Patents

Literature

168 results about "Sec-butyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sec-Butyl Alcohol B1187 | 78-92-2 sec-Butyl Alcohol is also known as 2-Butyl alcohol and sec-Butanol. It is used as a solvent and can be converted to butanone which is an industrial solvent.

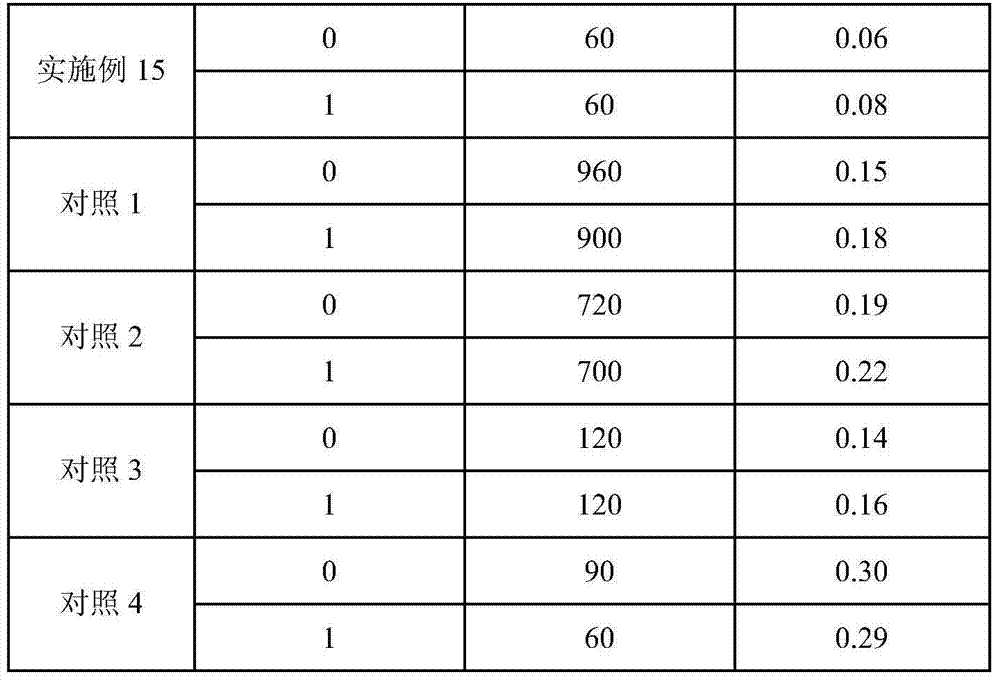

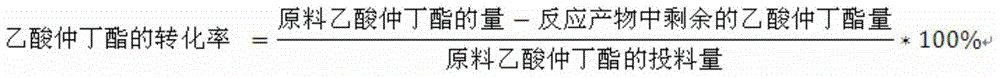

Method for producing sec-butyl alcohol

InactiveCN102659514AOvercome the disadvantage of low conversion rateOpen up new usesPreparation by hydrolysisSec-Butyl acetateAdditional values

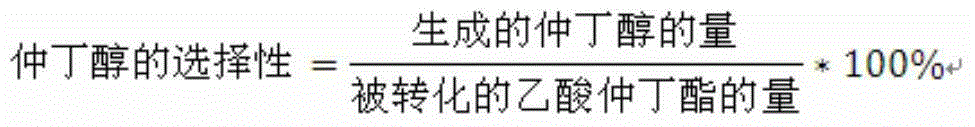

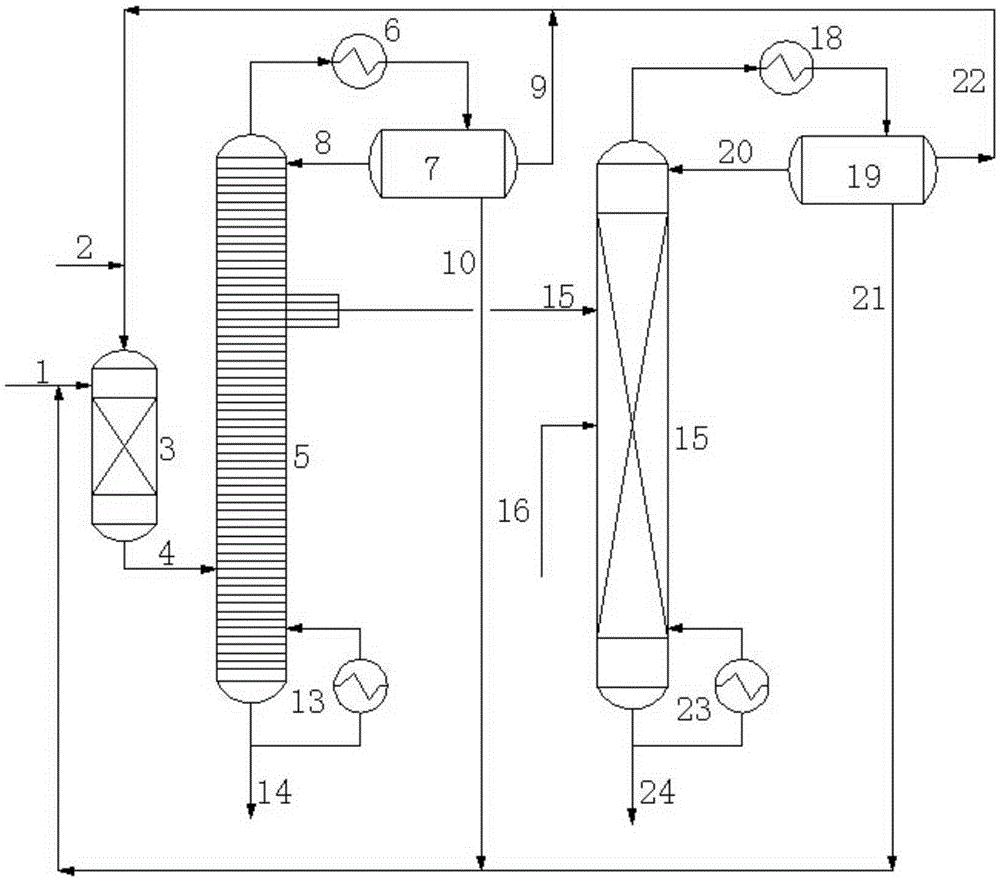

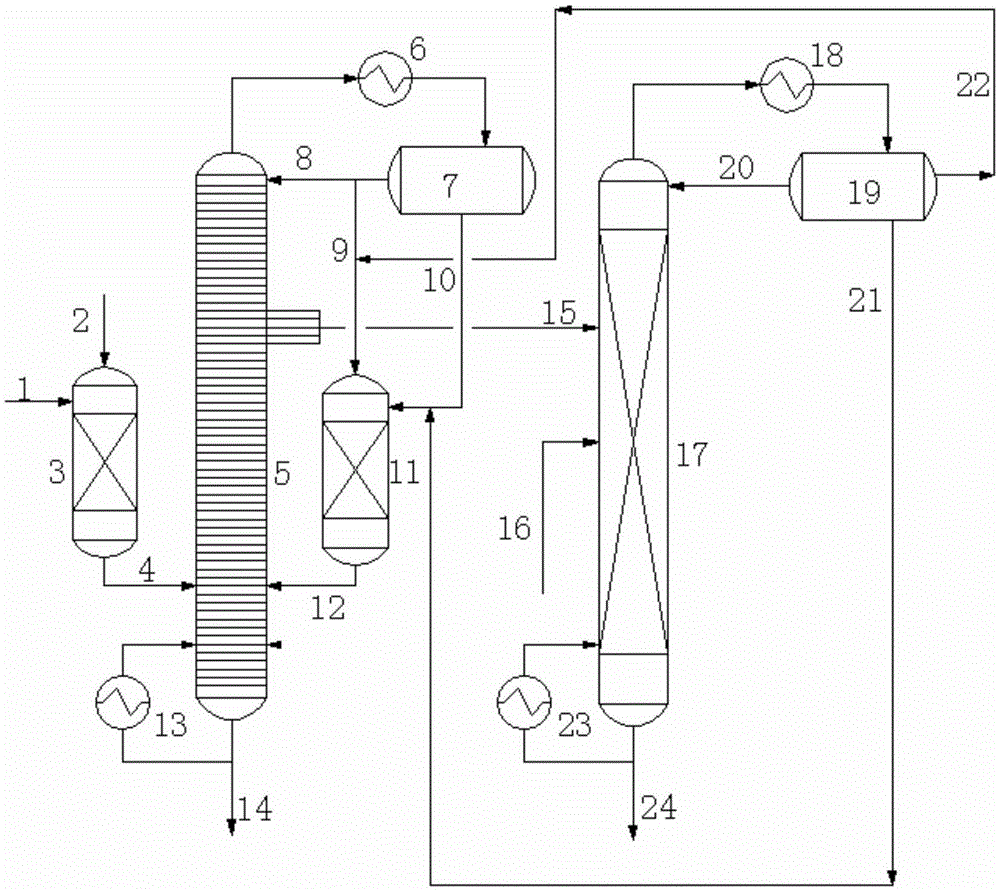

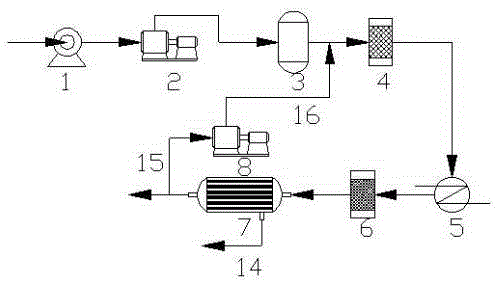

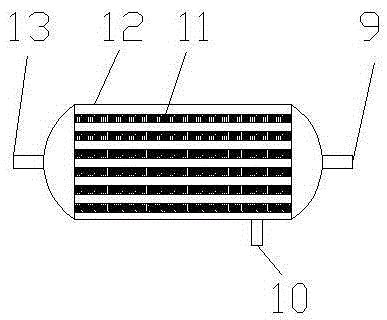

The invention provides a method for producing sec-butyl alcohol through the catalytic hydrolysis of alcohol sec-butyl acetate. The method comprises the following steps of: carrying out continuously catalytic hydrolysis in a stationary bed by using the alcohol sec-butyl acetate as a raw material, and filling a catalyst in continuous tubes of the cascade multitubular stationary bed, wherein a commercial styrene cation exchange resin catalyst is used as the catalyst, and the cascade multitubular stationary bed comprises multiple identical multitubular reactors; leading the raw material alcohol sec-butyl acetate and water to enter the multitubular reactors, carrying out continuously catalytic hydrolysis reaction under the action of the catalyst to generate a sec-butyl alcohol crude product, and refining the crude product to obtain the sec-butyl alcohol with high purity. The method for producing the sec-butyl alcohol has the advantages that the conversion rate of the sec-butyl alcohol is high, the application range of the alcohol sec-butyl acetate can be increased, and the additional value of the alcohol sec-butyl acetate is increased; and therefore, the method has market promotion value.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Method for synthesizing sec-butyl alcohol

InactiveCN102731250AIncrease reaction rateImprove conversion ratePreparation by ester-hydroxy reactionPreparation by alcoholysisButeneMethyl acetate

Owner:FUZHOU UNIV

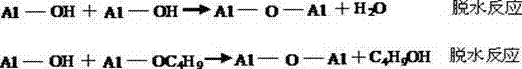

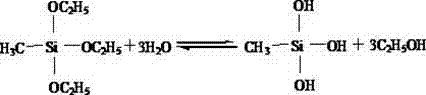

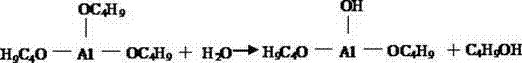

Method for preparing temperature-resistant and corrosion-resistant aluminum oxide/organic silicon/silicon dioxide hybridized coating

InactiveCN102604536AGood physical propertiesGood resistance to salt spray testPretreated surfacesCoatingsSilicic acidSalt spray test

The invention provides a method for preparing a temperature-resistant and corrosion-resistant aluminum oxide / organic silicon / silicon dioxide hybridized coating. The preparation method comprises the following steps of: preparing an organic silicon / silicon dioxide hybridized sol by using tetraethoxysilane as an inorganic phase precursor and methyl triethoxyl silane and diphenyl dimethyl silane as an organic phase precursor through a sol-gel method; preparing aluminum sol by using sec-butyl alcohol aluminum as an aluminum source through the sol-gel method; and then adding the aluminum sol into the organic silicon / silicon dioxide sol through a sol blending method, and preparing the aluminum oxide / organic silicon / silicon dioxide hybridized sol by using acetic acid as gel and a carbonyl-contained amide compound as a dry control chemical addition agent. The coating prepared by the invention has a good physical property. The hardness of the coating is 0.8825, the anti-impact intensity of the coating is 50 kg.cm, and the flexibility of the coating is 1 mm. The coating coated on an LY12 aluminum alloy plate is not destructive after being roasted at a temperature of 450 DEG C for 1 hour. The surface of the coating is non-corrosive after the coating salt spray test is carried out for 1368 hours.

Owner:NANCHANG HANGKONG UNIVERSITY

Ceramic product having alcoholic drink alcoholization function and preparation method thereof

InactiveCN102690102AGood colorSpicy and violent tasteAlcoholic beverage preparationClaywaresIsobutanolSilicic acid

The invention relates to an alcoholic drink storage utensil and a preparation method thereof. The alcoholic drink storage utensil is a ceramic product having an alcoholic drink alcoholization function and is composed of purple sand, an alcoholic drink purifying solvent, an energy activator and an environment-imitating solvent, wherein the purple sand accounts for 70-80% of the raw materials, the alcoholic drink purifying solvent accounts for 5-20% of the raw materials s, the energy activator accounts for 5-20% of the raw materials s, and the environment-imitating solvent accounts for 2-6% of the raw materials. The alcoholic drink purifying solvent contains major elements of potassium, sodium, calcium, magnesium and phosphorus and further contains zinc, iron, selenium, copper, strontium, iodine, fluorine and metasilicic acid; the energy activator can be tourmalinite or negative ion powder or a mixture of the tourmalinite and the negative ion powder; the environment-imitating solvent is diatomite. The function of the ceramic products is that parameters such as acetaldehyde, methanol, n-propanol, sec-butyl alcohol, isobutanol, n-butanol and isoamyl alcohol, and the like can be reduced to a different degree; parameters such as ethyl acetate, ethyl butyrate, ethyl lactate and ethyl caproate, and the like can be raised to different degrees. According to the invention, the alcoholic drink has good shade, virgin whiteness, no thickness, no pungent smell and no other off-flavors.

