Catalyst for preparing sec-butyl alcohol and preparation method of catalyst

A technology of catalyst and sec-butanol, which is applied in the field of catalyst for preparing sec-butanol and its preparation, can solve the problems of cumbersome preparation method operation, low preparation efficiency, general sec-butanol yield and conversion rate, etc., and achieve simple operation process , fast reaction rate, good activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

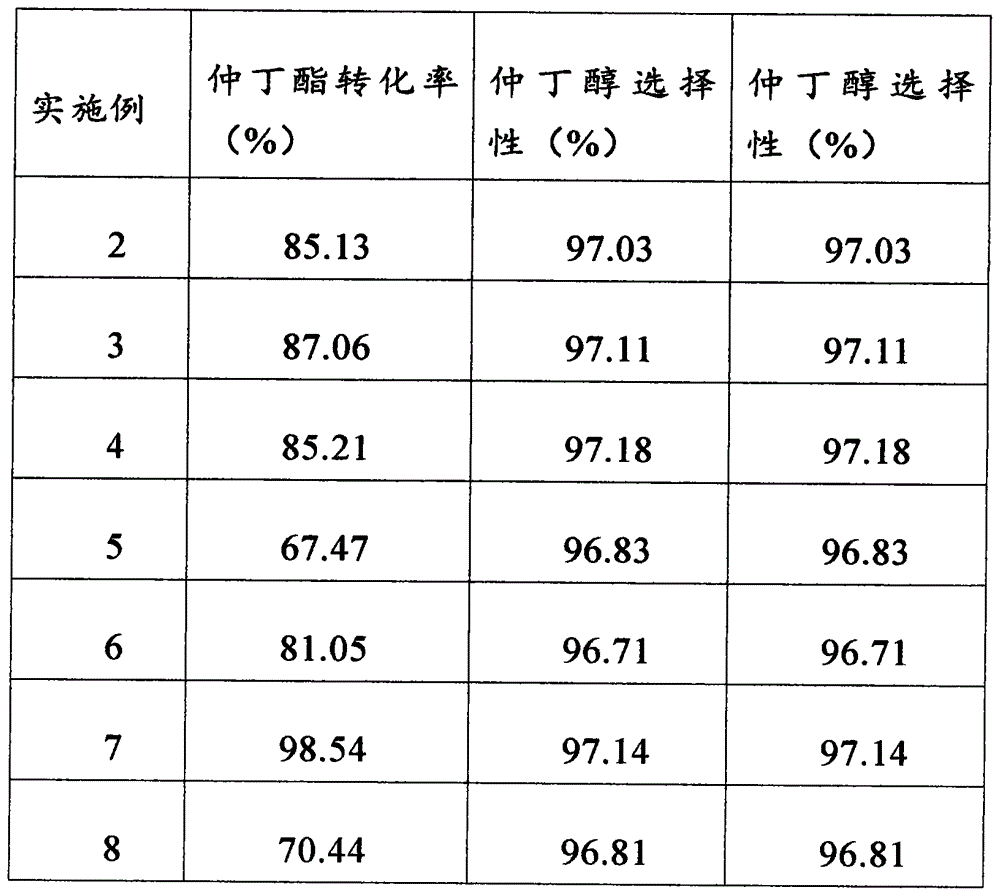

Examples

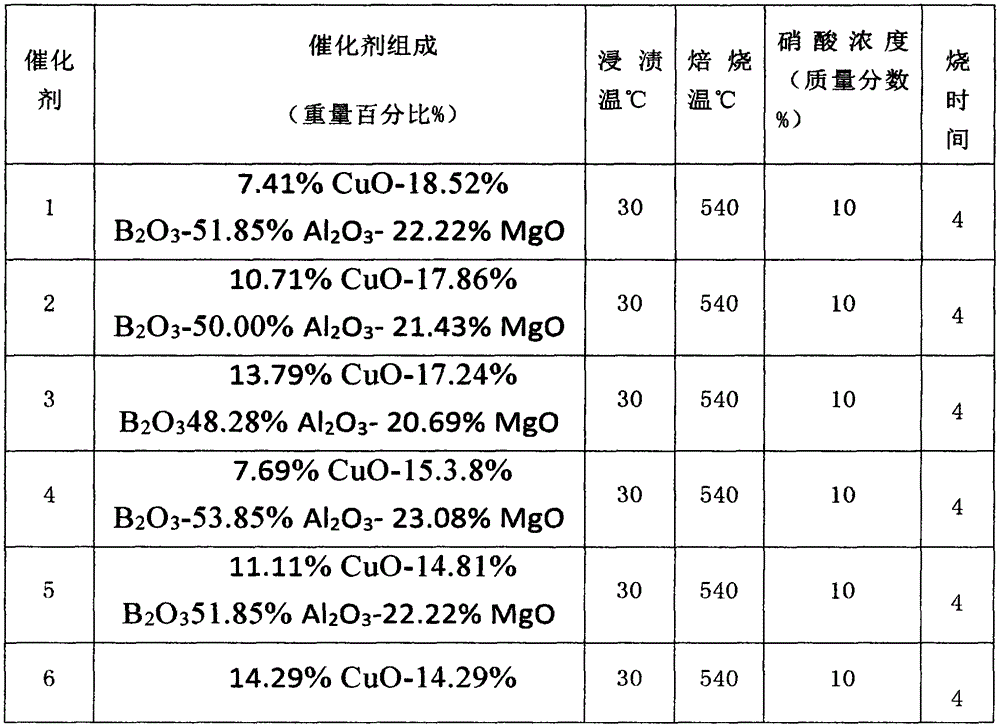

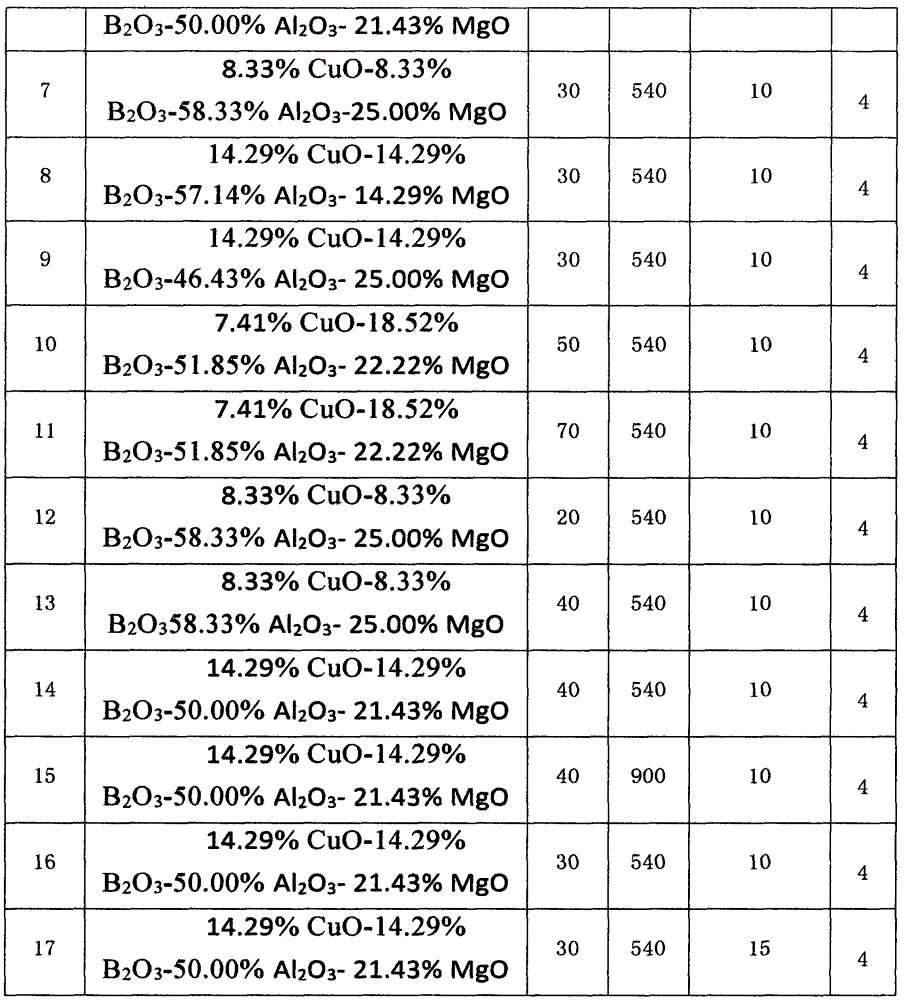

preparation example Construction

[0024] The present invention is used for the preparation method of the catalyst of sec-butanol, it may further comprise the steps:

[0025] S010, at least one selected from MgO, CaO or K2O in a required amount is mixed with Al2O3 powder;

[0026] S020, extruding the mixture of the above step S010 by powder extrusion molding, drying, and then roasting to obtain the carrier I required for the catalyst;

[0027] S030, using the impregnation method to impregnate the required amount of boric acid solution on the surface of the carrier I in the above step S020, after drying, and then calcining at a high temperature to obtain the modified carrier II of the catalyst;

[0028] S040, impregnating a required amount of Cu(NO)2 solution on the surface of the modified carrier II in the above step S030 by means of impregnation, drying, and then calcining at a high temperature to obtain the desired catalyst.

[0029] Wherein, in the process of preparing the carrier I in the above-mentioned s...

Embodiment 1

[0032] The catalyst for preparing sec-butanol in Example 1 of the present invention is made of the following raw materials in mass percentage: CuO20%, B2O310%, Al2O349%, MgO21%.

[0033] Embodiment 1 of the present invention is used to prepare the preparation method of the catalyst of sec-butanol, it comprises the following steps:

[0034] S110, mixing the required amount of MgO powder with Al2O3 powder;

[0035] S120, adopt the method of powder extrusion molding, and use 10% by mass of nitric acid as an adhesive to extrude the mixture of the above step S110, after drying, and then roasting at 540 ° C for 4 hours, and granulate to obtain MgO modification Al2O3 carrier;

[0036] S130, impregnating the required amount of boric acid solution at 50° C. on the surface of the Al2O3 carrier in the above step S120 in equal volume, after drying, and then calcining at 540° C. for 4 hours to obtain a B2O3 modified catalyst carrier;

[0037] S140, impregnating the required amount of Cu(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com