Patents

Literature

122results about How to "Meet material requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

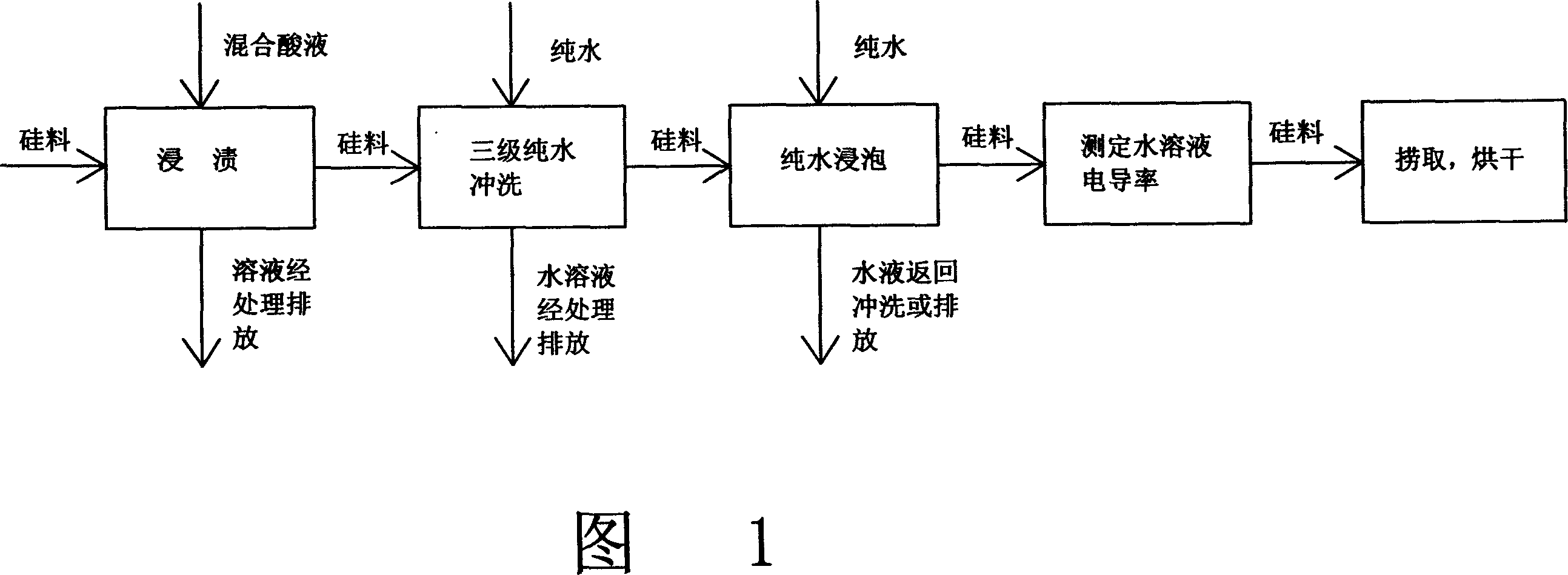

Method for cleaning silicon material

InactiveCN1947869AMeet material requirementsCreate pollutionCleaning using liquidsHydrofluoric acidSemiconductor materials

A cleaning method for removing the impurities from the surface of rejected Si material in order to reuse it includes such steps as immersing the rejected Si material in the mixed solution of hydrofluoric acid and nitric acid, flushing it with purified water several times, immersing it in purified water, measuring the electric conductivity of the immersing purified water, and baking.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

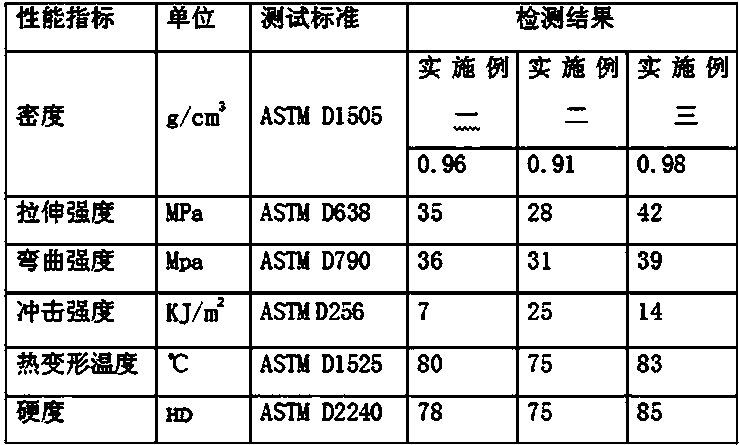

High-impact high-stiffness polypropylene rotational molding material and preparation method thereof

The invention relates to a high-impact high-stiffness polypropylene rotational molding material and a preparation method thereof. The rolling plastic rotational molding material comprises the following raw materials: by weight, 100 parts of polypropylene, 0-30 parts of polyethylene, 0-0.1 part of a crosslinking agent, 0-0.15 part of an auxiliary crosslinking agent, 1-10 parts of an elastomer, 0.1-0.5 part of an antioxidant, 0-10 parts of a nano filler, 0.1-0.5 part of a dispersing lubricant and 0-0.4 part of a surface treatment agent. According to the invention, the crosslinkable polyethylene is added in a polypropylene melt mixing process for melt curing to obtain the high-impact high-stiffness polypropylene modified rotational molding material with a semi interpenetrating network structure, and the high-impact high-stiffness polypropylene modified rotational molding material can meet the material requirements of vehicles and other different fields. The curing reaction of the polyethylene belongs to the in situ curing, the material has the unique semi interpenetrating network structure, different components are mutually bitten or buckled, the compatibility between the polyethylene and polypropylene resin can be improved, and the performance advantages of the both are full played.

