UV solidified elastic hand feeling paint and production method

A production method and technology of hand-feeling paint, applied in the direction of coating, etc., can solve the problems of complicated process and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of production method of UV curable elastic feel paint, comprises the following steps, and component ratio is by weight:

[0026] (1) Under light-shielding conditions, put 15 parts of methyl isobutyl ketone, 2 parts of photoinitiator 1# (CIBA 754), 0.8 part of photoinitiator 2# (CIBA 819) and 1 part of Light stabilizer, stirred until the solution is clear;

[0027] (2) Put 60 parts of four-functional long-chain urethane acrylate, 5 parts of reactive monomer (DPHA) and 5 parts of hyperbranched polyester resin with 16 functionalities into the large reactor successively, at a speed of 1000 rpm Stir for 10 minutes;

[0028] (3) Add 25 parts of matting agent (Tosoh E-1011) into the large reaction kettle while stirring, and stir for 30 minutes at a speed of 1200 rpm;

[0029] (4) Add the mixture in the small reactor to the large reactor, add 25 parts of methyl isobutyl ketone, and stir for 20 minutes at a speed of 1000 rpm to obtain component A; use Iwat...

Embodiment 2

[0032] Embodiment 2: a kind of production method of UV curable elastic feel paint, comprises the following steps, and component ratio is by weight:

[0033] (1) Under light-shielding conditions, put 25 parts of methyl isobutyl ketone, 1 part of photoinitiator 1# (CIBA 754), 0.2 part of photoinitiator 2# (CIBA 819) and 0.5 part of Light stabilizer, stirred until the solution is clear;

[0034] (2) 50 parts of four-functional long-chain polyurethane acrylate, 2 parts of reactive monomer (DPHA) and 2 parts of 16-functionality hyperbranched polyester resin are put into the large reactor successively, at a speed of 800 rpm Stir for 20 minutes;

[0035] (3) Add 15 parts of matting agent (Tosoh E-1011) into the large reaction kettle while stirring, and stir for 40 minutes at a speed of 1000 rpm;

[0036] (4) Add the mixture in the small reactor to the large reactor, add 5 parts of methyl isobutyl ketone, and stir at 800 rpm for 30 minutes to obtain component A; use Iwata 2 at 25°C ...

Embodiment 3

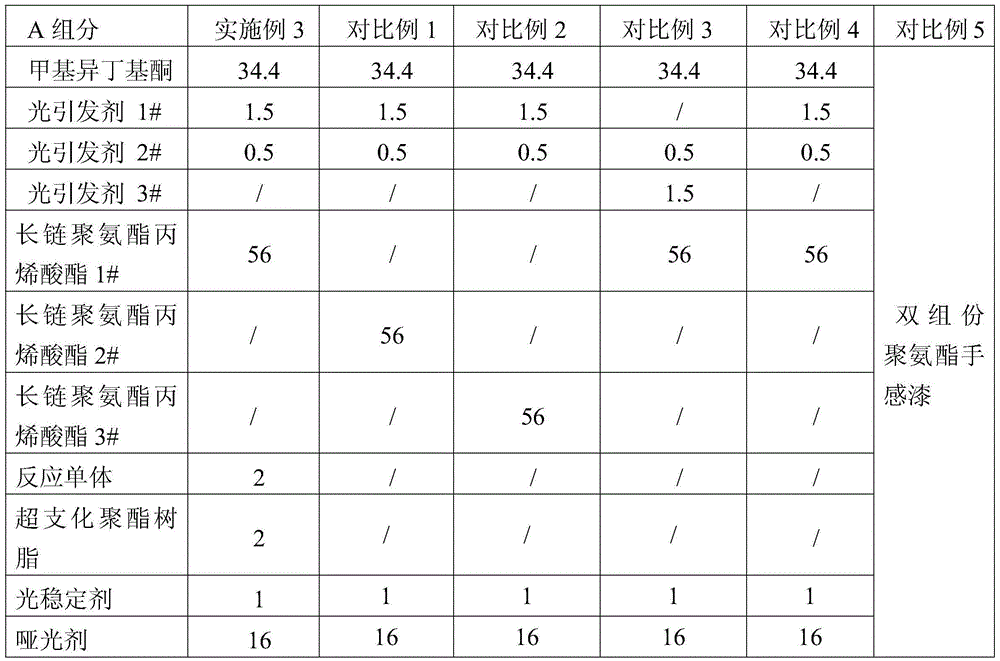

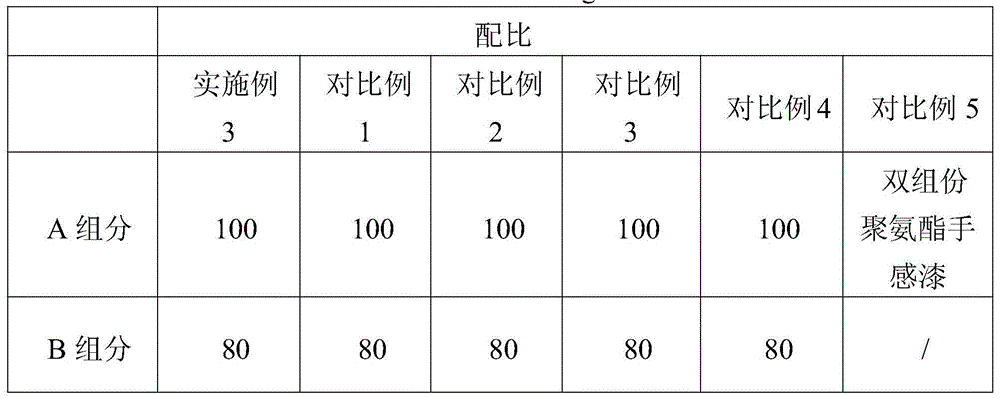

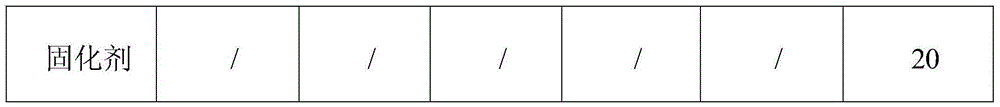

[0039] Embodiment 3: a kind of production method of UV curable elastic feel paint, comprises the following steps, and component ratio is counted in parts by weight:

[0040] (1) Under light-shielding conditions, put 20 parts of methyl isobutyl ketone, 1.5 parts of photoinitiator 1# (CIBA 754), 0.5 part of photoinitiator 2# (CIBA 819) and 1 part of Light stabilizer, stirred until the solution is clear;

[0041] (2) 56 parts of four-functionality long-chain urethane acrylate, 2 parts of reaction monomer (DPHA) and 2 parts of 16-functionality hyperbranched polyester resin are put into the large reactor successively, at a speed of 900 rpm Stir for 15 minutes;

[0042] (3) Add 16 parts of matting agent (Tosoh E-1011) into the large reaction kettle while stirring, and stir for 35 minutes at a speed of 1000 rpm;

[0043] (4) Add the mixture in the small reactor to the large reactor, and add 14.4 parts of methyl isobutyl ketone, stir at 800 rpm for 25 minutes to obtain component A; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com