Owner:冯政

Preparation method of orientation LTL type molecular sieving membrane for gas separation

ActiveCN105727757AEasy to operateGood repeatabilitySemi-permeable membranesDispersed particle separationAcquired membraneSeed crystal

The invention relates to a preparation method of an orientation LTL type molecular sieving membrane for gas separation. The preparation method comprises the following steps: (1) mixing an alkali source, an aluminum source, a silicon source and deionized water to obtain gel and performing hydrothermal crystallization for preparing a seed crystal; (2) performing acidic treatment on the seed crystal prepared in the step (1) so as to remove aluminum from the grain surface, and then preparing a suspension in sec-butyl alcohol, and stirring for modifying; (3) dropwise adding the LTL type molecular sieving suspension acquired by modifying in the step (2) into an LB liquid tank for forming a membrane, and then transferring the acquired membrane onto the surface of a carrier; (4) mixing an alkali source, an aluminum source, a silicon source and deionized water to obtain a secondary growth synthetic solution; (5) contacting the product from the step (3) with the secondary growth synthetic solution from the step (4), performing hydrothermal crystallization and acquiring the LTL type molecular sieving membrane on the carrier. According to by the invention, the simple, controllable, efficient and repeatable LB method is adopted for preparing the orientation LTL type molecular sieve seed crystal layer and the high c-axis orientation LTL type molecular sieving membrane is prepared through secondary growth; the operation is simple, the degree of orientation is easily controlled, and the repeatability is high.

Owner:NINGXIA UNIVERSITY

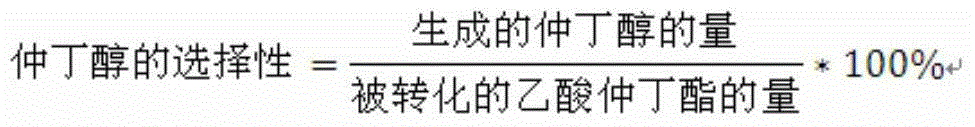

Method for catalyzing synthesizing sec-butyl alcohol through cation exchange resin

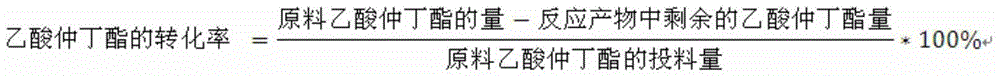

InactiveCN102838450AHigh catalytic activityGood choicePreparation by ester-hydroxy reactionPreparation by alcoholysisSec-Butyl acetateSec-butyl alcohol

The invention discloses a method for catalyzing synthesizing sec-butyl alcohol through cation exchange resin. The method comprises the step of carrying out ester exchange under the effect of the cation exchange resin with the sec-butyl acetate and the carbinol serving as the raw materials, so as to synthesize to obtain the sec-butyl alcohol. The sec-butyl acetate provided by the invention has the conversion rate up to 35 to 50%; and the method has the advantages that the reaction condition is mild, the corrosion to equipment is low, the selectivity and the activity of a catalyst are high, and repeated use is realized.

