pipelines and pipelines used for connecting the devices. The method and the device have the characteristics that the reactive distillation technology and devices are adopted, light components are separated at a tower top during a process of carrying out hydrogenation reaction of butyraldehyde in the reactive distillation tower; n-butanol and iso-butanol can be prepared by subsequent separation; a unit for producing butanol by using butyraldehyde and a unit for purifying, distilling and separating are operated and coupled in one device for simultaneously operating; reaction products are purified after the reaction is completed; the device investment is saved; the subsequent operation fee is also reduced; the quality purity of n-butanol prepared by separating through the subsequent butanol distillation tower and the n-butanol and iso-butanol separation tower can reach 99.5%; the quality purity of iso-butanol can reach 99%.

Owner:TIANJIN UNIV

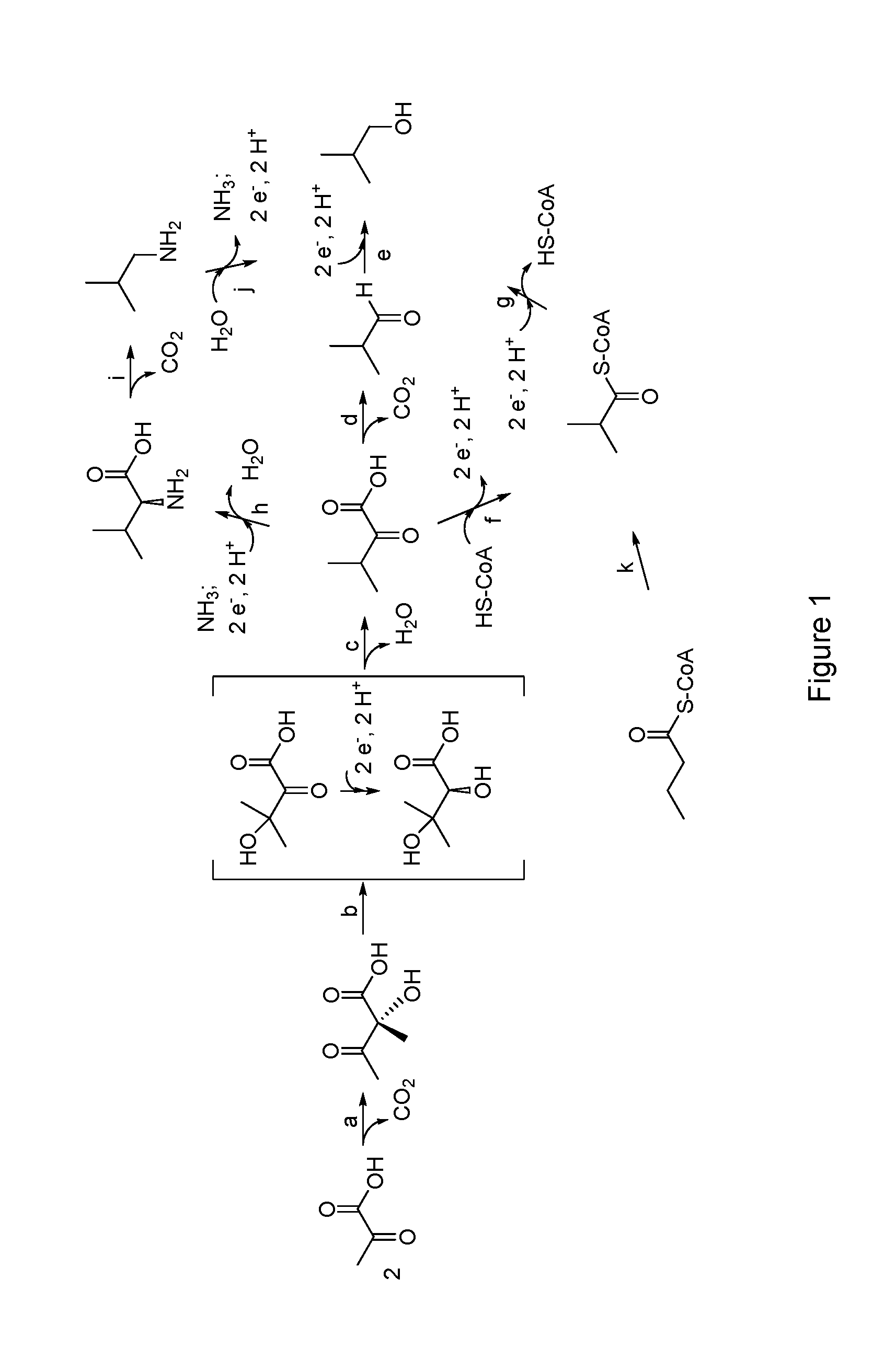

Biodesel and method for preparing same

InactiveCN101338213AHigh calorific valueImprove stabilityBiofuelsLiquid hydrocarbon mixture productionAlkaneIsobutanol