Owner:天津市华鑫达投资有限公司

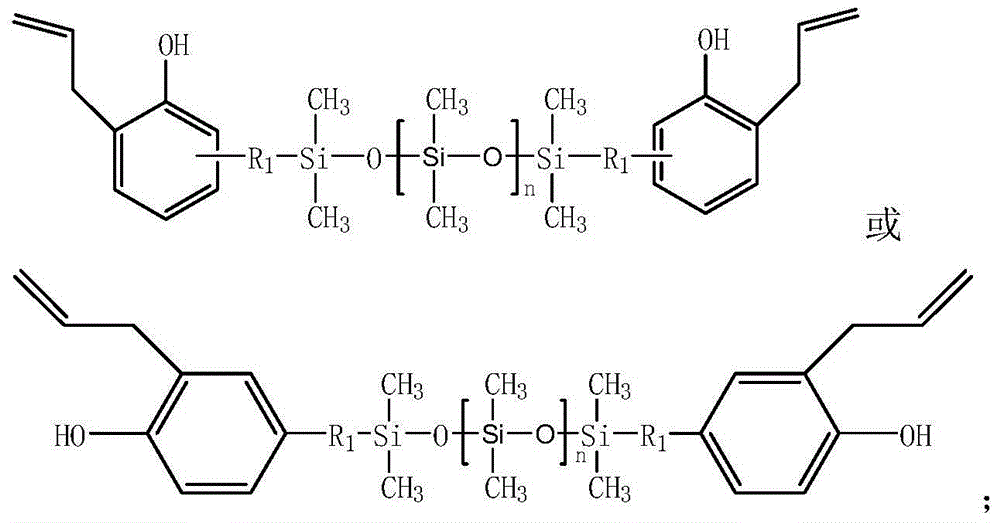

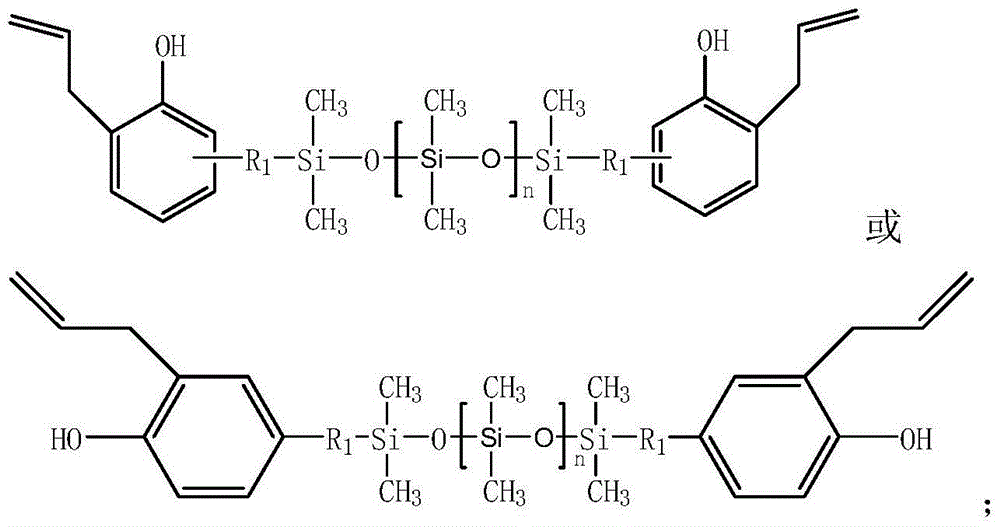

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

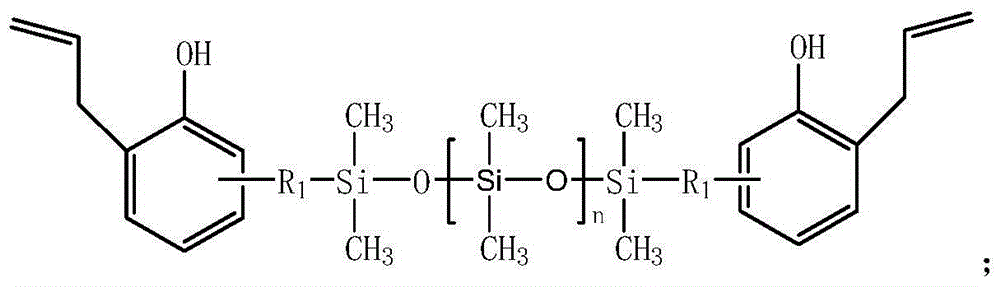

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

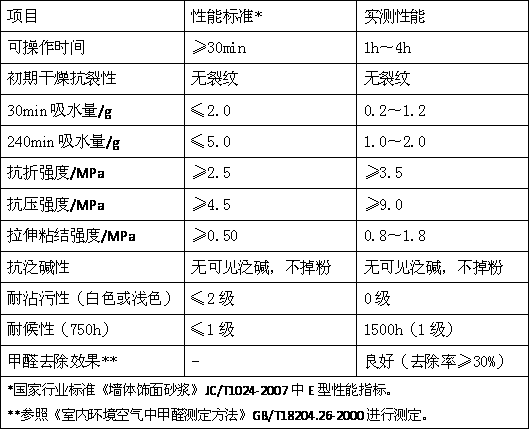

Self-clean self-purification cement-based facing material and production method thereof

InactiveCN102838330AMeet material requirementsFulfil requirementsSelf purificationInorganic pigments

The invention relates to a self-clean self-purification cement-based facing material and a production method thereof. The self-clean self-purification cement-based facing material comprises the following components in parts by weight: 20-30 parts of white silicate cements, 5-10 parts of mineral admixtures, 0-20 parts of quartz sands of 20-30 meshes, 20-30 parts of quartz sands of 40-70 meshes, 20-30 parts of quartz sands of 70-100 meshes, 1-4 parts of kieselguhr, 2-4 parts of zeolite, 0.2-0.6 part of nanometer titanium dioxide, 0.5-2.0 parts of EVA redispersible latex powder, 0.2-0.8 part of organic silicon water repellent, 0-1 part of ferric oxide inorganic pigment and 0.1-0.7 part of other chemical additive. The self-clean self-purification cement-based facing material, provided by the invention, has the advantages of good self-clean property, good self-purification property, good air purification capacity, good adhesive property, good construction property, good endurance quality, higher compression strength and the like, when the self-clean self-purification cement-based facing material is used for decoration of facings of an inner wall space and an outer wall space of a building, the air purification effect and the decoration effect are good, and the self-clean self-purification cement-based facing material can be applied for decoration engineering of all kinds of facings of walls of buildings.

Owner:TONGJI UNIV

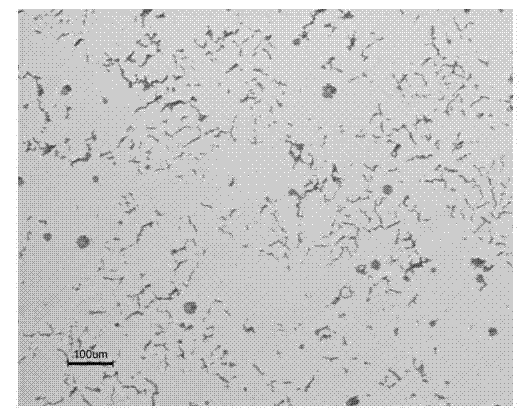

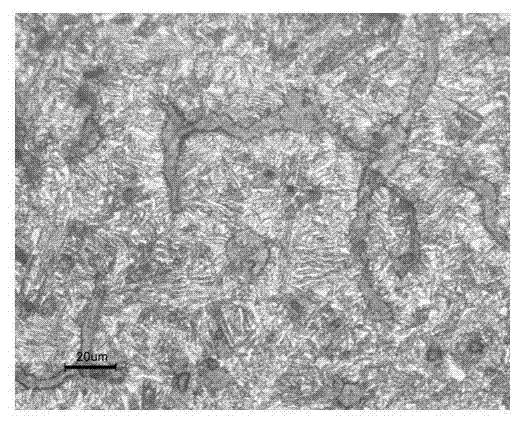

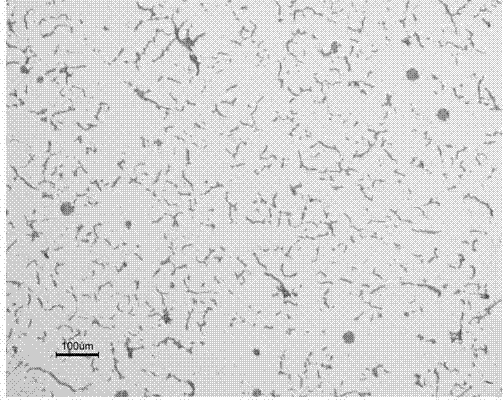

High-strength vermicular cast iron and preparation method thereof

The invention provides high-strength vermicular cast iron and a preparation method thereof. The high-strength vermicular cast iron consists of the following components in percentage by weight: 3.4-3.8 percent of C, 2.1-2.6 percent of Si, 0.2-0.6 percent of Cu, 0.2-0.5 percent of Mo, 0.2-0.8 percent of Mn, 0.02-0.04 percent of Sn, 0.004-0.032 percent of Sb and the balance of iron and inevitable impurities. The microscopic structure of the vermicular cast iron provided by the invention consists of a substrate and vermicular graphite, and the vermicular rate surpasses 85 percent. The vermicular cast iron can be prepared into vermicular cast iron with excellent comprehensive performance by preserving heat at the temperature 900-950 DEG C for 1.5-3 hours, preserving heat in a saline solution at the temperature 320-360 DEG C for 1.5-3 hours and performing air cooling. The vermicular cast iron provided by the invention has the characteristics of high strength, high plasticity, heat resistance, impact resistance, fatigue resistance, high casting forming performance, and the like. The tensile strength of the high-strength vermicular cast iron at the room temperature is 780-950 MPa, and theelongation percentage is more than or equal to 3 percent, so that the requirements of a high-power diesel engine on the materials of key parts are met. The preparation method of the high-strength vermicular cast iron provided by the invention has a stable vermiculation process, a high vermicular rate and a simple process, and is convenient to operate.

