VPO/SBA-15 catalyst, preparation method and application

A catalyst and application technology, applied in the field of organic catalysis, can solve the problems of lack of control means in the acetic acid project, and achieve good catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

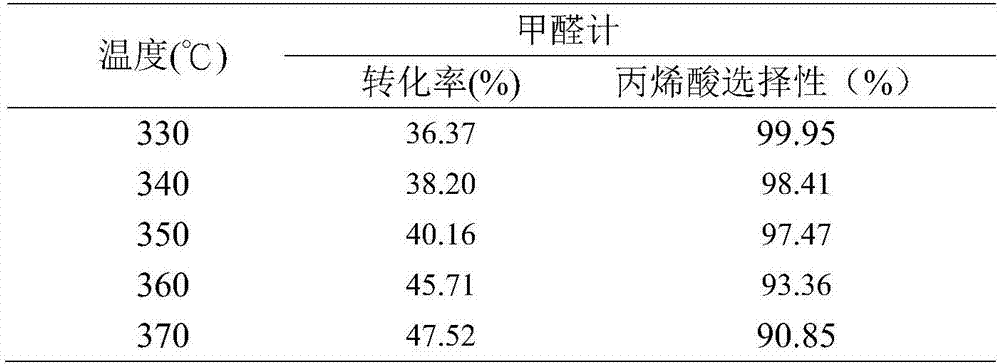

Embodiment 1

[0020] Catalyst preparation:

[0021] VPO / SBA-15 catalyst is prepared by organic phase method: first take by weighing the vanadium pentoxide of 1.5270g, join in the there-necked flask and then add 30ml isobutanol and 30ml benzyl alcohol (V:V=1:1), in Stir and reflux at 140°C for 6 hours until vanadium pentoxide is completely dissolved. According to the composition requirements of the P / V=1.2 ratio of the catalyst, weigh 3.3216g of phosphoric acid, slowly add it into the flask and reflux for 6h; turn off the heating switch, and add 8g SBA-15, stirring; rapid stirring for 3 hours, the VPO component and the carrier are fully mixed, the sample is suction filtered, washed with isobutanol and acetone, dried at 120°C for 24 hours, fully ground, and roasted at 500°C for 4.5h , The sample was pressed into tablets under a pressure of 10Mpa, and sieved to make a catalyst precursor of 20-40 meshes.

[0022] Formaldehyde condensation of acetic acid to prepare acrylic acid:

[0023] A fi...

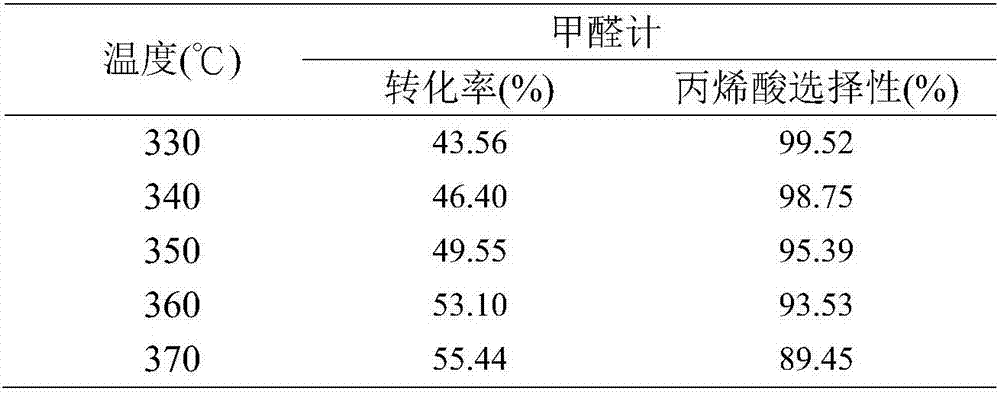

Embodiment 2

[0027] Same as Example 1, but the ratio of P / V in the catalyst is changed so that the P / V molar ratio is 2.0 / 1, and the results are shown in Table 2.

[0028] Table 2. VPO / SBA-15 (P / V=2.0 / 1) catalyzed formaldehyde acetate to prepare acrylic acid result table

[0029]

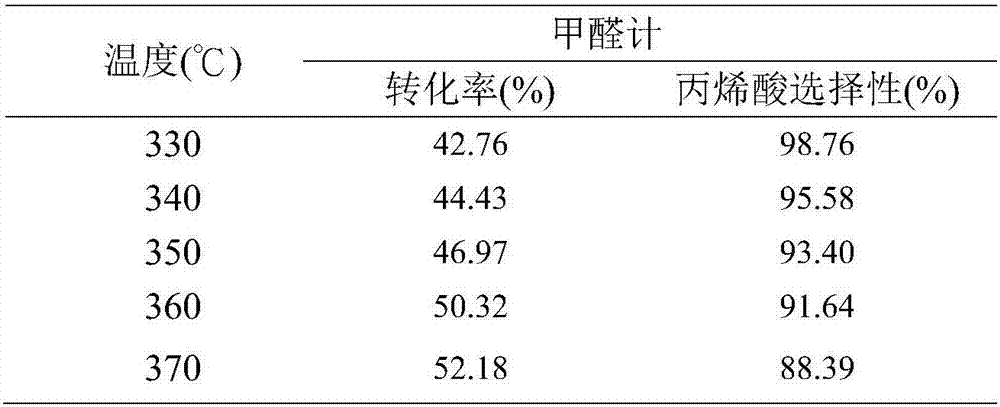

Embodiment 3

[0031] Same as Example 1, but the ratio of P / V in the catalyst is changed so that the P / V molar ratio is 2.8 / 1, and the obtained results are shown in Table 3.

[0032] Table 3. VPO / SBA-15 (P / V=2.8 / 1) catalyzed formaldehyde acetate to prepare acrylic acid result table

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com