Method and device for preparing sec butanol

A technology of sec-butanol and sec-butyl acetate, which is applied in the field of preparing sec-butanol by double-catalyzed rectification process, can solve the problems of long process, increased engineering cost, low conversion rate, etc., and achieve energy consumption reduction, cost saving, easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

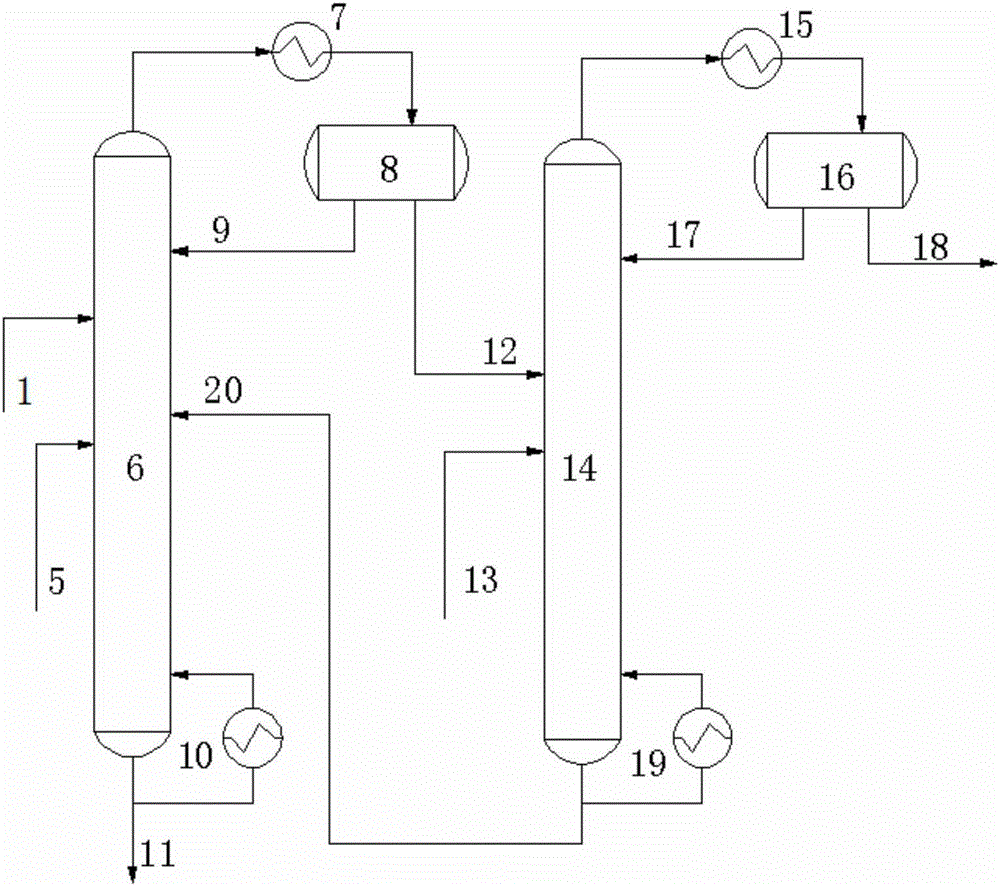

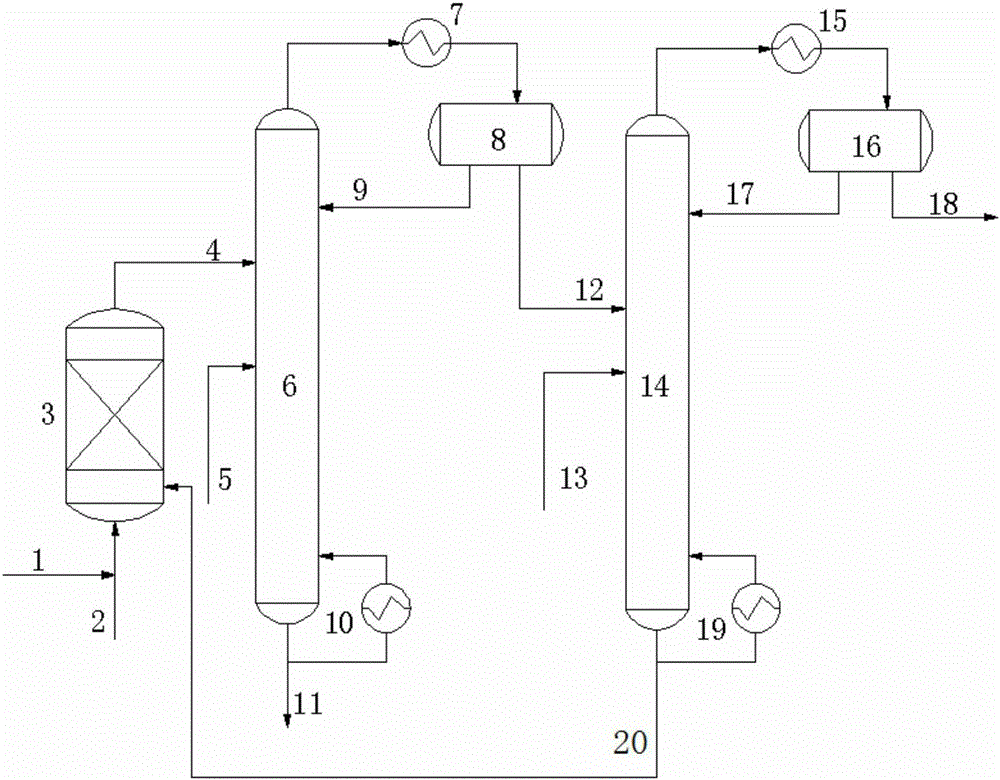

[0034] Second-butyl acetate 1 is sent into primary catalytic rectification tower 6 with the speed of 6.38t / h, and methyl alcohol 5 is added simultaneously, wherein, the theoretical plate number of primary catalytic rectification tower is 25, methanol and acetic acid secondary The molar ratio of butyl ester is 1.05:1, the pressure at the top of the tower is normal pressure, the temperature at the top of the tower is 57°C, and the temperature at the bottom of the tower is 99°C. Second-butanol falls into the bottom of the tower and is recovered as product 11 at a rate of 7.77t / h , the unreacted methanol and the reaction product methyl acetate are steamed from the top of the tower, and after being condensed by the condenser 7, part of it is used as the top reflux 9 of the first-stage catalytic rectification tower, wherein the reflux ratio is 1:1, and part 12 is 7.56t / The speed of h is sent to the secondary catalytic rectification tower 14, while adding excess sec-butyl acetate 13,...

Embodiment 2

[0041] Second-butyl acetate 1 is sent into primary catalytic rectification tower 6 with the speed of 3.48t / h, and ethanol 5 is added simultaneously, wherein, the theoretical plate number of primary catalytic rectification tower is 30, and ethanol and secondary acetic acid The molar