Owner:XIAN KANGBO NEW MATERIAL TECH

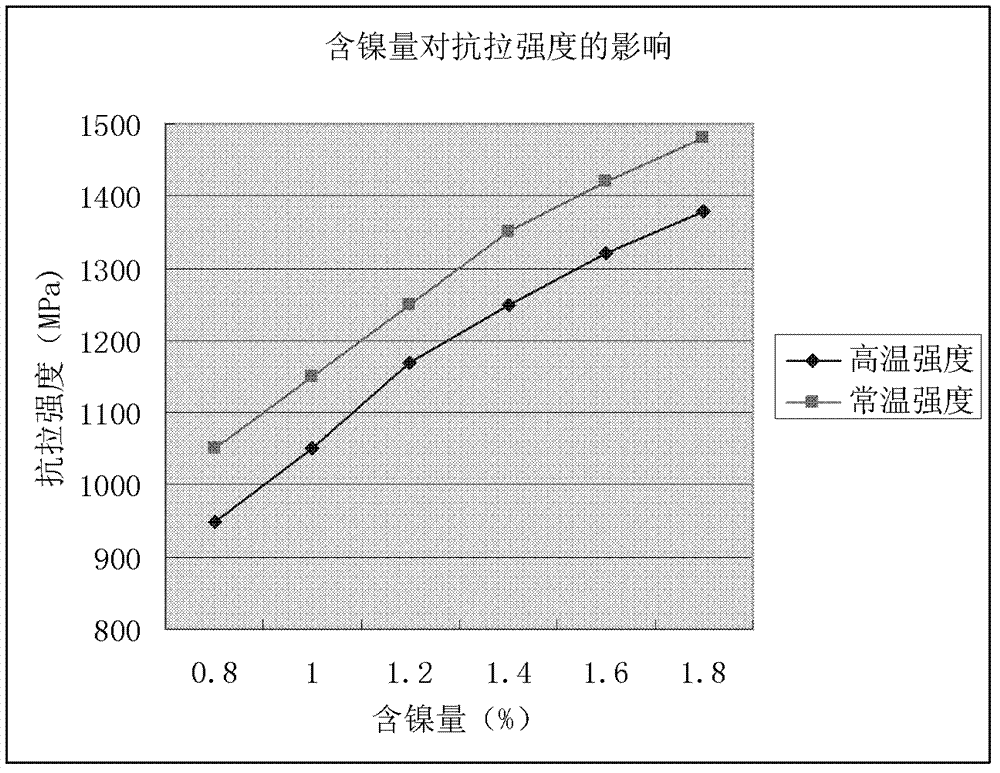

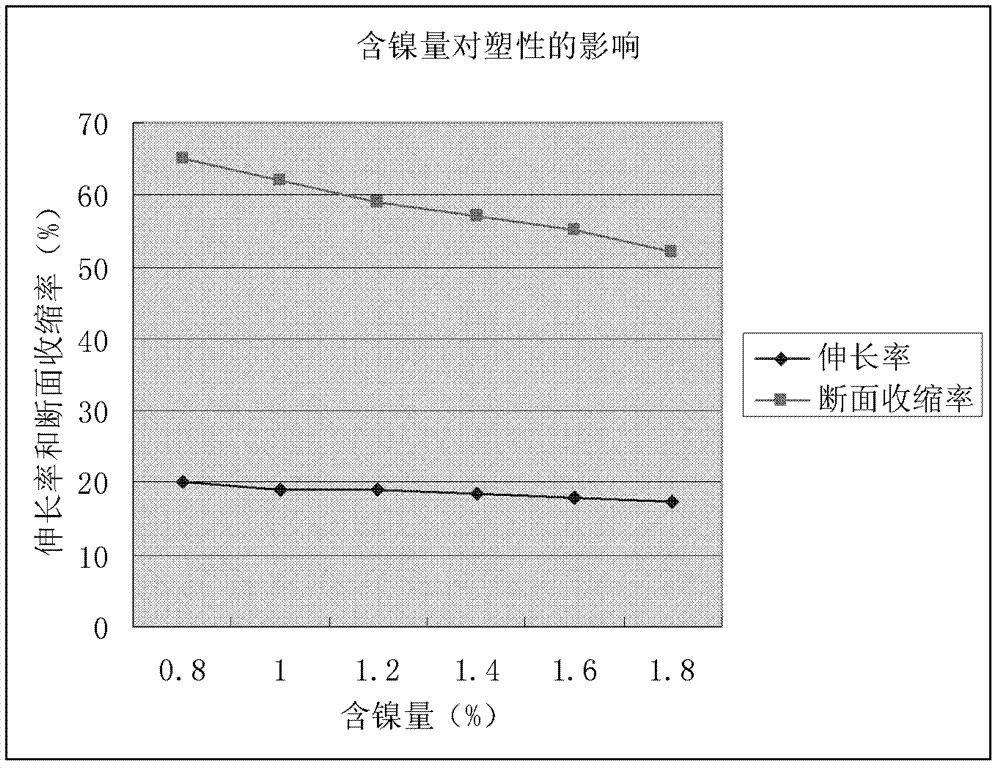

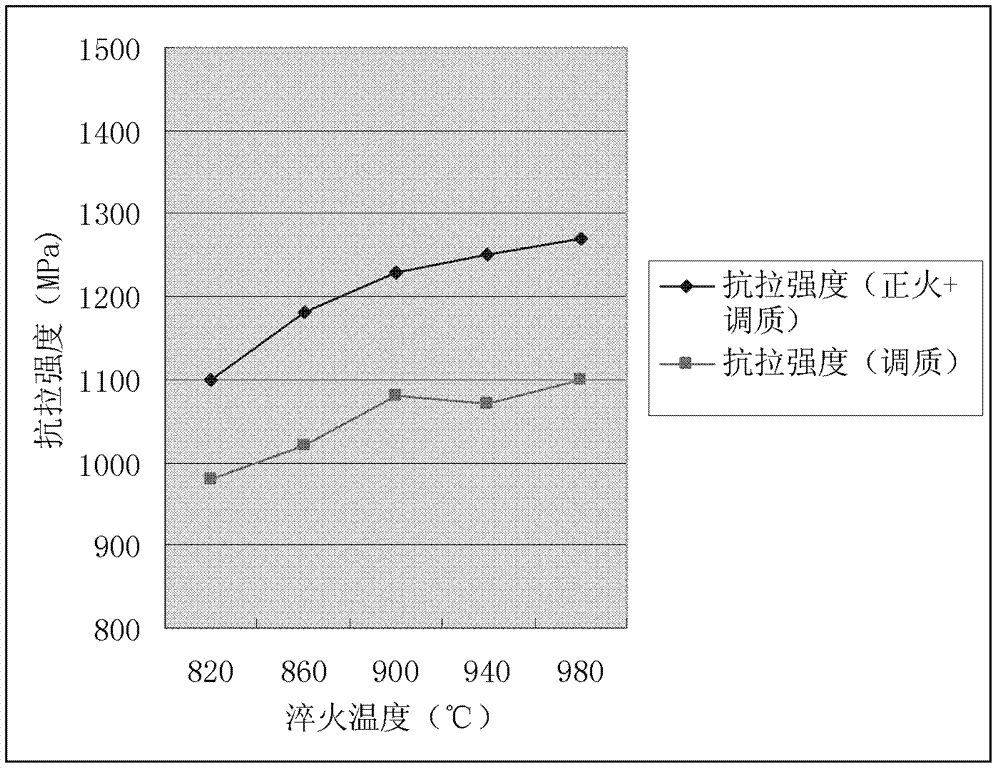

Alloy forged steel and its heat treatment method and use

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

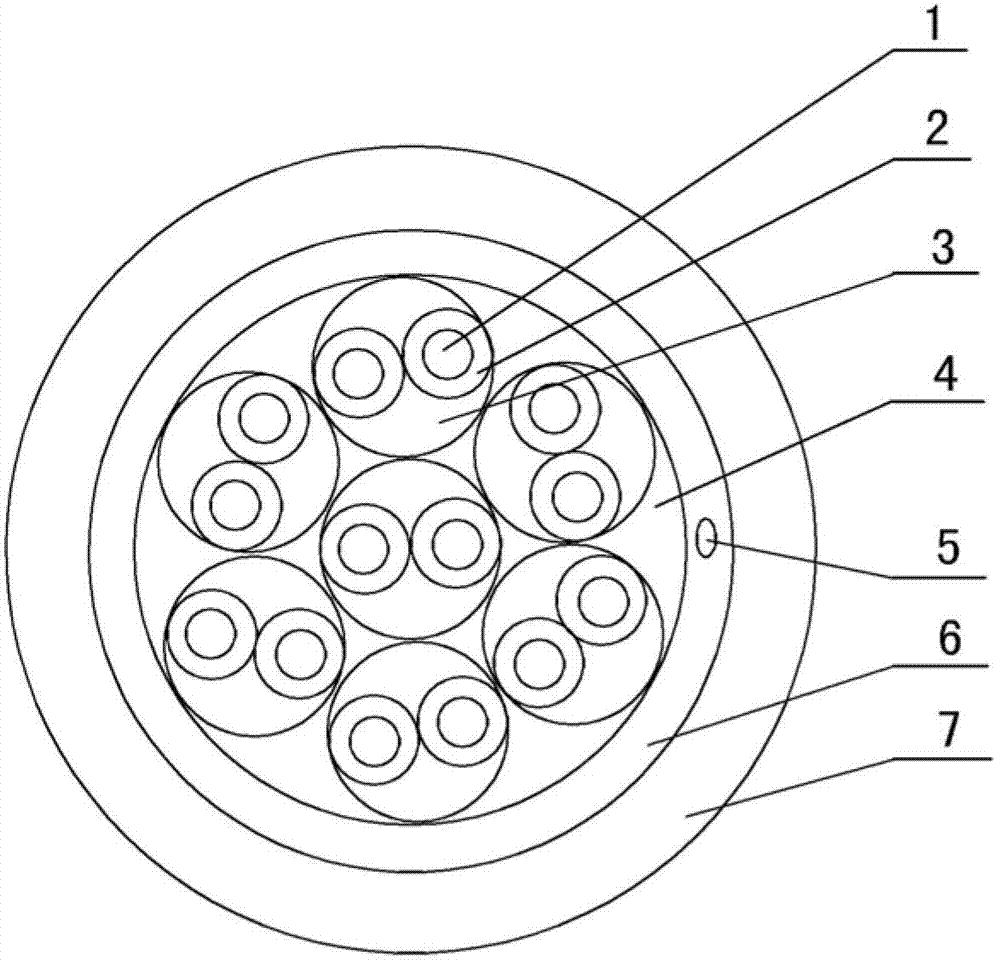

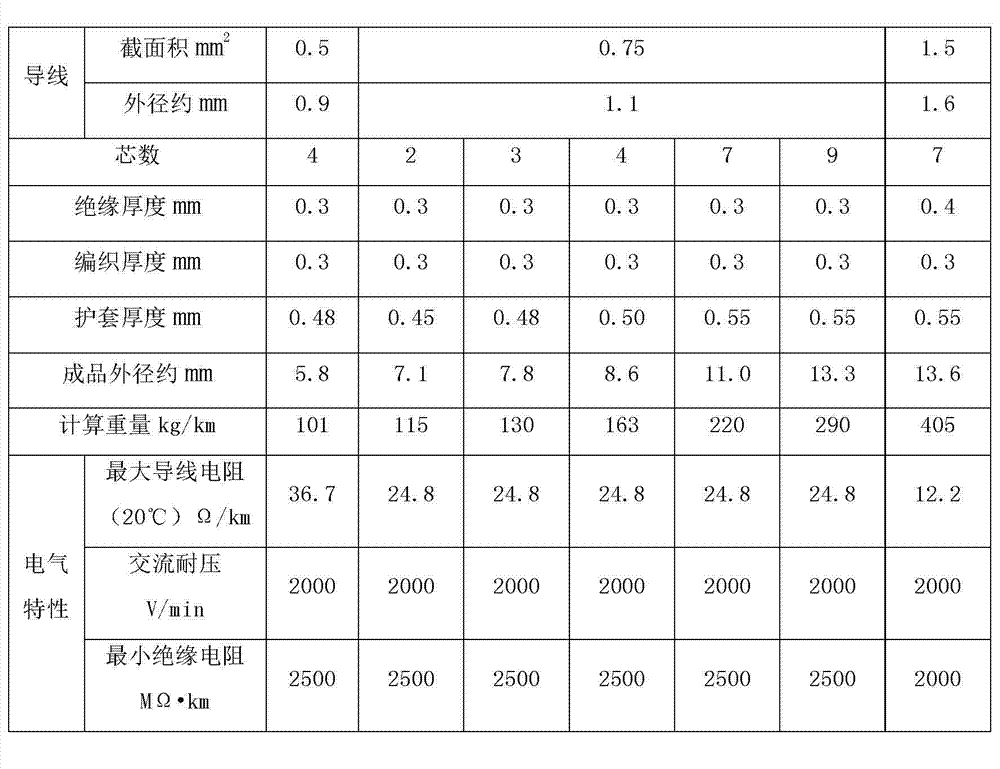

Heat-resistant instrument cable for ships and manufacturing process of heat-resistant instrument cable

ActiveCN102760517ASmall structure sizeImprove electrical performanceNon-insulated conductorsInsulated cablesElectrical conductorCopper wire

The invention discloses a heat-resistant instrument cable for ships and a manufacturing process of the heat-resistant instrument cable, and is characterized in that a cable conductor is formed by twisting a plurality of tin-plated copper wires which are drawn by a copper rod and are treated by annealing and tin plating; the conductor is extruded with an insulating layer to form an insulating cable core; a twisted-pair unit is formed by two insulating cable cores; a cable core is formed by twisting a plurality of twisted-pair units; the outer surface of the cable core is provided with a longitudinally-added drainage wire, a shielding layer weaved by the tin-plated copper wires and an extrusion sheath layer in sequence; and the insulating layer and the outer sheath layer are respectively made of fluororesin extruding materials. The heat-resistant instrument cable is suitable to be used as an electric instrument connecting line under the severe high-temperature environments such as near diesel engines and in control chambers, and has the advantages of small structural size, high temperature resistance, water vapor resistance, flame retardance, acid-alkaline chemical agent resistance, fire resistance and excellent electric performance and mechanical performance.

