Method and device for separating acetic acid sec-butyl ester and sec-butyl alcohol

A technology for sec-butyl acetate and sec-butanol, which is applied in the field of separation of sec-butyl acetate and sec-butanol, can solve the problems of low separation purity and difficult separation of sec-butyl acetate and sec-butanol, and achieve good separation effect, Easy operation, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

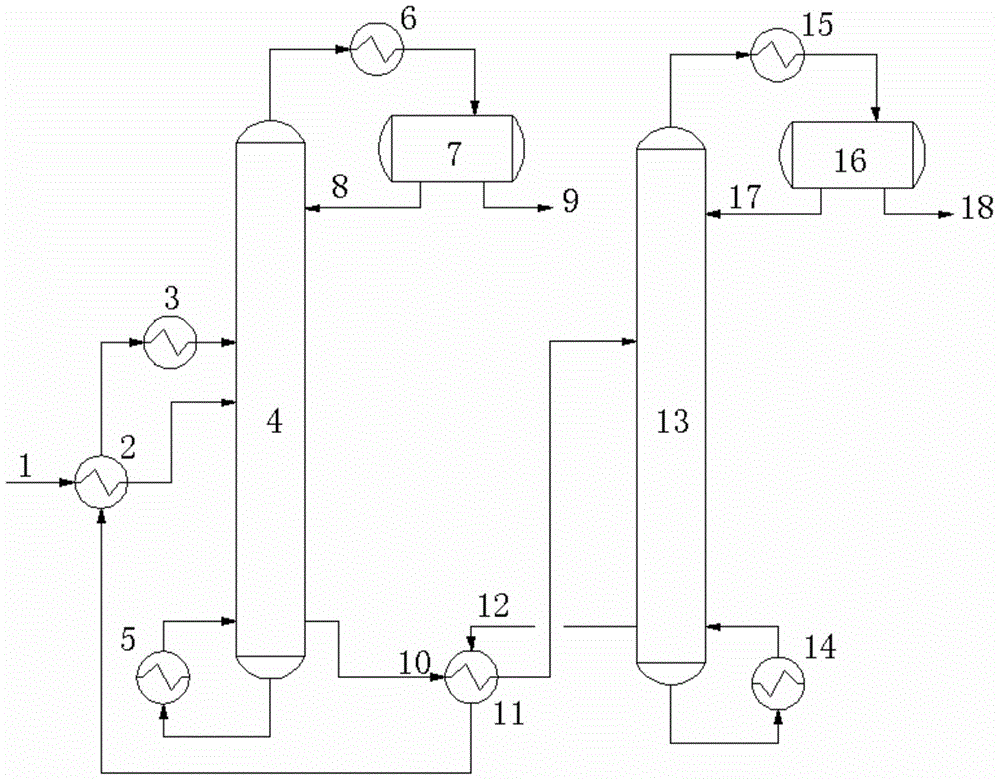

[0034] The mixed material containing sec-butyl acetate and sec-butanol is preheated and sent to the extractive distillation tower 4 at a speed of 10t / h, wherein the mixed material comes from the tower after the catalytic rectification reaction of sec-butyl acetate and methanol Kettle mixture, the content of sec-butyl acetate is 50%, the content of sec-butanol is 50%, the temperature of the mixture material is 140°C, and the extractant 1,3-propanediol is fed in at a speed of 40t / h (solvent ratio is 4) Extractive distillation tower 4, the top temperature of the extractive distillation tower is 125°C, the top pressure is normal pressure, and the reflux ratio is 2:1. After separation by extraction and rectification, sec-butyl acetate is steamed from the top of the tower and condensed Extract at a speed of 5t / h afterward to obtain sec-butyl acetate 9, and the mixture (rich solvent) of sec-butanol and extractant is sent into the solvent concentration tower 13 after taking out from th...

Embodiment 2

[0037] The mixed material containing sec-butyl acetate and sec-butanol is preheated and sent to the extractive distillation column 4 at a speed of 10t / h, wherein the mixed material comes from the tower after the catalytic rectification reaction of sec-butyl acetate and ethanol Still mixture, the content of sec-butyl acetate is 10%, the content of sec-butanol is 90%, the temperature of the mixture material is 120 ℃, and the extraction agent ethylene glycol is sent into the extractant with a speed of 200t / h (solvent ratio is 20). Distillation tower 4, the tower top temperature of extractive rectification tower is 107 ℃, and tower top pressure is normal pressure, and reflux ratio is 0.5:1, after extraction and rectification separation, sec-butyl acetate steams out from tower top and after condensing The speed extraction of 1t / h obtains sec-butyl acetate 9, and the mixture (rich solvent) of sec-butanol and extractant is sent into solvent concentration tower 13 after taking out from...

Embodiment 3

[0040] The mixed material containing sec-butyl acetate and sec-butanol is preheated and sent to the extractive distillation tower 4 at a speed of 10t / h, wherein the mixed material comes from the tower after the catalytic rectification reaction of sec-butyl acetate and methanol Kettle mixture, the content of sec-butyl acetate is 20%, the content of sec-butanol is 80%, the temperature of the mixture material is 110°C, and the extractant 1,2-propanediol is fed in at a speed of 100t / h (solvent ratio is 10) Extractive distillation tower 4, the top temperature of the extractive distillation tower is 110°C, the top pressure is normal pressure, and the reflux ratio is 0.8:1. After separation by extraction and rectification, sec-butyl acetate is steamed from the top of the tower and condensed Extract at a speed of 2t / h to obtain sec-butyl acetate 9 afterward, and the mixture (rich solvent) of sec-butanol and extractant is sent into solvent concentration tower 13 after taking out from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com