Catalyst for combined production of sec-butyl alcohol and ethanol by sec-butyl acetate hydrogenation and its preparation method and use

A sec-butyl acetate and catalyst technology, which is applied in the hydrogenation of sec-butyl acetate to co-produce sec-butanol and ethanol as a catalyst and its preparation and application field, can solve the problems of low product selectivity and high hydrogen ester, and achieve a simple preparation method , high selectivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

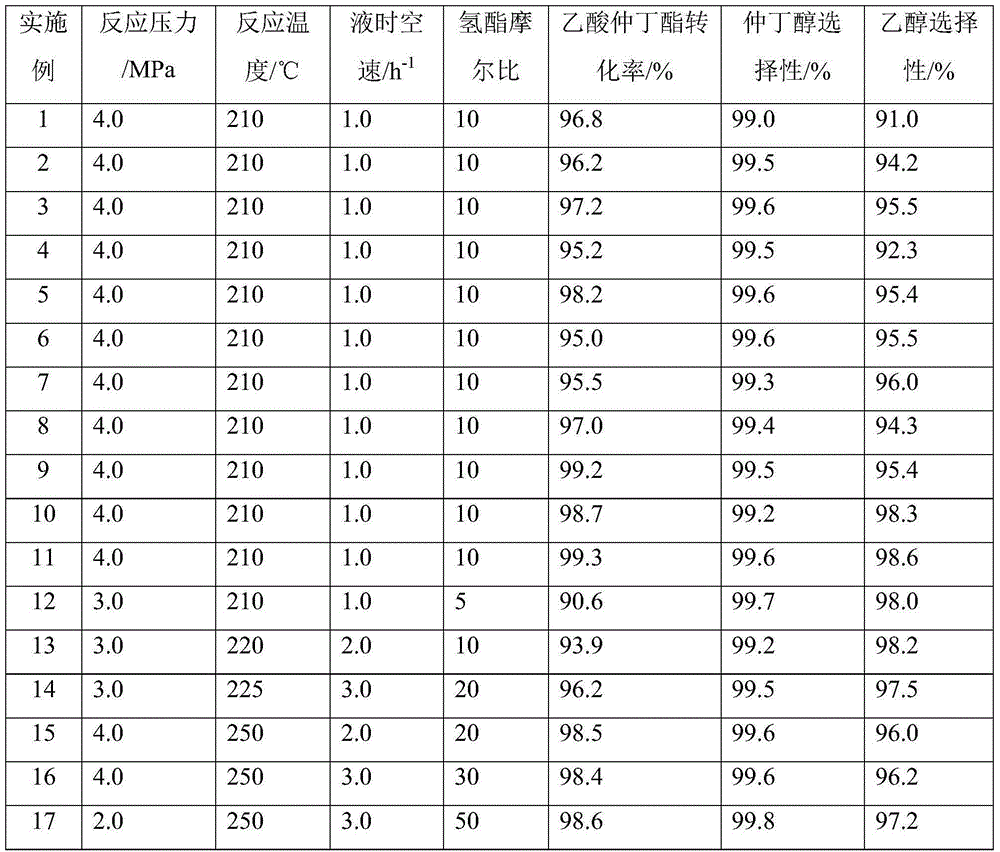

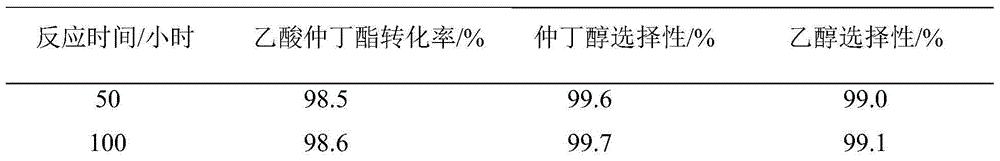

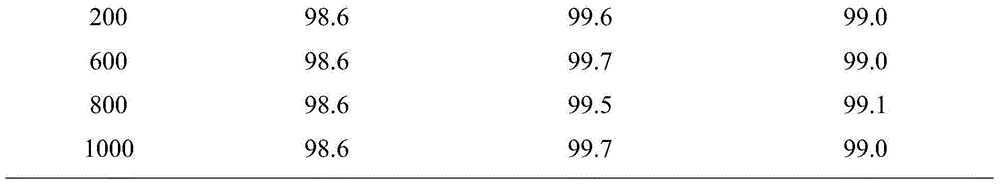

Examples

Embodiment 1

[0030] 100g of Cu(NO 3 ) 2 and 5.0g of Zn(NO 3 ) 2 Put it in a beaker, add 500g of distilled water to dissolve it completely, and record it as solution 1; weigh 180g of silica sol and dissolve it in it, then slowly drop concentrated nitric acid into it with a dropper, and record it as solution 2; put 90g of urea in another Add 500g of distilled water into the beaker to dissolve it completely, and record it as solution 3; prepare the catalyst by co-precipitation method, keep the temperature at 95°C, control the reaction end point pH=7.0, and age for 12 hours. The obtained catalyst precursor slurry is washed and filtered. Dry at 120°C for 24 hours and calcinate at 500°C for 6 hours to obtain the target product catalyst.

[0031] The catalyst prepared above was made into 20-30 mesh particles, loaded into a tubular reactor with a diameter of 12 mm, and activated at 300° C. for 6 hours under a hydrogen atmosphere. Using sec-butyl acetate as raw material, the reaction temperatur...

Embodiment 2

[0033] 100g of Cu(NO 3 ) 2 and 3.0g of Ca(NO 3 ) 2 Put it in a beaker, add 500g of distilled water to dissolve it completely, and record it as solution 1; weigh 160g of silica sol and dissolve it in it, then slowly drop concentrated nitric acid into it with a dropper, and record it as solution 2; put 100g of sodium carbonate in another Add 500g of distilled water into a beaker to make it completely dissolved, which is counted as solution 3. Prepare the catalyst by co-precipitation method, the precipitation temperature is 80°C, control the reaction end point pH=7.5, and age for 12 hours. The obtained catalyst precursor slurry is washed and filtered, dried at 100°C for 24 hours, and roasted at 450°C for 6 hours. That is, the target product catalyst is obtained.

[0034] The evaluation process conditions are the same as in Example 1.

Embodiment 3

[0036] 100g of Cu(NO 3 ) 2 and 5.0g of Zr(NO 3 ) 4 Put it in a beaker, add 500g of distilled water to dissolve it completely, and record it as solution 1; weigh 90g of white carbon black and dissolve it in water, then slowly drop concentrated nitric acid into it with a dropper, and record it as solution 2; put 100g of sodium carbonate in Add 500g of distilled water to another beaker to dissolve it completely, and record it as solution 3; prepare the catalyst by co-precipitation method, keep the temperature at 60°C, control the reaction end point pH=7.5, and age for 12 hours. The obtained catalyst precursor slurry is washed and filtered Afterwards, it was dried at 100°C for 24 hours and calcined at 550°C for 6 hours to obtain the target product catalyst.

[0037] The evaluation process conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com