The invention relates to bio-based diesel oil and a preparation method thereof. The biological diesel oil comprises the components with the weight percentage of 3-10 percent of mixed ester of methyl, ethyl and butyl, 2-5 percent of butanol and isobutanol, 0.1-0.3 percent of carbonate rare earth lanthanum cerium polyol oleate copolymer, and the rest is C<12-14> alkane and C<12-14> isoparaffin. The preparation method is divided into two steps: biological oil which is prepared through rapid middle temperature thermal cracking and plant grease with 35-40 percent of the C more than or equal to 18 fatty acid content are used as raw materials, and high pressure hydrofing cracking and all formulation screening process are used for the preparation. The prepared bio-based diesel oil has the advantages of high thermal value, high cleanness, low freezing point and good stability, can be used as both the necessary component of highly clean diesel oil and a novel environmental protection solvent and can completely substitute present various diesel oil fuels.

Owner:俏东方生物燃料集团有限公司

Diesel oil additive

InactiveCN105001927AIncrease profitReduce accumulationLiquid carbonaceous fuelsEthyleneglycol monobutyl etherTetralin

The invention provides a diesel oil additive. The diesel oil additive is prepared from the following raw materials by weight: 9 to 11 parts of potassium permanganate, 6 to 8 parts of sodium nitrate, 6 to 10 parts of manganese carbonate, 2 to 6 parts of a stabilizing agent, 8 to 12 parts of N,N-bis(salicylidene)propane diamine, 1.3 to 6 parts of tetralin, 4 to 8 parts of triethanolamine, 6 to 11 parts of methyl tert-butyl ether, 7 to 10 parts of isobutanol, 1.2 to 2 parts of amyl nitrate, 7 to 10 parts of glycol monobutyl ether, 2 to 4 parts of barium sulfonate, 7 to 12 parts of 5-methyl-2-hepten-4-one, 5 to 8 parts of methylbenzotriazol and 4 to 6 parts of glycol monobutyl ether. The invention has the following beneficial effects: the diesel oil additive can perfectly improve the utilization rate of fuel oil, reduces accumulation of carbon deposit and decreases discharge of toxic substances.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Light hydrocarbon fuel composition for vehicle

PendingCN112899044AImprove cleanlinessGood dispersionLiquid carbonaceous fuelsFuel additivesAnti oxidantTrimethylbenzenes

The invention discloses a light hydrocarbon fuel composition for a vehicle. The light hydrocarbon fuel composition comprises the following components in parts by weight: 500-600 parts of stable light hydrocarbon (octane site in a research method is greater than 92 #), 80-120 parts of isobutanol, 180-340 parts of aromatic hydrocarbon, 130-150 parts of xylene, 200-305 parts of isooctane, 0.25-0.5 part of lanthanum isooctanoate, 0.5-0.7 part of biphenyl, 0.1 part of a metal corrosion inhibitor and 0.1 part of an antioxidant. The stable light hydrocarbon is oil refinery downstream byproducts or methanol to olefin (MTO) and coal tar hydrogenation stable light hydrocarbons; the molecular formula of the isobutanol is C4H100; the aromatic hydrocarbon is a mixture of methylbenzene, dimethylbenzene and trimethylbenzene or one or two of methylbenzene, dimethylbenzene and trimethylbenzene for blending gasoline; the isooctane is alkylated oil and is also called isomer octane, and the research octane number is 98-100; and the metal corrosion inhibitor is benzotriazole. The light hydrocarbon fuel composition for the vehicle can improve power and reduce gasoline consumption; and emission of tail gas pollutants is reduced.