Owner:FUZHOU UNIV

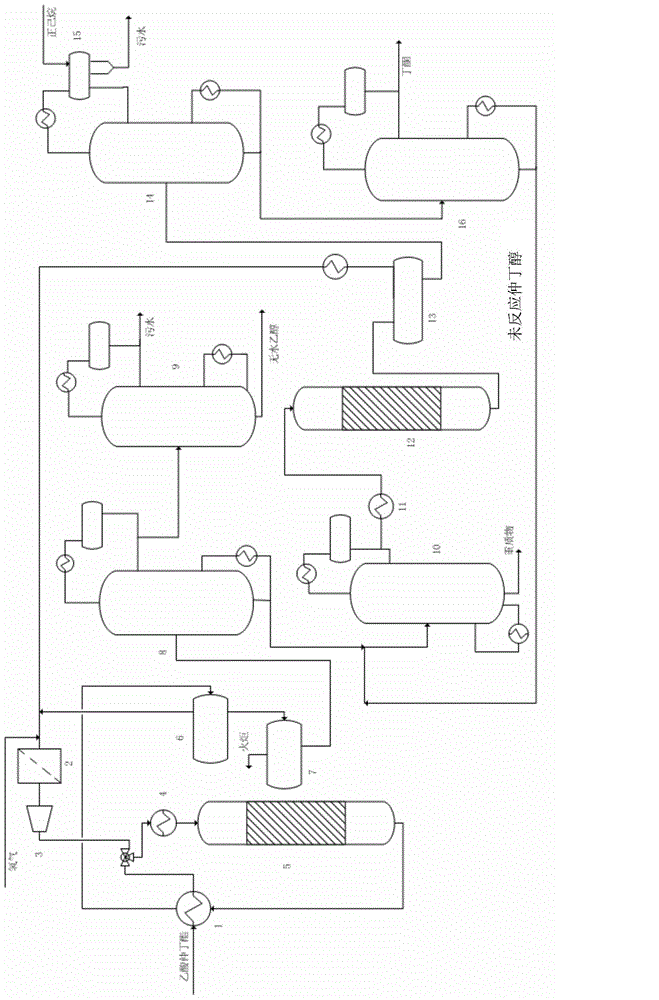

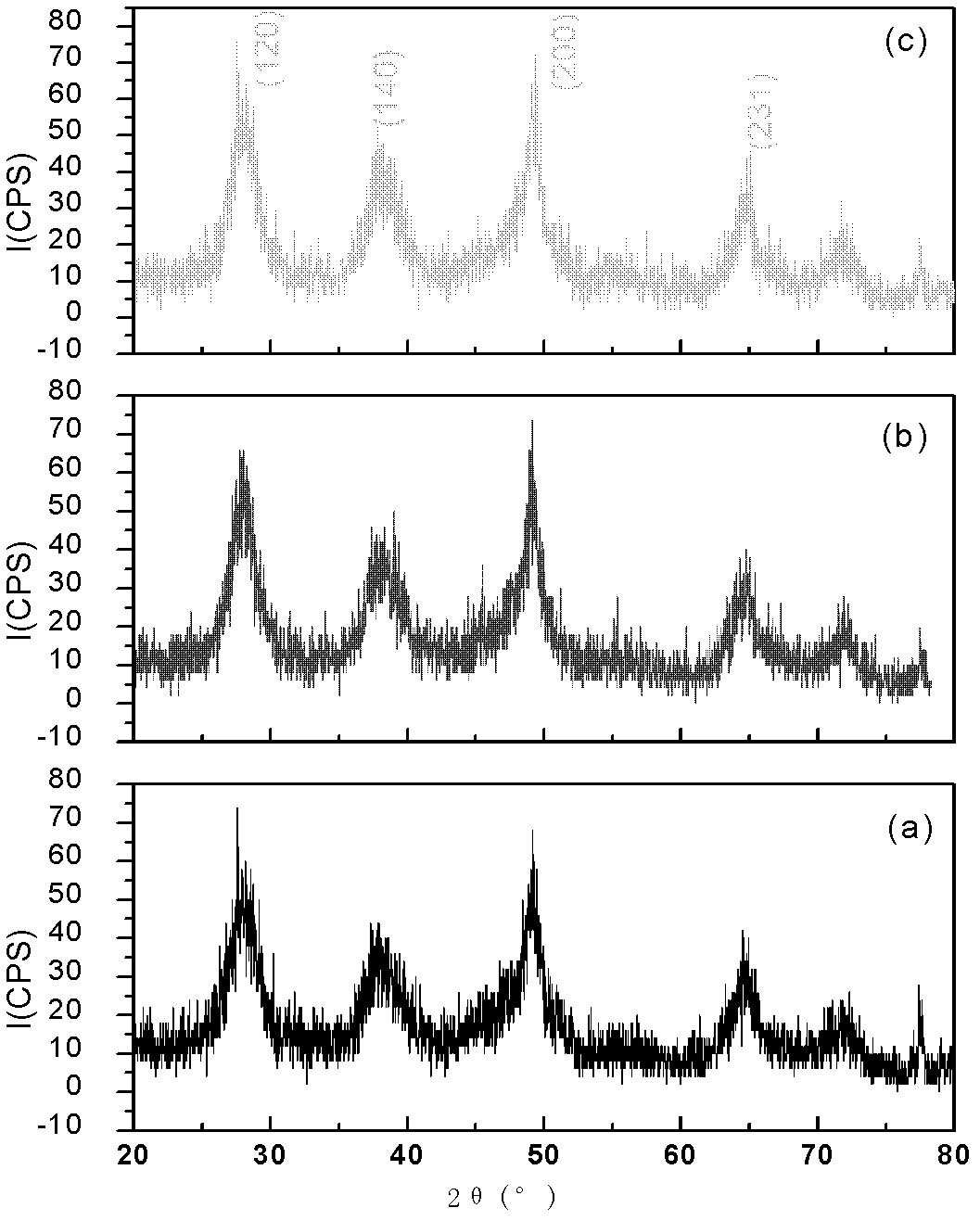

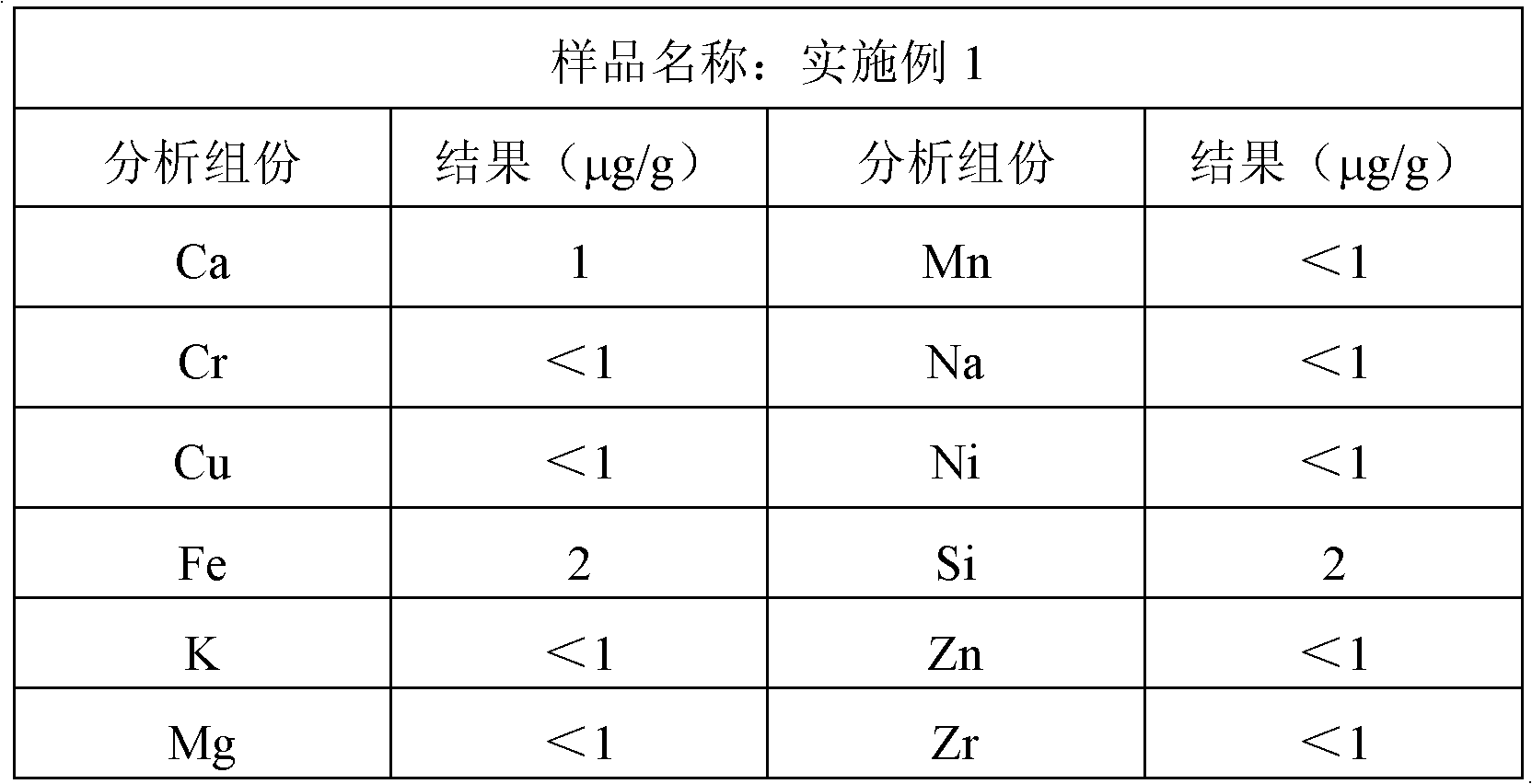

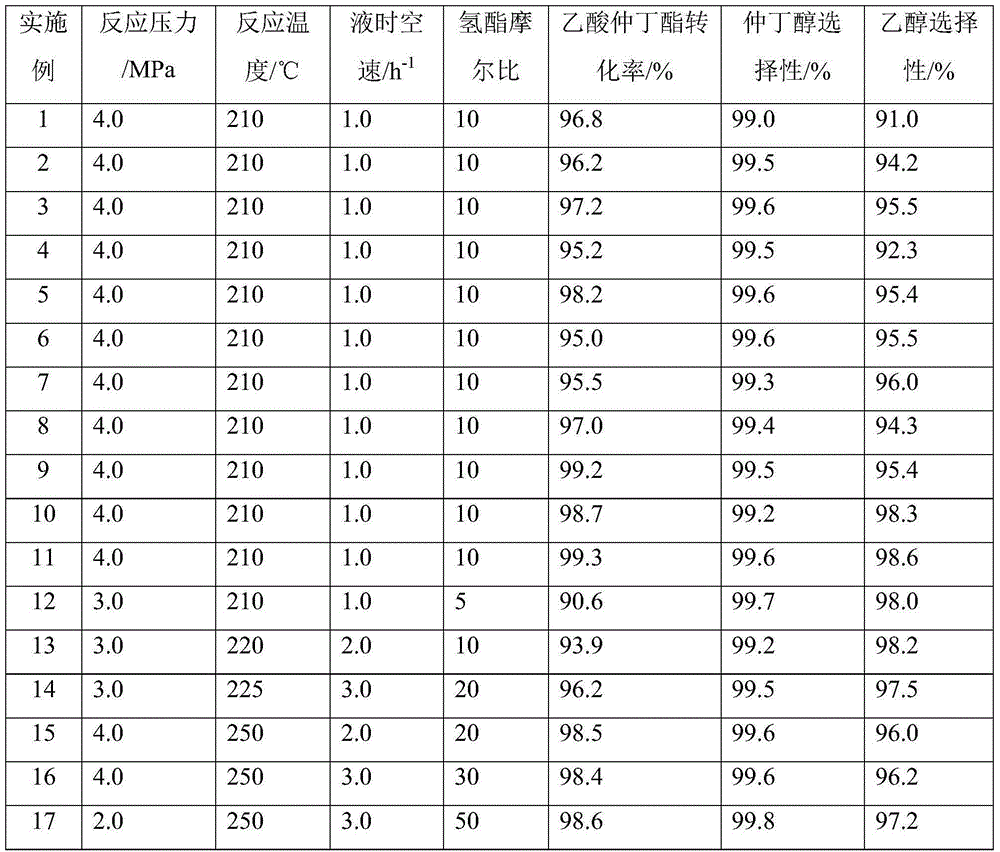

Preparation method of sec-butyl alcohol

InactiveCN103172492AReduce energy consumptionShort processOrganic compound preparationHydroxy compound preparationHydrogenFixed bed

The invention relates to a preparation method of sec-butyl alcohol. According to the preparation method, sec-butyl acetate generated through reaction between mixed C4 fractions and acetic acid is used as a raw material and is directly hydrogenated under the action of a copper-based solid catalyst to prepare sec-butyl alcohol with coproduct being ethanol, and in a fixed bed reactor the feed mass space velocity of sec-butyl acetate is 0.1-2.0h<-1>, the molar ratio of hydrogen to sec-butyl acetate is (2-40):1, the reaction temperature is 200-280 DEG C and the reaction pressure is 2.0-9.0MPa to directly prepare sec-butyl alcohol and cogenerate ethanol. The detailed preparation method refers to the specification. The conversion per pass of sec-butyl acetate is over 95%, the selectivity of sec-butyl alcohol is over 95% and ethanol is coproduced. The preparation method has the advantages that the energy consumption is reduced; circulation of mass raw materials is not needed, so the process flow is shortened; no other wastes are generated, so the process is clean; and separation is simple.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

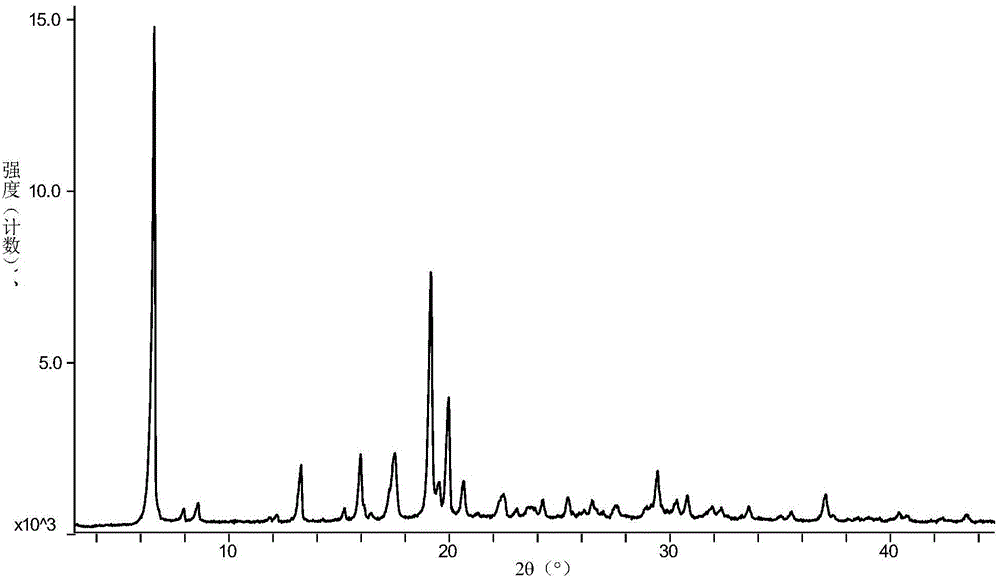

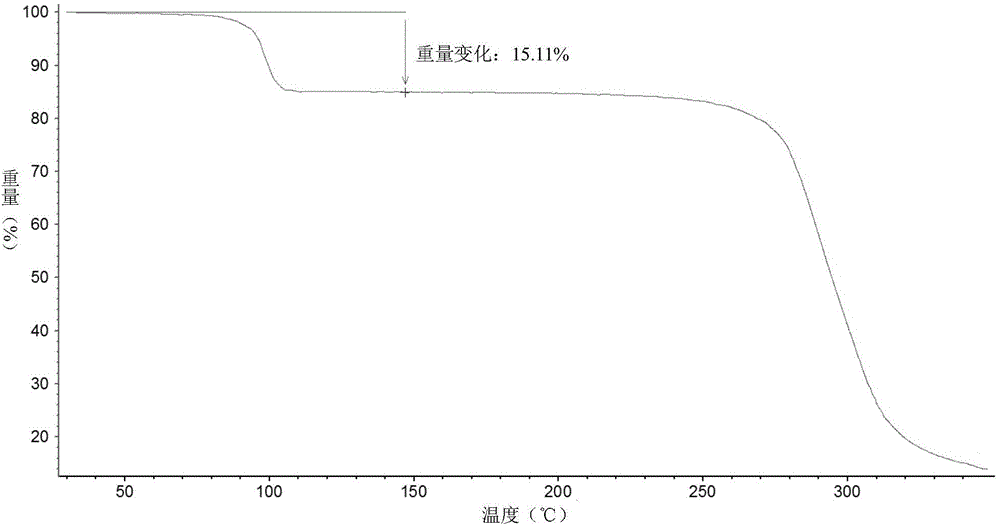

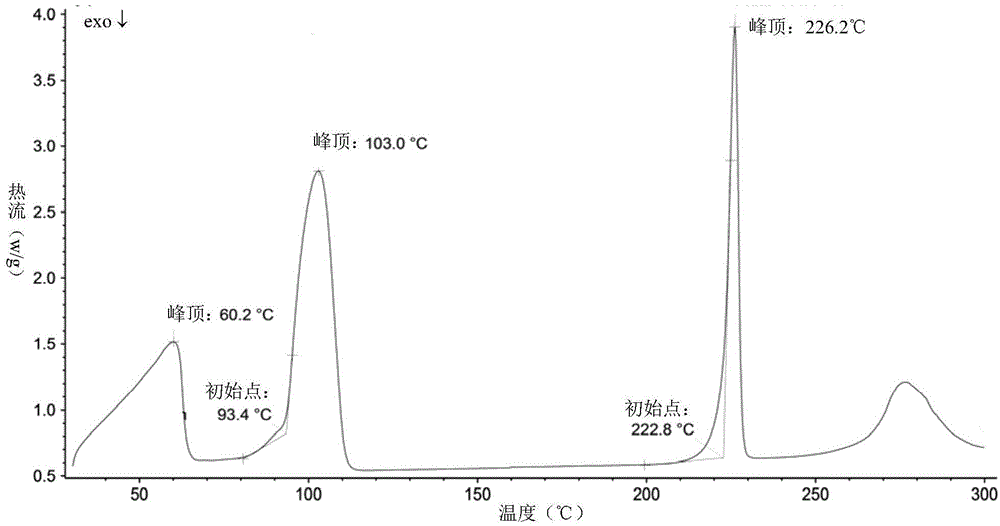

Preparing method for vortioxetine hydrobromide alpha crystal form

ActiveCN105367515AHigh crystal purityModerate granularityOrganic chemistryDesolvationSec-butyl alcohol

The invention discloses a preparing method for a vortioxetine hydrobromide alpha crystal form. The preparing method comprises the following step that sec-butyl alcohol is removed from a vortioxetine hydrobromide-sec-butyl alcohol complex to obtain the vortioxetine hydrobromide alpha crystal form. The method is low in desolvation temperature, and the prepared vortioxetine hydrobromide alpha crystal form is high in purity, suitable in particle size and suitable for industrial production.

Owner:BEIJING BEILU PHARM CO LTD

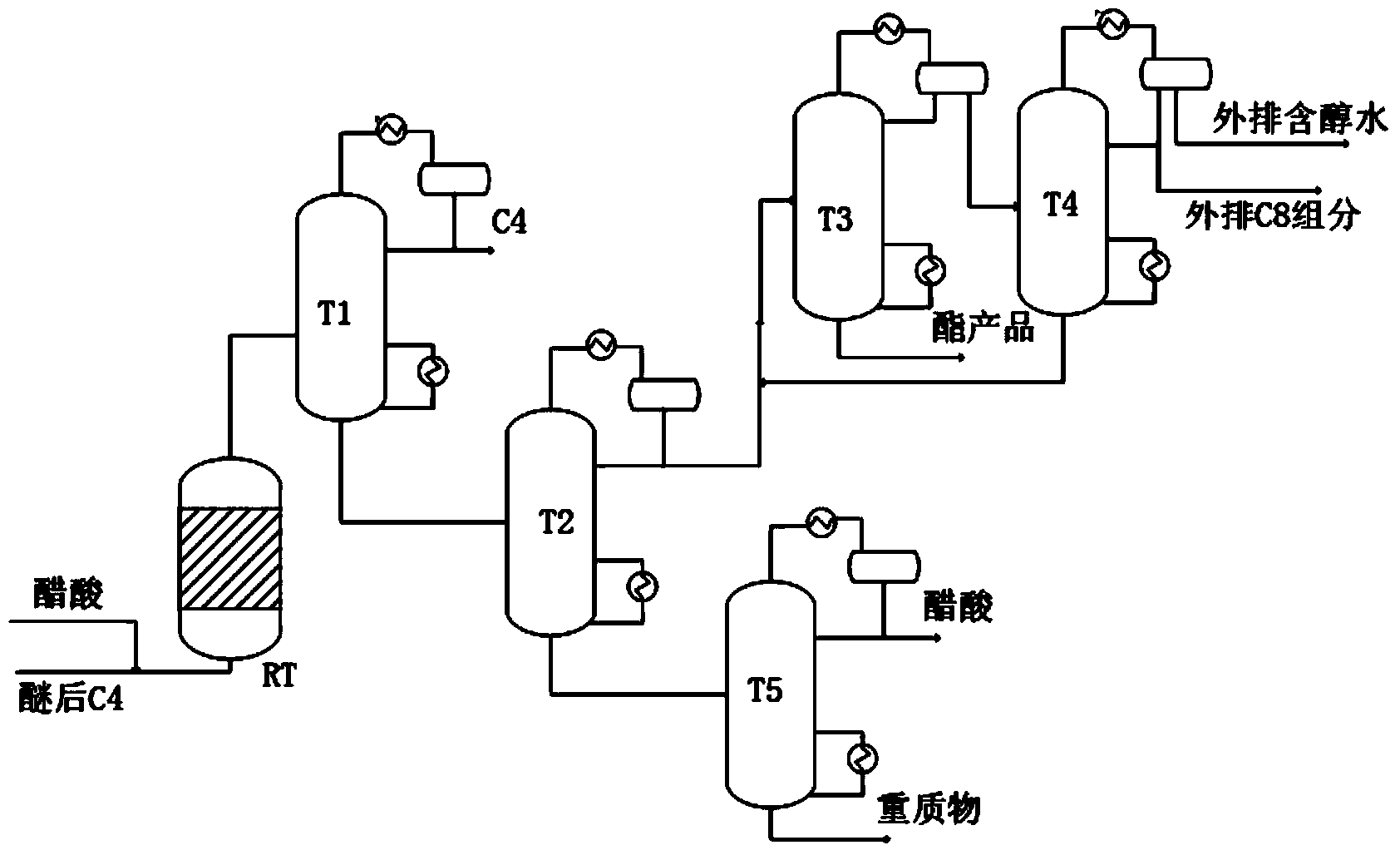

Method for recycling acetic acid sec-butyl ester from reaction product during preparation of acetic acid sec-butyl ester with high efficiency

ActiveCN103980115AIncrease concentrationReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic acid ear

The invention provides a method for recycling acetic acid sec-butyl ester from a reaction product during preparation of the acetic acid sec-butyl ester with high efficiency. The method for recycling the acetic acid sec-butyl ester from the reaction product during preparation of the acetic acid sec-butyl ester with high efficiency comprises the following steps: directly feeding acetic acid sec-butyl ester material into an impurity removing azeotropic tower, wherein the acetic acid sec-butyl ester material is discharged outside as byproduct from the top of an ester product purification tower and contains water, C8 olefin and sec-butyl alcohol impurities, removing water, C8 olefin and part sec-butyl alcohol which are contained in the acetic acid sec-butyl ester material at the top of the impurity removing azeotropic tower while the contained water is taken as entrainer, and feeding a product at the bottom of the tower into an ester product refining tower for recycling. The method for recycling the acetic acid sec-butyl ester from the reaction product during preparation of the acetic acid sec-butyl ester with high efficiency has the advantages of simple process, low energy consumption, high separation efficiency, and more than 92% of the acetic acid sec-butyl ester in the byproduct can be recycled.

