Method for recycling acetic acid sec-butyl ester from reaction product during preparation of acetic acid sec-butyl ester with high efficiency

A technology for sec-butyl acetate and reaction products, which is applied in the field of recovering sec-butyl acetate, and can solve problems such as the composition, yield and utilization of C8 olefins that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

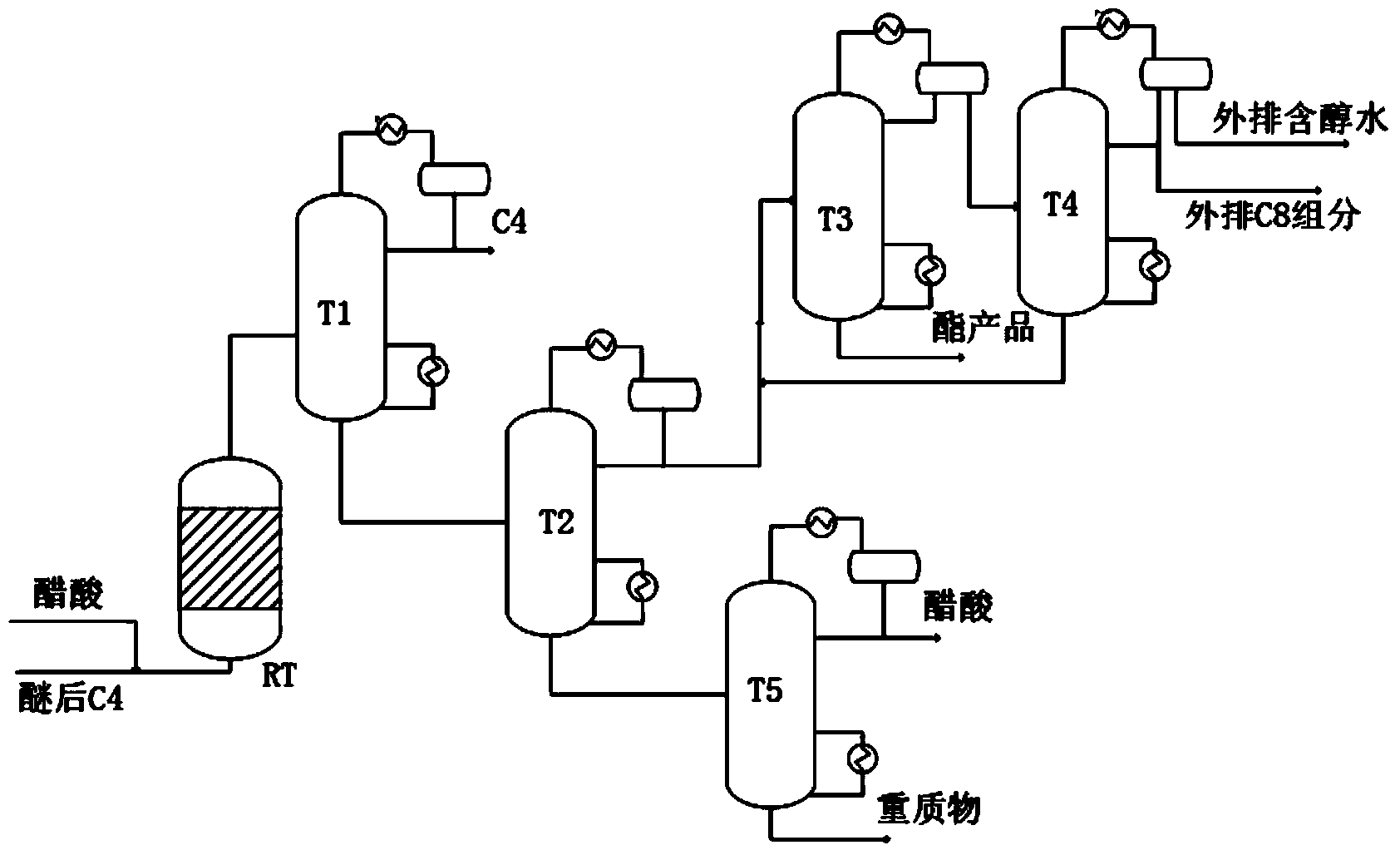

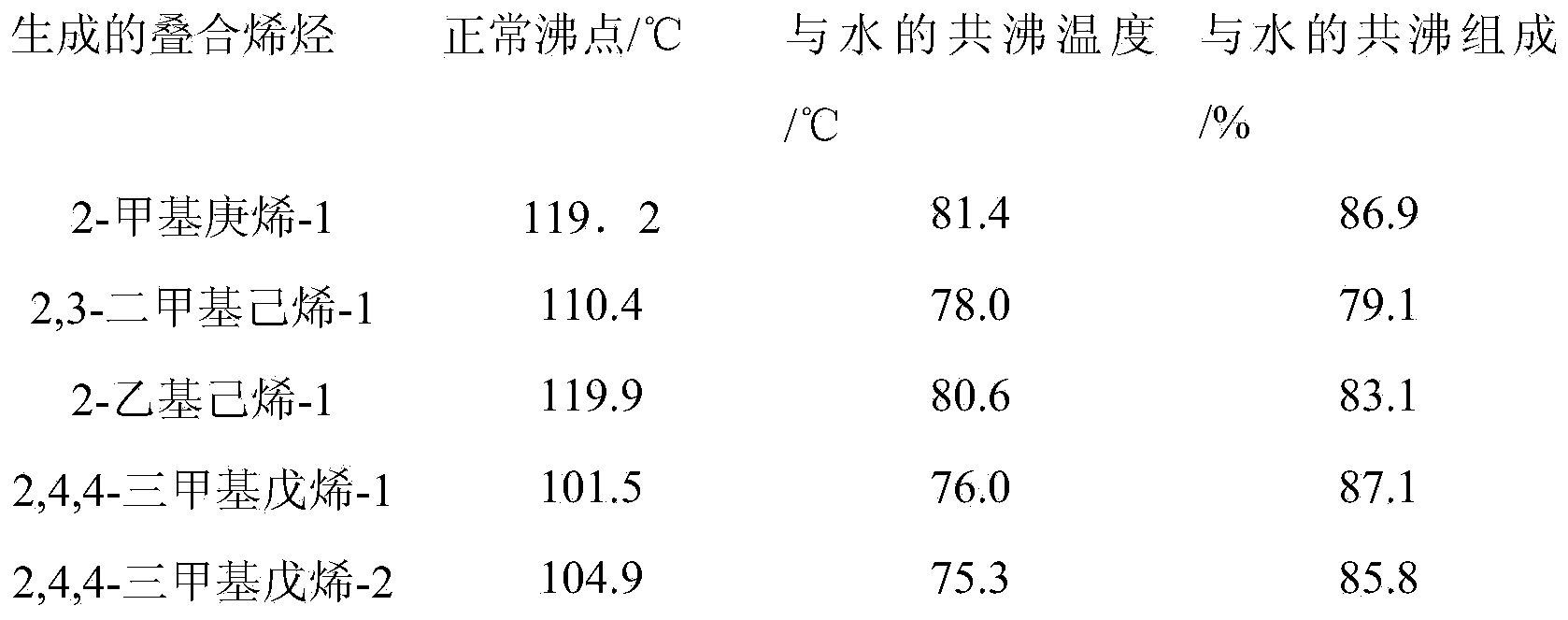

[0034] Such as figure 1 As shown, according to the similar method and process conditions of Example 1 of the patent publication CN101486640A, the same catalyst was used to react the C4 olefin mixture with acetic acid. The reaction product extracted from the outlet of the reactor RT is passed into the C4 separation tower T1 for rectification and separation. The operating conditions of T1 include operating pressure of 0.5 MPa, tower top temperature of 40°C, tower bottom temperature of 180°C, reflux ratio of 0.8, and T1’s The number of theoretical trays is 20, and C4 light components are extracted from the top of the tower, which can be returned to the C4 olefin feed pipe of the reactor. The tower bottom product that extracts at the bottom of C4 separation tower T1 tower is passed continuously in the azeotropic tower T2 together with the water as entrainer and carries out azeotropic rectification, and the operation condition of T2 comprises that operating pressure is normal press...

Embodiment 2

[0038]According to the similar method and process conditions of Example 1 of the patent publication CN101486640A, the same catalyst was used to react the C4 olefin mixture with acetic acid. The reaction product extracted from the outlet of the reactor is passed into the C4 