Owner:平湖市晨星科技实业有限公司

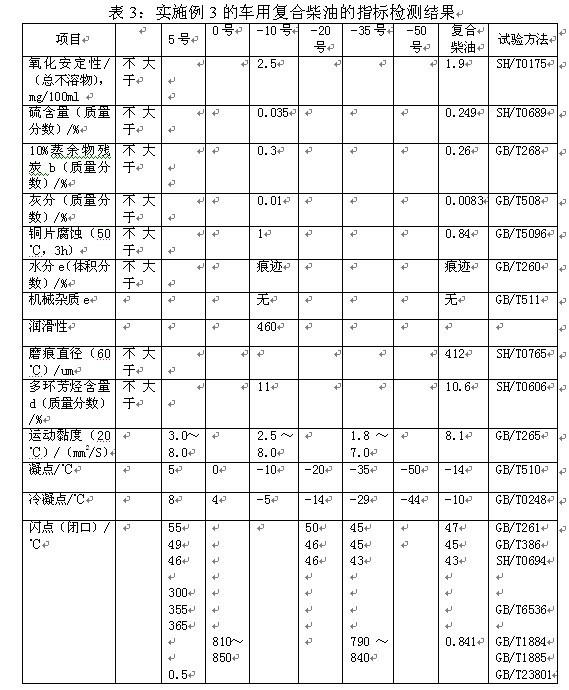

Composite diesel and preparation method thereof

InactiveCN104862021AImprove powerHigh freezing pointLiquid carbonaceous fuelsProcess engineeringAromatic hydrocarbon

The invention discloses a composite diesel composed of the components of, by weight, diesel, dimethyl carbonate, tert-butanol, isobutanol, common kerosene, absorber oil and heavy aromatic hydrocarbon. The composite diesel provided by the invention has relatively high flash point, solidifying point and cetane number. The miscibility of the components is good, and the corrosivity is low. The diesel can be used for replacing a common diesel fuel. The composite diesel provided by the invention meets the indexes in automotive diesel GB19147-2009.

Owner:刘敏

Two-component carbon nanotube type epoxy zinc-rich coating

InactiveCN111675929AImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsXylylenePolymer science

The invention discloses a two-component carbon nanotube type epoxy zinc-rich coating, which is composed of a paint component and a curing agent component. The two components are packed. The coating ischaracterized by being prepared from the following raw materials in percentage by weight: 30 to 40wt% of epoxy resin, 5 to 8 wt% of xylene; 1 to 3 wt% of isobutanol; 0.3 to 1 wt% of polyamide wax; 22.3 to 27.5 wt% of a pigment and filler; 30 to 60 wt% of zinc powder; 0.1 to 0.5 wt% of an organic silicon polymer; and 2 to 10 wt% of a carbon nanotube; wherein the curing agent component is preparedfrom the following raw materials in percentage by weight: 10-20 wt% of xylene; 15 to 25 wt% of isobutanol; 15 to 20 wt% of phenolic aldehyde ammonia; 2 to 6 wt% of propylene glycol monomethyl ether; 5to 10 wt% of epoxy resin; and 20 to 50 wt% of modified polyamide. The product blank in the field of anticorrosive paints is filled, and the anticorrosive performance can be improved by 2-3 times compared with that of a conventional epoxy zinc-rich coating.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Preparation method of degradable engine lubricating oil

ActiveCN103695100AImprove the lubrication effectAvoid pollutionLubricant compositionButanedioic acidVegetable oil

The invention relates to engine lubricating oil, and particularly relates to a preparation method of degradable engine lubricating oil, belonging to the technical field of lubricating oil. The preparation method comprises the following steps: uniformly mixing vegetable oil and sodium hydrogen carbonate, heating, preserving heat by reflux, cooling and taking the supernate; distilling the supernate and collecting fractions in a 170-190 DEG C section; and adding vulcanized triphenyl phosphate, succinimide, isobutanol, trialkyl ester oleate phosphate, diglycol butyl ether, 2-aminoethyl heptadecenyl imidazole dodecenyl sodium succinate, an antioxidant, a plasticizer and calcium petroleum sulfonate into the fractions, heating, preserving by reflux and cooling. The engine lubricating oil provided by the invention is good in lubricating effect and can be biodegraded, so that the environmental pollution caused by abandoning the lubricating oil is avoided.