Owner:ANHUI GUODIAN CABLE GRP

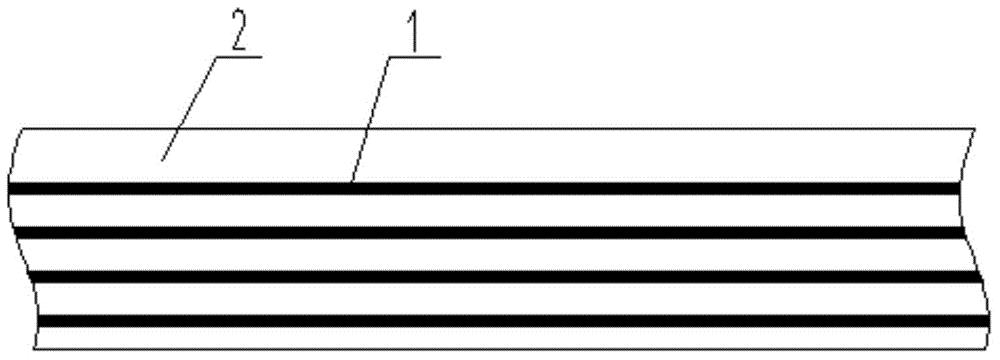

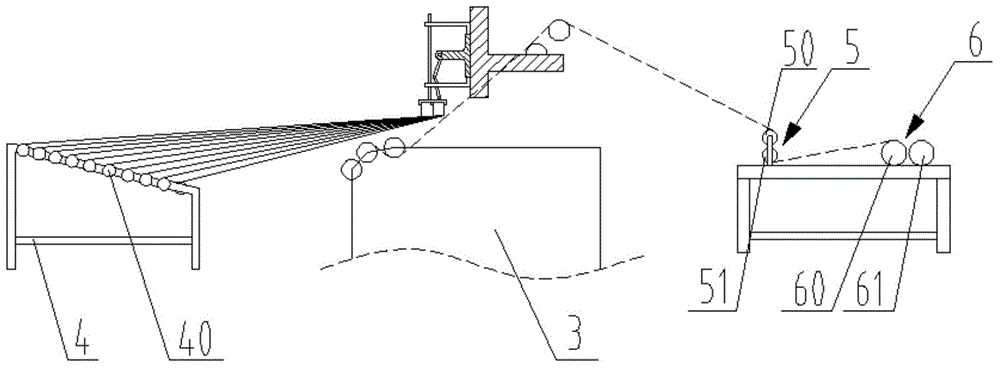

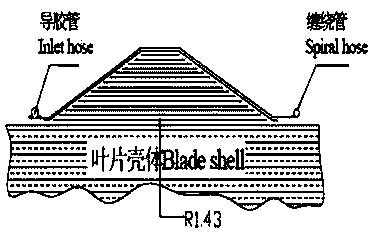

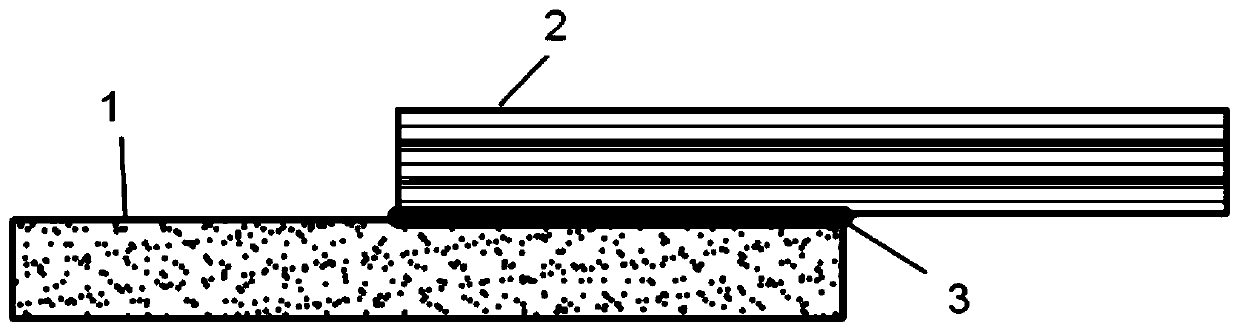

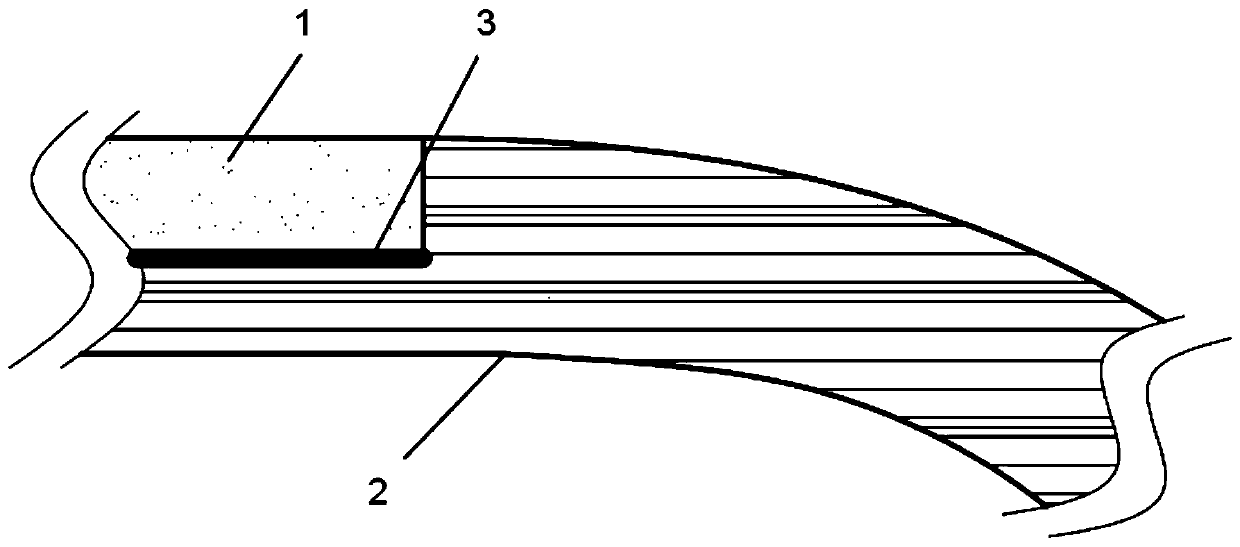

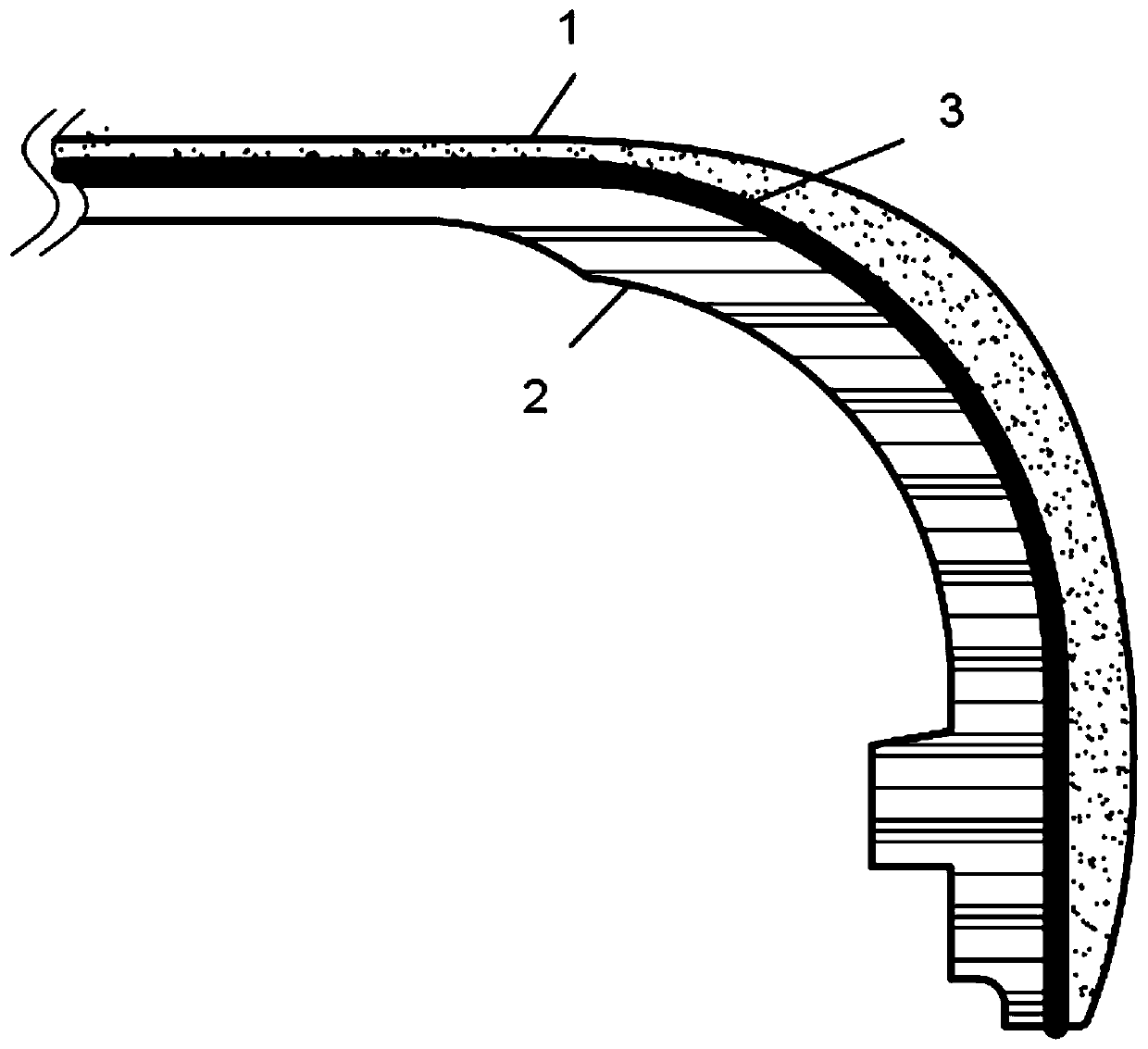

Wind-driven generator electrothermal ice melting rotor blade, electrothermal chip and forming device and method

InactiveCN103826336AImprove permeabilityMeet material requirementsFinal product manufactureOhmic-resistance heatingElectricityThermal energy

The invention provides a wind-driven generator electrothermal ice melting rotor blade, an electrothermal chip and a forming device and a method. The electrothermal chip comprises glass fiber cloth, and a carbon fiber bundle is sewn on the glass fiber cloth. The forming device comprises a forming machine, a feeding support arranged in front of the forming machine, and a heating device and a material receiving device sequentially arranged behind the forming machine, wherein a plurality of rolling?shafts are arranged on the feeding support; and the?rolling?shafts are winded with?carbon fiber. As the carbon fiber bundle is sewn on the glass fiber cloth by the forming machine, the manufacturing technology is simple and integration is high; as the electrothermal chip is composed of glass fiber cloth and carbon fiber and free of metal, material demands of the rotor blade can be met; and the glass fiber cloth is high in