Process method for synthesizing sec-butyl acetate from C4 fractions

A technology of sec-butyl acetate and C4 fraction, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. The effect of low ene molar ratio, prolonging service life and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

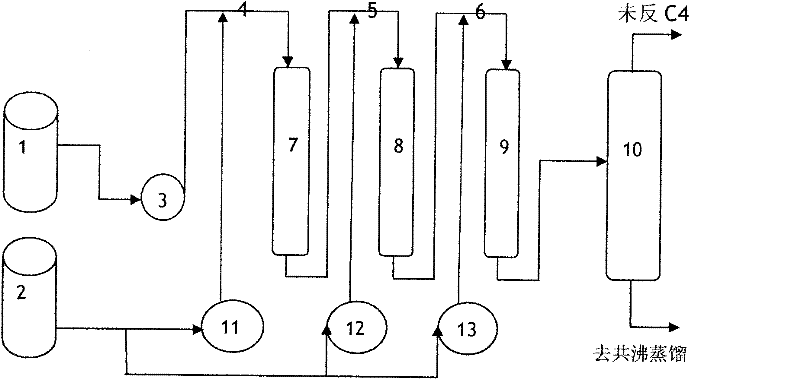

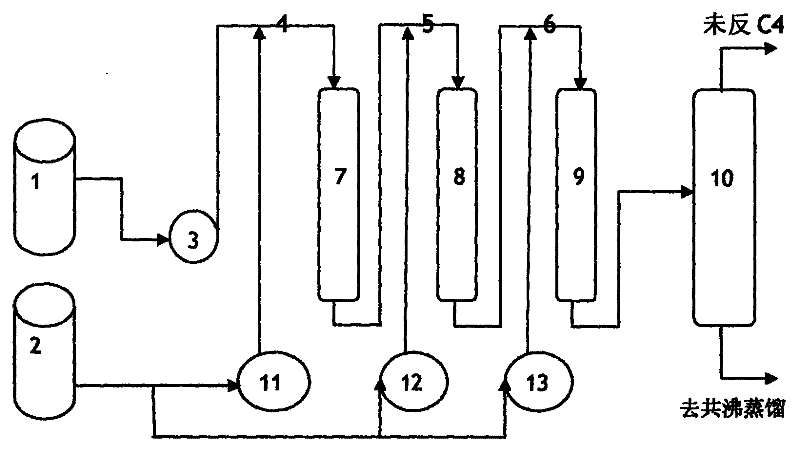

[0022] according to figure 1 As shown in the flow chart of the process and equipment, the macroporous strongly acidic cation exchange resin, model A-35, 90 g on a dry basis, is evenly divided into 3 equal parts, each 30 grams, and loaded into 3 boxes with an inner diameter of 10 mm and a length of 80 mm. Tube-and-tube reactors 7, 8, and 9 of stainless steel tubes, hot water is passed through the shell side, and then acetic acid is loaded into storage tank 1, and the C4 fraction is loaded into storage tank 2. The molar ratio of the two olefins is 3, and the acetic acid Add olefin polymerization inhibitor RP-1412, the content is 100μg / g, acetic acid is continuously fed through each stage with pump 3 from the top of the first stage, and the feed rate of acetic acid per hour is 120 grams, and then the molar ratio of ester acid to C4 fraction olefin The amount greater than 9 passes through the metering pumps 11, 12, 13 of each section and the acetic acid pipes 4, 5, 6 to mix and th...

Embodiment 2

[0024] With the equipment of embodiment 1, add a reactor (accompanying drawing not shown), macroporous strongly acidic cation exchange resin, model K-300, dry basis 120g is evenly divided into 4 equal parts, every part of 30 grams, respectively packs into 4 The inner diameter is 10 millimeters, long 80 millimeters of stainless steel tube tube type thousand 4 reactor shell pass hot water, then put acetic acid into storage tank 1, C4 distillate into storage tank 2, the olefin molar ratio of the two is 2, And add olefin polymerization inhibitor RP-1412 in acetic acid, the content is 200μg / g, acetic acid is fed through each section continuously with the pump from the top of the first section, and the acetic acid feeding amount per hour is 192 grams, and then the ester acid and the C4 fraction The amount of olefins with a molar ratio greater than 9 is connected to each section through the metering pumps of each section and the acetic acid pipe, and then mixed, and then passed into e...

Embodiment 3

[0026] With embodiment 1 equipment, increase two reactors (accompanying drawing is not shown), with macroporous strongly acidic cation exchange resin, model D-06, dry basis 150g is evenly divided into 5 equal parts, every part of 30 grams, packs 5 respectively A tube-and-tube reactor with an internal diameter of 10 mm and a length of 80 mm stainless steel tube is passed through hot water in the shell side, then the acetic acid is loaded into the storage tank 1, and the C4 fraction is loaded into the storage tank 2, and the olefin molar ratio of the two is 2. , and add olefin polymerization inhibitor RP-1412 in acetic acid, the content is 20μg / g, acetic acid is fed through each section continuously with the pump from the top of the first section, and the acetic acid feeding amount per hour is 150 grams, and then ester acid and C4 The amount of distillate olefin molar ratio greater than 9 is connected to each section through the metering pump of each section and the acetic acid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com