Owner:HUNAN RUIYUAN PETROCHEM

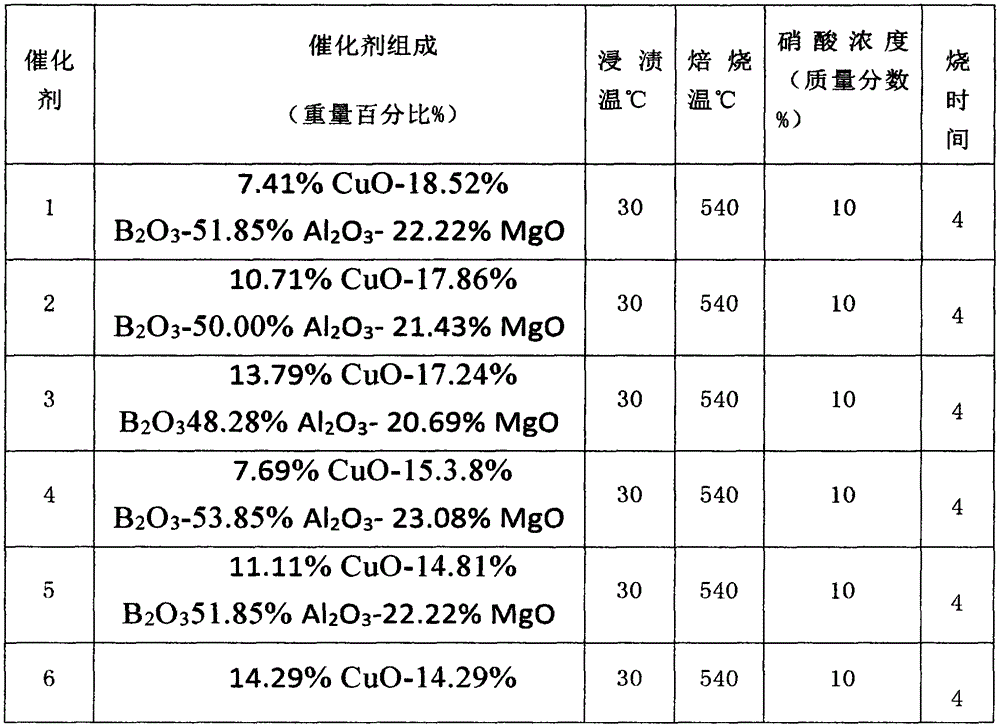

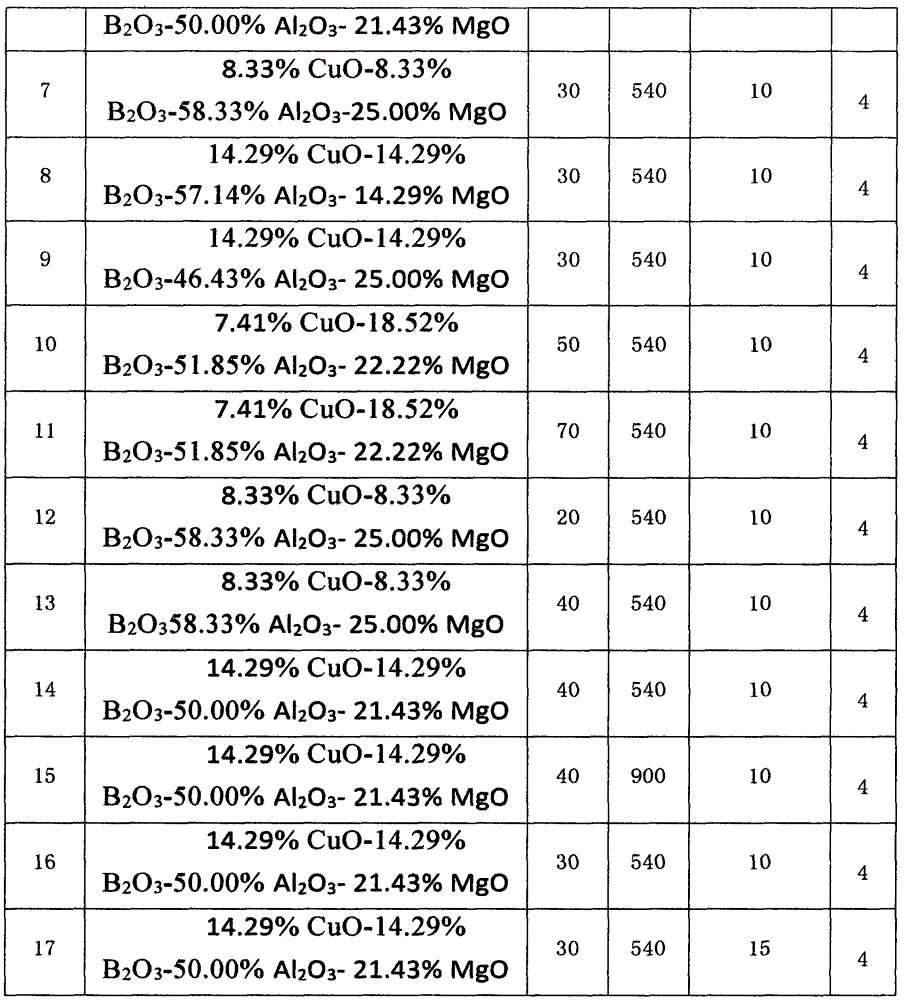

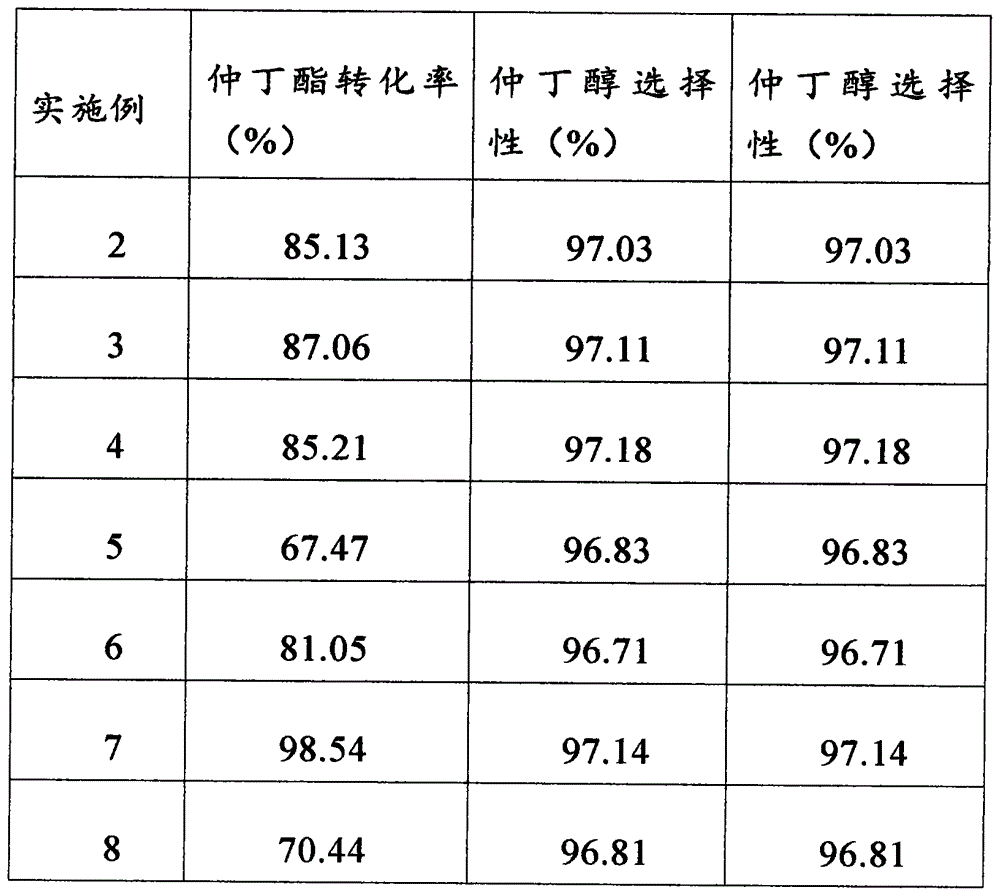

Catalyst for preparing sec-butyl alcohol and preparation method of catalyst

InactiveCN104475109AGood activity and stabilityHigh selectivityOrganic compound preparationHydroxy compound preparationReaction rateBoric acid

The invention relates to a catalyst for preparing sec-butyl alcohol and a preparation method of the catalyst. The catalyst is prepared from the following raw materials by weight percent: 5.0 to 25.0 percent of CuO, 5.0 to 25.0 percent of B2O3, 40.0 to 70.0 percent of Al2O3 and 15.0 to 35.0 percent of at least one of MgO, CaO or K2O. The preparation method of the catalyst comprises the following steps: mixing the at least one of MgO, CaO or K2O with Al2O3 powder to obtain a mixture; extruding and molding the mixture, drying, roasting the mixture to obtain a needed carrier (I); immersing the surface of the carrier (I) by utilizing a boric acid solution, drying the carrier, and roasting the carrier at a high temperature to obtain a modified carrier (II) of the catalyst; and finally immersing the surface of the modified carrier (II) by utilizing a Cu(NO)2 solution, drying, and roasting the modified carrier at high temperature to obtain the needed catalyst. The catalyst is good in activity stability and capable of increasing the yield and conversion ratio of the sec-butyl alcohol; the preparation method of the catalyst is high in selectivity, relatively high in reaction rate, moderate in reaction condition and small in corrosion performance.

Owner:BEIJING ENZE FULAI TECH +1

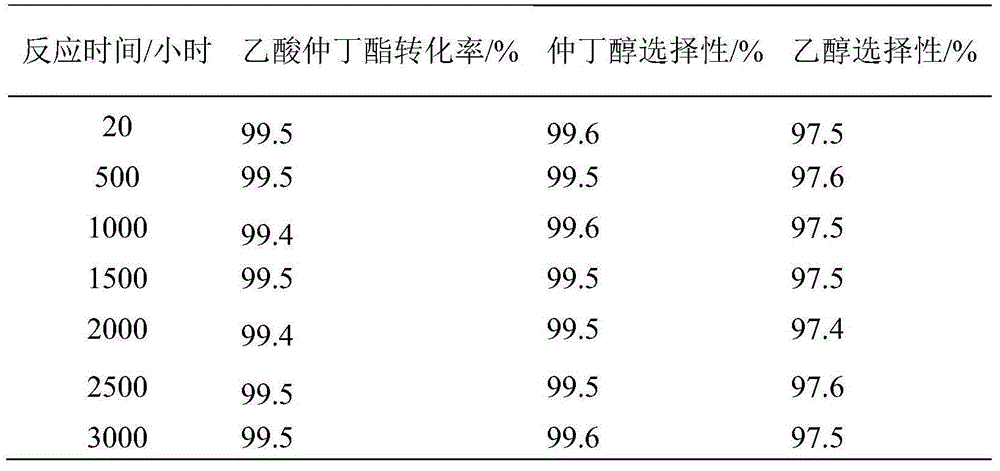

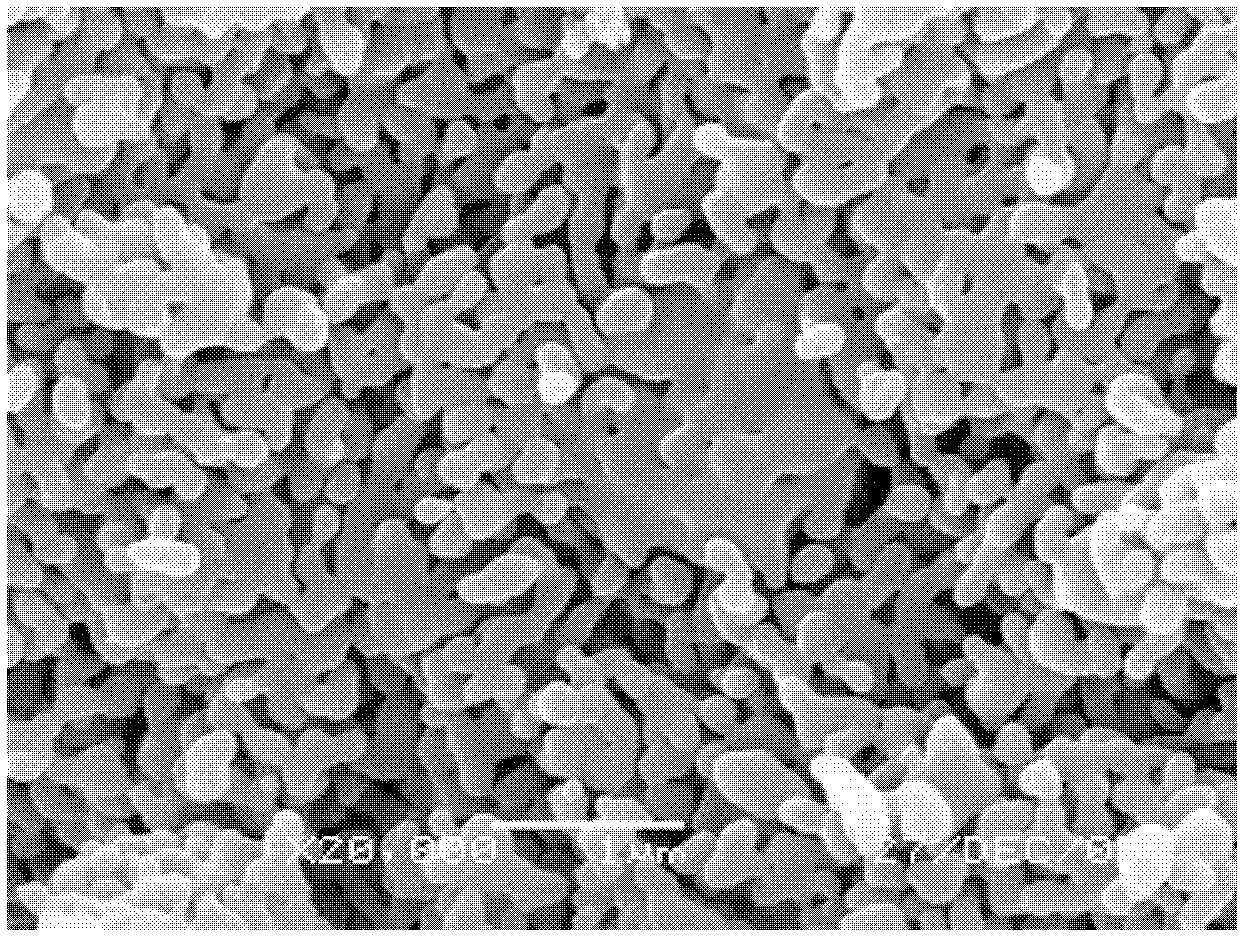

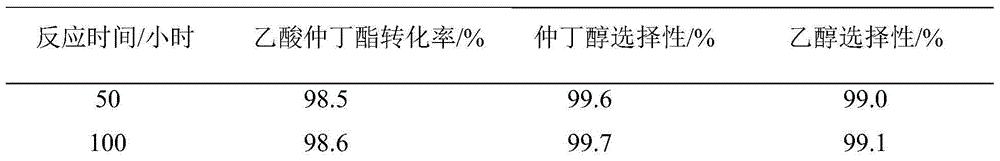

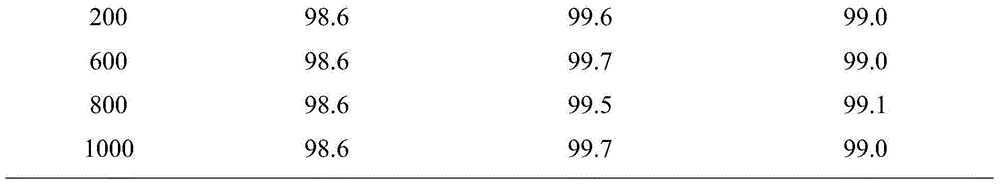

Catalyst for producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm, preparation method and application thereof

