Patents

Literature

290 results about "Sec-Butyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sec-Butyl acetate, or s-butyl acetate, is a solvent commonly used as a solvent in lacquers and enamels, where it is used in the production of acyclic polymers, vinyl resins, and nitrocellulose. It is a clear flammable liquid with a sweet smell.

Preparation of sec-butyl acetate

ActiveCN101486640AEffective dispersion concentrationHigh purityOrganic compound preparationCarboxylic acid esters preparationOil phaseSec-Butyl acetate

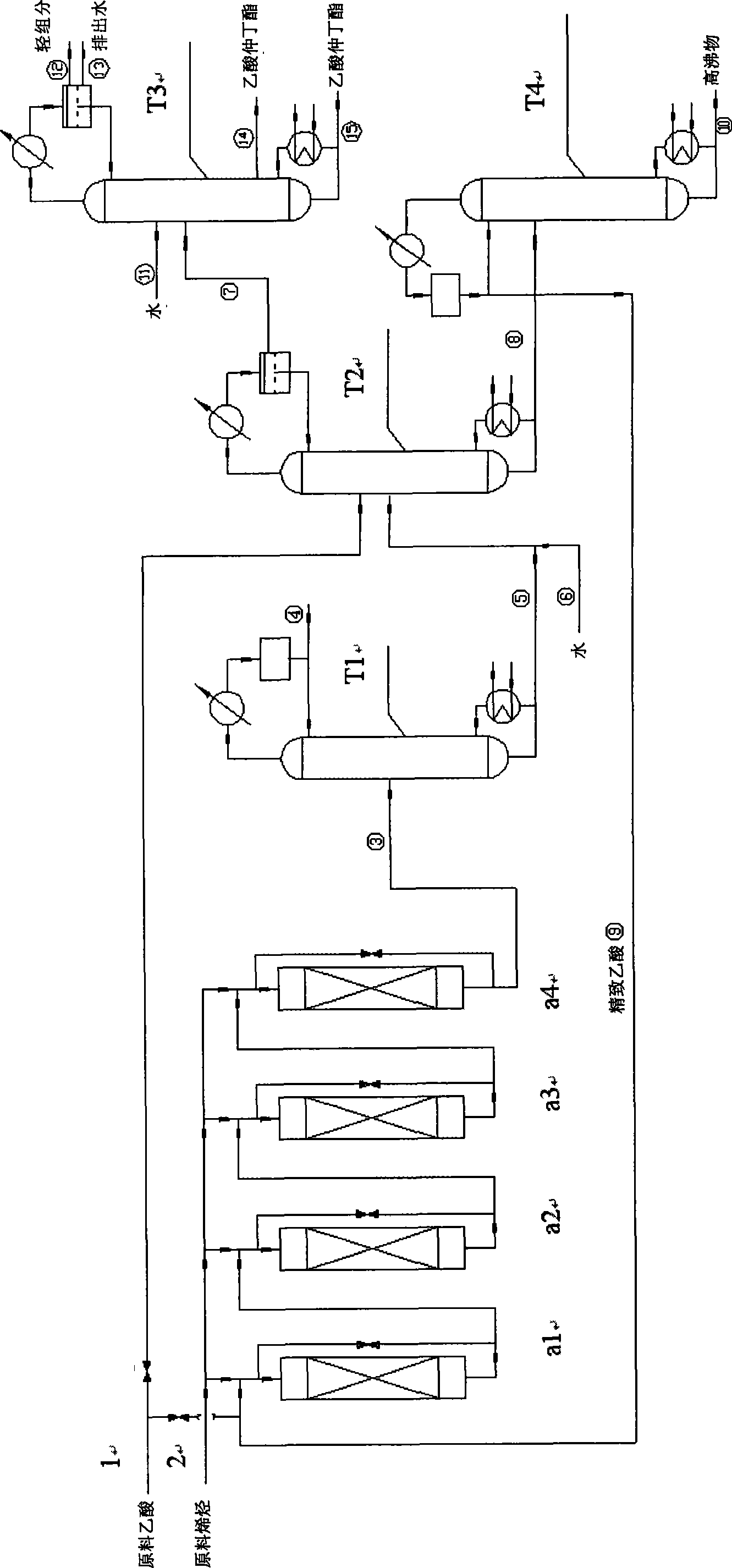

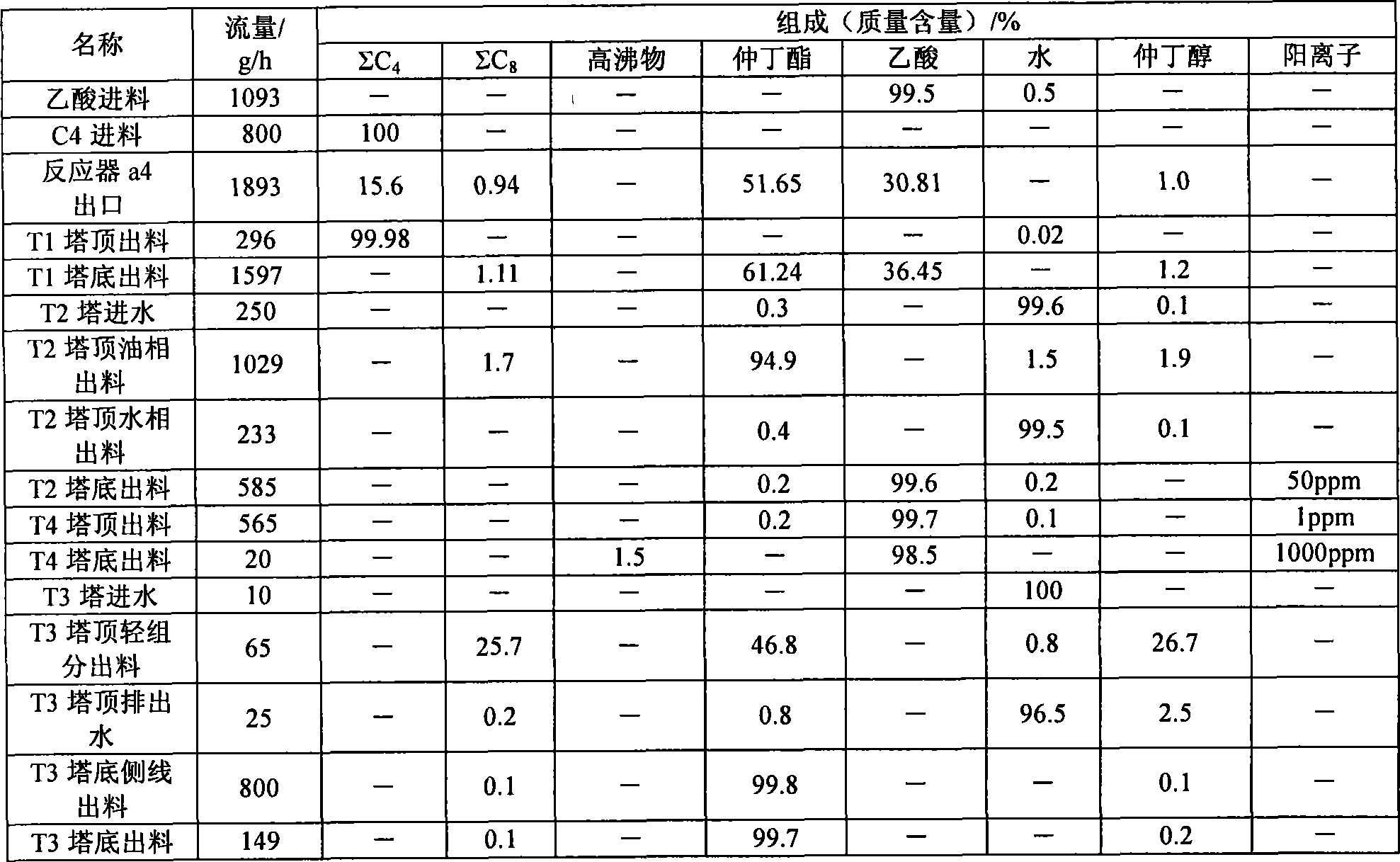

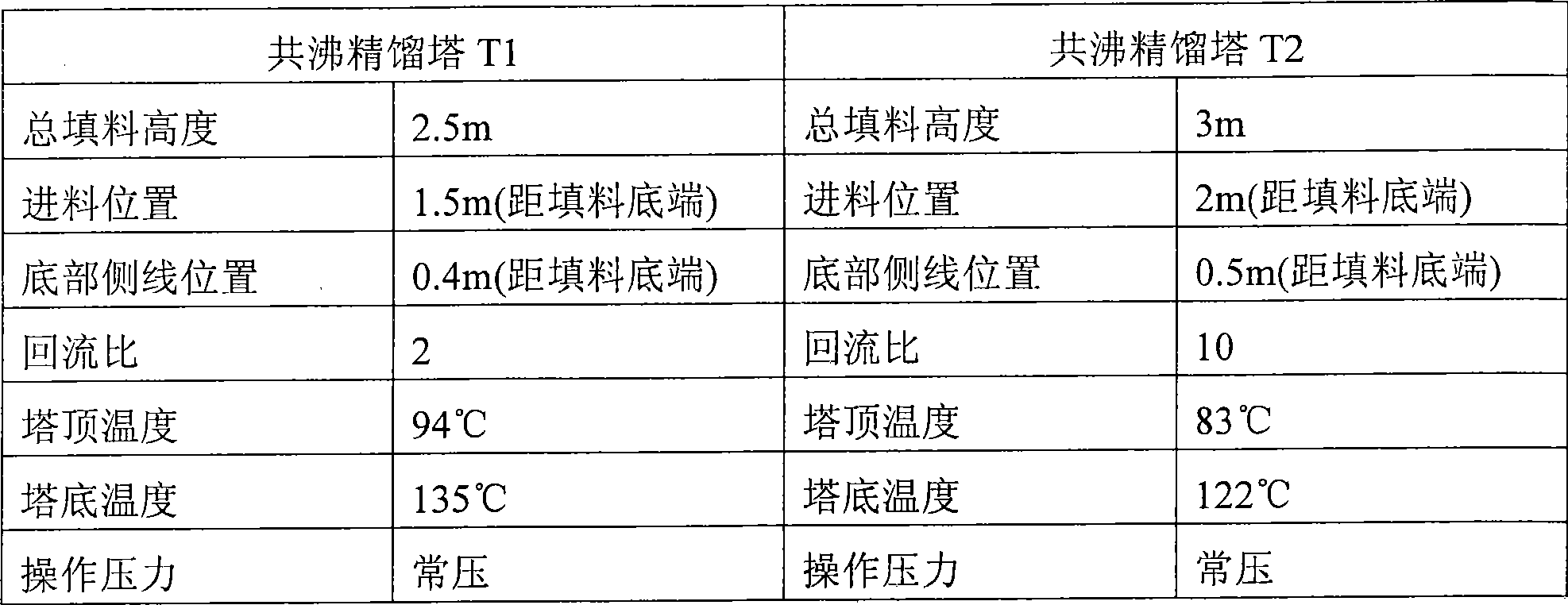

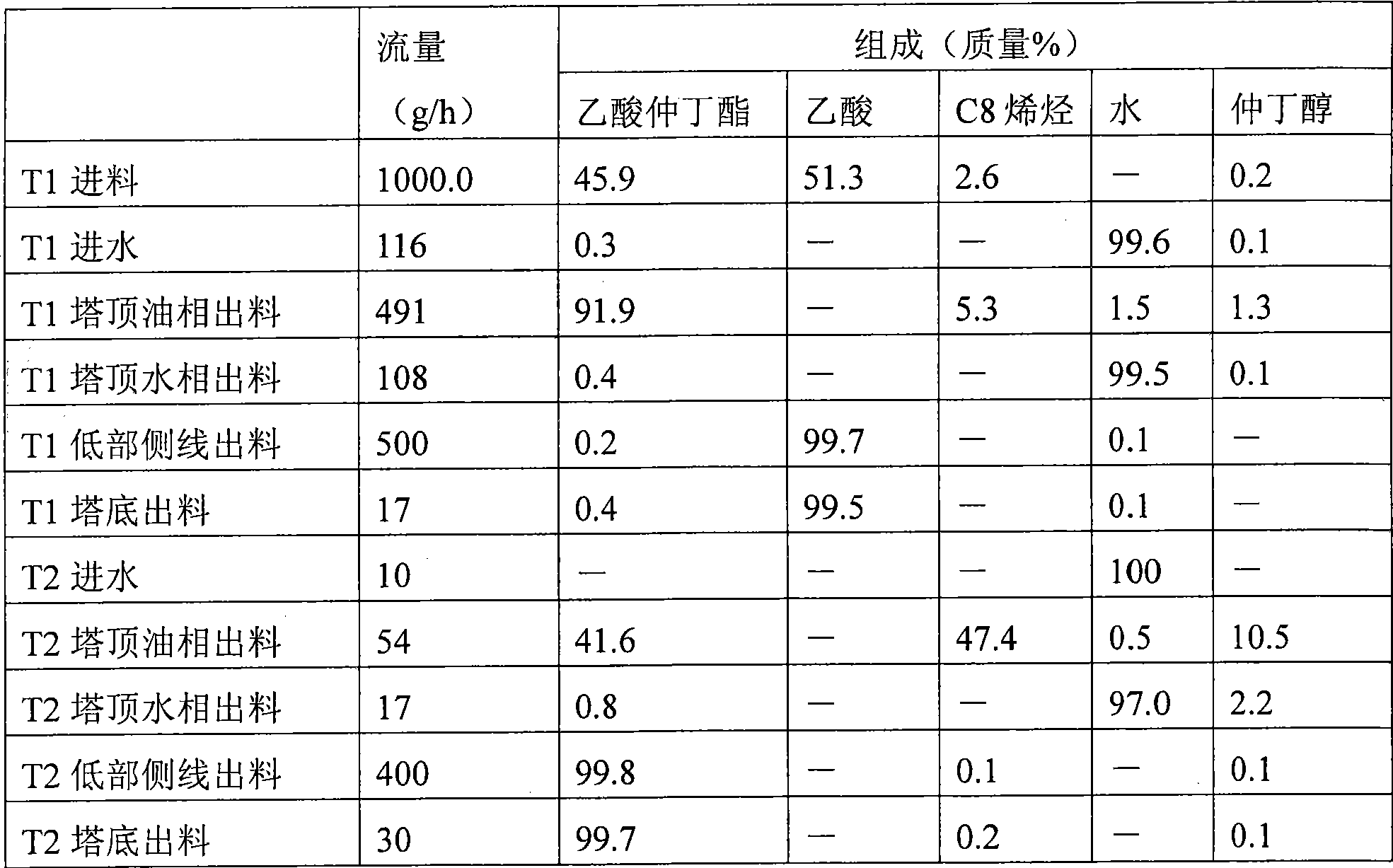

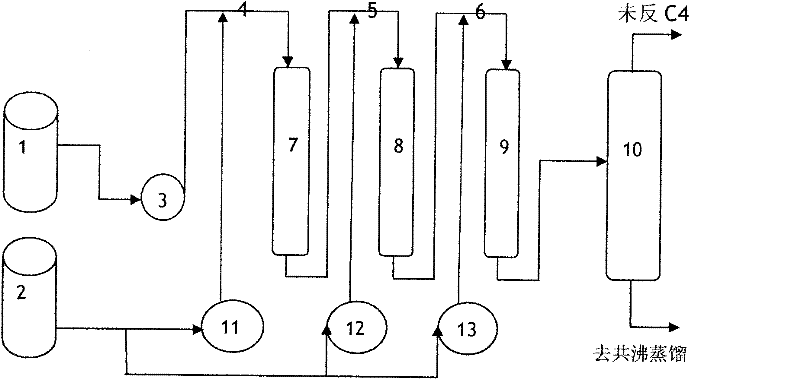

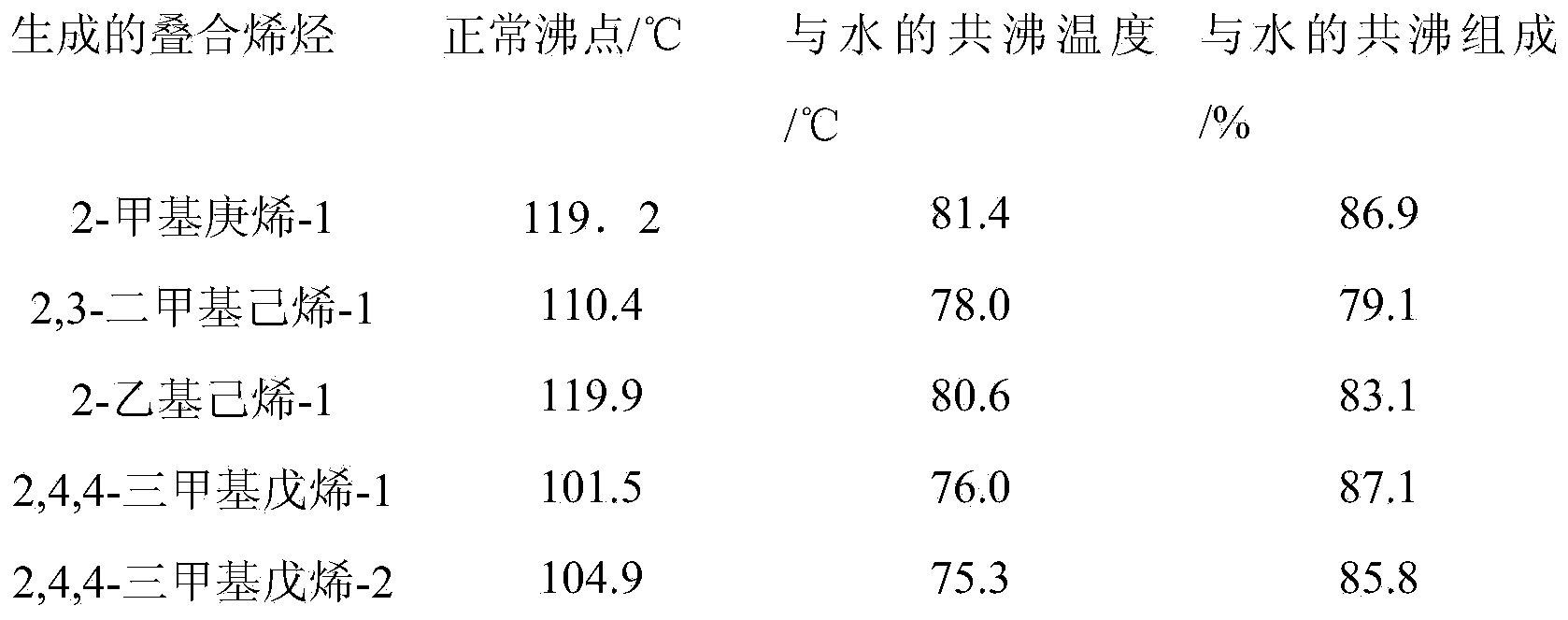

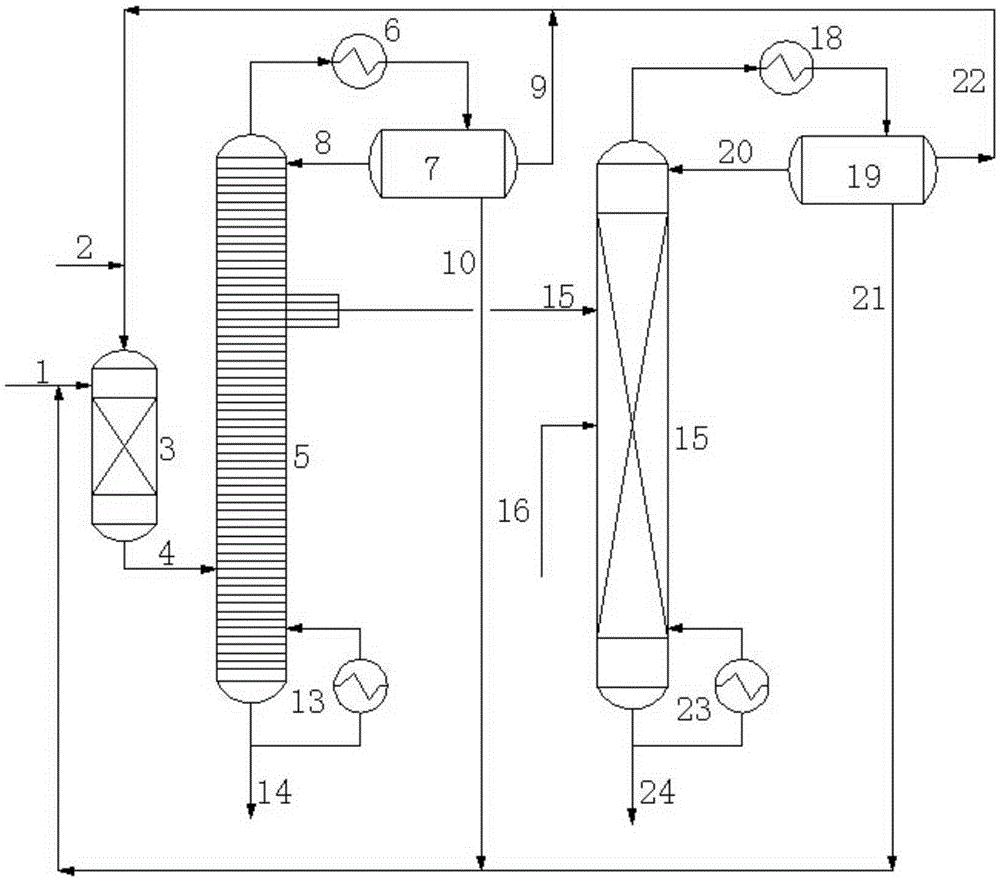

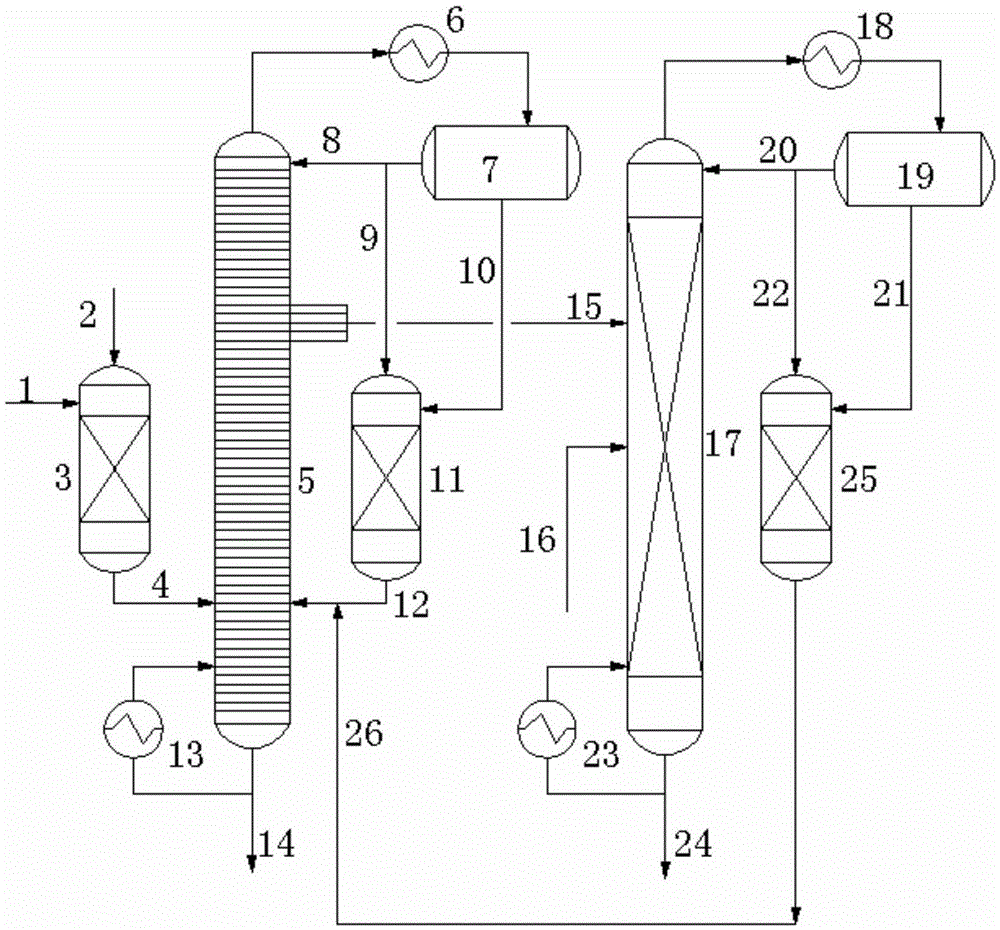

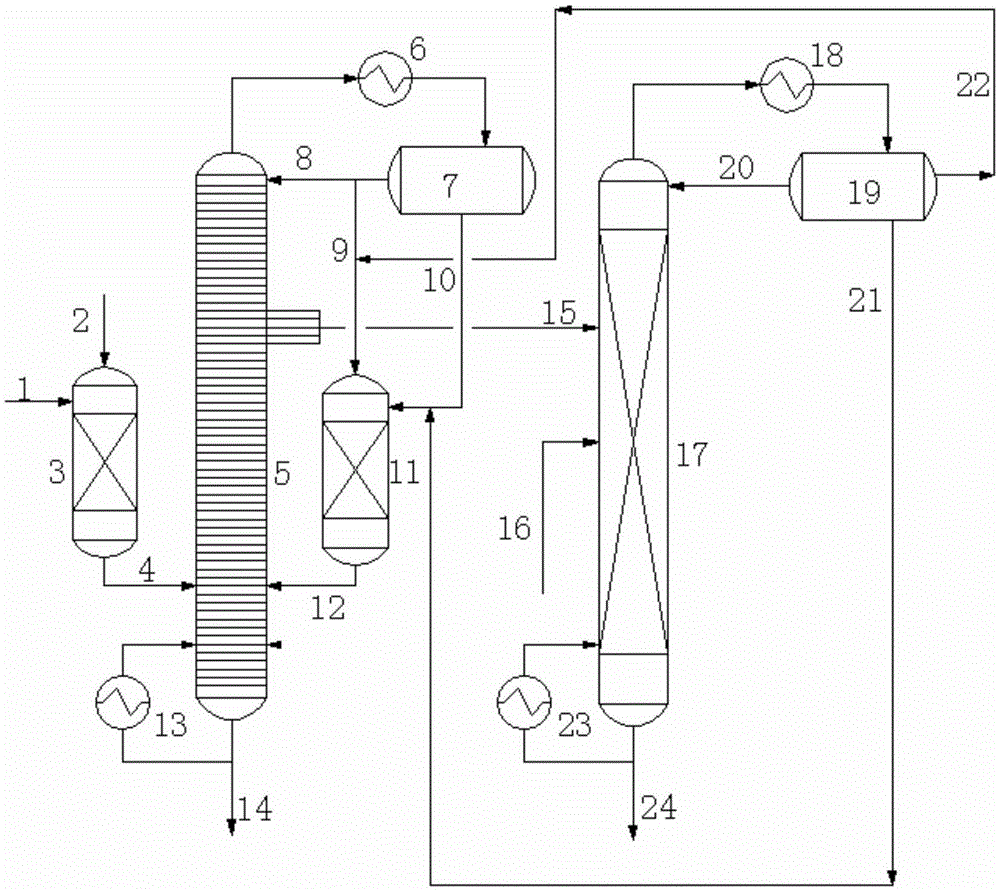

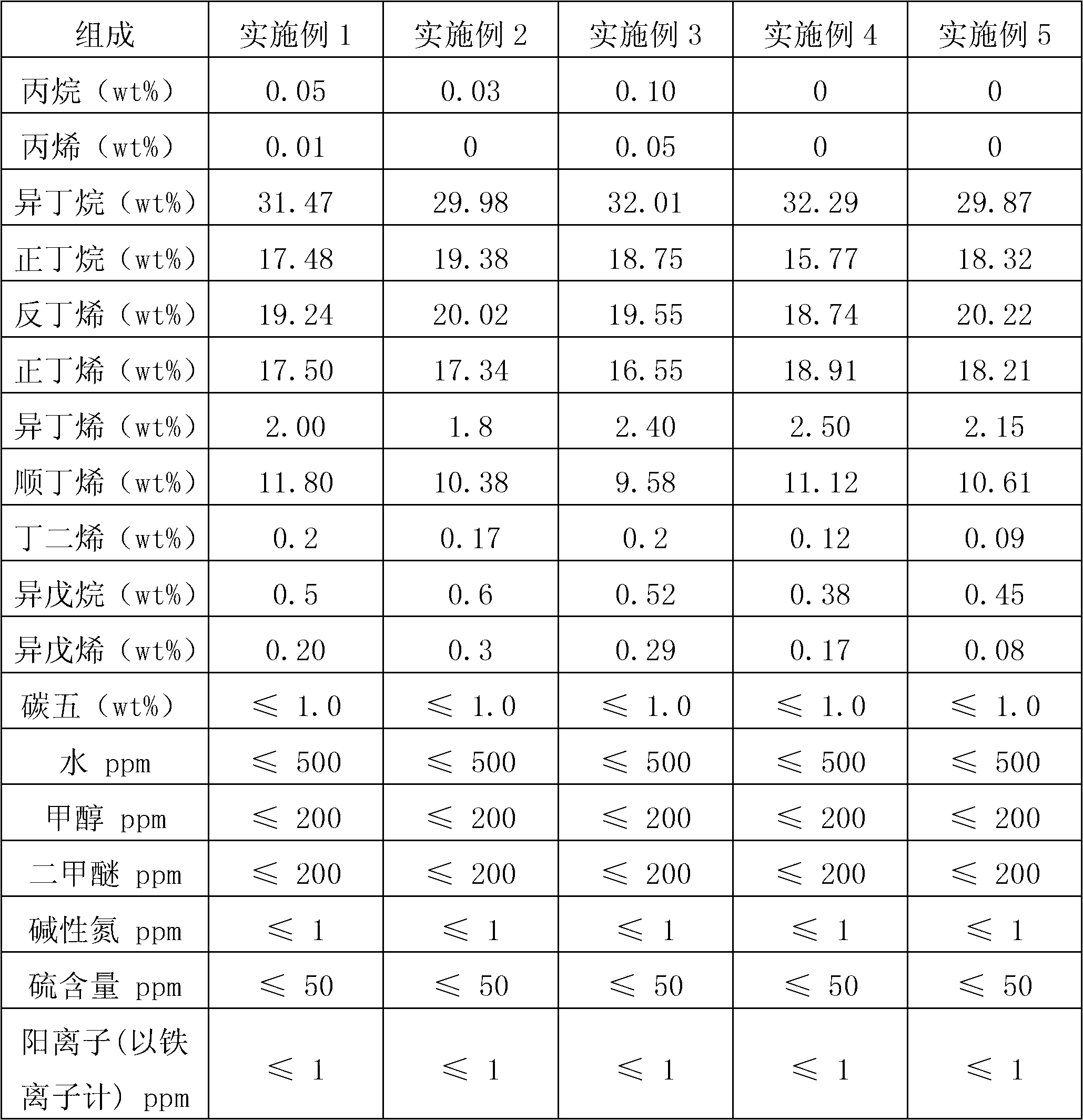

The invention relates to a method for preparing sec-butyl acetate, which includes steps as follows: (1) with the existence of a catalyst and under the condition of addition reaction, C4 olefin contacts and reacts with acetic acid for a plurality of times; (2) the reaction products obtained in Step (1) are rectified and separated, C4 light components are obtained from the top of a tower and tower bottoms are obtained from the bottom of the tower; (3) the tower bottoms obtained in Step (2) and water are boiled and rectified, sec-butyl acetate and C8 olefin are obtained from the top of the tower in the form of azeotrope and acetic acid is obtained from the bottom of the tower; (4) the azeotrope obtained in Step (3) is condensed, oil and water separation is carried out and aqueous phase products and oil phase products containing C8 olefin and sec-butyl acetate are obtained; and (5) the oil phase products obtained in Step (4) and water are boiled and rectified, C8 olefin is obtained from the top of the tower in the form of azeotrope and sec-butyl acetate is obtained from the bottom of the tower. The method provided by the invention can obtain relatively high yield of sec-butyl acetate and can obtain sec-butyl acetate and recycle acetic acid at a relatively high purity.

