Biological microcrystalline glass prepared by utilizing phosphate tailings and preparation method thereof

A technology of glass-ceramics and phosphate rock tailings, which is applied in the field of biological glass-ceramics and its preparation, can solve the problems of poor biocompatibility, high production cost and low mechanical strength of biological glass-ceramics, and improve biological Compatibility, beneficial to environmental governance, good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

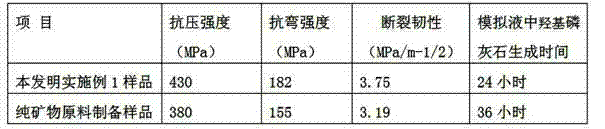

Embodiment 1

[0058] Embodiment 1, this biological glass-ceramic prepared by utilizing phosphate rock tailings, its raw material composition proportioning by weight is as follows:

[0059] 35 parts of apatite tailings, 15 parts of quartz sand, 16 parts of aluminum hydroxide, 24 parts of calcium hydrogen phosphate, 10 parts of calcium fluoride, and 0.5 parts of borax.

[0060] Weigh the raw materials according to the above proportions, and mix them evenly to form the batch. The glass is melted in a platinum crucible using a molybdenum silicon rod electric furnace. The furnace temperature was raised to 1500°C in advance. Put the homogeneously mixed batch into a platinum crucible in a high-temperature electric furnace at 1500°C to maintain a constant temperature. After melting for 2 hours, pour the molten glass directly into the water basin, which is the glass water quenching material.

[0061]Grind the water-quenched glass material into a fine powder of less than 300 meshes, then place it ...

Embodiment 2

[0065] Embodiment 2, this biological glass-ceramic prepared by utilizing phosphate rock tailings, its raw material composition proportioning by weight is as follows:

[0066] 35 parts of apatite tailings, 16 parts of quartz sand, 14 parts of aluminum hydroxide, 26 parts of calcium hydrogen phosphate, 9 parts of calcium fluoride, and 0.5 parts of borax.

[0067] Weigh the raw materials according to the above proportions, and mix them evenly to form the batch. The glass is melted in a platinum crucible using a molybdenum silicon rod electric furnace. The furnace temperature was raised to 1500°C in advance. Put the homogeneously mixed batch into a platinum crucible in a high-temperature electric furnace at 1500°C to maintain a constant temperature. After melting for 2 hours, pour the molten glass directly into the water basin, which is the glass water quenching material.

[0068] Grind the water-quenched glass material into a fine powder of less than 300 meshes, then place it ...

Embodiment 3

[0072] Embodiment 3, this biological glass-ceramic prepared by utilizing phosphate rock tailings, its raw material composition proportioning by weight is as follows:

[0073] 32 parts of apatite tailings, 17 parts of quartz sand, 10 parts of aluminum hydroxide, 28 parts of calcium hydrogen phosphate, 13 parts of calcium fluoride, and 0.5 parts of borax.

[0074] Weigh the raw materials according to the above proportions, and mix them evenly to form the batch. The glass is melted in a platinum crucible using a molybdenum silicon rod electric furnace. The furnace temperature was raised to 1500°C in advance. Put the homogeneously mixed batch into a platinum crucible in a high-temperature electric furnace at 1500°C to maintain a constant temperature. After melting for 2 hours, pour the molten glass directly into the water basin, which is the glass water quenching material.

[0075] Grind the water-quenched glass material into a fine powder of less than 300 meshes, then place it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com