permeability, the electrothermal chip is poured in the rotor blade, the pouring technology demand of the rotor blade can be met, the manufactured electrothermal ice melting rotor blade can use thermal energy generated after the carbon fiber is electrified, and the rotor blade can be prevented from being frozen.

Owner:刘中威 +1

Polycarbonate composite material for 3D printing and preparation method thereof

ActiveCN105504749AEvenly heatedUniform solidificationAdditive manufacturing apparatusBoronic acidCarboxylic group

The invention relates to a polycarbonate composite material for 3D printing and a preparation method thereof. Magnesium borate whiskers and graphene oxide are introduced into polycarbonate, so that not only is the polycarbonate strengthened, but also carboxyl, hydroxyl and epoxy functional groups can be promoted to be connected with the polycarbonate and to be uniformly dispersed, the thermal superconductivity of the graphene oxide allows powder in the polycarbonate to be uniformly heated and solidified, thereby reducing the thermal shrinkage of a product during 3D printing. Further, by virtue of polyelectrolytes, the polycarbonate powder is subjected to surface modification at a fluidized bed, so that the surface of the polycarbonate powder is more in a spherical shape, the mobility of the polycarbonate is greatly improved, the powder agglomeration is effectively prevented, and the polycarbonate is suitable for a 3D printing material.