Owner:HUNAN RUIYUAN PETROCHEM

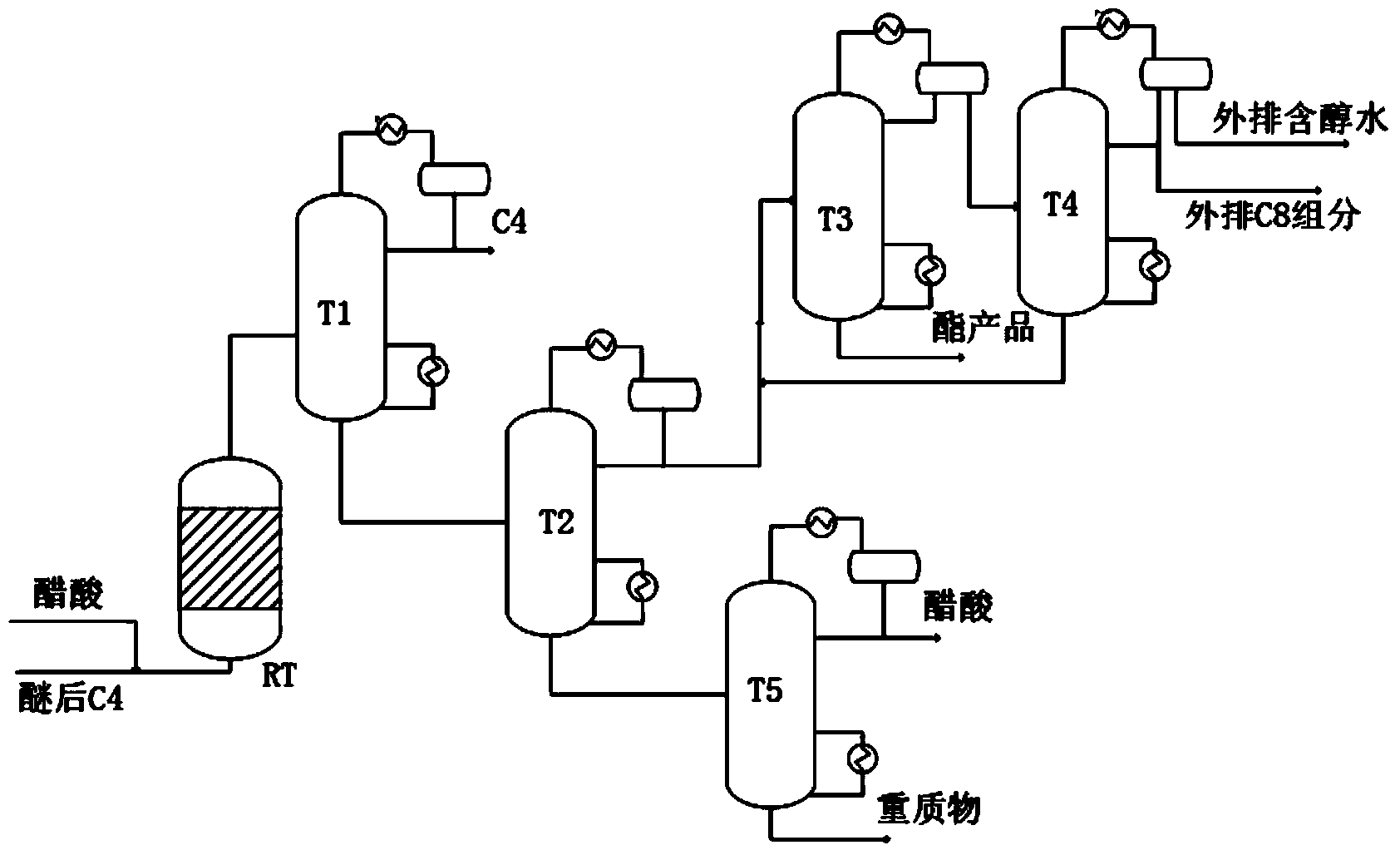

Method for separating acetic acid and sec-butyl acetate from reaction products

ActiveCN101481307AReduce energy consumptionLess investmentOrganic compound preparationCarboxylic acid esters preparationSec-Butyl acetateOil phase

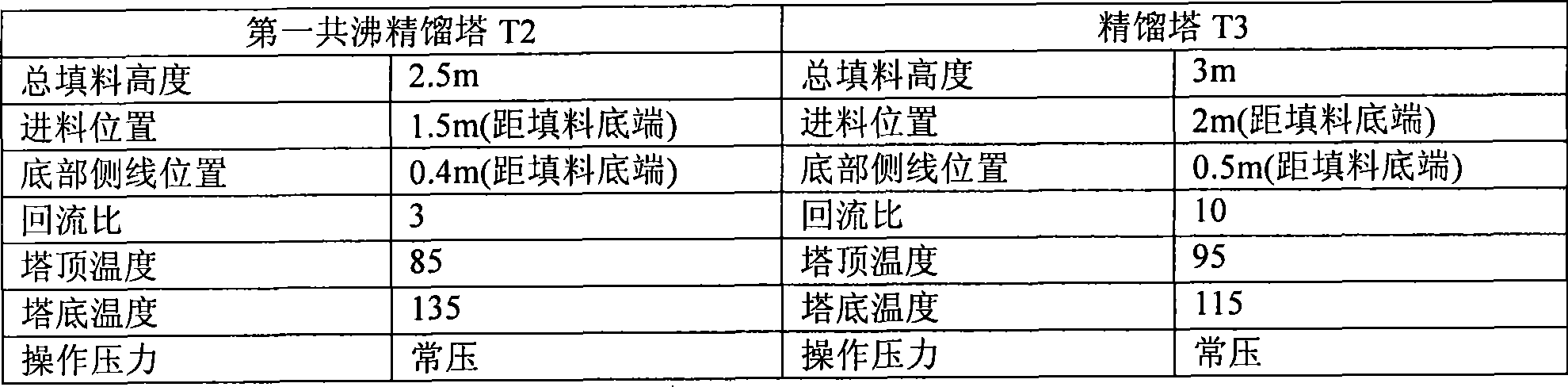

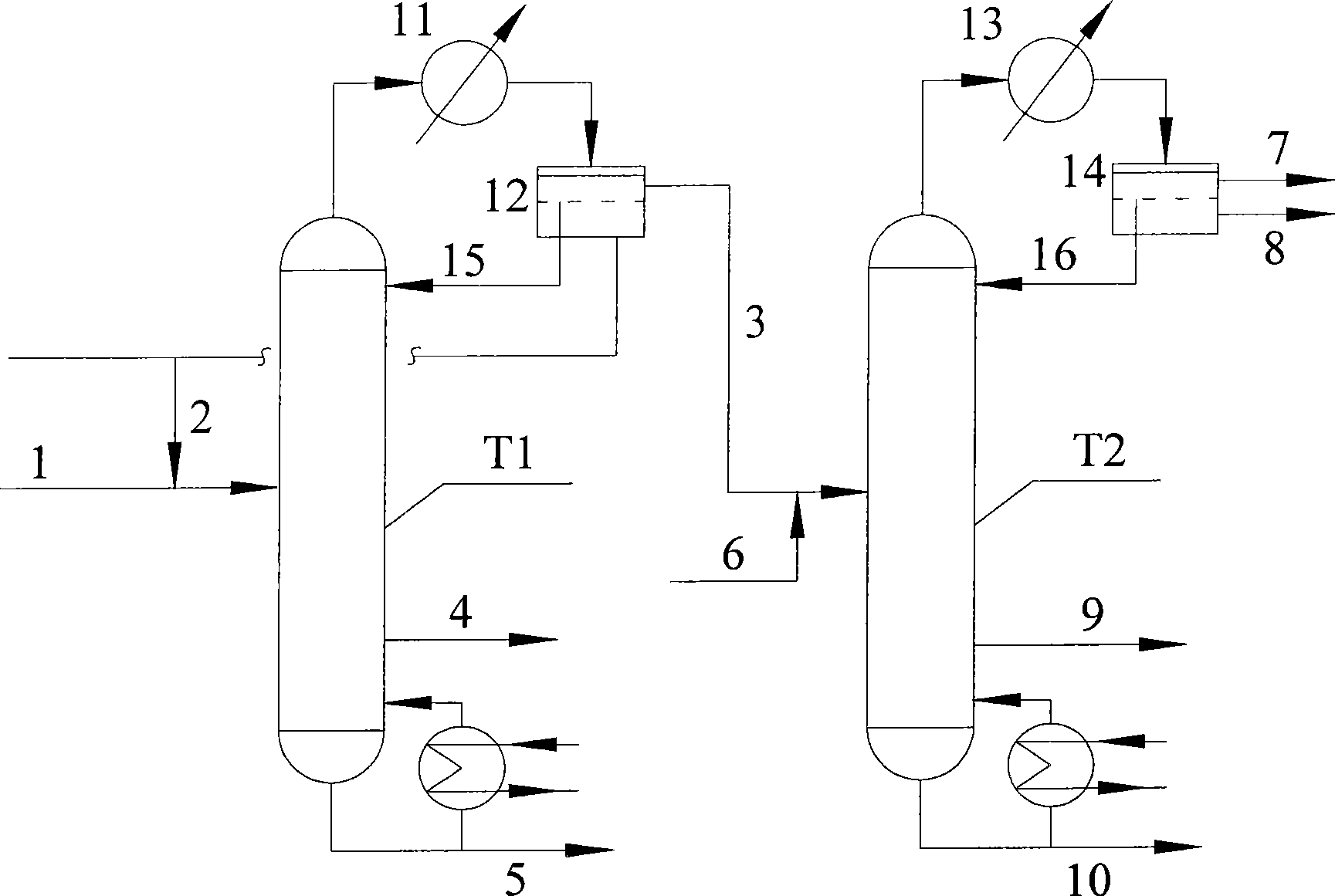

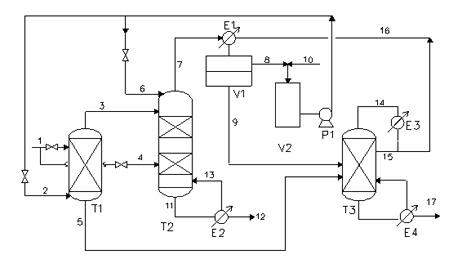

The invention provides a method for separating acetic acid and sec-butyl acetate from reaction products for preparing the sec-butyl acetate. The reaction products contain the sec-butyl acetate, the acetic acid and C8 alkene. The method comprises the following steps: under operating condition of azeotropic distillation, allowing water and the reaction products to enter a first azeotrope tower for azeotropic distillation, obtaining an azeotrope from the tower top, and obtaining the acetic acid from the tower bottom; performing oil-water separation on the obtained azeotrope after condensation to obtain an aqueous phase product and an oil-phase product containing the C8 alkene and the sec-butyl acetate; and under the operating condition of azeotropic distillation, allowing the water and the obtained oil-phase product to enter a second azeotrope tower for azeotropic distillation, obtaining the azeotrope from the tower top, and obtaining the acetic acid from the tower bottom. The method can help obtain the high-purity sec-butyl acetate product by separating the reaction products, and recover the high-purity acetic acid; and the method has simple operation process, low energy consumption and lower investment in the whole device.

Owner:HUNAN RUIYUAN PETROCHEM

Method for synthesizing sec-butyl acetate from acetic acid and linear butylene

InactiveCN101121656AOvercome intractabilityOvercoming the problem of increased consumptionOrganic compound preparationCarboxylic acid esters preparationCelsius DegreeHeteropoly acid

The invention relates to a synthetic method of the sec-butyl acetate with the acetic acid and linear butylene. The invention is characterized in that a fixed-bed reactor is used; the solid catalyst is used; when the butylenes pressure is between 2 and 15 kilograms per square centimeters and the reaction temperature is between 90 and 160 Celsius system, the acetic acid and olefin react and compose the sec-butyl acetate under the gas-liquid-solid reaction condition; therein, the ratio between the cetic acid and olefin is from 1 to 1.15 to 1 to 1.80; the material feeding airspeed of the acetic acid is 1.0 to 1.8 liters per hour; the solid catalyst is the modified resin catalyst, silica gel loading heteropoly acid catalyst, silica gel loading phosphoric acid catalyst or super acid catalyst. The invention overcomes the erosion of the equipment, the side reaction, the difficult treatment of the waste liquid of the reaction, and the difficult separation of water in the traditional process, which may cause the increase of the energy consumption; the invention can greatly lower the production cost of the product.

Owner:SOUTH CHINA UNIV OF TECH

Method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate

InactiveCN102153458AGood value for moneyReduce lossCarboxylic compound separation/purificationPhysical chemistryEthylic acid

