Composite environmentally-friendly antibacterial paint and preparation method thereof

A paint and environmental protection technology, applied in the field of paint, can solve the problems of high price of silver ion antibacterial agent, poor durability, harmful to the environment, etc., and achieve the effect of small surface friction coefficient, long service life and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

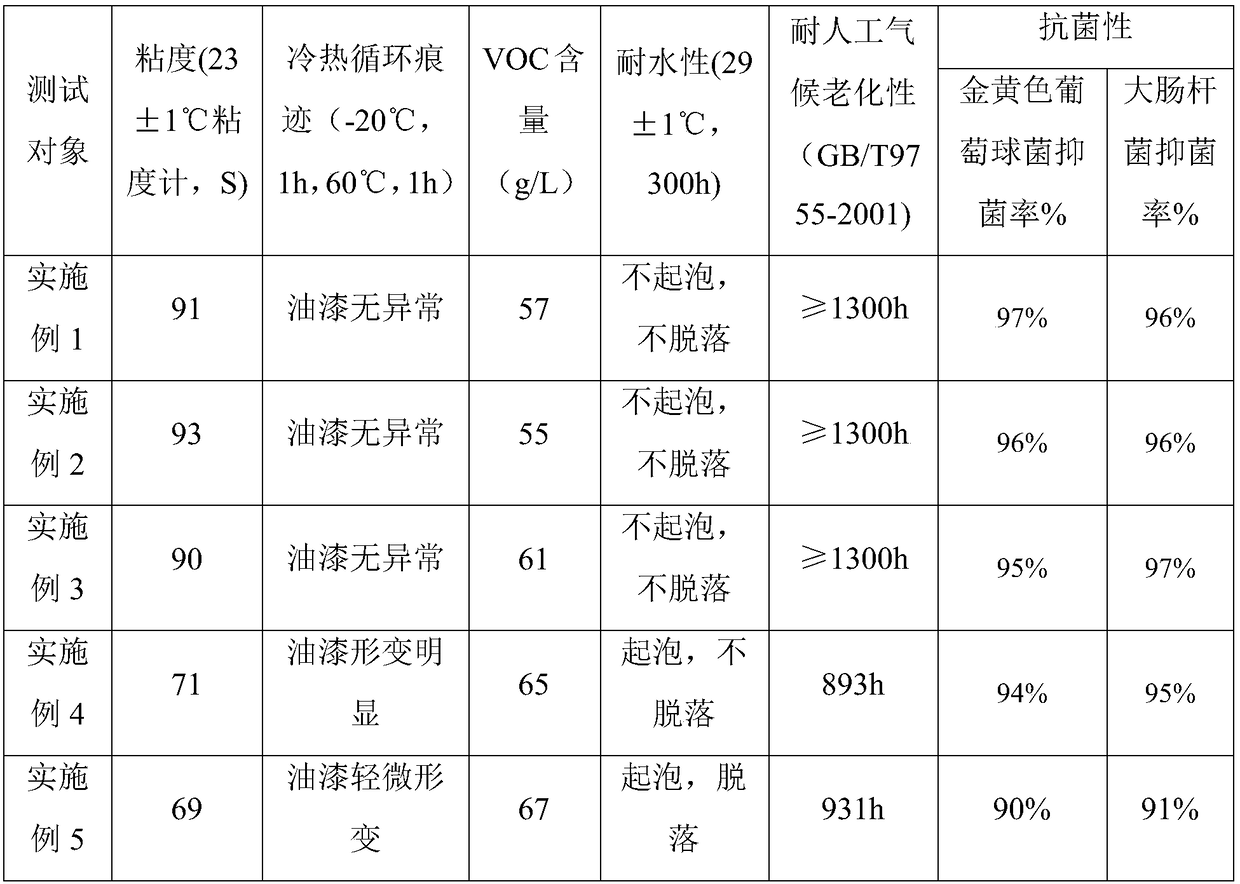

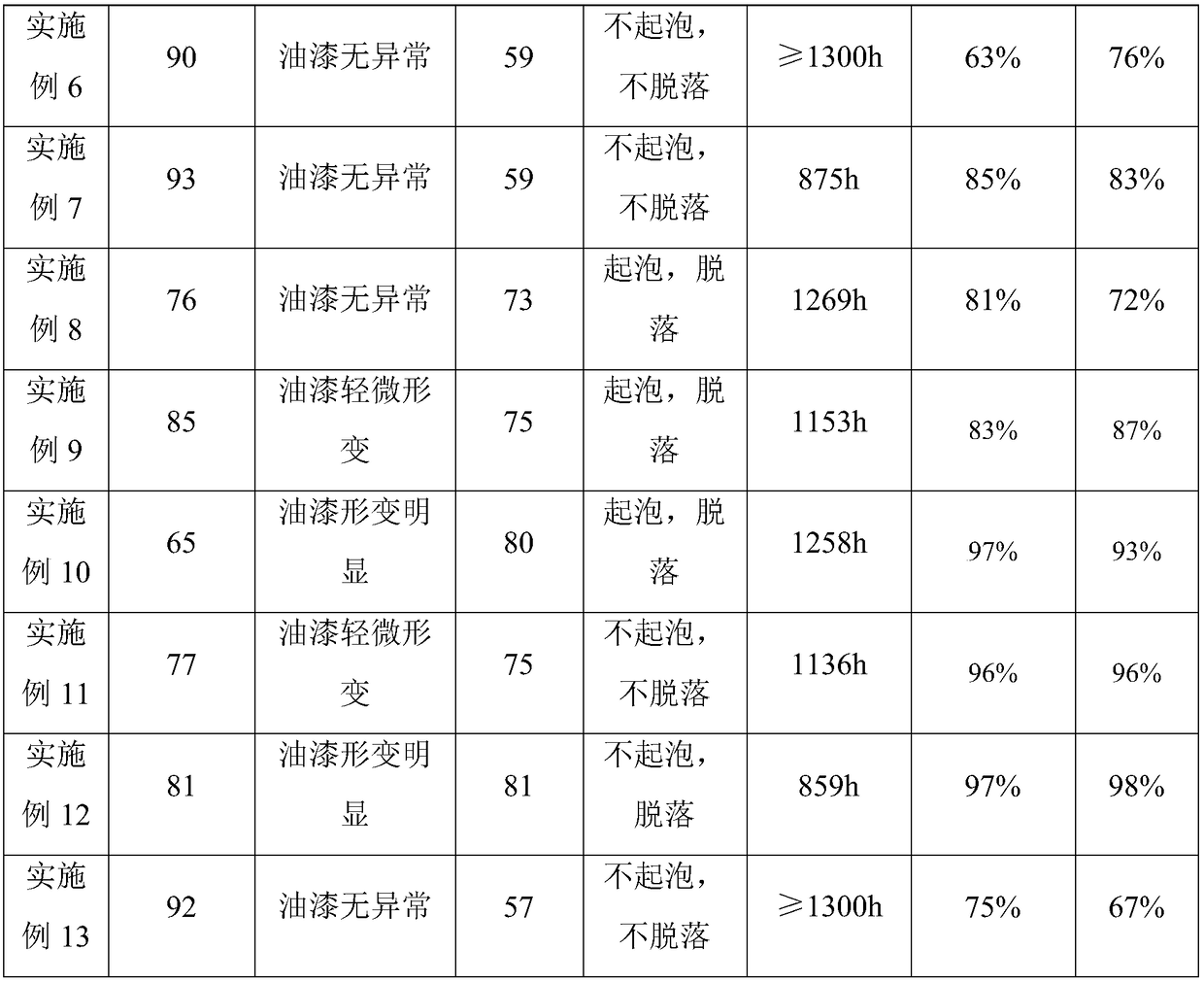

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the composite environmentally friendly antibacterial paint. The method may include the following steps:

[0035] (1) Take polyester modified silicone resin, polypropylene grafted glycidyl acrylate, polyester modified acrylic resin, limonene, phthalic anhydride and coupling agent, and mix under stirring conditions of 1200-1500r / min 20-30min, add zirconium-containing composite silicate mineral powder, cooked tung oil, cellulose acetate and nano zinc oxide powder, continue to stir for 10-15min, to obtain mixture A;

[0036] (2) Take bamboo fiber superfine powder, polyethylene wax, palm wax, nickel slag powder, and pearl powder and stir in a disperser at a stirring speed of 1000-1200r / min and a stirring time of 20-30min to obtain mixture B;

[0037] (3) Mix the mixture A and the mixture B obtained in step (1) and step (2) uniformly, and then add dibutyl tin dilaurate, titanium dioxide suspending agent, propyl methoxyacetat...

Embodiment 1

[0047] Take the following raw materials to prepare paint: 15 parts of polyester modified silicone resin, 10 parts of polypropylene grafted glycidyl acrylate, 15 parts of polyester modified acrylic resin, 12 parts of zirconium-containing composite silicate mineral