InactiveCN105032439AEasy to prepareHigh activityOrganic compound preparationHydroxy compound preparationHydrogenSec-Butyl acetate

The invention relates to a catalyst for producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm, a preparation method and application thereof, and mainly solves the problems that in the prior art, hydrogen ester is relatively high, and the product is relatively low in selectivity. Through the adoption of the technical scheme of the catalyst for producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm, the preparation method and application thereof, the problems are well solved. The catalyst contains copper or copper oxide, a second component and a third component, wherein the second component is one or more selected from ZnO, ZrO2, TiO2 and Al2O3; the third component is one or more selected from La2O3, CeO2, Fe2O3, CaO, MgO, MnO and B2O3; the mass content of copper or copper oxide in the catalyst is 20-70%; the mass content of the second component is 15-60%; the mass content of the third component is 1-40%. The catalyst can be used for co-producing sec-butyl alcohol and ethyl alcohol through sec-butyl acetate hydrogenationm.

Owner:SHANGHAI HUAYI GRP CO

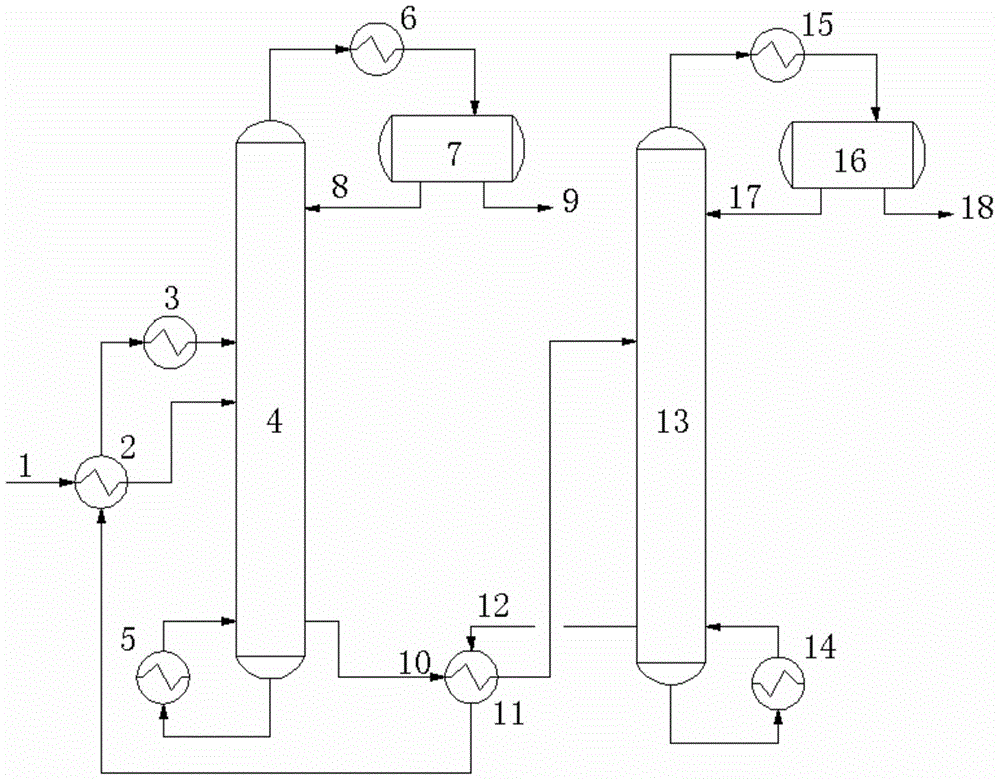

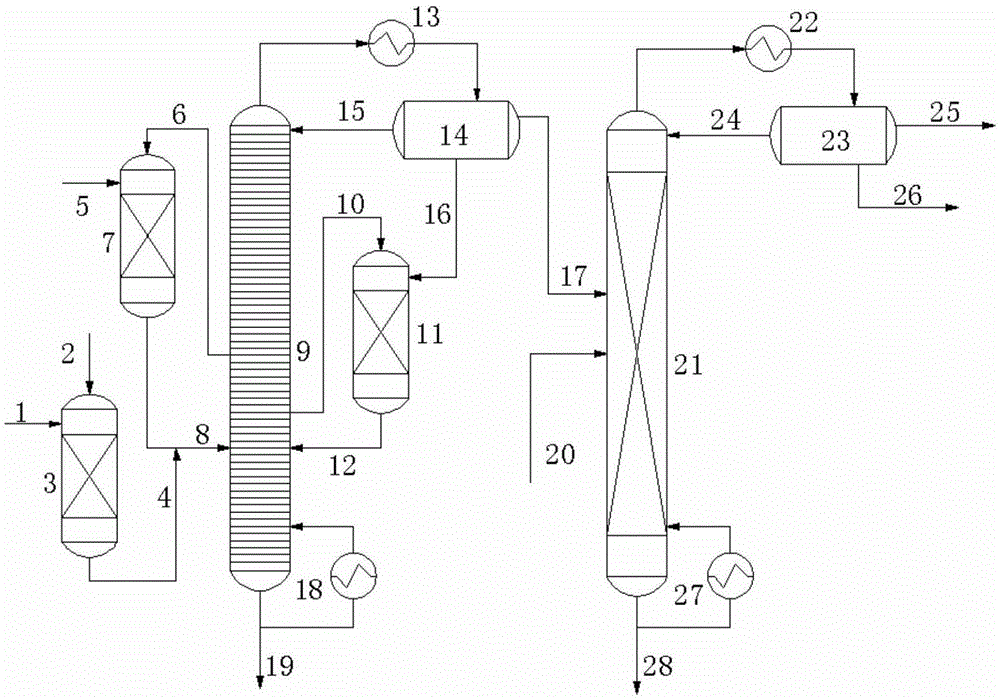

Butanone preparation and refining method

ActiveCN104370722AUniform temperature distributionHigh selectivityOrganic compound preparationPreparation by hydrogenolysisHydrogenation reactionDehydrogenation

The invention provides a butanone preparation and refining method. The method includes: (A), subjecting sec-butyl acetate and hydrogen to hydrogenation reaction in a fixed-bed reactor filled with hydrogenation catalyst; (B), feeding a hydrogenation product obtained in the step (A) into a crude alcohol separating tower for separation so as to obtain crude ethanol at the tower top, and feeding tower bottom components into a sec-butyl alcohol refining tower for refining; (C), preheating high-purity sec-butyl alcohol obtained at the tower top of the sec-butyl alcohol refining tower prior to feeding the preheated high-purity sec-butyl alcohol into a dehydrogenation reactor filled with dehydrogenation catalyst for dehydrogenation reaction; (D), feeding a dehydrogenation product obtained in the step (C) into a butanone drying tower via a buffer tank, supplementing entrainer from the top of a return tank, and removing water in crude butanone by means of azeotropic distillation; (E), feeding the dewatered crude butanone in the step (D) into a butanone refining tower for distillation so as to obtain butanone with the mass fraction above 99% from the top of the butanone refining tower.

Owner:HUNAN RUIYUAN PETROCHEM

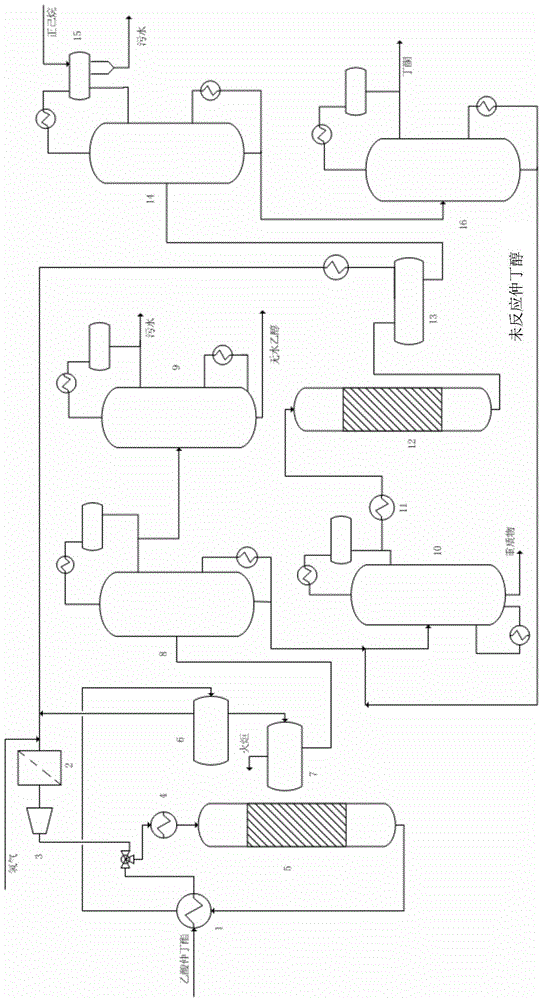

Method for preparing SBA(sec-butyl alcohol) through hydrolysis with sec-butyl acetate

ActiveCN106631684AHigh puritySimple processOxygen-containing compound preparationOrganic compound preparationRefluxSec-Butyl acetate

A method for preparing sec-butyl alcohol through hydrolysis with SBA(sec-butyl alcohol)comprises steps as follows: (1) SBA is sent to a first hydrolysis reactor to react after being mixed with water; (2) a mixture after the reaction is sent to the lower part of a deacidification tower for separation, and separated acetic acid falls into the tower bottom; (3) a strand of material is extracted out of an SBA enrichment area of the deacidification tower and sent to an SBA refinement tower, an entrainer and water are added, an azeotrope formed by water, sec-butyl acetate and part of SBA is evaporated to the tower top, one part of oil phase is subjected to reflux after condensation layering, the other part returns to a reaction system for recycling with an aqueous phase, most of SBA falls into the tower bottom, and the SBA product is produced from the tower bottom. The SBA separated with the method has the purity of 99% or above, the purity of acetic acid separated by the deacidification tower is 97% or above, the yield of SBA is 70% or above, meanwhile, the method adopts a simple process and is simple to operate, and energy consumption is lower.

Owner:HUNAN ZHONGCHUANG CHEM

Method and device for separating acetic acid sec-butyl ester and sec-butyl alcohol

InactiveCN105111079AEasy to separateFulfil requirementsOrganic compound preparationCarboxylic acid esters preparationAcetic acidSolvent

The invention provides a method and device for separating acetic acid sec-butyl ester and sec-butyl alcohol. The method comprises the steps that 1, a mixture of the acetic acid sec-butyl ester and the sec-butyl alcohol is put into an extraction rectifying tower, an extraction agent is added, after extraction rectifying separation is performed, the acetic acid sec-butyl ester is steamed out from the tower top and condensed, then part of the acetic acid sec-butyl ester is used for reflux, part of the acetic acid sec-butyl ester is extracted to obtain the acetic acid sec-butyl ester, and a mixture of the sec-butyl alcohol and the extraction agent falls into the tower bottom; 2, the mixture of the sec-butyl alcohol and the extraction agent is extracted out from the tower bottom and then put into a solvent concentration tower, the sec-butyl alcohol is steamed out from the tower top and then condensed, then part of the sec-butyl ester is put into the solvent concentration tower for reflux, part of the sec-butyl ester is extracted to obtain the sec-butyl ester, and the extraction agent falls into the tower bottom; 3, the extraction agent is extracted out from the tower bottom and then returns to the extraction rectifying tower for cyclic utilization. According to the method, the problem that in the prior art, the acetic acid sec-butyl ester and the sec-butyl alcohol are difficult to separate is solved, the purity of the separated acetic acid sec-butyl ester is above 99 percent, and the purity of the separated sec-butyl ester is above 99.9 percent; meanwhile, the energy consumption of the separation process is low, the procedures are simple, and operation is easy.