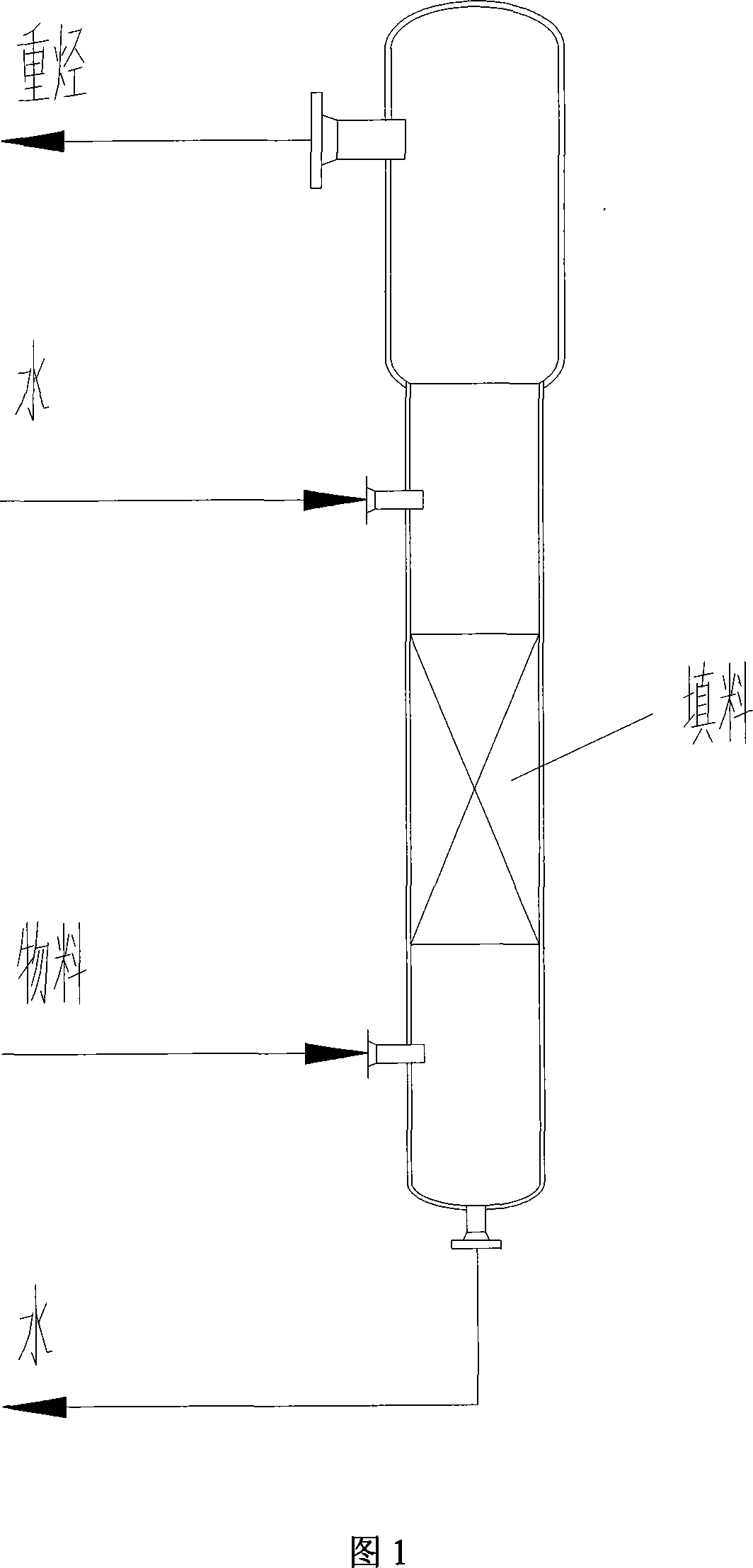

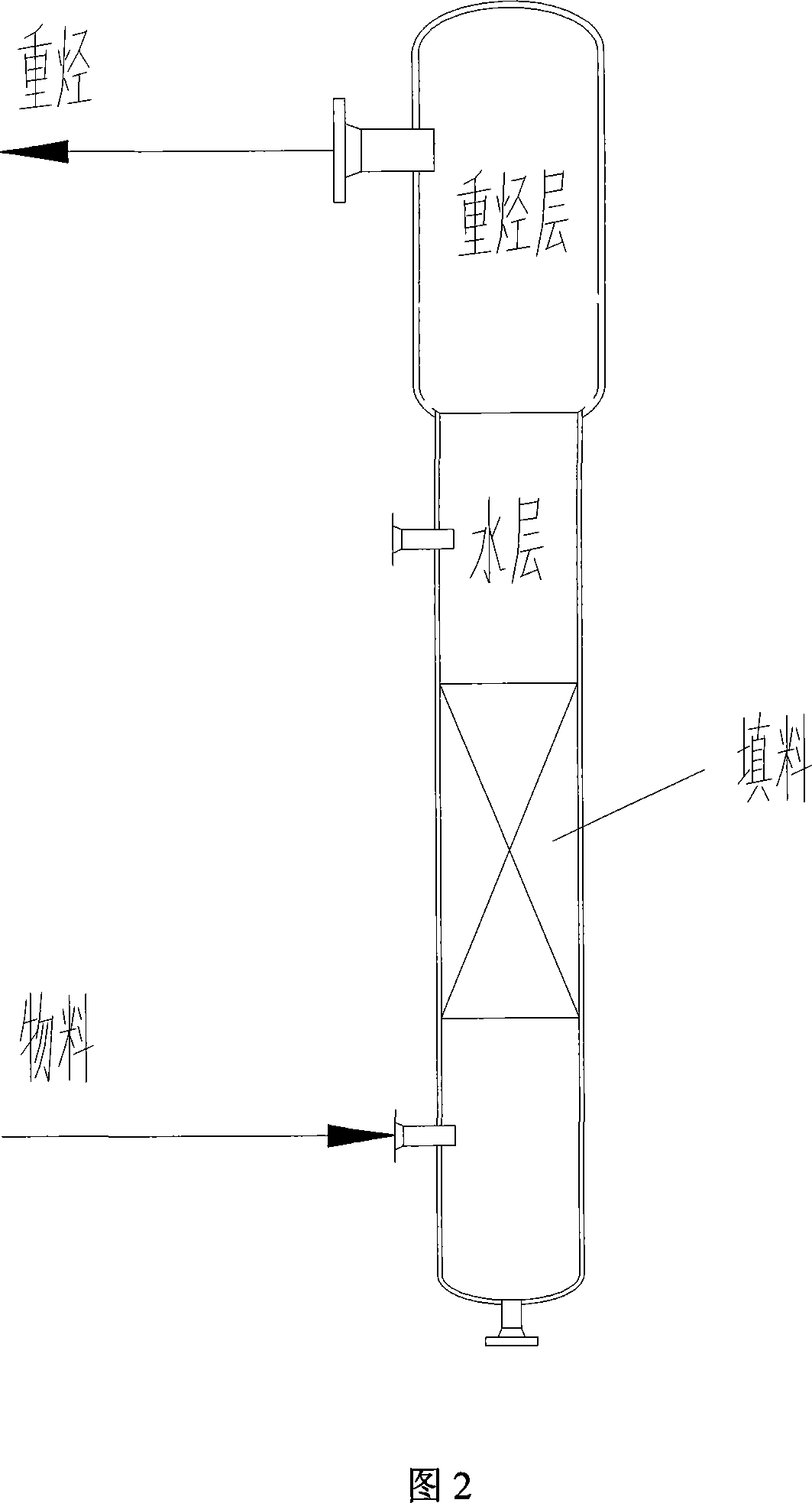

The invention relates to a method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate. In the method, the sec-butyl acetate is an extractant of an extraction tower and an entrainer of an azeotropic distillation tower. The method is characterized in that a part of dilute acetic acid is fed into the top of a filler extraction tower, a small portion of tower top reflux liquid of the azeotropic distillation tower is used as the extratant to be fed to the bottom of the extraction tower, and is subjected to room temperature counter current contact extraction together with the dilute acetic acid; an extraction phase containing the sec-butyl acetate, acetic acid and little water is obtained on the top of the extraction tower; raffinate water containing trace acetic acid is obtained at a tower kettle, and enters into a solvent recovering tower; and the extraction phase in the extraction tower is fed to the upper half part of the azeotropic distillation tower for further concentration, and the other part of sec-butyl acetate is fed to the tower top of the azeotropic distillation tower. The method has the characteristic of high separation efficiency; and the recovery of the acetic acid is more than 95%, and the content of the acetic acid in waste water is below 0.5%. By using the method, the defects of large reflux ratio, high energy consumption and the like which are caused by using a rectification method are directly overcome, and the production capability of dilute acetic acid recovery is enlarged.

Owner:FUZHOU UNIV

Method for producing sec-butyl alcohol

InactiveCN102659514AOvercome the disadvantage of low conversion rateOpen up new usesPreparation by hydrolysisSec-Butyl acetateAdditional values

The invention provides a method for producing sec-butyl alcohol through the catalytic hydrolysis of alcohol sec-butyl acetate. The method comprises the following steps of: carrying out continuously catalytic hydrolysis in a stationary bed by using the alcohol sec-butyl acetate as a raw material, and filling a catalyst in continuous tubes of the cascade multitubular stationary bed, wherein a commercial styrene cation exchange resin catalyst is used as the catalyst, and the cascade multitubular stationary bed comprises multiple identical multitubular reactors; leading the raw material alcohol sec-butyl acetate and water to enter the multitubular reactors, carrying out continuously catalytic hydrolysis reaction under the action of the catalyst to generate a sec-butyl alcohol crude product, and refining the crude product to obtain the sec-butyl alcohol with high purity. The method for producing the sec-butyl alcohol has the advantages that the conversion rate of the sec-butyl alcohol is high, the application range of the alcohol sec-butyl acetate can be increased, and the additional value of the alcohol sec-butyl acetate is increased; and therefore, the method has market promotion value.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Method for separating sec-butyl acetate from reaction mixture of acetic acid and hybrid C4

ActiveCN101007761AThe mass content of acetic acid is smallOrganic compound preparationCarboxylic acid esters separation/purificationSec-Butyl acetateChemistry

The invention discloses a separating method of butyl para-acetate from the reacted compound of acetic acid and C4, which comprises the following steps: flashing to remove non-reacted C4 and light component; flowing production from the bottom of flashing tower into coboiling rectifying tower; adding coboiler A to separate butyl para-acetate and acetic acid; transmitting mass from coboiler into acid condensing tower; adding coboiler B to coboil and rectify again; condensing acetic acid; obtaining the product with purity over 99% and acetic acid content less than 0.01% and water less than 0.05%; recycling acetic acid.

Owner:HUNAN ZHONGCHUANG CHEM

Composite catalyst for preparing sec-butyl acetate with direct esterification of ethyl ester and butylene

InactiveCN101293210ASolve the problem of reduced catalytic efficiencyCatalyst carriersOrganic compound preparationHeteropoly acidCordierite

The present invention relates to a composite catalyst for preparing sec-butyl acetate by direct esterification of ethyl ester and butylene, which takes heteropoly acid as the catalyst active component and porous carrier as the dispersant; the weight proportion of the heteropoly acid and the porous carrier is 0.01:1 to 10:1. The heteropoly acid is one with Keggin structure, which consists of phosphotungstic acid, silicotungstic acid, germanium tungstic acid, arsenowolframic acid, phosphomolybdate, germanomolybdate or arsenicomolybdate. The porous carrier comprises porous SiO2, Al2O3, SBA-15, MCM-41, white carbon black, porous SiC, corallite, andalusite, cordierite, meerschaum, Attapulgite or kaolin. The composite catalyst of the present invention solves the problem that the catalysis efficiency is low if the heteropoly acid is separated out from the reaction system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for synthesizing sec-butyl alcohol

InactiveCN102731250AIncrease reaction rateImprove conversion ratePreparation by ester-hydroxy reactionPreparation by alcoholysisButeneMethyl acetate

Owner:FUZHOU UNIV

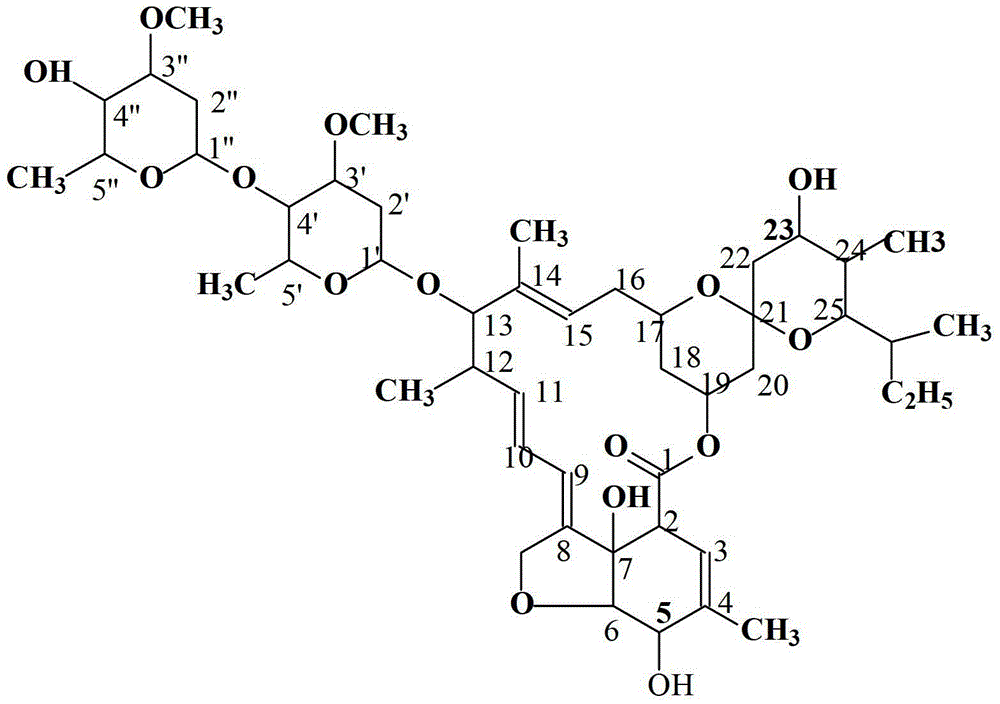

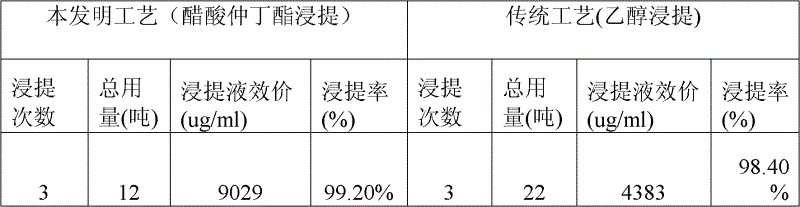

Preparation method of Avermectin B2a fine powder

ActiveCN103333214AEnhance layeringGood cleaning effectSugar derivativesSugar derivatives preparationDissolutionSolvent

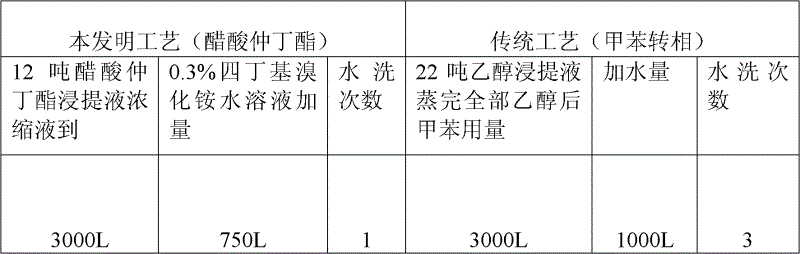

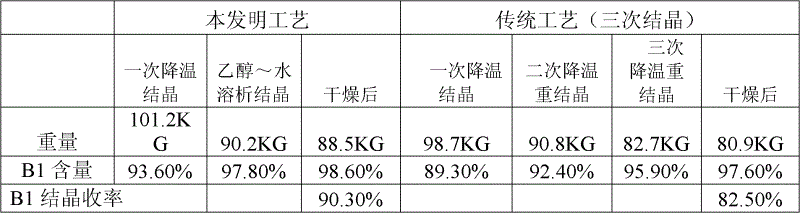

The invention relates to a preparation method of an Abamectin B2a fine powder. The method comprises the following steps: A, concentrating an Abamectin B1a crystallization mother liquor into a paste state; B, dissolving the obtained paste with sec-butyl acetate, and then adding a tetrabutyl ammonium bromide aqueous solution for washing and layering; C, concentrating the sec-butyl acetate solution subjected to washing and layering, then adding a crystallization solvent for dissolution, naturally cooling to room temperature, crystallizing, and filtering to obtain an Abamectin B2a fine powder crude product; and D, recrystallizing the Abamectin B2a fine powder crude product to obtain the Abamectin B2a fine powder. According to the invention, waste Abamectin crystallization mother liquor is recovered and utilized to extract effective substances; tetrabutyl ammonium bromide aqueous solution is used for washing, which has better impurity removal effect than traditional water washing or saturated brine washing, and makes the solution layer more easily; aromatic hydrocarbon is used as the crystallization solvent; and the content of obtained B2a fine powder is higher than 93%.

Owner:DAQING JEFENE BIO CHEM

Method for catalyzing synthesizing sec-butyl alcohol through cation exchange resin

InactiveCN102838450AHigh catalytic activityGood choicePreparation by ester-hydroxy reactionPreparation by alcoholysisSec-Butyl acetateSec-butyl alcohol

The invention discloses a method for catalyzing synthesizing sec-butyl alcohol through cation exchange resin. The method comprises the step of carrying out ester exchange under the effect of the cation exchange resin with the sec-butyl acetate and the carbinol serving as the raw materials, so as to synthesize to obtain the sec-butyl alcohol. The sec-butyl acetate provided by the invention has the conversion rate up to 35 to 50%; and the method has the advantages that the reaction condition is mild, the corrosion to equipment is low, the selectivity and the activity of a catalyst are high, and repeated use is realized.