Owner:南通市通州区五接农业机电管理站有限公司

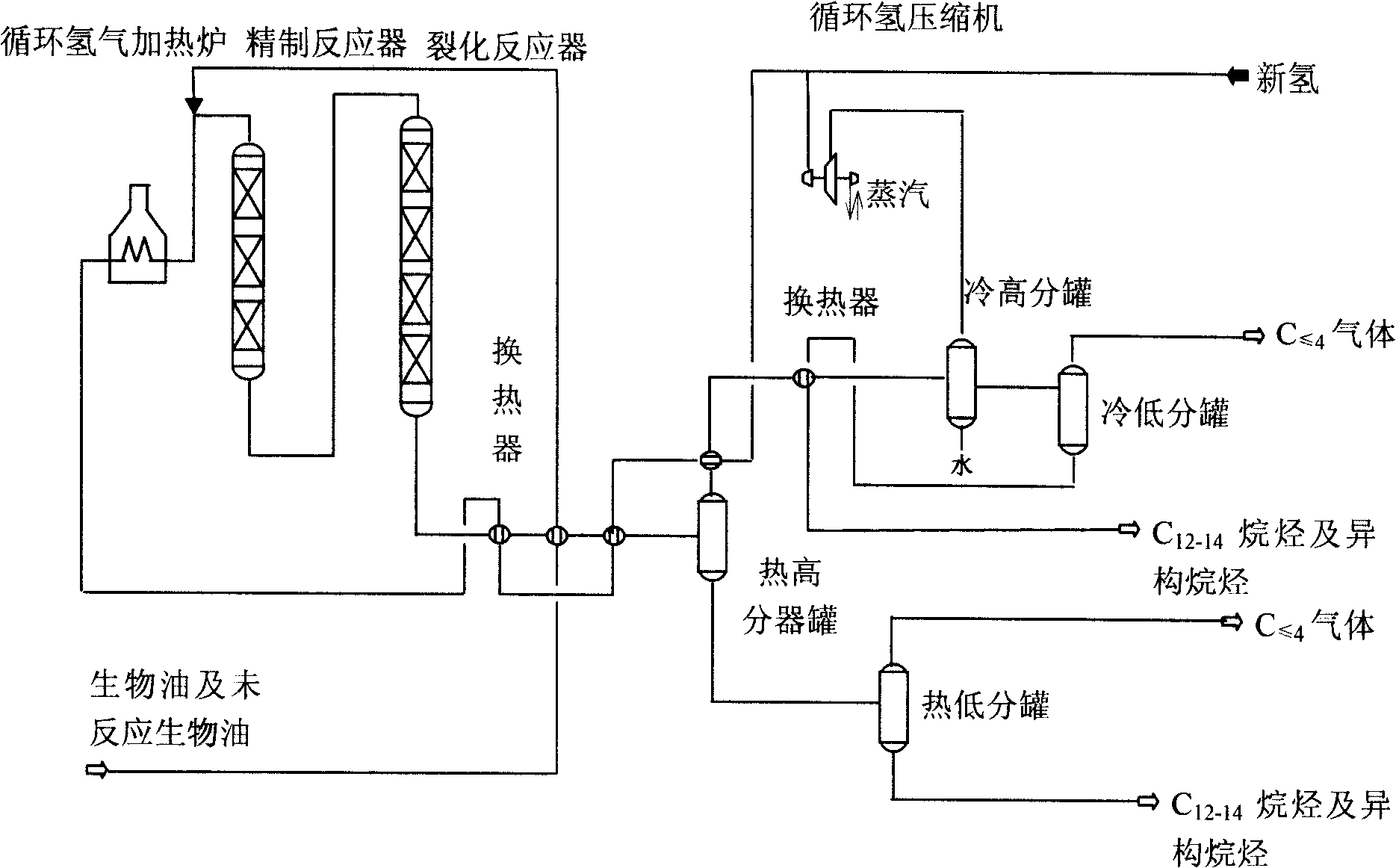

UV solidified elastic hand feeling paint and production method

The invention relates to UV solidified elastic hand feeling paint and a production method. The method is characterized by including the following steps of firstly, sequentially throwing part of methyl isobutyl ketone, photoinitiator and light stabilizer in a small reaction still under a shielding condition, and conducting stirring till the solution is clear; secondly, sequentially throwing long-chain urethane acrylate, reactive monomer and branched polyester resin in a large reaction still, and conducting stirring; thirdly, adding matte agent into the large reactions till while stirring, and conducting stirring; fourthly, adding the mixture in the small reaction still into the large reaction still, adding the rest of methyl isobutyl ketone, and conducting stirring to obtain a component A; fifthly, throwing isobutanol, butyl cellosolve, ethyl acetate, 3-methyl-3-ethyl methoxyacetate, butanone and methyl isobutyl ketone in the large reaction still, and conducting stirring to obtain a component B; sixthly, packaging the component A and the component B independently, and mixing the component A and the component B for use in the use process. The hand feeling and performance of PU elastic paint can be achieved, and meanwhile no organic tin or other harmful substances are contained.