Owner:HUNAN ZHONGCHUANG CHEM

Catalyst for preparing methyl ethyl ketone through dehydrogenation of sec-butyl alcohol and preparation method thereof

InactiveCN103599786ASimple preparation processImprove conversion rateOrganic compound preparationCarbonyl compound preparationActive componentPotassium

The invention relates to a catalyst for preparing methyl ethyl ketone through the dehydrogenation of sec-butyl alcohol and a preparation method thereof. The catalyst takes CuO and SiO2 as active components, and takes M2O as a modifier; and the catalyst comprises the following components in percentage by mass: 50-68% of CuO, 9.5-30% of SiO24, and 0.1%-10% of M2O. The preparation method of the catalyst comprises the following steps: firstly, preparing a Cu / SiO2 catalyst by using a coprecipitation method, and forming the Cu / SiO2 catalyst by tabletting; and then, soaking the catalyst by using a potassium or sodium salt solution, and drying and roasting the catalyst so as to obtain the modified catalyst. The catalyst disclosed by the invention is simple in preparation process; and when the catalyst is applied to a process for preparing methyl ethyl ketone through the dehydrogenation of sec-butyl alcohol, a high conversion rate of sec-butyl alcohol is kept, and the selectivity of methyl ethyl ketone is further improved.

Owner:DAQING ZHONGLAN PETROCHEMICAL CO LTD +1

Preparation method for 5-hydroxymethylfurfural

The invention discloses a preparation method for 5-hydroxymethylfurfural. The preparation method is characterized by comprising the steps of mixing fructose, glucose or saccharose and dimethylsulfoxide, n-butyl alcohol, sec-butyl alcohol, cyclohexanol, 1,4-dioxane, polyethylene glycol 400 or acetonitrile according to the mass volume ratio of 1g: (5-10ml) and stirring; performing heating reaction in the presence of a solid acidic catalyst FeCl3.6H2O / C, and concentrating and purifying reaction liquid to obtain a product 5-hydroxymethylfurfural. Compared with the prior art, the preparation method disclosed by the invention has the characteristics of simple technology, convenient operation, low production cost, high yield and mild reaction conditions; the use of high-toxicity chemical raw materials is avoided, and the environment cannot be polluted; furthermore, the catalyst is low in price, readily available and high in efficiency and can be recycled for multiple times; environment protection aims of environment friendliness, low carbon, low price, ready availability and circulating sustainable development are fulfilled; and the preparation method is particularly suitable for industrial large-scale production.

Owner:EAST CHINA NORMAL UNIV

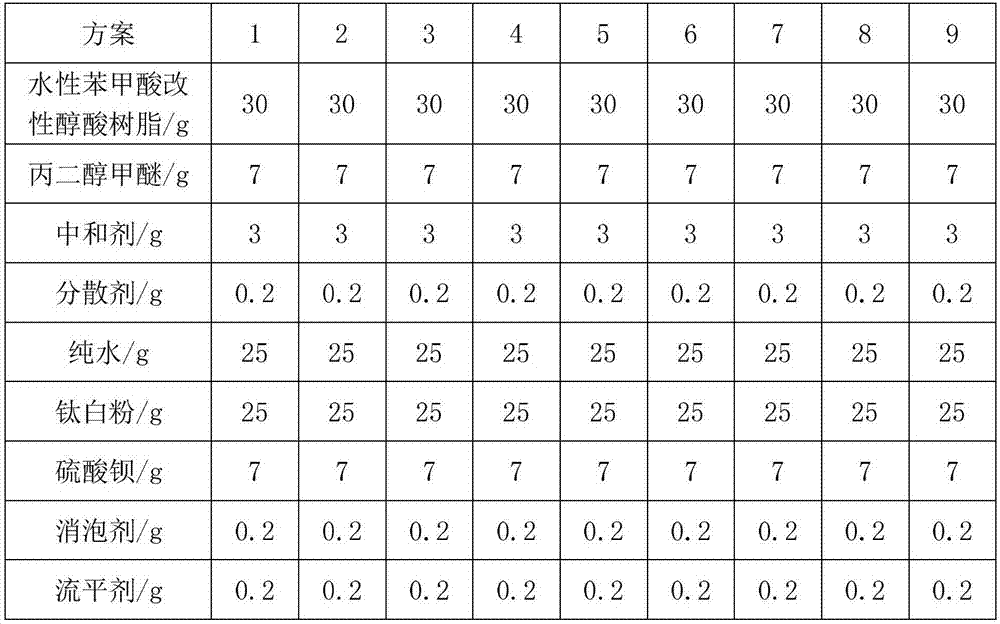

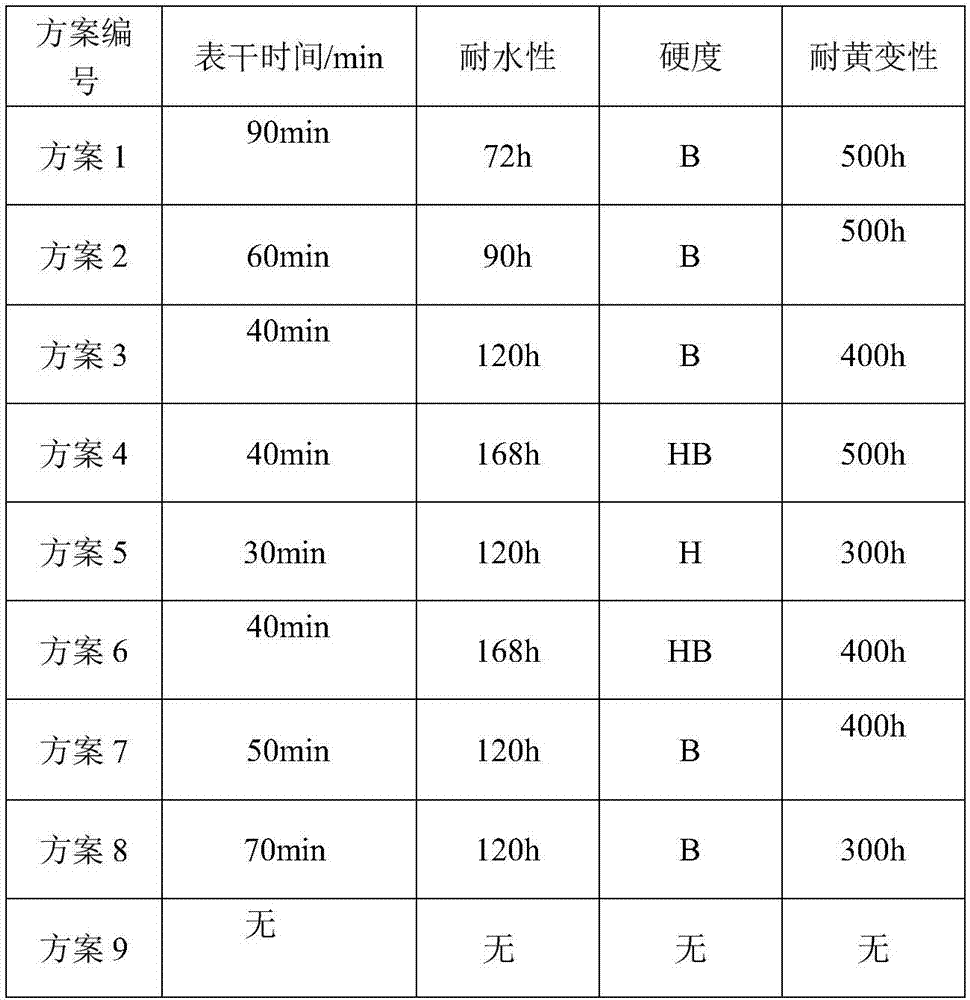

Water-based benzoic acid modified alkyd resin for air-dry paint and preparation method of water-based benzoic acid modified alkyd resin

InactiveCN106978049AFast dry timeImprove water resistanceEmulsion paintsPolyester coatingsWater basedBenzoic acid

The invention provides water-based benzoic acid modified alkyd resin for an air-dry paint and a preparation method of the water-based benzoic acid modified alkyd resin and belongs to the technical field of paints. The water-based benzoic acid modified alkyd resin is prepared from the following raw materials of oleic acid, benzoic acid, polyhydric alcohol, polybasic acid, a catalyst, trimellitic anhydride, ethylene glycol butyl ether and sec-butyl alcohol at the mass ratio of (20-35):(5-20):(20-30):(15-30):(0.01-0.05):(4-10):(8-12):(6-8), wherein the oleic acid is any one or more of soya oil acid, tall oil acid, linoleic acid, linseed oil acid, calophyllum inophyllum oleic acid and dehydrated ricinolic acid. According to the water-based benzoic acid modified alkyd resin for the air-dry paint and the preparation method of the water-based benzoic acid modified alkyd resin, the prepared water-based benzoic acid modified alkyd resin has the beneficial effects of short surface drying time, high hardness and excellent water resistance and yellowing resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Methyl ethyl ketone preparation method

InactiveCN102992984AImprove conversion rateHigh selectivityOrganic compound preparationCarbonyl compound preparationDehydrogenationSec-Butyl acetate

The invention relates to a methyl ethyl ketone preparation method. The method comprises the following steps: 1, carrying out an ester exchange reaction of sec-butyl acetate and low carbon alcohol in a catalytic rectifying tower in the presence of an ester exchange catalyst, wherein the low carbon alcohol is C1-C3 alcohol; and 2, carrying out a dehydrogenation reaction of the tower bottoms obtained in step 1 or sec-butyl alcohol separated from the tower bottoms obtained in the step 1 in the presence of a dehydrogenation catalyst. The method which allows sec-butyl alcohol to be prepared through using the sec-butyl acetate and the low carbon alcohol has the advantages of high raw material conversion rate and high sec-butyl alcohol selectivity.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Method for synthesizing cane sugar-6-acetic ester by using lipase for catalyzing

The invention discloses a method for synthesizing a cane sugar-6-acetic ester by using lipase for catalyzing. The method comprises the following steps of: based on 72,000 to 150,000 enzyme activity unit enzyme in 100 ml buffer solution, adding the lipase into buffer solution with a pH value of between 8.1 and 8.7 to obtain enzyme solution; adding an organic solvent into the enzyme solution; adding cane sugar until the cane sugar in reaction solution is saturated; stirring until the cane sugar is solved and adding an acetic ester compound; reacting at the temperature of between 40 and 65 DEG C with stirring; adding the acetic ester compound after reacting for 11 to 13 hours; ending an reaction after reacting totally for 23 to 25 hours; and washing the reaction product with distilled water, decompressing and distilling to obtain cane sugar-6-acetic ester, wherein the acetic ester compound is vinyl acetate or isopropenyl acetate; the volume ratio of the enzyme solution to the organic solvent is 0.1-1:100; and the organic solvent is tertiary amyl alcohol, sec-butyl alcohol or tetrahydrofuran. The organic solvent is selected and the water content of a reaction system is less than 1.0 percent, so that the purity of the obtained high-purity cane sugar-6-acetic ester is over 75 percent, and 99 percent in maximum.

Owner:ZHEJIANG UNIV OF TECH

Process for treating tail gases of methyl ethyl ketone unit

ActiveCN106669375ALow investment costReduce energy consumptionMembranesDispersed particle separationFiberButene

The invention discloses a process for treating tail gases of a methyl ethyl ketone unit. The process comprises the following steps: performing dehydration and dust extraction treatment on the tail gases of the methyl ethyl ketone unit, so that the content of micro dust in the treated tail gases is less than or equal to 0.01mg / Nm<3>, and the moisture content is less than or equal to 1PPm; enabling the treated tail gases to enter a membrane reactor under the conditions of 0.1-1.0MPa and 40-100 DEG C, wherein the gas inlet speed is 0.5-5m / s, and a membrane material filled in the membrane reactor is a hollow fiber composite organic membrane; separating osmotic gas enriched in butane and permeation residue gases enriched in alcohols, ethers and methyl ethyl ketone, enabling the osmotic gas to return to a sec-butyl alcohol section to serve as a raw material, enabling one part of the permeation residue gases to return to the membrane reactor so as to be further purified, and recovering the alcohols, ethers and methyl ethyl ketone from the other part of the permeation residue gases. The method has the advantages of high efficiency, low energy consumption and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

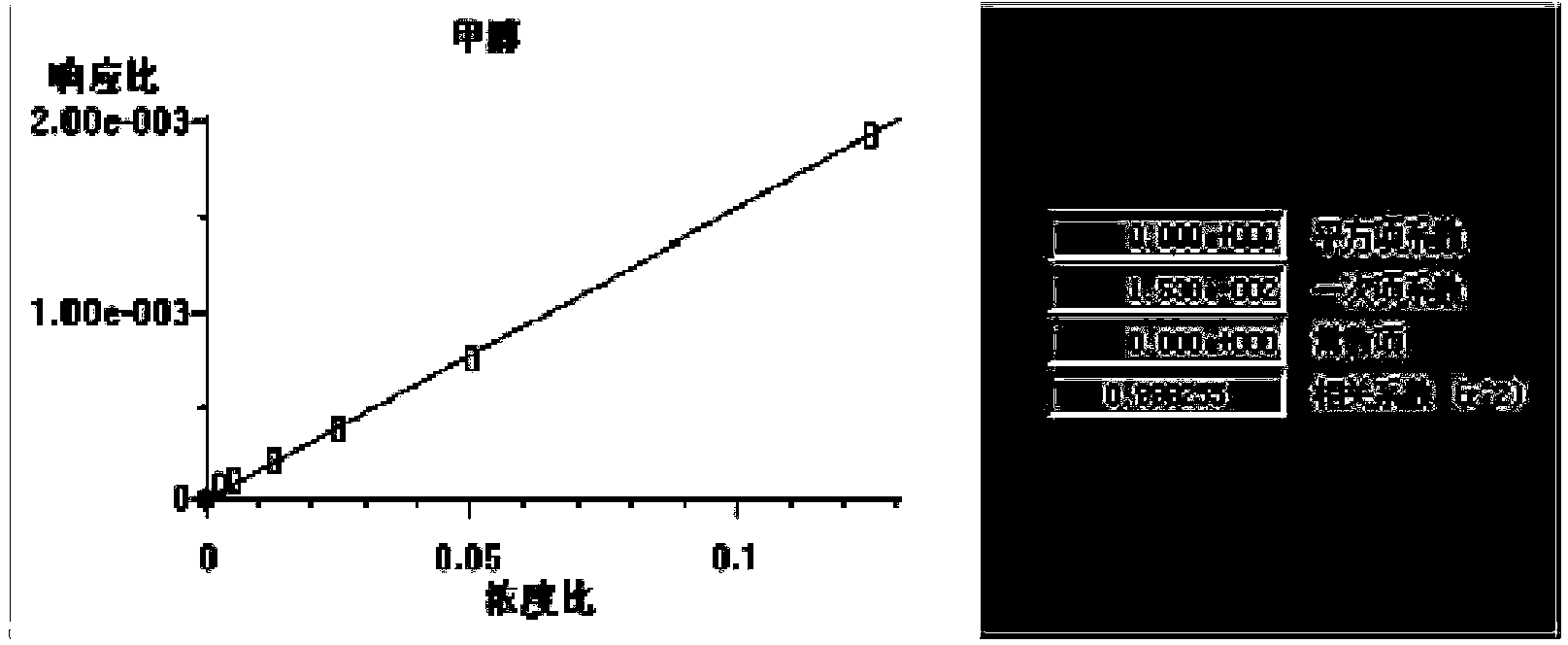

Method for detecting seven prohibited compounds in flavors and fragrances

ActiveCN103869039AEfficient detection methodModerate polarityComponent separationChemical industrySolvent

The invention discloses a method for detecting seven prohibited compounds in flavors and fragrances. The seven prohibited compounds are methanol, sec-butyl alcohol, safrole, imidazole, coumarin, musk xylene and sesamol. The detection method can accurately and rapidly detect the contents of the seven prohibited compounds in flavors and fragrances, is suitable for quality safety control of fragrance raw liquid and auxiliary solvents in the industries such as food, daily-use chemical industry, tobacco and pharmacy, and the has the characteristics of simple operation, rapidness, accuracy, good repeatability, high sensitivity and the like.