Owner:FUZHOU UNIV

Preparation method of sec-butyl alcohol

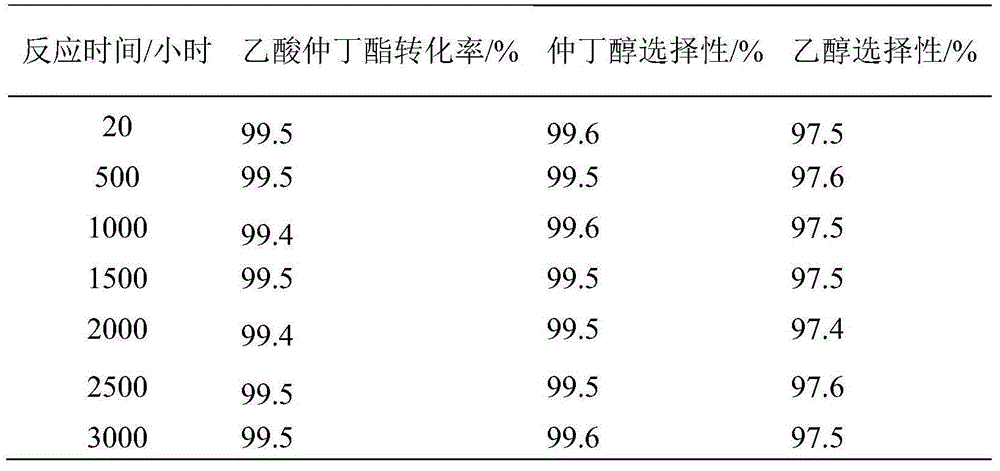

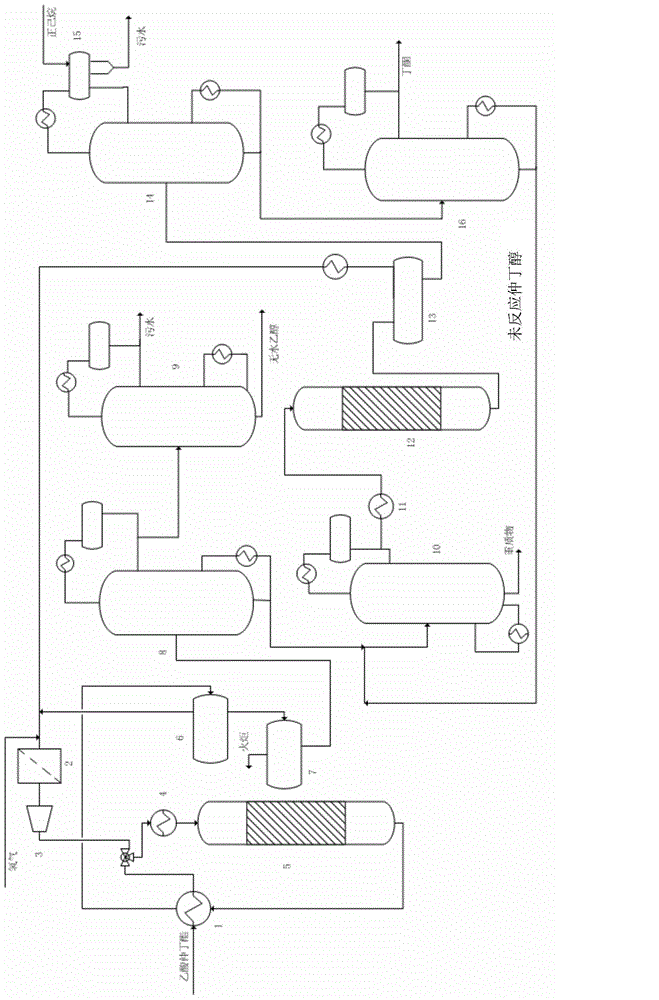

InactiveCN103172492AReduce energy consumptionShort processOrganic compound preparationHydroxy compound preparationHydrogenFixed bed

The invention relates to a preparation method of sec-butyl alcohol. According to the preparation method, sec-butyl acetate generated through reaction between mixed C4 fractions and acetic acid is used as a raw material and is directly hydrogenated under the action of a copper-based solid catalyst to prepare sec-butyl alcohol with coproduct being ethanol, and in a fixed bed reactor the feed mass space velocity of sec-butyl acetate is 0.1-2.0h<-1>, the molar ratio of hydrogen to sec-butyl acetate is (2-40):1, the reaction temperature is 200-280 DEG C and the reaction pressure is 2.0-9.0MPa to directly prepare sec-butyl alcohol and cogenerate ethanol. The detailed preparation method refers to the specification. The conversion per pass of sec-butyl acetate is over 95%, the selectivity of sec-butyl alcohol is over 95% and ethanol is coproduced. The preparation method has the advantages that the energy consumption is reduced; circulation of mass raw materials is not needed, so the process flow is shortened; no other wastes are generated, so the process is clean; and separation is simple.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Preparation method for sec-butyl acetate with product separating and reclaiming technique

ActiveCN101168505ASimple separation processReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationButeneSec-Butyl acetate

The invention relates to a process for preparing sec-butyl acetate, with product separation and reclamation technology, which is characterized in that the reaction is processed in one catalysis distillation column composed of a column reactor, an exhausting section, a reaction section, a distillation section, and a column top reflux condenser, wherein the reaction section is filled with catalyst,acetic acid and mixture C4 or butene which are reversely contacted and reacted on the surface of catalyst, the non-reacted mixture C4 or butene is evaporated out from the top of the catalyst distillation column, the product mixture is fed into an azeotropic distillation column, added with an entrainer a which can form azeotropic material with sec-butyl acetate, the distillate at the top of the azeotropic distillation column is fed into a treating column, to be distilled to obtain sec-butyl acetate, and the fraction at the lower portion of the azeotropic distillation column, is fed into an acidconcentrating tower, added with an entrainer b which can form azeotropic material with the entrainer a, to process azeotropic distillation to be circulated and feedback to the reaction system. The invention has the advantages of simplified separation, low cost, low energy consumption, high material utilization and the like.

Owner:HUNAN ZHONGCHUANG CHEM

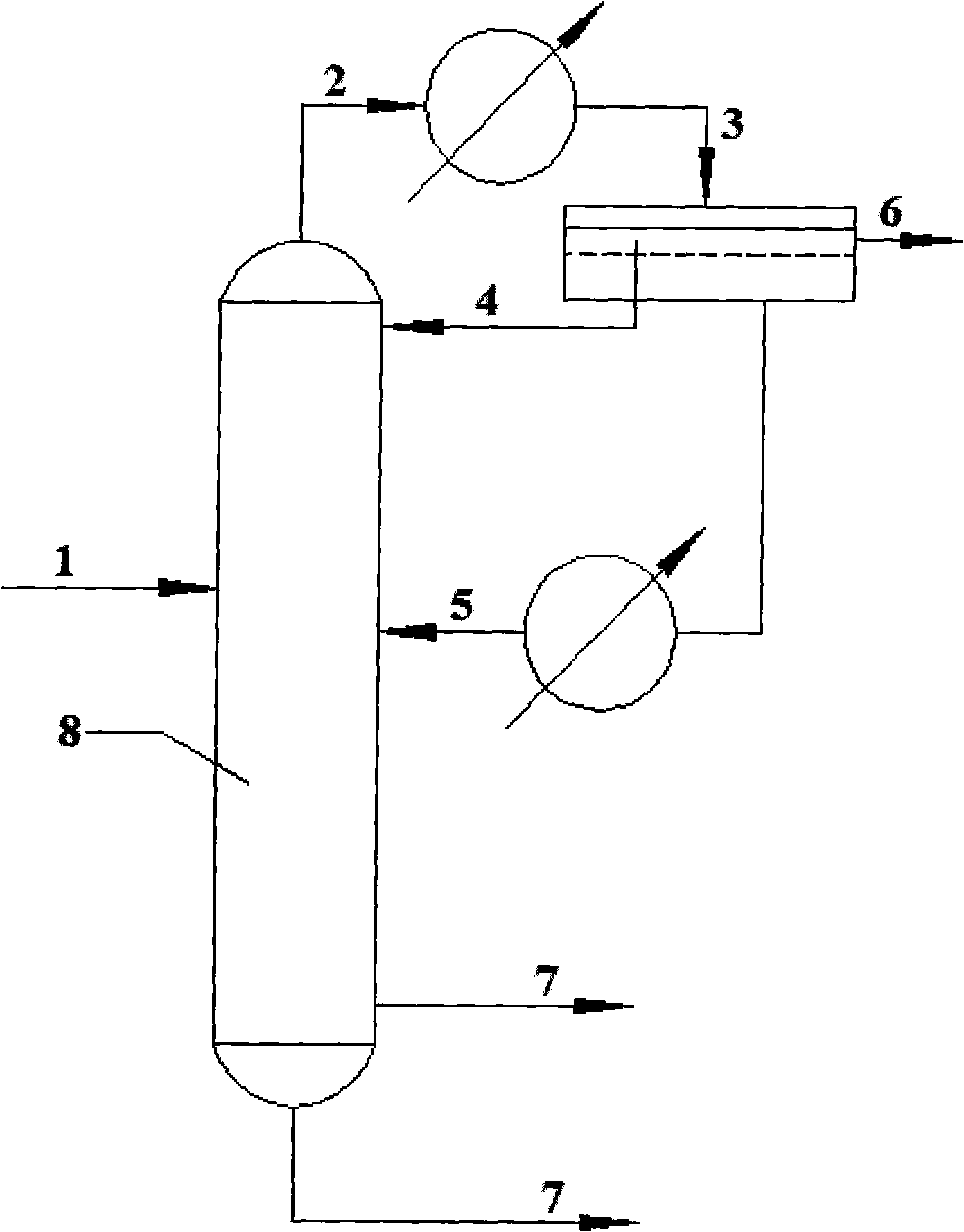

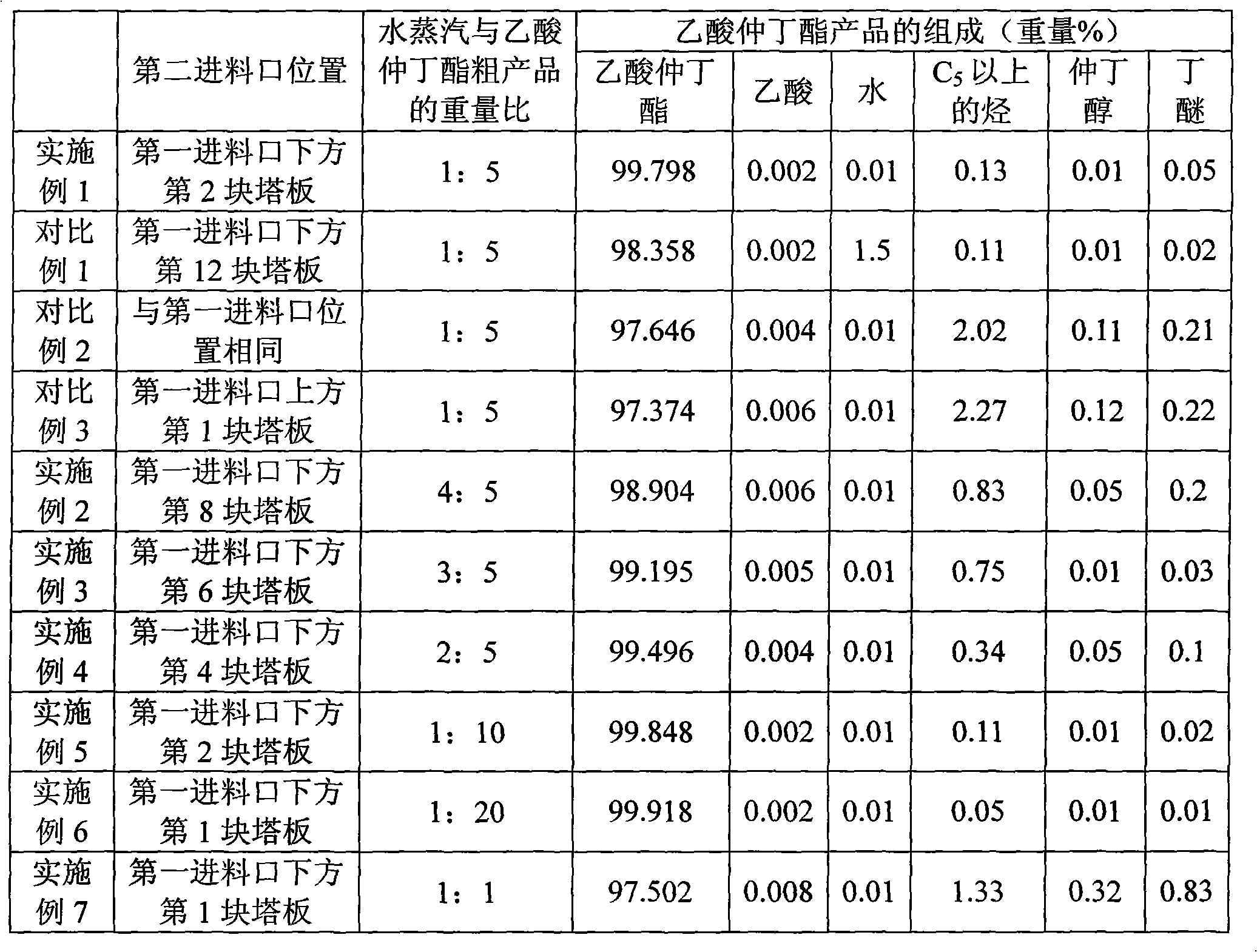

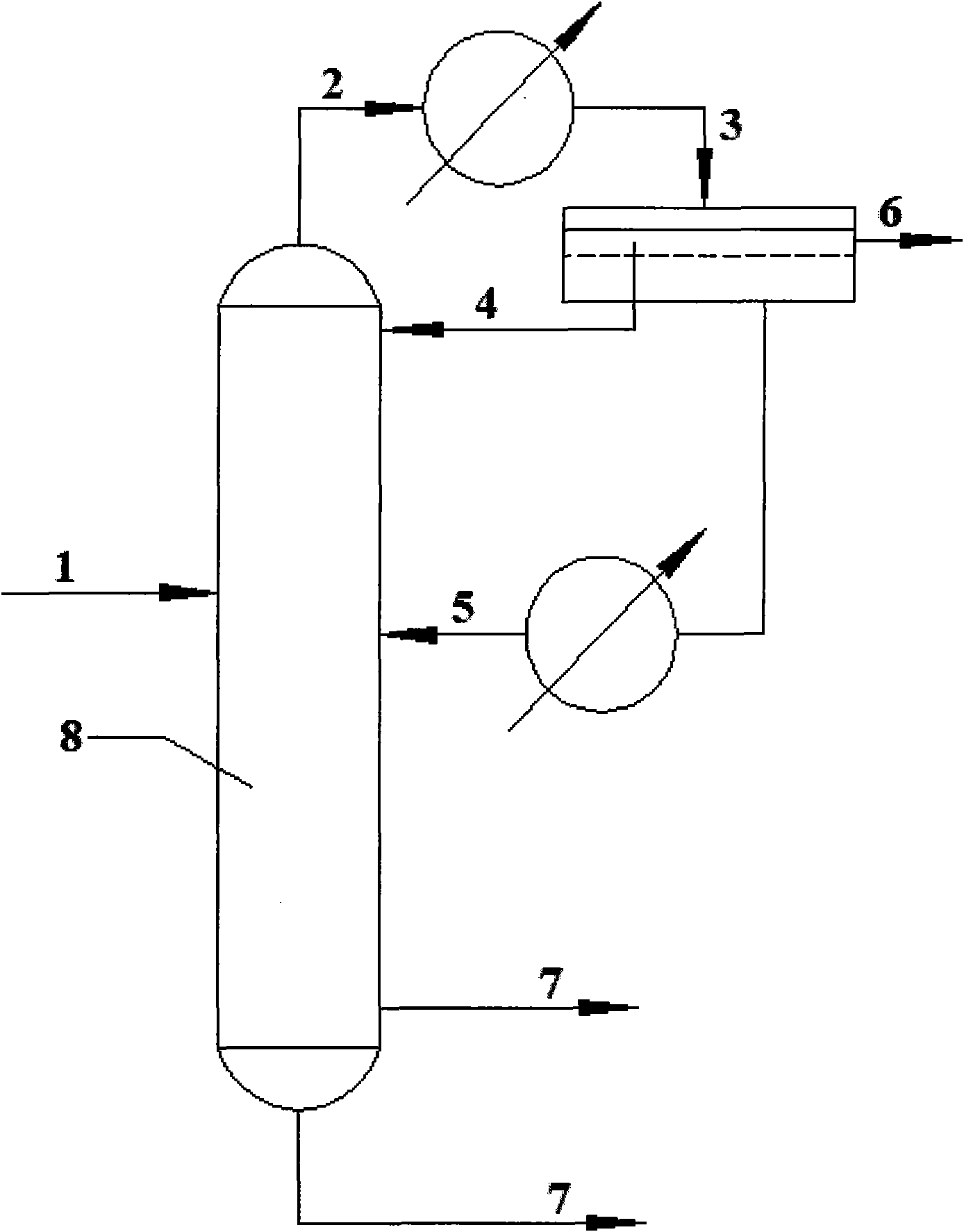

Method for refining sec-butyl acetate coarse products through dual-reflux and preparation method of sec-butyl acetate

ActiveCN102584575AHigh purityWill not cause excessive water contentOrganic compound preparationCarboxylic acid esters preparationRefluxTheoretical plate

The invention provides a method for refining sec-butyl acetate coarse products through dual-reflux and a preparation method of sec-butyl acetate comprising the refining process. The refining method of the sec-butyl acetate coarse products comprises (1) enabling the sec-butyl acetate coarse products to feed in a rectifying tower through a first feed port, enabling the water to feed in the rectifying tower through a second feed port in a water vapor mode, conducting azeotropy rectification under operation conditions of the azeotropy rectification, and obtaining mixture mainly containing water and impurities from a tower top; and (2) cooling the mixture, conducting oil-water separation to obtain the water phase and the oil phase, enabling reflux maters at least containing partial oil phase to flow back the rectifying tower, enabling at least partial water phase to form the water vapor and returning the water vapor to return and add in the rectifying tower from a third feed port. The second feed port and the third feed port are same or different, and both located at the position of 1-10 tower boards or theoretical tower boards below the first feed port. The method can be used for preparing the sec-butyl acetate with high purity.