Owner:卡秀万辉(无锡)高新材料有限公司

Two-dimensional nano low-surface-treatment graphene anticorrosive primer and preparation method thereof

InactiveCN110845934AImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsXylyleneZinc phosphate

The invention discloses a two-dimensional nano low-surface-treatment graphene anticorrosive primer and a preparation method thereof. The two-dimensional nano low-surface-treatment graphene anticorrosive primer is prepared from, by mass, 30-40wt% of epoxy resin, 5-8wt% of xylene; 1-3wt% of isobutanol; 0.3-1% of polyamide wax; 22.3-27.5wt% of a pigment and filler; 5-8wt% of zinc phosphate; 0.1-0.5wt% of an organosilicon polymer; 10-30wt% of two-dimensional nano graphene; and 12-15wt% of a curing agent. Different from a preparation formula and a preparation method adopting an epoxy system and ananti-rust pigment in the conventional technology, the graphene anticorrosion primer prepared by the invention possesses the anti-corrosion performance improved by 1-2 times compared with that of a conventional anti-corrosion paint.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

Composite diesel oil for automobile

InactiveCN102304393AImprove powerHigh freezing pointLiquid carbonaceous fuelsDiesel combustionFuel oil

The invention discloses composite diesel oil for an automobile. The composite diesel oil is characterized by comprising the following components in parts by weight: 0.03-1.09 parts of ferrocene, 20-30 parts of diesel oil, 2-5 parts of dimethyl carbonate, 1 part of tertiary butanol, 1-3 parts of isobutanol, 15-20 parts of kerosene, 20-35 parts of coal tar and 40-50 parts of heavy aromatic hydrocarbon. In the composite diesel oil for the automobile, ferrocene can improve the dynamic property of the composite diesel oil and takes effects of reducing carbon deposition of a nozzle, eliminating smoke and supporting combustion; dimethyl carbonate can greatly reduce or basically eliminate the combustion smoke of a diesel engine, reduce the pollution of diesel oil combustion to environment and simultaneously improve the heat engine efficiency of the diesel engine, dose not lower fuel oil kilometers, and is nontoxic and environmentally-friendly; organic matters such as tertiary butanol and isobutanol can improve the intersolubility among the components of the composite diesel oil for the automobile, can improve the condensation point of the diesel oil and improve the condensation point of the composite diesel oil for the automobile; and isobutanol can also reduce the content of sulfur in the fuel and the emission of harmful substances.

Owner:彭爱国

Synthetic gasoline

InactiveCN102965159AGood combustion performanceEasy to startLiquid carbonaceous fuelsIsobutanolCombustion

The invention relates to synthetic gasoline. The synthetic gasoline is characterized by comprising the following raw materials in percentage by weight: 20%-30% of gasoline, 20%-50% of methanol, 10%-20% of acetone, and 10%-15% of isobutanol. The synthetic gasoline provided by the invention is good in combustion dynamic performance, easy to start in winter, and less in exhaust emission, and cannot cause lead pollution after combustion. After tests, the content of carbon monoxide in exhaust gas is 0.40, and is in line with the national emission standards.

Owner:QINGZHOU SHENGHONG IND & TRADE

VPO/SBA-15 catalyst, preparation method and application

InactiveCN107149945AHigh catalytic activityImprove catalytic stabilityMolecular sieve catalystsOrganic compound preparationPhosphoric acidBenzyl alcohol