Owner:东莞市盈合精密塑胶有限公司

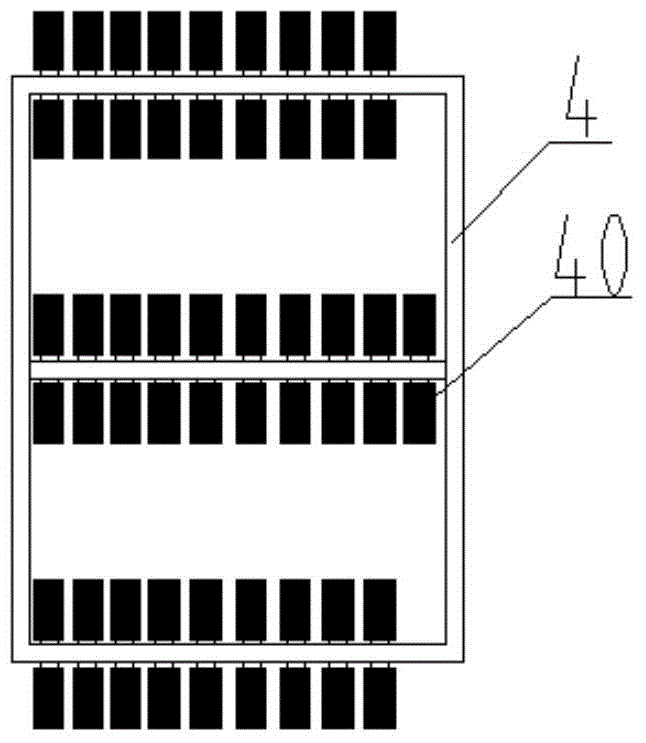

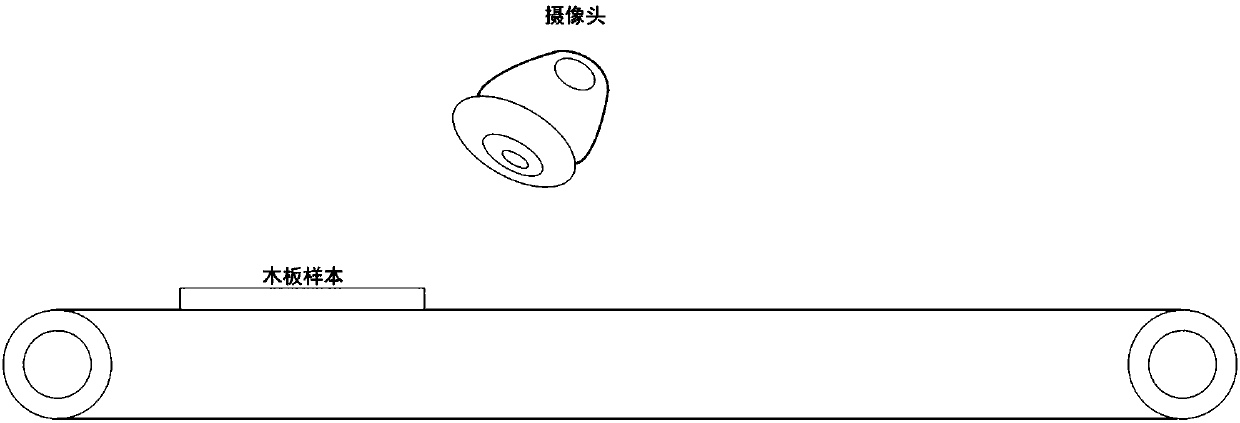

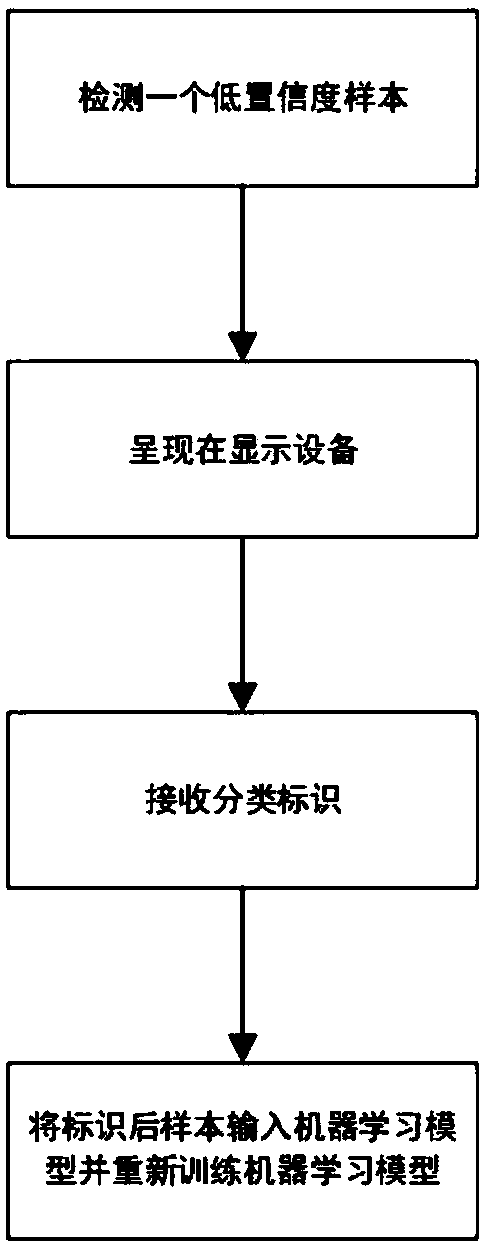

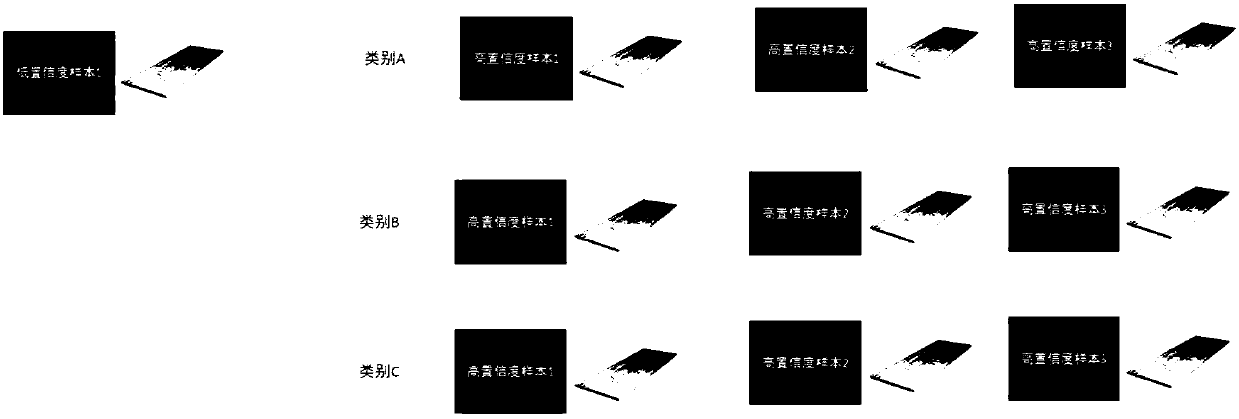

AI (Artificial Intelligence) based low-confidence sample processing method and system of board sorting

ActiveCN107832780AImprove classification accuracyImprove training efficiencyCharacter and pattern recognitionMachine learningLow Confidence

The invention provides an AI based low-confidence sample processing method and system of board sorting. Image data of at least one format of a low-confidence sample is obtained; an image of at least one format of the low-confidence sample is presented in a display device; a new class marked by the low-confidence sample is obtained; and a training method is input to the marked low-confidence sample, and a new classification model is obtained via re-training. According to the method and system, the low-confidence sample can be discovered continuously and utilized, so that the classification precision of a machine learning method is improved gradually.