powder, cellulose acetate 8 parts, 4 parts of nano zinc oxide powder, 7 parts of bamboo fiber ultrafine powder, 8 parts of dibutyltin dilaurate, 4 parts of cooked tung oil, 3 parts of limonene, 6 parts of phthalic anhydride, 13 parts of titanium dioxide suspension, A 4 parts of propyl oxyacetate, 2 parts of polyethylene wax, 7 parts of palm wax, 3 parts of nickel slag powder, 3 parts of pearl powder, 7 parts of leveling agent, 5 parts of toughening agent, 1 part of defoamer, coupling 5 parts of agent and 13 parts of solvent.

[0048] Wherein, the zirconium-containing composite silicate ore powder is a composite silicate mainly composed of aluminosilicate, where Al 2 O 3 ≥53%, SiO 2 ≤30%, Fe 2 O 3 ≤1%, TiO 2 ≤2%, ZrO 2 ≤1...

Embodiment 2

[0051] Take the following raw materials to prepare paint: 18 parts of polyester modified silicone resin, 13 parts of polypropylene grafted glycidyl acrylate, 17 parts of polyester modified acrylic resin, 14 parts of zirconium-containing composite silicate mineral powder, cellulose acetate 9 parts, 5 parts of nano zinc oxide powder, 8 parts of bamboo fiber ultrafine powder, 10 parts of dibutyl tin dilaurate, 5 parts of cooked tung oil, 4 parts of limonene, 8 parts of phthalic anhydride, 15 parts of titanium dioxide suspension, A 5 parts of propyl oxyacetate, 2 parts of polyethylene wax, 9 parts of palm wax, 4 parts of nickel slag powder, 4 parts of pearl powder, 9 parts of leveling agent, 8 parts of toughening agent, 3 parts of defoamer, coupling 7 parts of agent and 17 parts of solvent.

[0052] Wherein, the zirconium-containing composite silicate ore powder is a composite silicate mainly composed of aluminosilicate, where Al 2 O 3 ≥53%, SiO 2 ≤30%, Fe 2 O 3 ≤1%, TiO 2 ≤2%, ZrO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com