The invention provides a VPO / SBA-15 catalyst, a preparation method and application. The preparation method comprises the following preparation steps: firstly, weighing vanadium pentoxide, adding the vanadium pentoxide in a three-neck flask, then adding isobutanol and phenylcarbinol, and stirring and refluxing at constant temperature until vanadium pentoxide is dissolved completely; weighing a certain amount of phosphoric acid, slowly adding the phosphoric acid in the flask, and then continuing carrying out refluxing reaction at constant temperature until a solution is sapphirine to obtain vanadium phosphorous oxide referred as VPO; adding SBA-15 in the three-neck flask, and rapidly stirring to react; and after reaction is finished, taking out a sample, carrying out suction filtration, washing the sample with the isobutanol and acetone, then drying, grinding and roasting the sample, carrying out tabletting on the sample, and sieving the tablets to obtain the VPO / SBA-15 catalyst. The VPO / SBA-15 catalyst has the remarkable characteristic that the used VPO / SBA-15 catalyst has good catalytic activity and stability in a reaction process.

Owner:JIANGSU UNIV

Production process of brominated SBS

The invention discloses a production process of brominated SBS, and belongs to the technical field of flame retardant production, and the production process comprises the following steps: adding SBS and isobutanol into a reaction kettle, heating to 20-40 DEG C, stirring, and keeping the temperature until the materials are completely dissolved; adding sodium bromide, introducing oxidizing agent chlorine, filling lime milk at the tail end of the reaction kettle to absorb unreacted chlorine in the reaction kettle, and heating to 60-75 DEG C and then stopping heating; cooling to 20 DEG C, adding acatalyst, and continuously heating to 75 DEG C to react for 1 hour, wherein the catalyst being tin tetrachloride and ferric trichloride; and cooling to room temperature, adding peroxide and alkali metal alkoxide into the material liquid after the reaction is finished, heating to 30-40 DEG C, keeping the temperature for 2 hours, filtering, washing, removing impurities, and drying to obtain the target product brominated SBS, wherein the peroxide is hydrogen peroxide, and the alkali metal alkoxide is sodium methoxide. The preparation of the brominated SBS is realized by adopting a direct bromination method, the reaction is mild, the bromine content, the yield and the thermal stability of the brominated SBS are improved, and the use requirements are met.

Owner:山东东信新材料科技股份有限公司

Method and device for preparing sec butanol

ActiveCN106518620AHigh purityThe method flow is simpleOrganic compound preparationChemical industrySec-ButanolAlcohol

The present invention provides a method and a device for preparing sec butanol, and the method is as follows: (1) sec-butyl acetate is introduced into a first-stage catalytic distillation column, excessive C1-C3 alcohols are added simultaneously for ester exchange, the sec butanol as a product falls into a tower kettle to collect, and the unreacted C1-C3 alcohols and reaction product acetic acid C1-C3 esters partly are sent into a second-stage catalytic distillation column for further reaction separation; (2) excessive sec-butyl acetate is added into the second-stage catalytic distillation column, the acetic acid C1-C3 esters are distilled off from the top of the column, and then congealed to partly reflux to the top of the second-stage catalytic distillation column and partly use as a product to collect; and (3) the sec butanol obtained by the step (2) and the unreacted sec-butyl acetate are returned to the first-stage catalytic distillation column for further reaction separation. The purity of the sec butanol obtained by the method is high above 99.9%, the purity of the separated acetic acid C1-C3 esters is more than 99%, at the same time, the method has the advantages of simple process and easy operation, compared with the process of butylene hydration for preparing the sec butanol, energy consumption is greatly reduced, and cost is saved.