Owner:CHINA TOBACCO FUJIAN IND +1

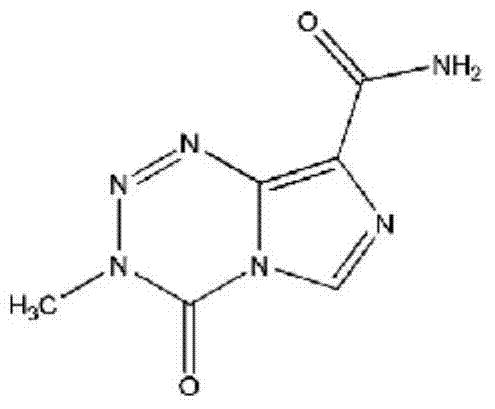

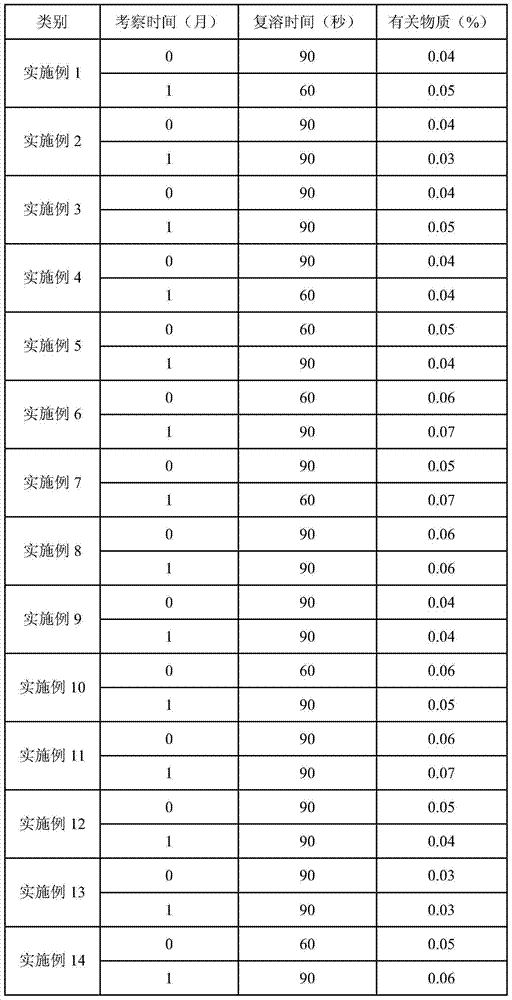

Temozolomide lyophilized powder preparation and preparation method thereof

ActiveCN104721155AReduce adverse reactionsLow toxicityOrganic active ingredientsPowder deliveryDissolutionBULK ACTIVE INGREDIENT

The invention belongs to the technical field of pharmaceutical preparations and specifically relates to a temozolomide lyophilized powder preparation. The temozolomide lyophilized powder preparation comprises an active ingredient of temozolomide or a pharmaceutically acceptable salt thereof, and a solution before lyophilization further contains an excipient, a wetting agent, a buffer agent, an osmotic pressure regulating agent, a pH regulating agent, water for injection and an organic solvent, wherein the organic solvent is selected from one or any combination of ethanol, acetone, isopropanol, n-propanol, butanone, sec-butyl alcohol and methanol, and is preferably ethanol. The temozolomide lyophilized powder preparation provided by the invention has the advantages of stable quality, high re-dissolution speed and a small residual amount of the organic solvent. The invention further provides a method for preparing the preparation. The process provided by the invention is simple and convenient in preparation process and easy to control production links, the organic solvent accounts for a relatively small part of total volume of material liquid, the pollution to production equipment and environment caused by the organic solvent is reduced, and thus the method is suitable for large-scale production.

Owner:QILU PHARMA HAINAN

Method for preparing sec-butyl alcohol

ActiveCN106631699AImprove conversion rateMeet material requirementsOrganic compound preparationPreparation by hydrolysisSec-Butyl acetateSec-butyl alcohol

The invention provides a method for preparing sec-butyl alcohol. The method comprises the steps of (1) mixing sec-butyl acetate and water, then putting the mixture into a hydrolysis reactor, and carrying out hydrolysis reaction so as to obtain a mixture of the sec-butyl alcohol, the water and the sec-butyl acetate; (2) after the reaction is finished, sending the obtained mixture to the lower part of a deacidification tower, and enabling separated acetic acid to fall into the bottom of the tower; (3) sending a mixture of the sec-butyl acetate and the sec-butyl alcohol to a sec-butyl alcohol refining tower, adding an entrainer water, enabling an azeotrope of the water, the sec-butyl acetate and part of the sec-butyl alcohol to be evaporated to the top of the tower, carrying out condensation and then enabling a product to be recycled back to a reaction system so as to enable most sec-butyl alcohol to fall into the bottom of the tower, and collecting the sec-butyl alcohol from the bottom of the tower to obtain a product sec-butyl alcohol. After the method is used for preparing the sec-butyl alcohol, the single-pass conversion rate of the sec-butyl acetate is 60% or above, the separated sec-butyl alcohol is high in purity, and the purity reaches 99% or higher; furthermore, the purity of the acetic acid obtained at the bottom of the deacidification tower is also higher and reaches 96% or higher; the yield of the sec-butyl alcohol separated by the method is higher and reaches 65% or above. The method is simple in process and operation, and lower in energy consumption.

Owner:HUNAN ZHONGCHUANG CHEM

Preparation method of ethylene glycol monoacetate and ethylene glycol diacetate

ActiveCN103183609ALow priceIncrease valuePreparation by ester-hydroxy reactionBulk chemical productionChemical reactionSynthesis methods

The invention discloses a preparation method of ethylene glycol monoacetate and ethylene glycol diacetate. The preparation method is to take sec-butyl acetate and ethylene glycol as raw materials, perform transesterification in the presence of a base catalyst to prepare ethylene glycol monoacetate and ethylene glycol diacetate, and comprises the specific steps of primary transesterification, chemical reaction equilibrium breaking of transesterification, final-phase transesterification, separation and purification of the products ethylene glycol monoacetate and ethylene glycol diacetate, and the like. The preparation method of ethylene glycol monoacetate and ethylene glycol diacetate is high in product yield, quick in reaction speed, low in power consumption, easy to separate and purify the products, low in cost and simple in technique. In addition, the synthesis method provided by the invention can prepare an important common solvent sec-butyl alcohol. The products are all required by application, so that the utilization ratio of the products is high, the three wastes are less, and the preparation method is green and environment-friendly.

Owner:深圳市飞扬特化新材料有限公司

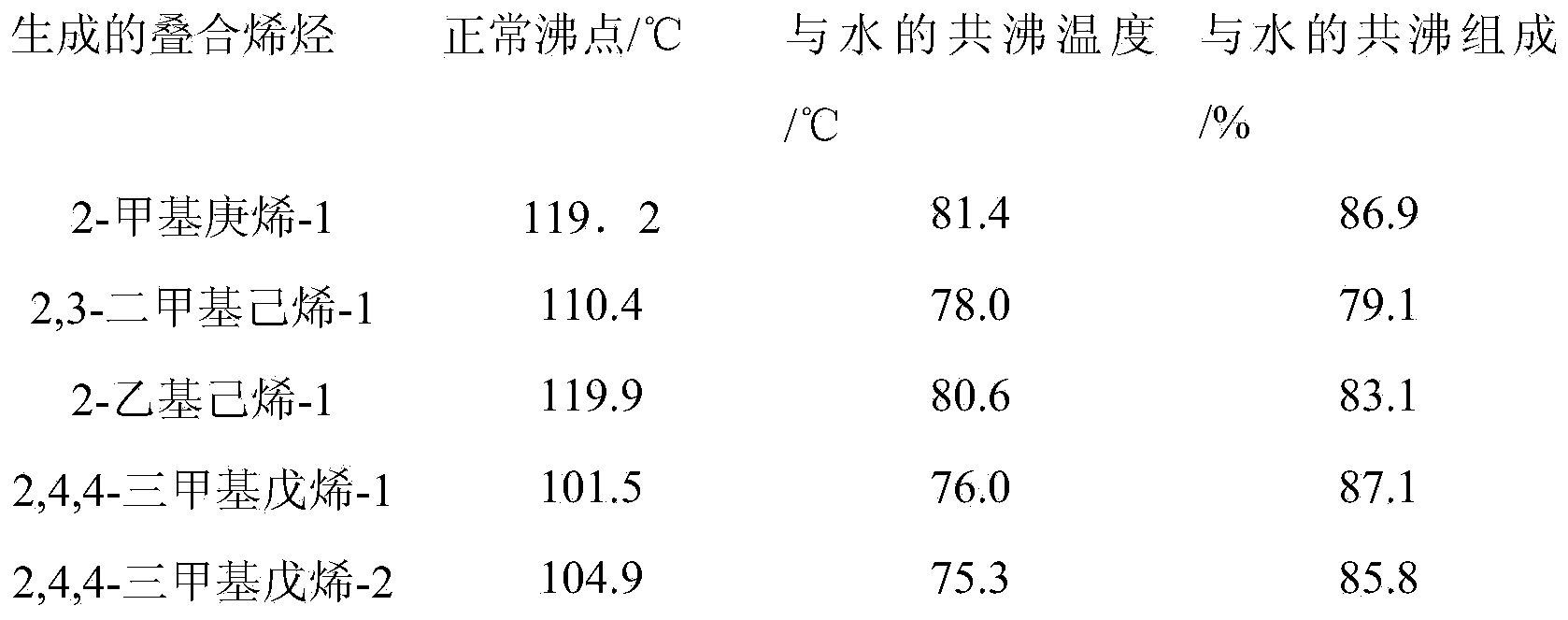

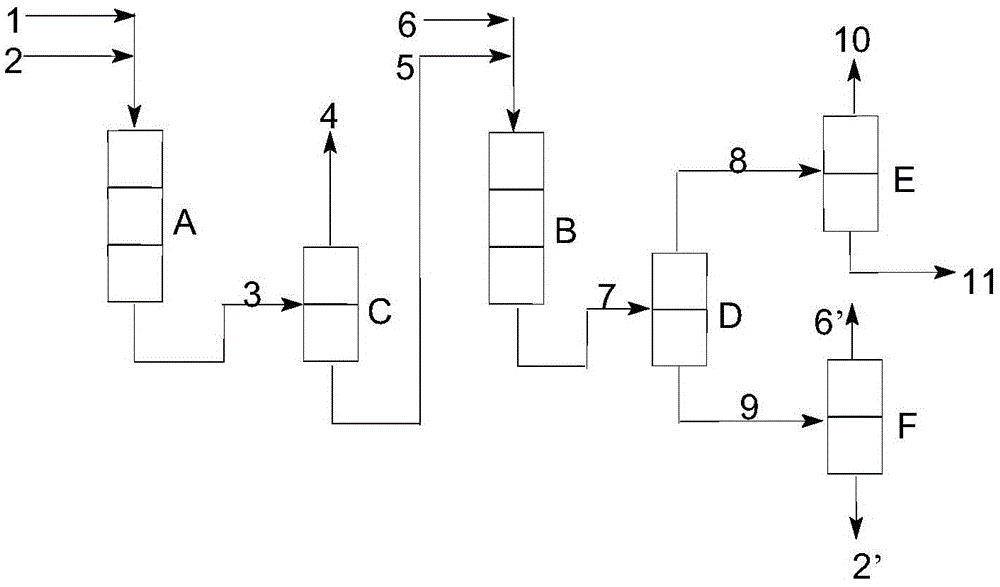

A method of comprehensively utilizing C4 fractions after etherification

InactiveCN106554275AFlexible control of sec-butyl acetateThe proportion of flexible sec-butanol productsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsEtherSec-Butyl acetate

A method of comprehensively utilizing C4 fractions after etherification is disclosed. The method includes i) a step of reacting the C4 fractions after etherification and acetic acid in the presence of a catalyst to obtain an acetic-acid-containing sec-butyl acetate crude product, ii) a step of subjecting water and the acetic-acid-containing sec-butyl acetate crude product to a hydrolysis reaction in the presence of a catalyst, and separating a mixture of sec-butyl acetate and sec-butyl alcohol from the mixture obtained by the reaction, and iii) a step of rectifying the mixture of sec-butyl acetate and the sec-butyl alcohol to obtain a sec-butyl acetate product and a sec-butyl alcohol product respectively. According to the method, the sec-butyl acetate and the sec-butyl alcohol which have high purity can be obtained, process procedures are simple, the utilization rate of the C4 fractions is increased and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Butanone preparing and refining system

ActiveCN104478676AUniform temperature distributionHigh selectivityOrganic compound preparationHydroxy compound separation/purificationRefluxDehydrogenation

The invention provides a butanone preparing and refining system which comprises a first preheater, a separator, a compressor, a second preheater, a hydrogenation reactor, a high-pressure buffer tank, a low-pressure buffer tank, a crude alcohol separation tower, a sec-butyl alcohol refining tower, an ethanol refining tower, a third preheater, a dehydrogenation reactor, a dehydrogenation reactor buffer tank, a butanone drying tower, a reflux tank and a butanone refining tower which are connected through a pipeline. In the butanone preparing and refining system provided by the invention, since the purity of raw materials is high, the temperature distribution is uniform and the material staying time is strictly controlled in the reaction of preparing sec-butyl alcohol through hydrogenation of sec-butyl acetate, an additional azeotropic agent is not needed in an ethanol dehydration tower, and the water in ethanol can be removed simply by use of the azeotropic effect of the byproduct and water; and the raw material conversion rate and sec-butyl alcohol selectivity are relatively high, few side reactions occur, the refining process is easy, and the byproduct heavy components of the two reactors are extracted from the tower kettle of the sec-butyl alcohol refining tower.

