Environment-friendly water-based plastic coating as well as preparation method and application thereof

A kind of plastic coating, environment-friendly technology, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., can solve problems such as waste of petroleum resources, air pollution, etc., achieve less environmental pollution and good adhesion , Good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation methods of traditional plastic coatings:

[0041] ① Weigh 51 parts of polyurethane acrylate and add 25 parts of water, 0.2 parts of propylene glycol wetting agent, 0.3 parts of ammonia regulator, 11 parts of isobutanol solvent, and 0.13 parts of water-based silicone at 500r / min. Defoamer and disperse at 500r / min for 15min;

[0042] ② Then add 4 parts of hydroxyethyl cellulose thickener, slowly increase the speed to 1500r / min and disperse for 15 minutes;

[0043] ③ When the speed is reduced to 400r / min, slowly add 0.2 parts of acrylate leveling agent and 1 part of polyether copolymerized modified polyorganosiloxane slip agent and disperse for 30 minutes;

[0044] ④Use 14 parts of water to adjust the viscosity to 30s under the conditions of the Ford 4# cup to obtain the traditional plastic coating.

Embodiment 2

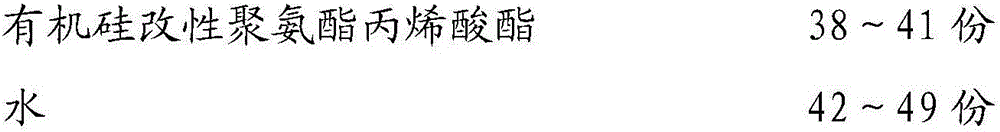

[0046] An environment-friendly water-based plastic paint, which is prepared from the following component distribution ratios and preparation methods:

[0047] S1. Preparation of silicone-modified polyurethane acrylate:

[0048] S11. Mix 16g of alkoxysilicone oil and 13g of β-hydroxyethyl acrylate to obtain a mixed solution P;

[0049] S12. Dissolve 34g of isophorone diisocyanate in 6g of isobutanol solvent, heat to 86°C, add the mixed solution P prepared by S11 dropwise under the condition of nitrogen gas, and drop it in 2.5h. After 1.5 hours of constant temperature reaction, the temperature was raised to 86°C, then 6g of isobutanol solvent and 4g of tert-butyl peroxybenzoate initiator were added, and then constant temperature reaction was carried out for 2.5h, and the reaction was stopped after the conversion rate reached 99%. Under reduced pressure, the isobutanol solvent was filtered out under reduced pressure, and 8 g of water and 4 g of triethanolamine were added under s...

Embodiment 3

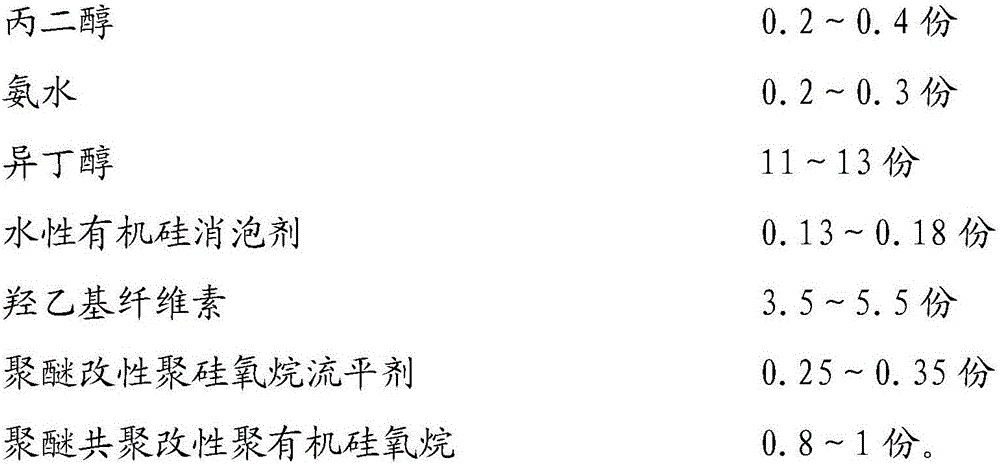

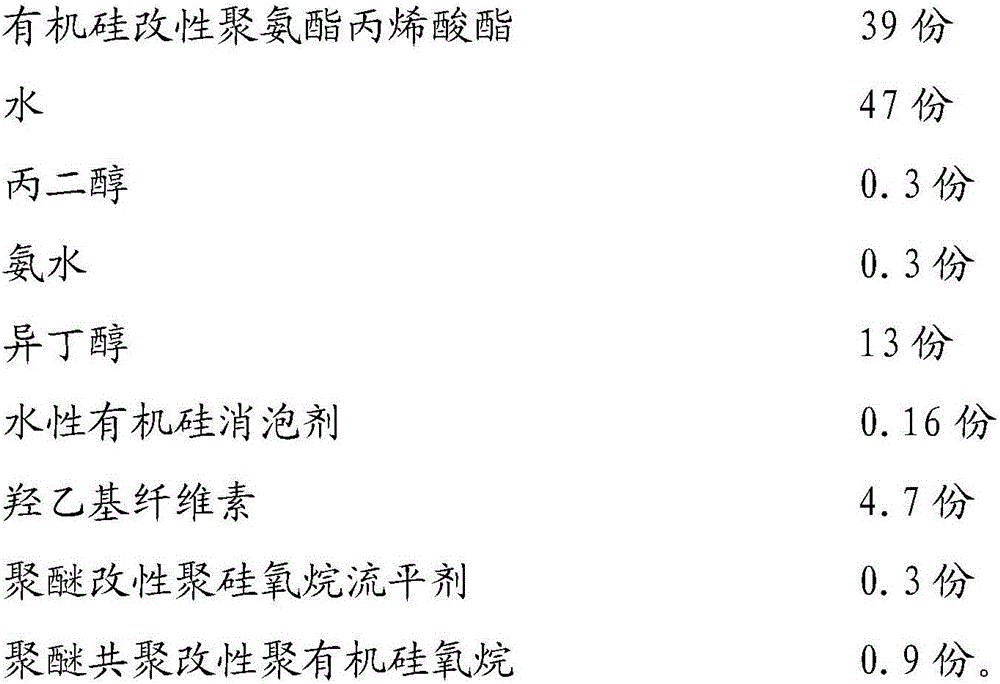

[0059] An environment-friendly water-based plastic paint, which is prepared from the following component distribution ratios and preparation methods:

[0060] S1. Preparation of silicone-modified polyurethane acrylate:

[0061] S11. Mix 22g of alkoxysilicone oil and 16g of β-hydroxyethyl acrylate to obtain a mixed solution P;

[0062] S12. Dissolve 30 g of isophorone diisocyanate in 4 g of isobutanol solvent, heat to 90° C., add the mixed solution P prepared through S11 dropwise under the condition of nitrogen gas, and drop it in 2.5 hours. After 1.5 hours of constant temperature reaction, the temperature was raised to 83°C, then 4g of isobutanol solvent and 2g of tert-butyl peroxybenzoate initiator were added, and then constant temperature reaction was carried out for 2.5h, and the reaction was stopped after the conversion rate reached 99%. Under reduced pressure, the isobutanol solvent was filtered out under reduced pressure, and 11 g of water and 7 g of triethanolamine wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com