Owner:HUNAN ZHONGCHUANG CHEM

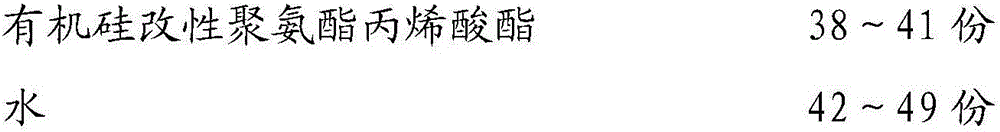

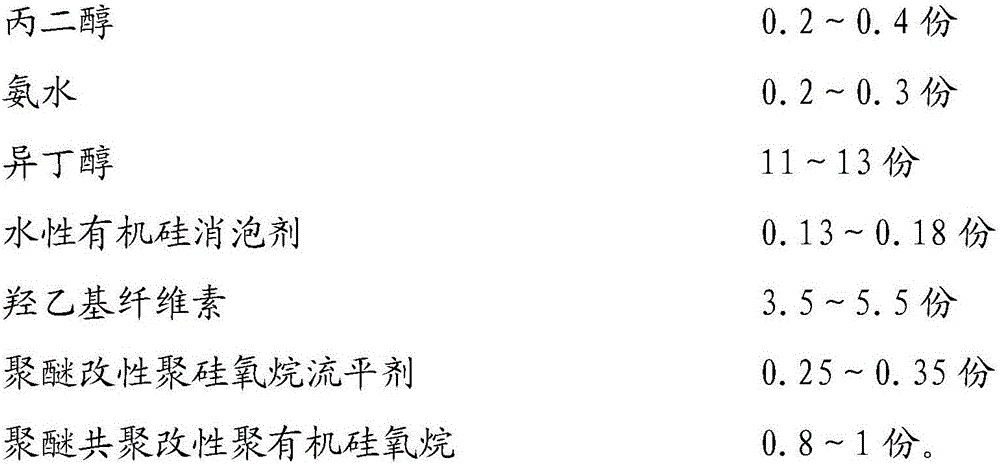

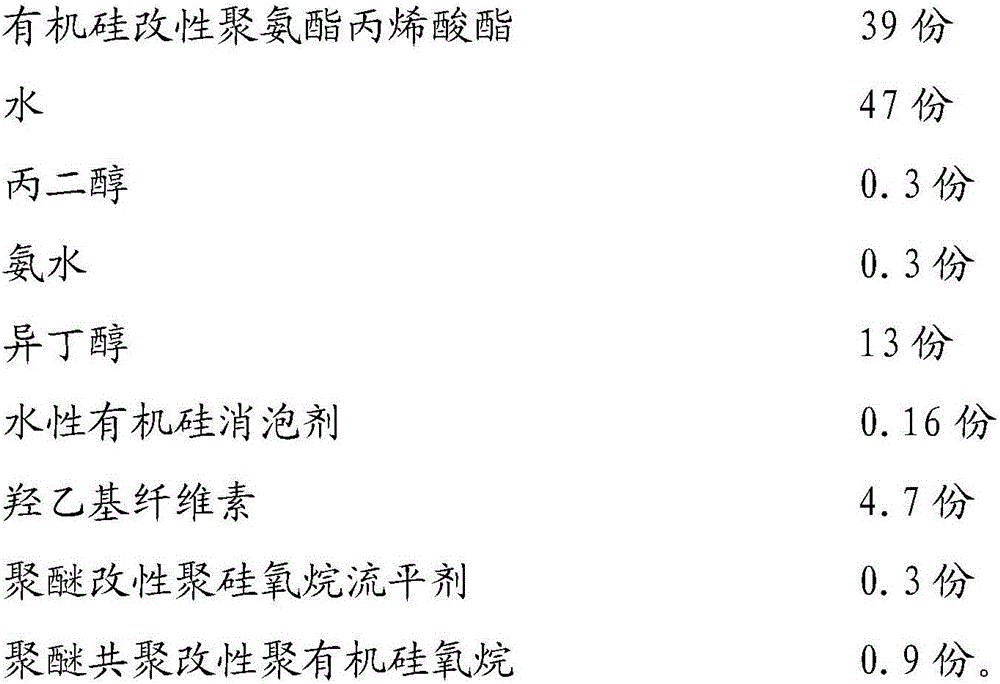

Environment-friendly water-based plastic coating as well as preparation method and application thereof

InactiveCN106433444AReduce pollutionEliminate the disadvantages of long curing timePretreated surfacesPolyurea/polyurethane coatingsLeveling effectIsobutanol

The invention discloses an environment-friendly water-based plastic coating. The coating is prepared from the following components in parts by mass: 38-41 parts of organosilicon-modified urethane acrylate, 29-33 parts of water, 0.2-0.4 parts of propylene glycol, 0.2-0.3 parts of ammonia water, 11-13 parts of isobutanol, 0.13-0.18 parts of a water-based organosilicone antifoaming agent, 3.5-5.5 parts of hydroxyethyl cellulose, 0.25-0.35 parts of a polyether modified polysiloxane leveling agent, 0.8-1 part of polyether copolymerization modified polysiloxane and 13-16 parts of water. The coating not only is good in leveling effect, resistant to hydrolysis and good in adhesion, but also discharges little volatile organic matter, thereby being an environment-friendly coating with excellent comprehensive performance.

Owner:叶有国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com