ratio of butyl ester is 1.1:1, the pressure at the top of the tower is normal pressure, the temperature at the top of the tower is 77°C, and the temperature at the bottom of the tower is 100°C. Second-butanol falls into the bottom of the tower and is recovered as product 11 at a rate of 8.14t / h , the unreacted ethanol and the reaction product ethyl acetate are steamed from the top of the tower, and after being condensed by the condenser 7, the part 9 is used as the top reflux of the first-stage catalytic distillation column, wherein the reflux ratio is 2:1, and the part 12 is 9.26t / The speed of h is sent to the secondary catalytic rectification tower 14, while adding excess sec-butyl acetate 13, the...

Embodiment 3

[0048] Second-butyl acetate 1 is sent into primary catalytic rectification tower 6 with the speed of 6.96t / h, and isopropanol 5 is added simultaneously, wherein, the theoretical plate number of primary catalytic rectification tower is 40, and isopropanol The molar ratio of alcohol to sec-butyl acetate is 1.2:1, the pressure at the top of the tower is normal pressure, the temperature at the top of the tower is 89°C, the temperature at the bottom of the tower is 99.5°C, and the sec-butanol falls into the bottom of the tower at a rate of 8.88t / h as Product 11 is taken out, unreacted isopropanol and reaction product isopropyl acetate are steamed from the top of the tower, and part 9 after being condensed by the condenser 7 is used as the top reflux of the first-stage catalytic rectification tower, wherein the reflux ratio is 3:1, Part 12 is sent into secondary catalytic rectification tower 14 with the speed of 11.4t / h, adds excessive sec-butyl acetate 13 simultaneously, and alcohol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com