Owner:HUIZHOU YUSSEN CHEM CO LTD

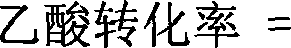

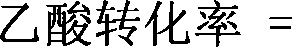

Process method for synthesizing sec-butyl acetate from C4 fractions

InactiveCN102234230AImprove conversion rateHigh selectivityOrganic compound preparationCarboxylic acid esters preparationFixed bedReaction temperature

The invention relates to a process method for synthesizing sec-butyl acetate from C4 fractions. The process method is characterized in that acetic acid and C4 fractions are used as raw materials, macroporous strongly-acidic cation exchange resin is used as a catalyst, a 3-5-segment tubular fixed-bed reactor is employed, the acetic acid is fed in only one step, the C4 fractions are fed segment by segment, and the molar ratio of acetic acid to olefin in each segment of the reactor is greater than 9 when the total molar ratio of acetic acid to olefin in the reaction is 2-3; and an olefin polymerization inhibitor is simultaneously added to the reaction system at the adding amount of 20-200 mu g / g, and reaction is carried out at the reaction temperature of 50-120 DEG C and the reaction pressure of 1.0-2.0 MPa to generate sec-butyl acetate. The method has the advantages and effects that the selectivity of sec-butyl acetate is improved, the catalyst can be recycled and has long life, and the product has good quality.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method for recycling acetic acid sec-butyl ester from reaction product during preparation of acetic acid sec-butyl ester with high efficiency

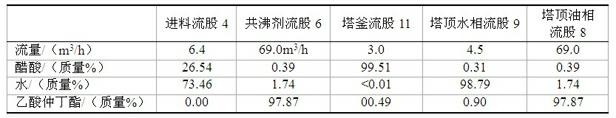

ActiveCN103980115AIncrease concentrationReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic acid ear

The invention provides a method for recycling acetic acid sec-butyl ester from a reaction product during preparation of the acetic acid sec-butyl ester with high efficiency. The method for recycling the acetic acid sec-butyl ester from the reaction product during preparation of the acetic acid sec-butyl ester with high efficiency comprises the following steps: directly feeding acetic acid sec-butyl ester material into an impurity removing azeotropic tower, wherein the acetic acid sec-butyl ester material is discharged outside as byproduct from the top of an ester product purification tower and contains water, C8 olefin and sec-butyl alcohol impurities, removing water, C8 olefin and part sec-butyl alcohol which are contained in the acetic acid sec-butyl ester material at the top of the impurity removing azeotropic tower while the contained water is taken as entrainer, and feeding a product at the bottom of the tower into an ester product refining tower for recycling. The method for recycling the acetic acid sec-butyl ester from the reaction product during preparation of the acetic acid sec-butyl ester with high efficiency has the advantages of simple process, low energy consumption, high separation efficiency, and more than 92% of the acetic acid sec-butyl ester in the byproduct can be recycled.

Owner:HUNAN RUIYUAN PETROCHEM

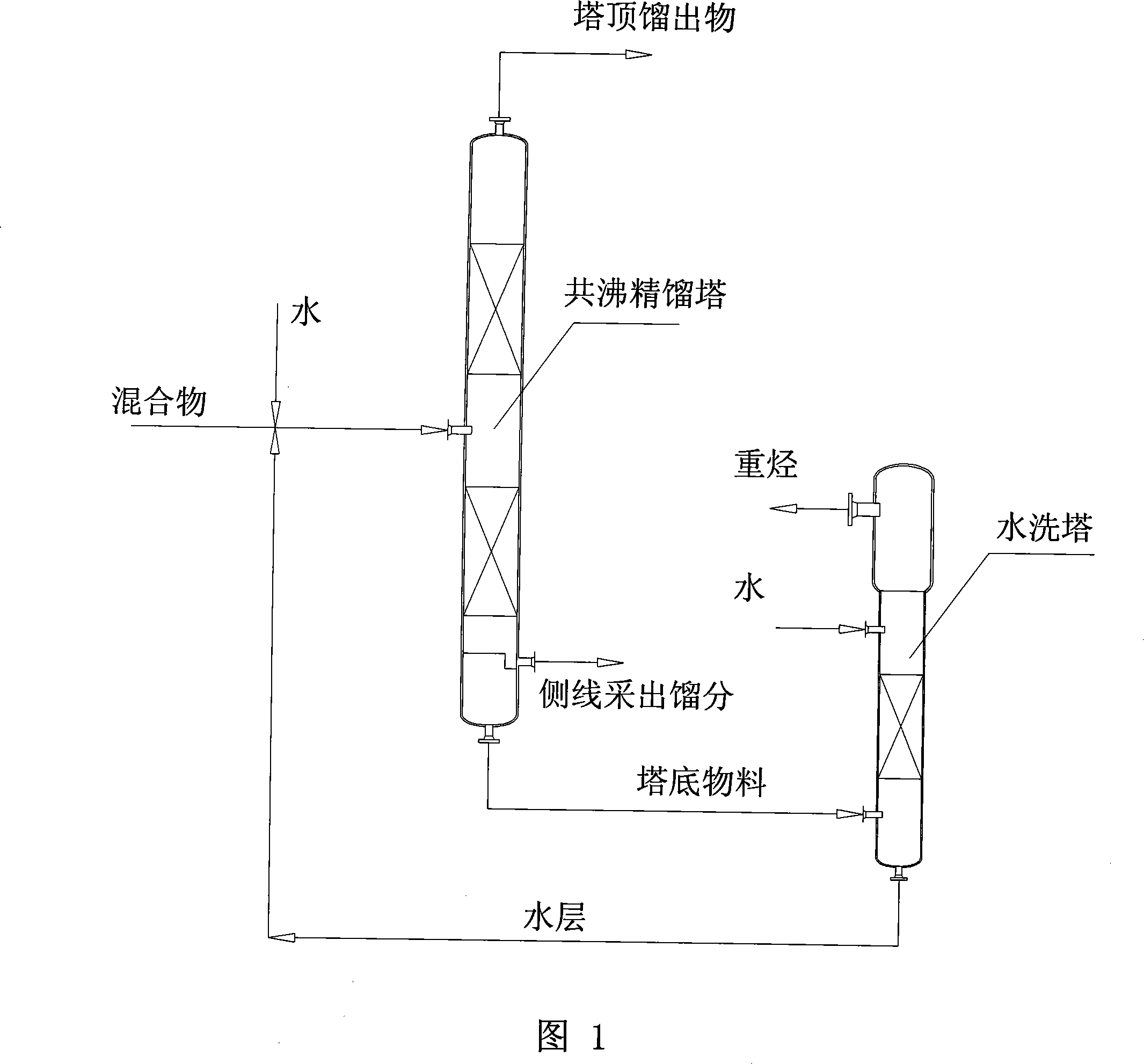

Method for separating sec-butyl acetate, acetic acid and heavy hydrocarbon

InactiveCN101168504AAlleviate fouling-prone conditionsEfficient separationCarboxylic acid esters separation/purificationExtractive distillationButeneSec-Butyl acetate

The invention relates to a process for separating sec-butyl acetate, acetic acid and heavy hydrocarbon when preparing sec-butyl acetate by reacting acetic acid and butane or mixed C4. The invention is characterized in that the mixture containing sec-butyl acetate, acetic acid and heavy hydrocarbon is fed into an azeotropic distillation column, one entrainer which can form azeotropic material with sec-butyl acetate is added, sec-butyl acetate and acetic acid are separated via azeotropic distillation, while the azeotropic material formed by sec-butyl acetate and entrainer is evaporated out from column top, acetic acid and heavy hydrocarbon are fallen into a column reactor, bottom material is pumped out from the azeotropic distillation column, to be contacted with water completely, heavy hydrocarbon and water in the bottom material are naturally layered, while the upper heavy hydrocarbon is discharged and lower water is filled into the azeotropic distillation column. The invention has the advantages that the invention can discharge foreign substances as heavy hydrocarbon from system when effectively separating sec-butyl acetate and acetic acid, to improve product quality, improve operation condition, and reduce material and energy consumptions.

Owner:HUNAN ZHONGCHUANG CHEM

Method for removing heavy hydrocarbon from reaction product of preparation of sec-butyl acetate

ActiveCN101130496AImprove operating conditionsLow energy and material consumptionOrganic compound preparationCarboxylic acid esters separation/purificationSec-Butyl acetateImpurity

The invention discloses a separating method of impurity such as heavy hydrocarbon from reacting product in the acetate para-butyl making technique reacted by acetic acid and C4 olefin, which is characterized by the following: extracting materials from heavy hydrocarbon enriching area; contacting the material and water sufficiently; laminating the heavy hydrocarbon and water naturally; draining the heavy hydrocarbon; injecting water into the system again. The method can strip heavy hydrocarbon in the reacting product to prepare acetate para-butyl, which improves the quality of the product and modifies the operating condition to reduce the energy consumption.

Owner:HUNAN ZHONGCHUANG CHEM

Catalyst for producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm, preparation method and application thereof

InactiveCN105032439AEasy to prepareHigh activityOrganic compound preparationHydroxy compound preparationHydrogenSec-Butyl acetate

The invention relates to a catalyst for producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm, a preparation method and application thereof, and mainly solves the problems that in the prior art, hydrogen ester is relatively high, and the product is relatively low in selectivity. Through the adoption of the technical scheme of the catalyst for producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm, the preparation method and application thereof, the problems are well solved. The catalyst contains copper or copper oxide, a second component and a third component, wherein the second component is one or more selected from ZnO, ZrO2, TiO2 and Al2O3; the third component is one or more selected from La2O3, CeO2, Fe2O3, CaO, MgO, MnO and B2O3; the mass content of copper or copper oxide in the catalyst is 20-70%; the mass content of the second component is 15-60%; the mass content of the third component is 1-40%. The catalyst can be used for co-producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm.

Owner:SHANGHAI HUAYI GRP CO

Butanone preparation and refining method

ActiveCN104370722AUniform temperature distributionHigh selectivityOrganic compound preparationPreparation by hydrogenolysisHydrogenation reactionDehydrogenation

The invention provides a butanone preparation and refining method. The method includes: (A), subjecting sec-butyl acetate and hydrogen to hydrogenation reaction in a fixed-bed reactor filled with hydrogenation catalyst; (B), feeding a hydrogenation product obtained in the step (A) into a crude alcohol separating tower for separation so as to obtain crude ethanol at the tower top, and feeding tower bottom components into a sec-butyl alcohol refining tower for refining; (C), preheating high-purity sec-butyl alcohol obtained at the tower top of the sec-butyl alcohol refining tower prior to feeding the preheated high-purity sec-butyl alcohol into a dehydrogenation reactor filled with dehydrogenation catalyst for dehydrogenation reaction; (D), feeding a dehydrogenation product obtained in the step (C) into a butanone drying tower via a buffer tank, supplementing entrainer from the top of a return tank, and removing water in crude butanone by means of azeotropic distillation; (E), feeding the dewatered crude butanone in the step (D) into a butanone refining tower for distillation so as to obtain butanone with the mass fraction above 99% from the top of the butanone refining tower.

Owner:HUNAN RUIYUAN PETROCHEM

Method for preparing SBA(sec-butyl alcohol) through hydrolysis with sec-butyl acetate

ActiveCN106631684AHigh puritySimple processOxygen-containing compound preparationOrganic compound preparationRefluxSec-Butyl acetate

A method for preparing sec-butyl alcohol through hydrolysis with SBA(sec-butyl alcohol)comprises steps as follows: (1) SBA is sent to a first hydrolysis reactor to react after being mixed with water; (2) a mixture after the reaction is sent to the lower part of a deacidification tower for separation, and separated acetic acid falls into the tower bottom; (3) a strand of material is extracted out of an SBA enrichment area of the deacidification tower and sent to an SBA refinement tower, an entrainer and water are added, an azeotrope formed by water, sec-butyl acetate and part of SBA is evaporated to the tower top, one part of oil phase is subjected to reflux after condensation layering, the other part returns to a reaction system for recycling with an aqueous phase, most of SBA falls into the tower bottom, and the SBA product is produced from the tower bottom. The SBA separated with the method has the purity of 99% or above, the purity of acetic acid separated by the deacidification tower is 97% or above, the yield of SBA is 70% or above, meanwhile, the method adopts a simple process and is simple to operate, and energy consumption is lower.

Owner:HUNAN ZHONGCHUANG CHEM

Gasoline composition and preparation method thereof

ActiveCN102234549ABoost octaneLow toxicityLiquid carbonaceous fuelsFuel additivesSec-Butyl acetateChemistry

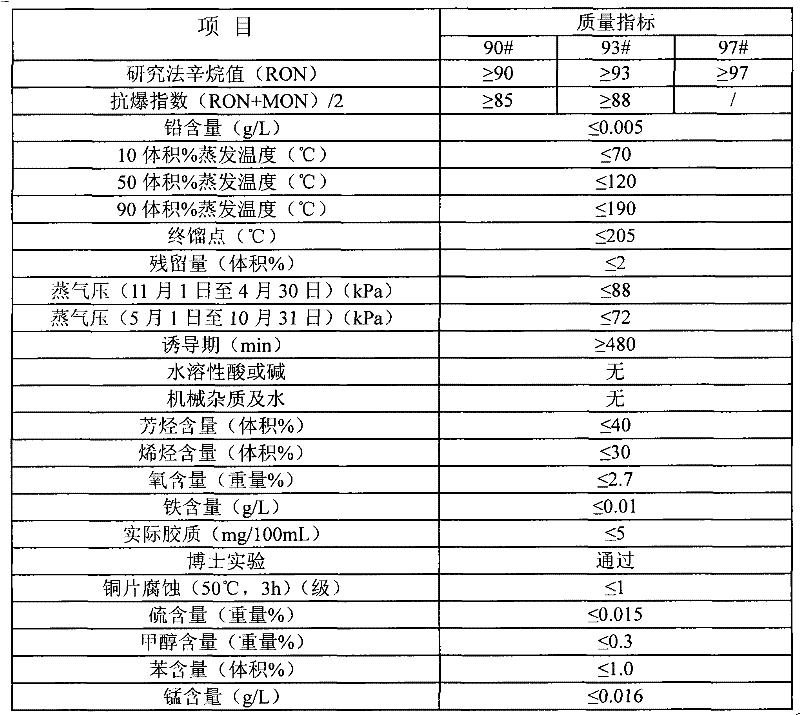

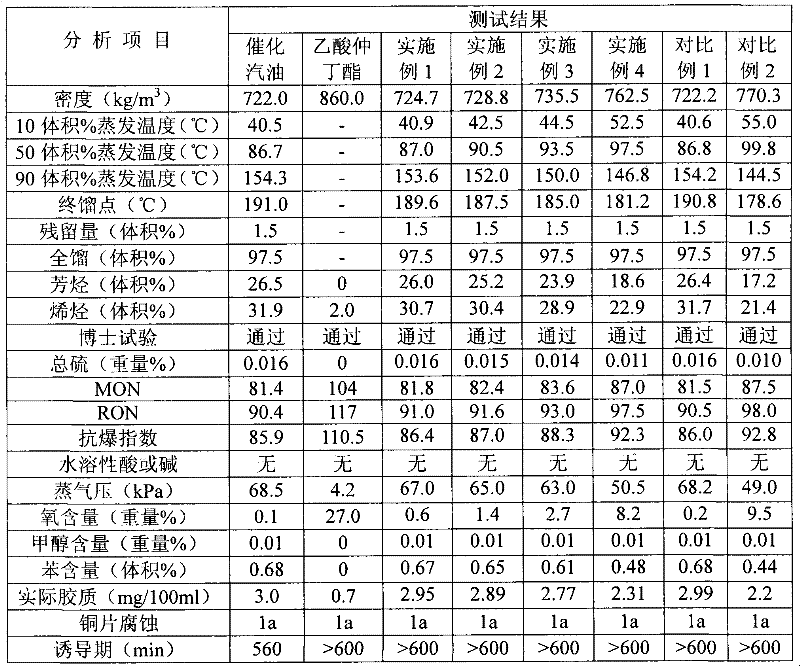

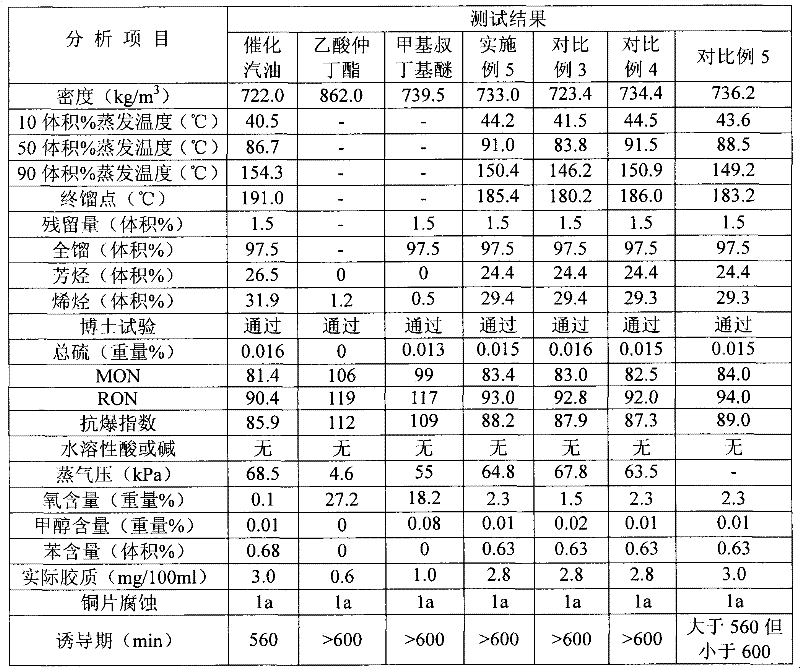

The invention provides a gasoline composition and a preparation method thereof. The gasoline composition comprises 70-99wt% of raw gasoline and 1-30wt% of sec-butyl acetate measured as the total weight of the gasoline composition, with good anti-knock property, green and environmental protection and low cost. The raw materials used in the preparation method have strong adaptability and good broadspectrum activity, and are simple and easy to do. By comparing the gasoline composition obtained by adding 9.8wt% of sec-butyl acetate in catalytic gasoline with the catalytic gasoline used as raw gasoline, the research octane number (RON) increases to 93.0 from 90.4, the motor octane number (MON) increases to 83.6 from 81.4, the anti-knock index increases to 88.3 from 85.9, the induction period is longer than 600min, the content of the existent gum is only 2.77mg / 100ml, and other indexes all meet the prescribed standards of Stage III.

