Process for producing ultralow sulfur diesel fuels

A technology of ultra-low sulfur diesel oil and production method, which is applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc., to achieve the effects of high cetane number, reduced processing cost, and low hydrogen consumption in reaction chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

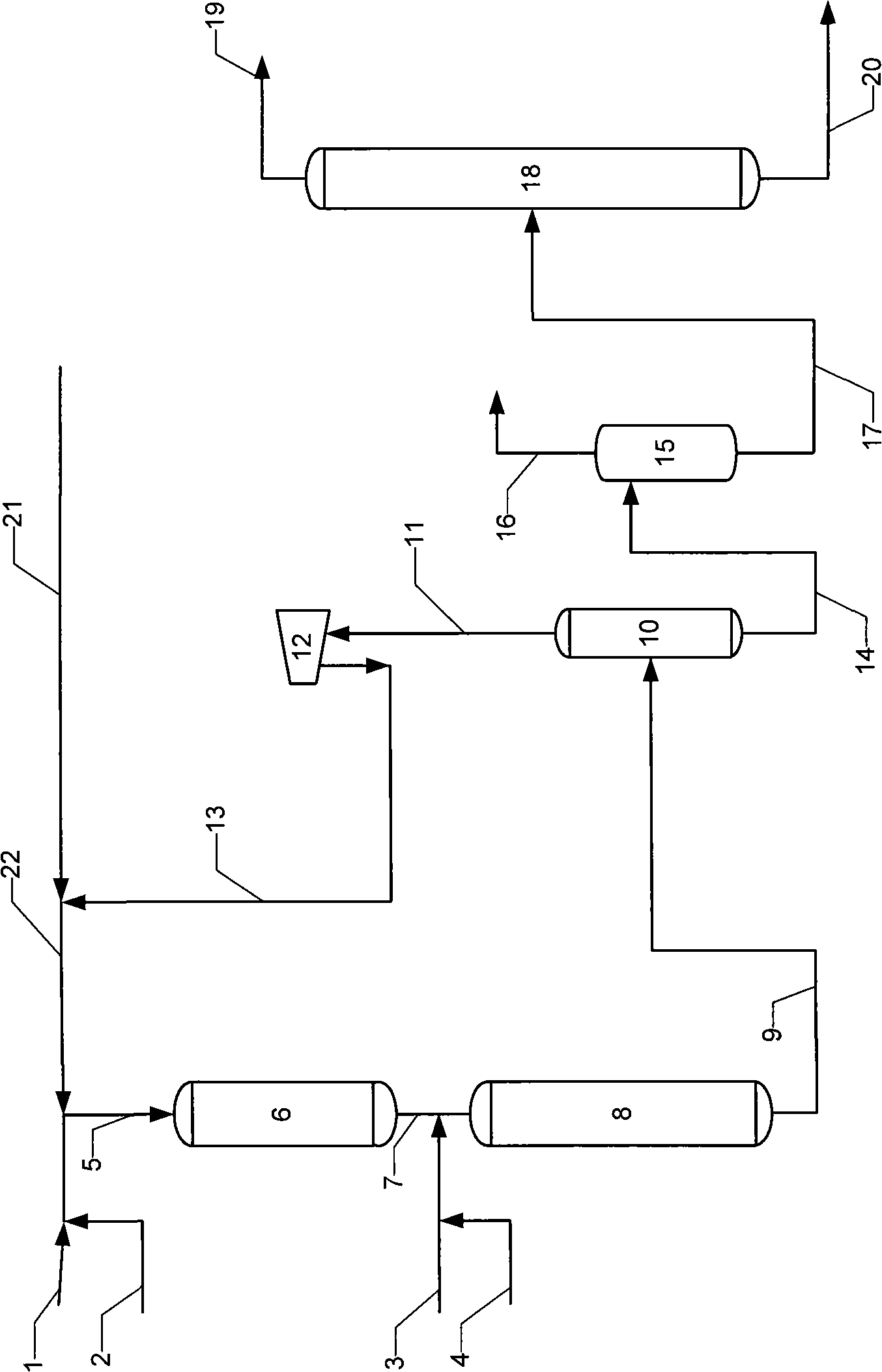

[0017] Through the above analysis and understanding of the advantages and disadvantages of the composition and distribution of sulfides, aromatics, hydrodesulfurization and hydrodearomatization, the specific embodiments of the present invention are:

[0018] (1) Straight-run normal third-line fraction and / or diesel heavy fraction are mixed with hydrogen and enter the first hydrogenation reaction zone, where hydrodesulfurization, hydrodenitrogenation, hydrodenitrogenation, PAH saturation and partial ring opening reactions. The reaction conditions are: reaction temperature 250-450°C, preferably 260-420°C, hydrogen partial pressure 1.0-12.0MPa, preferably 2.0-10.0MPa, liquid hourly volume space velocity 0.3-8.0h -1 , preferably 0.5~6.0h -1 , Hydrogen oil volume ratio 100~1500Nm 3 / m 3 , preferably 150-1000Nm 3 / m 3 .

[0019] (2) Straight-run normal second-line fraction and / or diesel light fraction are mixed with the reaction effluent of the first hydrogenation reaction zon...

Embodiment 1

[0042] Raw oil A is cut into light and heavy components at 300°C. The heavy fraction of diesel oil above 300°C is mixed with hydrogen and enters the first reaction zone, under the action of hydroreforming catalyst and hydrofinishing catalyst I (loading volume ratio is 4:6) to carry out the ring-opening cracking reaction of polycyclic aromatic hydrocarbons and hydrodesulfurization reaction; the reaction product enters the second hydrogenation reaction zone together with the light fraction of diesel oil less than 300°C, and undergoes deep hydrodesulfurization reaction under the action of hydrofining catalyst II, and the reaction product is cooled and separated After fractionation and fractionation, a small amount of naphtha fraction and high-quality diesel products are obtained.

[0043] The reaction conditions of the present embodiment are as shown in Table 2, and the main properties of the product are as shown in Table 3. As can be seen from Table 3, the sulfur content of the ...

Embodiment 2

[0045] The raw material oil C is mixed with hydrogen and enters the first hydrogenation reaction zone, and reacts under the action of the hydroupgrading catalyst and the hydrofinishing catalyst II (loading volume ratio is 3:7), and the reaction product is mixed with the raw material oil B Mix and enter the second hydrogenation reaction zone together, and react under the action of the hydrorefining catalyst II, and the reaction products are cooled, separated and fractionated to obtain naphtha fractions and high-quality diesel products.

[0046]The reaction conditions of the present embodiment are as shown in Table 2, and the main properties of the product are as shown in Table 3. As can be seen from Table 3, the sulfur content of the diesel product is 5 μg / g, the polycyclic aromatic hydrocarbon content is 1.8% by weight, cetane The index is 60, which is clean diesel meeting Euro IV emission standards, and the yield of diesel products is above 99.0% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com