Owner:HUNAN RUIYUAN PETROCHEM

Combined technique for synthesizing iso-propylidene acetone and sec-butyl alcohol

ActiveCN103772175ABreak the reaction balanceImprove conversion rateOrganic compound preparationPreparation by hydroxy group additionPtru catalystFluid phase

The invention relates to a combined technique for synthesizing iso-propylidene acetone and sec-butyl alcohol. According to the technique, a fixed bed reactor is adopted, solid acid is used as a catalyst, feedstock includes acetone and n-butene, and acetone is subjected to condensation reaction at a catalytic reaction bed to generate iso-propylidene acetone and water; n-butene and water react to generate sec-butyl alcohol; products from the reactor are sent into a high-pressure separator after being cooled and depressurized, and unreacted n-butene is gasified, subjected to gas-liquid separation and recycled to the reactor; the liquid phase is separated to obtain corresponding substances. The technique provided by the invention provides a new method for producing MO at one step by condensation of bimolecular acetone, and can break reaction balance and improve the conversion rate so as to reduce energy consumption and the production cost of products.

Owner:CHINA PETROLEUM & CHEM CORP +1

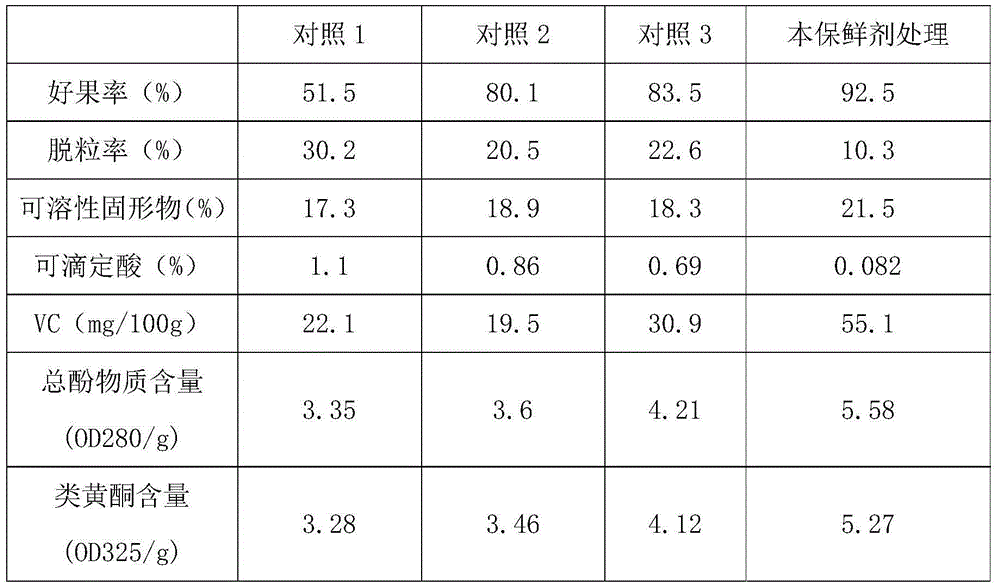

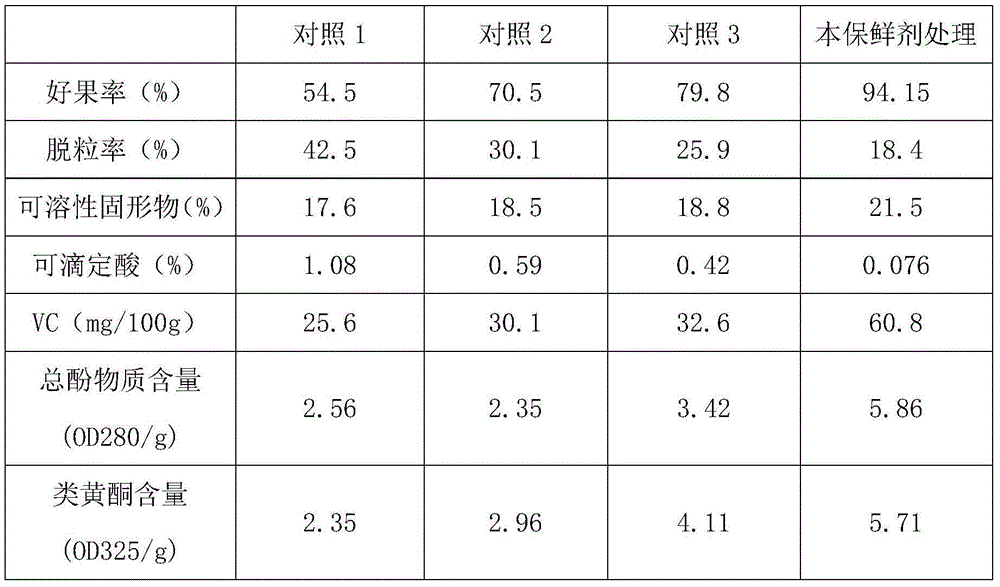

Preservative for longan and preparation method and preservation method thereof

InactiveCN104920600AEasy to storeReasonable formulaFruits/vegetable preservation by coatingAdditive ingredientEugenol

The invention provides preservative for longan and a preparation method and a preservation method thereof. The preservative for longan comprises, by weight percentage, 1-4% of fructus forsythia, 2-3% of herba houttuyniae, 1-2% of folium mori, 0.1-0.5% of clove, 0.2-0.8% of stemonae, 0.5-1.5% of lotus leaves, 1-4% of folium artemisiae argyi, 0.2-0.8% of ginkgo biloba extract, 0.5-1.5% of tea tree oil, 0.2-0.6% of eugenol, 1-1.5% of chitosan, and 0.02-0.2% of sec-butyl alcohol, 0.05-0.1% of emulgator, and the rest is water. According to the preservative for longan and the preparation method and the preservation method thereof, the formula is reasonable, the rotten degree is low, the respiratory rate is inhibited obviously, and nutritional ingredient such as VC, organic acid and soluble solid sugar can be preserved properly.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

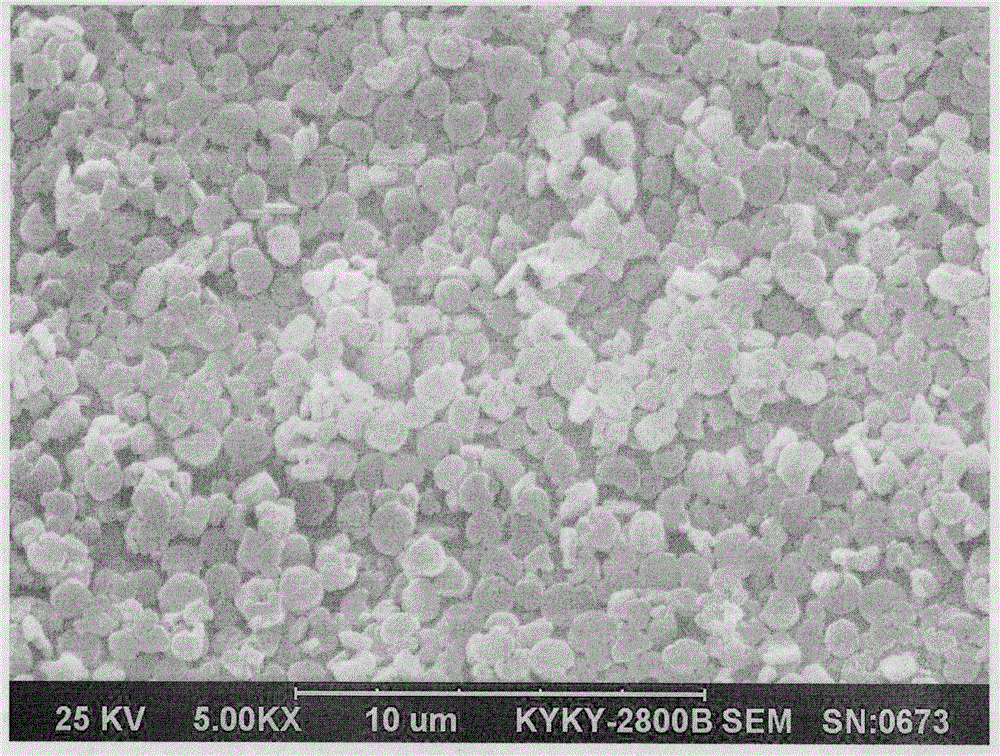

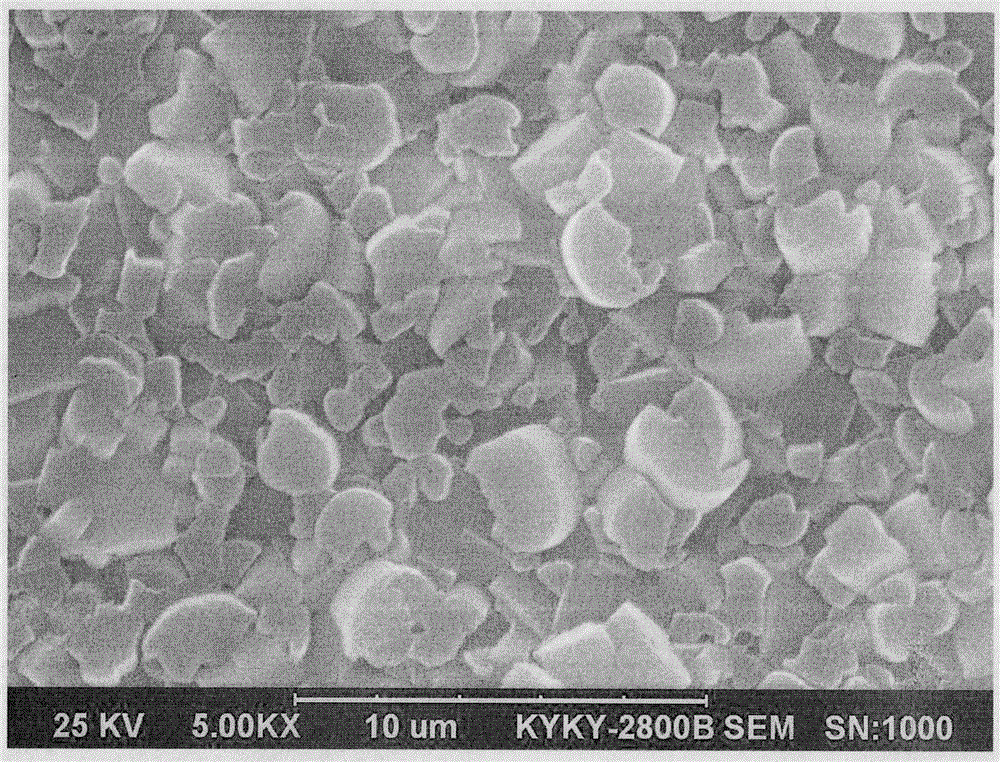

Preparation method for high-purity alumina

InactiveCN102491391AUniform hydrolysisFully hydrolyzedAluminium oxide/hydroxide preparationMetallic aluminumSapphire

A preparation method for high-purity alumina powder includes: preparing aluminum alkoxide in liquid state at the room temperature by means of reaction of metallic aluminum with sec-butyl alcohol, using the reduced pressure distillation method for purifying, and preparing the high-purity alumina powder by means of hydrolyzing, reduced pressure distillation and calcinations. Using the method to prepare high-purity alumina powder has the advantages of simple preparation process, no pollution, low energy consumption, fine operating conditions, zero emission and the like. The alumina powder prepared by the method is applicable to the field of catalysts and can also be applied to the fields of laser crystals, sapphires, transparent alumina ceramics, sodium lamps, metal halides, high-grade abrasives and the like.

Owner:DALIAN JIAOTONG UNIVERSITY

Catalyst for combined production of sec-butyl alcohol and ethanol by sec-butyl acetate hydrogenation and its preparation method and use

ActiveCN105126798AEasy to prepareHigh activityOrganic compound preparationHydroxy compound preparationHydrogenCopper oxide

The invention relates to a catalyst for combined production of sec-butyl alcohol and ethanol by sec-butyl acetate hydrogenation and its preparation method and use. The catalyst mainly solves the problem that the prior art has a high hydrogen-ester ratio and low product selectivity. The catalyst for combined production of sec-butyl alcohol and ethanol by sec-butyl acetate hydrogenation comprises copper or copper oxide, and a silica carrier and an assistant. The assistant comprises at least one of CaO, La2O3, ZnO, ZrO2, K2O, BaO, B2O3, MgO, MnO and Li2O. The catalyst comprises, by mass, 20-75% of the copper or copper oxide, 20-80% of the silica carrier and 1-40% of the assistant. The catalyst and its preparation method and use solve the above problem and can be used for combined production of sec-butyl alcohol and ethanol by sec-butyl acetate hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com