Owner:HUNAN ZHONGCHUANG CHEM

Method for preparing sec-butyl acetate with direct esterification of acetic acid and butylene

ActiveCN101293824ASolve the problems caused by usingCatalyst carriersOrganic compound preparationButeneHeteropoly acid

A method relates to a method for preparing sec-butyl acetate from acetic acid and butylene. The sec-butyl acetate is prepared from acetic acid and butylene at a mole ratio of (0.1-10):1 by reacting in the presence of heteropoly acid as catalyst with a weight content being 0.02%-5% in acetic acid of under 0.5-6MPa at 70-180 DEG C. The method prevents device corrosion due to sulfuric acid catalyst and regeneration of resin catalyst. Since butylene material is adopted to react with acetic acid, no water generation in the reaction process and a separation process is simplified. The method can adopt a continuous high-pressure fixed bed reaction or a kettle batch operation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

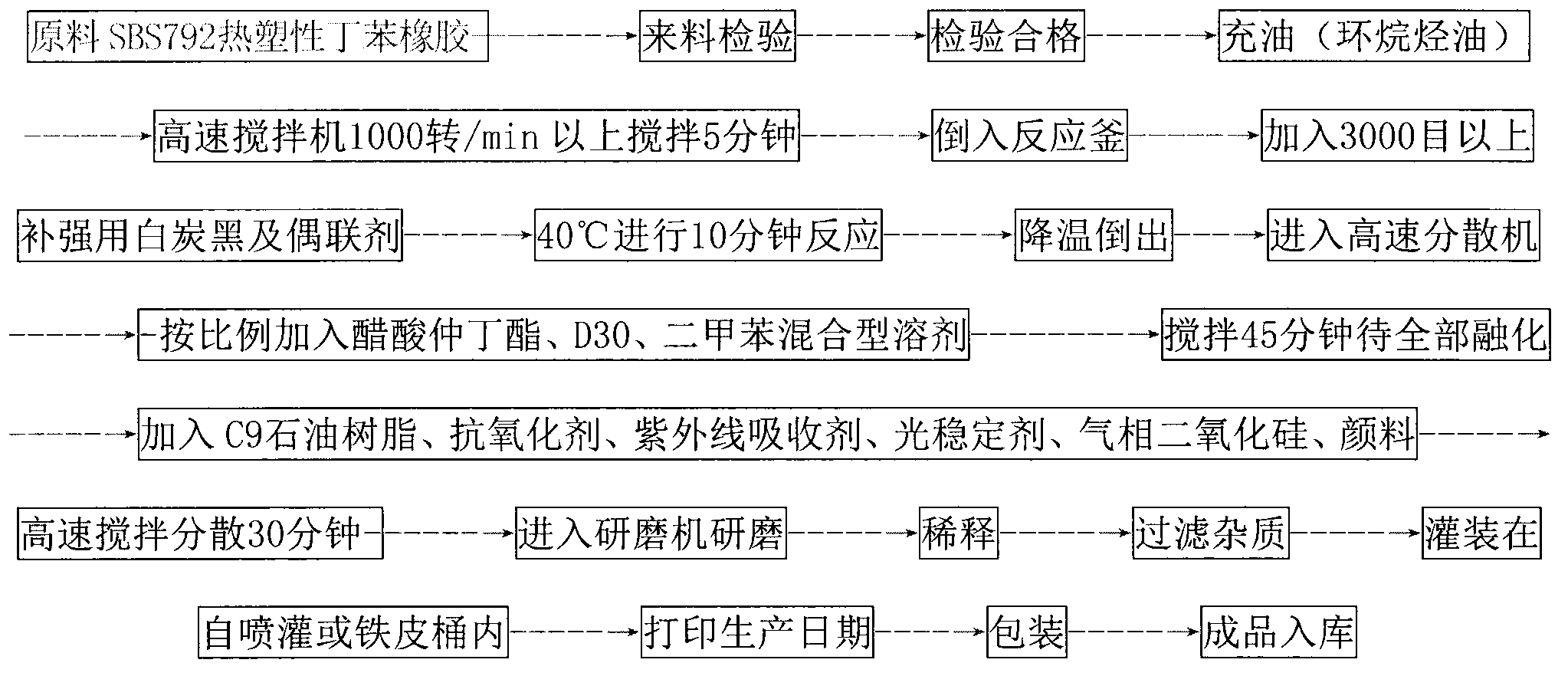

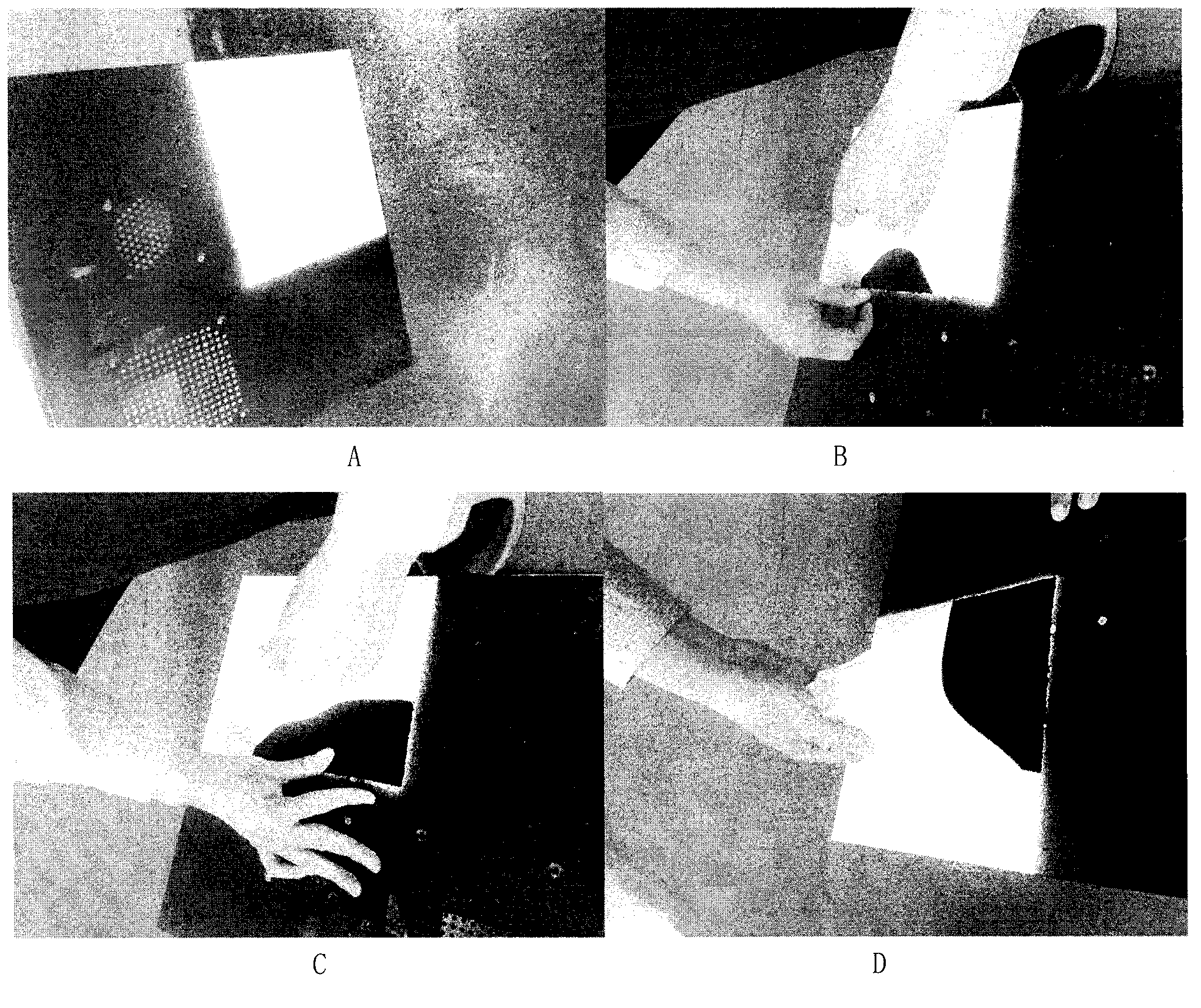

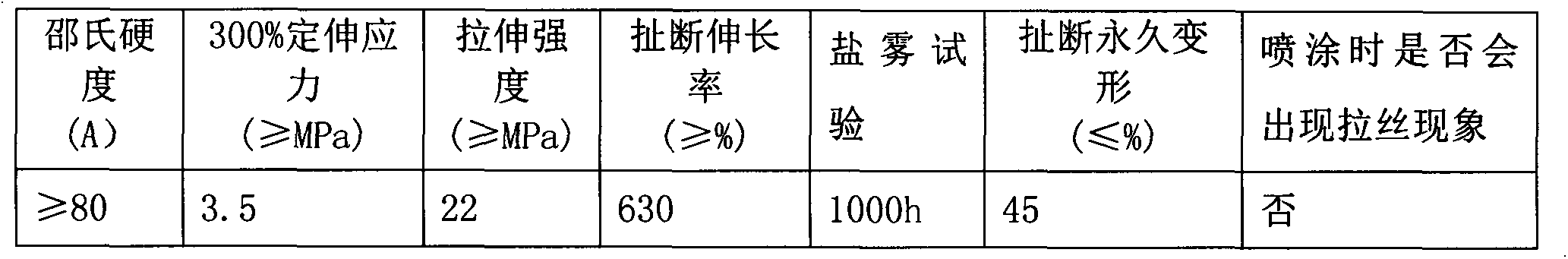

Coating with protection and color alteration functions

The invention discloses a coating with protection and color alteration functions. The coating is prepared from the following components in parts by weight: 150-200 parts of thermoplastic butadiene styrene rubber A, 50-100 parts of thermoplastic butadiene styrene rubber B, 300-400 parts of sec-butyl acetate, 300-400 parts of 120# solvent naphtha, 300-400 parts of xylene, 30-50 parts of C9 petroleum resin, 5-10 parts of antioxidant, 5-10 parts of ultraviolet light absorber, 3-10 parts of light stabilizer, 12-25 parts of fumed silica, 3-6 parts of defoaming agent and 0 or 15-32 parts of pigment. Compared with a chloroprene rubber strippable coating, the coating with protection and color alteration functions, disclosed by the invention, belongs to an environment-friendly coating and is greatly improved on the aspects of elasticity and toughness such as tensile strength, stretching strength, resilience coefficient, surface hardness, adhesive force and the like.

Owner:济宁恒泰机械有限公司 +1

Methyl ethyl ketone preparation method

InactiveCN102992984AImprove conversion rateHigh selectivityOrganic compound preparationCarbonyl compound preparationDehydrogenationSec-Butyl acetate

The invention relates to a methyl ethyl ketone preparation method. The method comprises the following steps: 1, carrying out an ester exchange reaction of sec-butyl acetate and low carbon alcohol in a catalytic rectifying tower in the presence of an ester exchange catalyst, wherein the low carbon alcohol is C1-C3 alcohol; and 2, carrying out a dehydrogenation reaction of the tower bottoms obtained in step 1 or sec-butyl alcohol separated from the tower bottoms obtained in the step 1 in the presence of a dehydrogenation catalyst. The method which allows sec-butyl alcohol to be prepared through using the sec-butyl acetate and the low carbon alcohol has the advantages of high raw material conversion rate and high sec-butyl alcohol selectivity.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Production process of high-purity abamectin fine powder

ActiveCN102617668AHigh purityImprove product qualitySugar derivativesSugar derivatives preparationAbamectinFermentation

The invention relates to a production process of abamectin fine powder. The production process method comprises the steps: extracting fermentation liquid filter cake with sec-butyl acetate for three times; combining organic-ester-phase extracts, adding tetrabutyl ammonium bromide aqueous solution for washing, and filtering, concentrating filtrate, and cooling and crystallizing to obtain once crude product; and dissolving the once crude product with ethanol, filtering, naturally cooling to room temperature, adding water at a volume ratio of ethanol to water being (7 : 1)-(4 : 1) for dilution crystallization, washing and drying to obtain the abamectin fine powder product. By adopting the method, the abamectin crystal product with higher purity and yield can be obtained; and compared with the traditional methods, the method has the advantages that the crystallizing time is shorter, the repeated crystallizing frequency is reduced and the production cost is low, thereby being a low-cost and high-efficiency production process of the high-purity abamectin fine powder.

Owner:DAQING JEFENE BIO CHEM

Solvent composition for preparing neonicotinoid pesticide liquid preparation

ActiveCN103238590AEasy to prepareGood stability of active ingredientsBiocideAnimal repellantsButyl acetateOrganic solvent

The invention discloses a solvent composition for preparing a neonicotinoid pesticide liquid preparation. The solvent composition is formed by dipyrrolidone and sec-butyl acetate, wherein the mass ratio of the dipyrrolidone to the sec-butyl acetate is in a range from 1: 17 to 6: 1; and the mass percentage of the solvent composition in the neonicotinoid pesticide liquid preparation is 10-90%. The solvent composition is directly mixed with a pesticide effective component and a surfactant to prepare the neonicotinoid pesticide liquid preparation. The solvent composition is safe to produce and safe, is environment-friendly and is easily degradable; and the solvent composition is the optimal solvent composition capable of replacing current organic solvents including aromatic hydrocarbons, alcohols, N,N-dimethyl formamide and the like, which are massively used.