separation tower T1 for rectification and separation. The operating conditions of T1 include operating pressure 0.5MPa, tower top temperature 40°C, tower bottom temperature 180°C, reflux ratio 0.8, T1 theory The number of trays is 20, and C4 light components are extracted from the top of the tower, which can be returned to the C4 olefin feed pipe of the reactor. The tower bottom product that extracts at the bottom of C4 separation tower T1 tower is passed continuously in the azeotropic tower T2 together with the water as entrainer and carries out azeotropic rectification, and the operation condition of T2 comprises that operating pressure is normal pressure (0.1MPa), tower The top temperature is 85°C, the bo...

Embodiment 3

[0040] According to the similar method and process conditions of Example 1 of the patent publication CN101486640A, the same catalyst was used to react the C4 olefin mixture with acetic acid. The reaction product extracted from the outlet of the reactor is passed into the C4 separation tower T1 for rectification and separation. The operating conditions of T1 include operating pressure 0.5MPa, tower top temperature 40°C, tower bottom temperature 180°C, reflux ratio 0.8, T1 theory The number of trays is 20, and C4 light components are extracted from the top of the tower, which can be returned to the C4 olefin feed pipe of the reactor. The tower bottom product that extracts at the bottom of C4 separation tower T1 tower is passed continuously in the azeotropic tower T2 together with the water as entrainer and carries out azeotropic rectification, and the operation condition of T2 comprises that operating pressure is normal pressure (0.1MPa), tower The top temperature is 85°C, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com