Owner:GAUNGXI TIANYUAN BIOCHEM

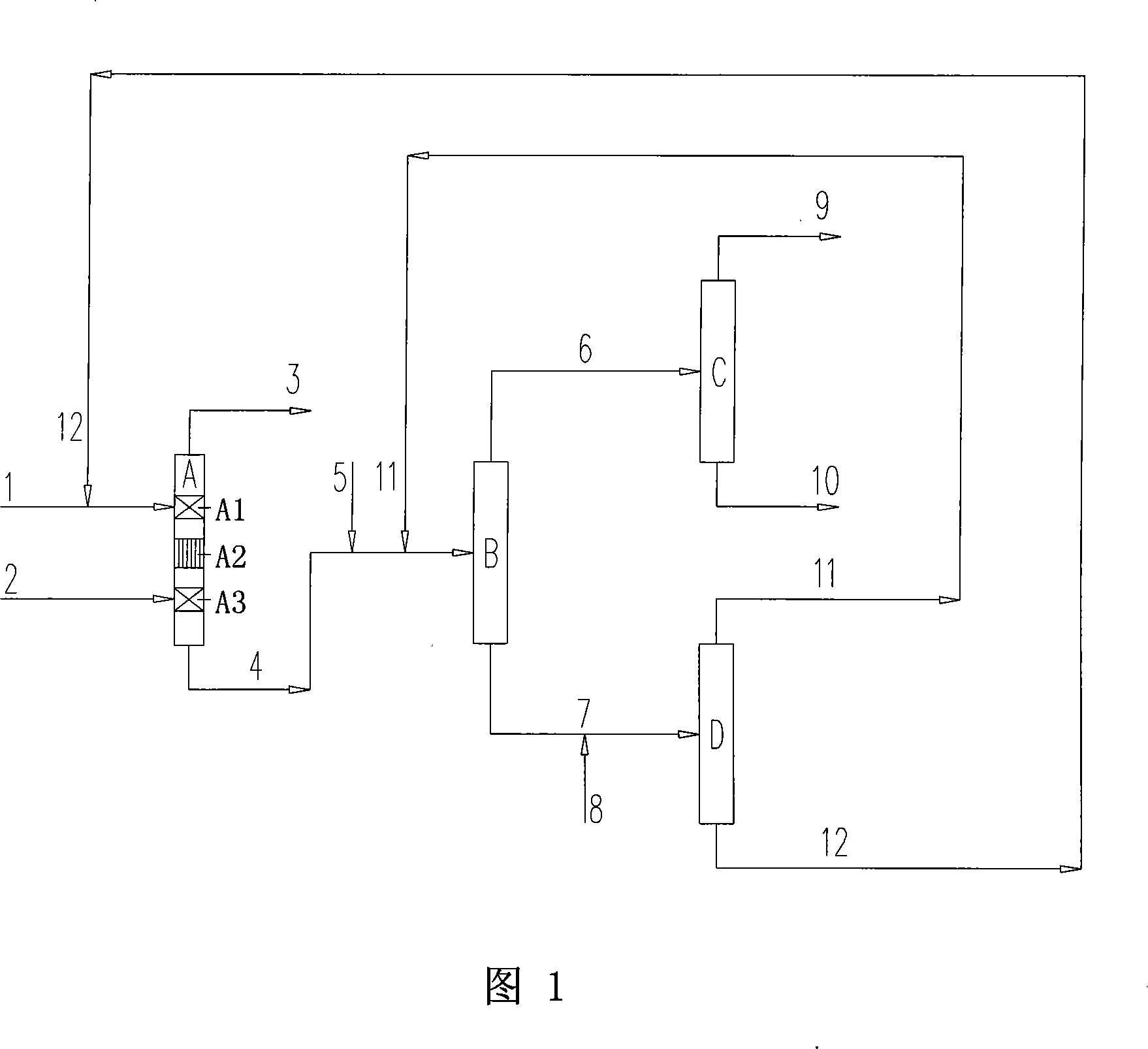

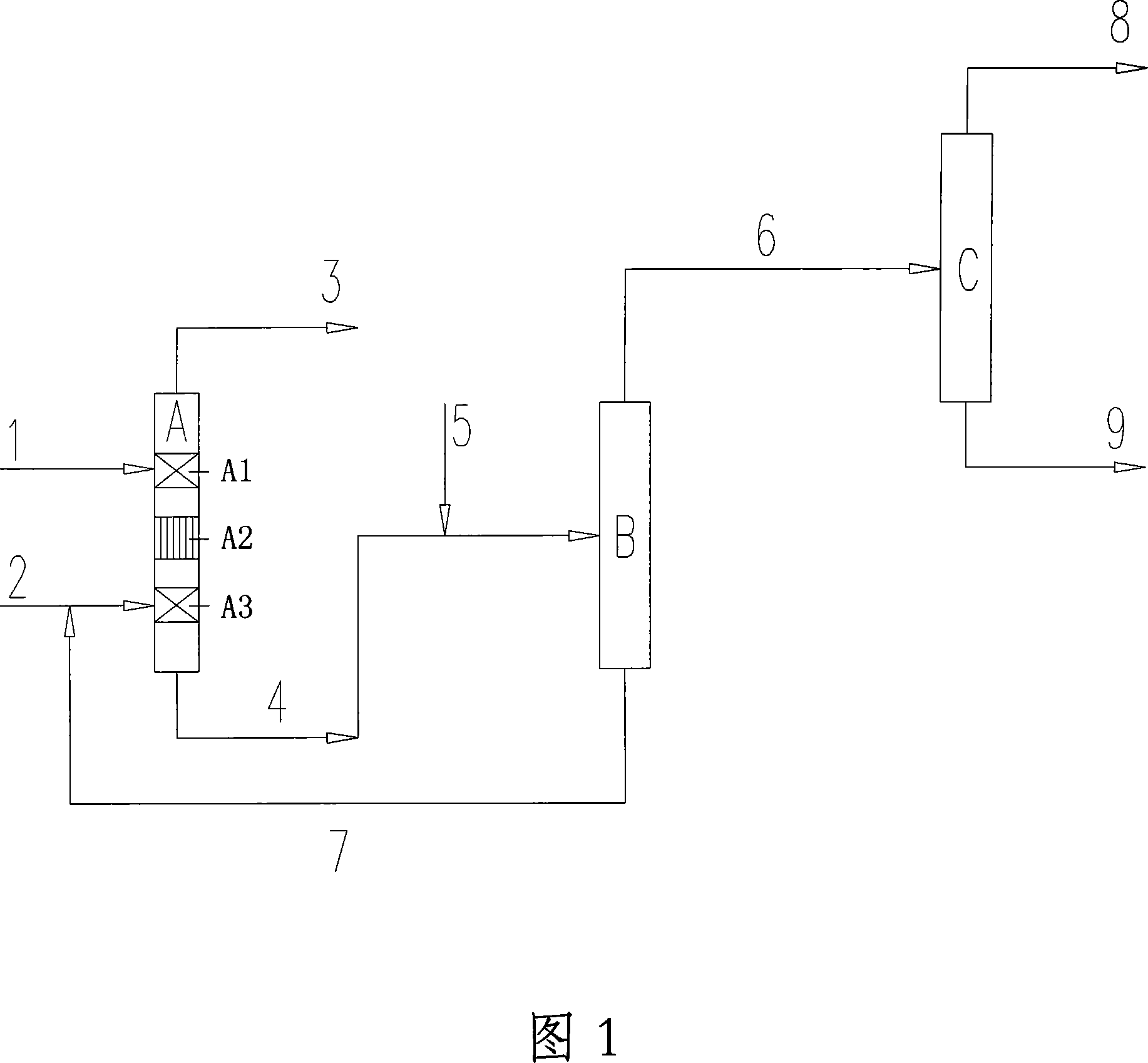

Method for separating sec-butyl acetate from mixture after reaction of acetic acid and butylene or mixture of C4

ActiveCN101130495AExtended service lifeReduce corrosionOrganic compound preparationCarboxylic acid esters separation/purificationButeneDistillation

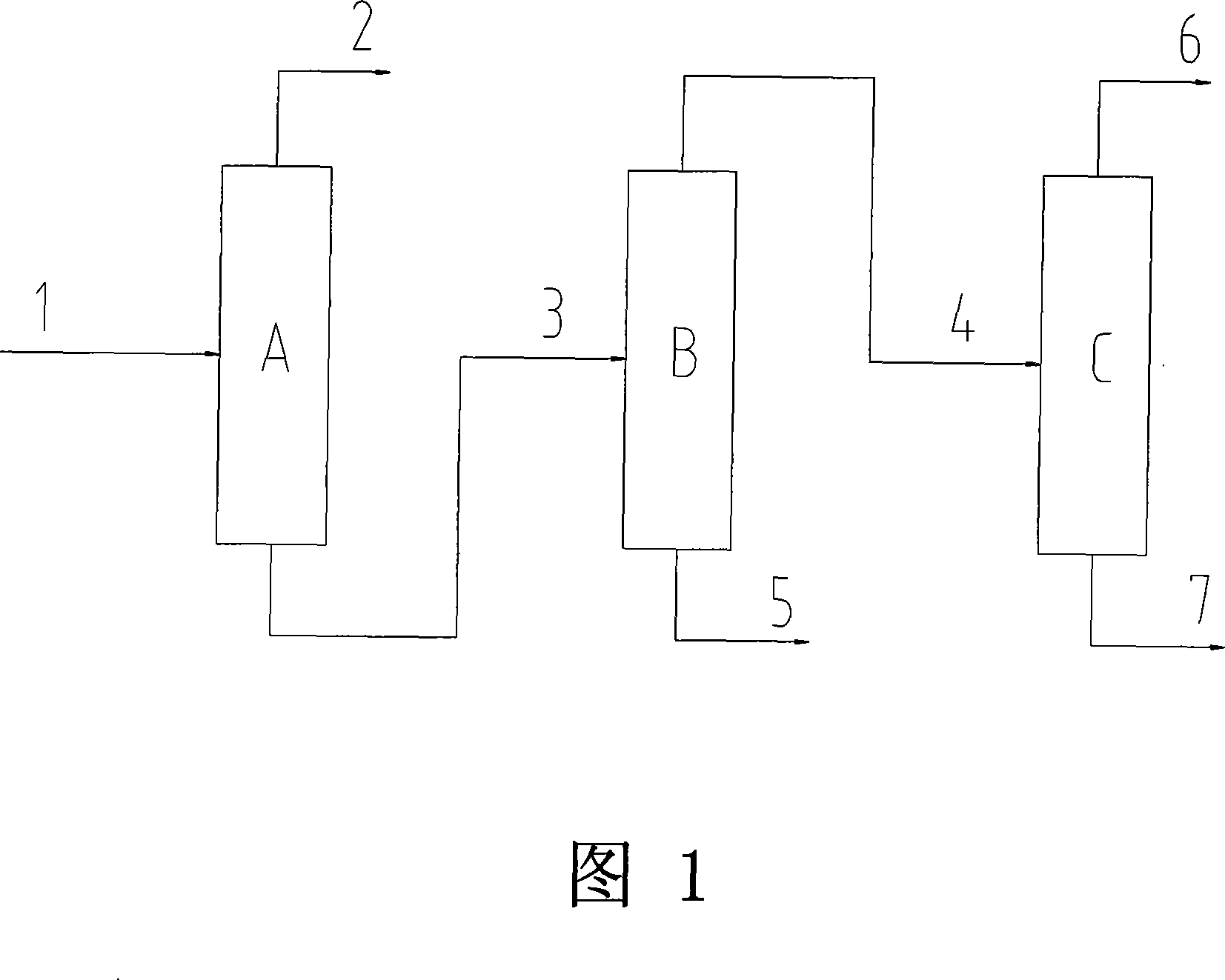

The invention provides a separating method of butyl acetate from mixture after reaction of acetic acid and butane or mixing C4, which comprises the following steps: stripping non-reacting butane or mixing C4 and light component through flash evaporation; separating butyl acetate and acetic acid under atmosphere pressure and decompression after entering flash tower (A) bottom product into the acetic acid and the butyl acetate knockout tower (B); obtaining the butyl acetate by distillation after materials on top of the acetic acid and the butyl acetate knockout tower (B) to enter into treating tower (C); recycling bottom materials of acetic acid and butyl acetate knockout tower (B). The invention reduces erosion of acetic acid to device for not introducing water to system to extend durability of accelerant and reduces equipment investment and operating expenditure, and the purity of butyl acetate is more than 99% and quality content of acetic acid is less than 0. 01%, and quality content of water is less than 0. 01%.

Owner:HUNAN ZHONGCHUANG CHEM

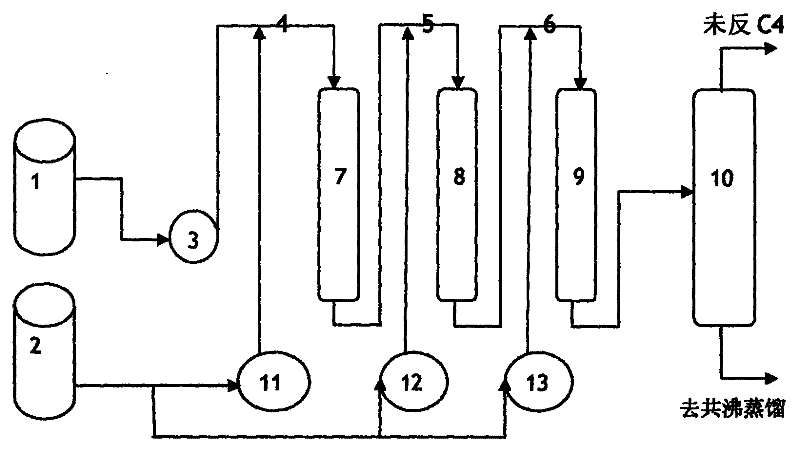

Etherified C4 superimposition esterification cogeneration method of isooctane and sec-butyl acetate

InactiveCN102701969AExpand the scope of procurementGuaranteed supplyOrganic compound preparationCarboxylic acid esters preparationHeteropoly acidDistillation

The invention discloses an etherified C4 superimposition esterification cogeneration method of isooctane and sec-butyl acetate. The etherified C4 superimposition esterification cogeneration method of the isooctane and the sec-butyl acetate comprises the following steps: (1), passing an etherified C4 raw material through a reactor filled with a solid acidic catalyst, performing superimposition reaction under reaction conditions that the reaction temperature is 60-90 DEG C and the pressure is 0.8-1.6Mpa, and distilling a superimposition reaction product to obtain the refined C4 raw material on the top of a distillation tower and obtain C8 olefin, with iso-octene as a main part, at the bottom of the distillation tower; and (2) mixing and preheating the refined C4 raw material with acetic acid, passing the mixture through an esterification reactor filled with an esterified heteropoly acid catalyst, and reacting under reaction conditions that the temperature is 70-110 DEG C and the pressure is 1.0-1.4Mpa to obtain the sec-butyl acetate. The superimposition reaction is high in selectivity; the procurement index of the C4 raw material of the sec-butyl acetate is lowered; the supply of the raw material is ensured; and the generated C8 olefin can be used as a high-octane gasoline component, thus improving the economic benefit.

Owner:WEIFANG YIXING CHEM TECH

Preparation method for sec-butyl acetate with product separating technique

ActiveCN101168506ASimple separation processIncrease profitOrganic compound preparationCarboxylic acid esters preparationButeneSeparation technology

The invention relates to a process for preparing sec-butyl acetate, with product separation technology, which is characterized in that the reaction is processed in one catalysis distillation column composed of a column reactor, an exhausting section, a reaction section, a distillation section, and a column top reflux condenser, wherein the reaction section is filled with catalyst, acetic acid andmixture C4 or butene which are reversely contacted and reacted on the surface of catalyst, the non-reacted mixture C4 or butene is evaporated out from the top of the catalyst distillation column, theproduct mixture is fed into an azeotropic distillation column, added with an entrainer, the distillate at the top of the azeotropic distillation column can be laminated naturally, the entrainer or entrainer and part of sec-butyl acetate are refluxed into the top of the azeotropic distillation column, the azeotropic distillation column carrying little entrainer is fed into a treating column, to bedistilled to obtain sec-butyl acetate, and the bottom material of the azeotropic distillation column can be circulated and feedback to the reaction system. The invention has the advantages of high reaction conversion rate, simple separation process, low cost, low energy consumption, high material utilization and the like.

Owner:HUNAN ZHONGCHUANG CHEM

Porous acidic resin catalyst, preparation method and applications thereof

InactiveCN105618137ASolve Pore VolumeSolution areaOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsButeneSolid acid

The present invention provides a porous acidic resin catalyst, wherein a nanometer material adopted as a pore forming hard template agent is directly doped into a macromolecule resin, reaction dissolving is performed in an acid solution to remove the nanometer material so as to form nanometer pore channels in the macromolecule resin, and then a sulfonation reaction is performed to achieve acid functionalization so as to prepare the nano-pore resin solid acid. The present invention further provides a preparation method and applications of the porous acidic resin catalyst. According to the present invention, the porous acidic resin catalyst has characteristics of large pore volume, large specific surface area, and strong acidity; and with the application of the porous acidic resin catalyst as the solid acid catalyst in the catalytic reaction for esterification synthesis of sec-butyl acetate from acetic acid and butene, the reaction activity is high, the reaction stability is good, and the butene conversion rate and the sec-butyl acetate yield of the esterification reaction can be significantly improved.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com