Owner:BEIJING WOOD AI TECH LTD

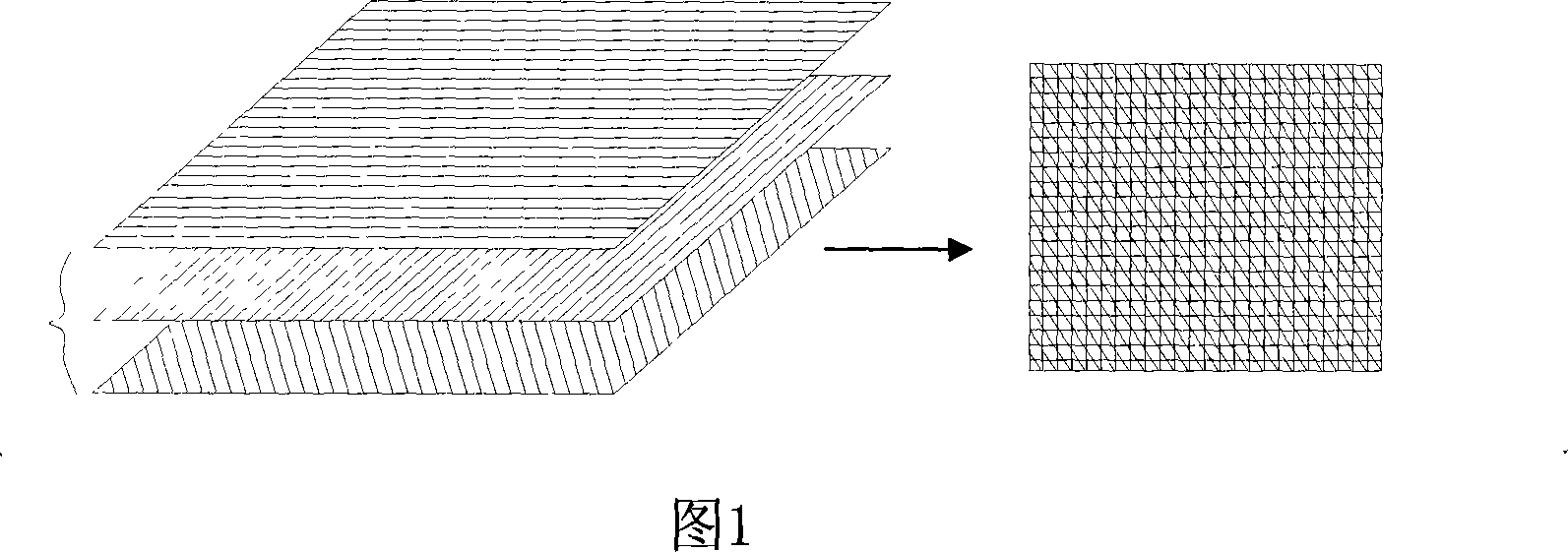

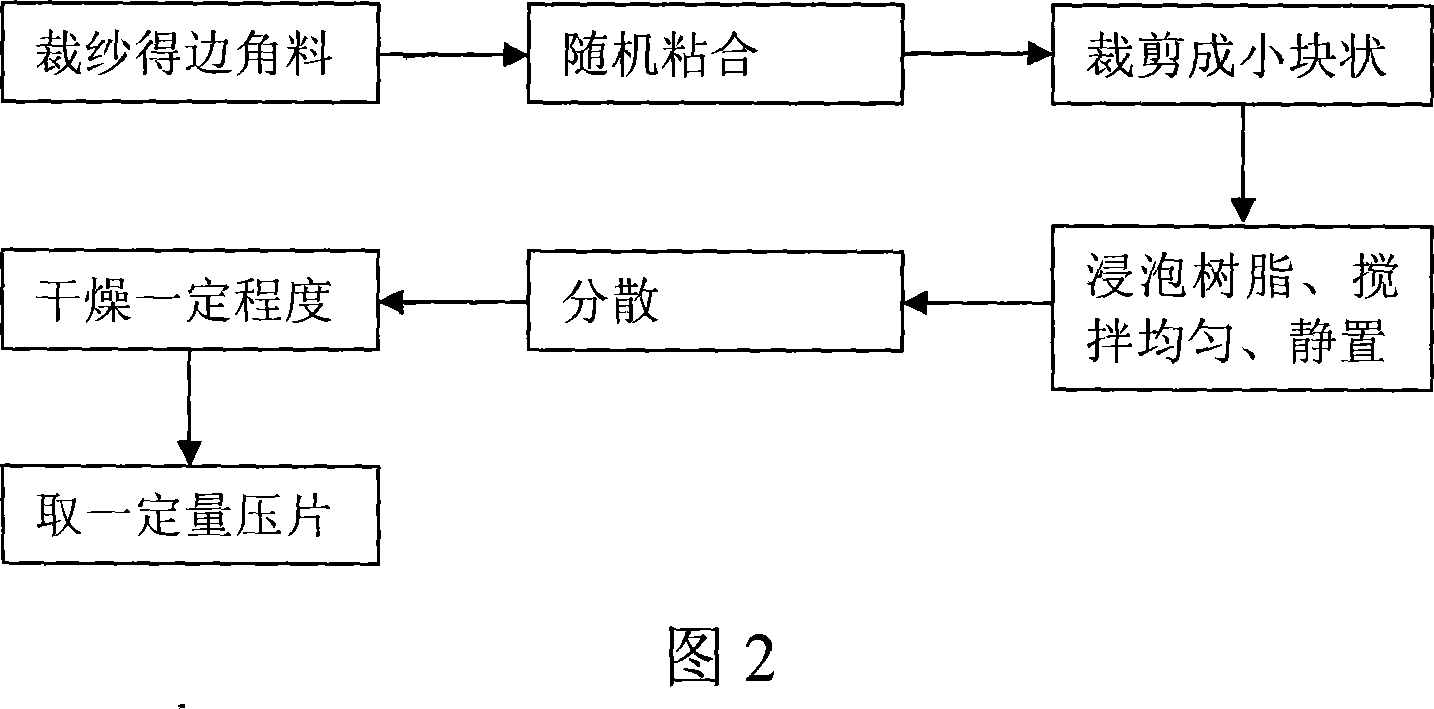

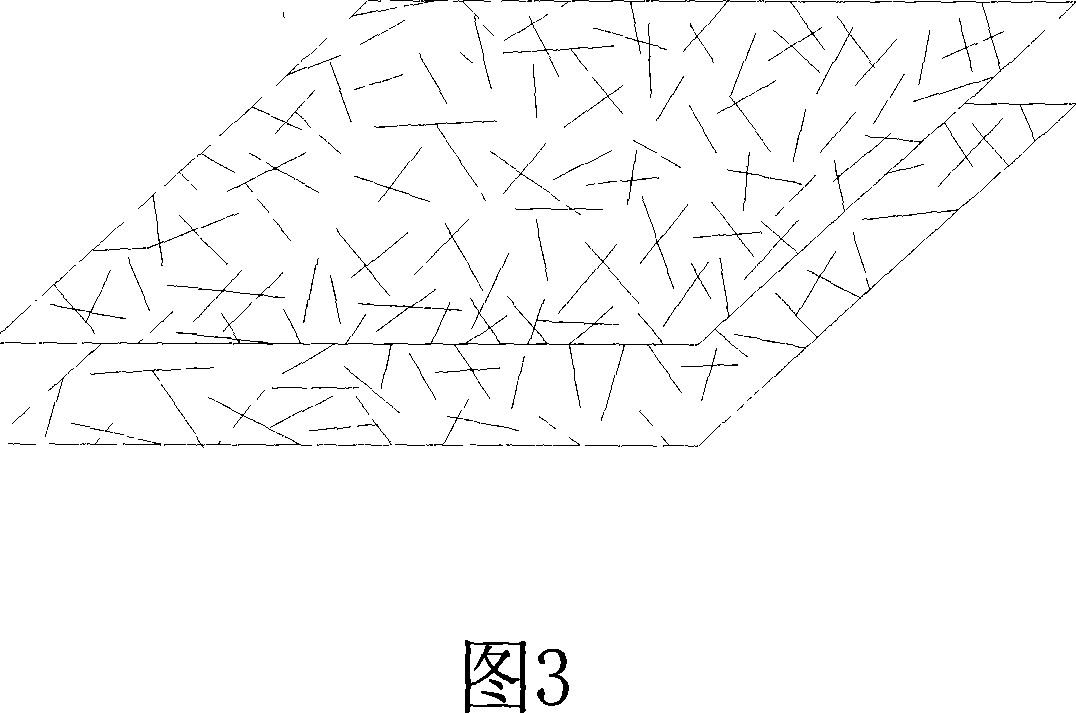

Application for waste scrap in carbon fiber/glass fiber composite material production process and products thereof

InactiveCN101062595AReduce wasteSolve pollutionSynthetic resin layered productsPlastic recyclingGlass fiberCarbon fibers

The invention relates to the carbon fiber compound material technique, particularly carbon fiber compound material sheet clippings in the processing. The leftovers are recycled by making into fiber directional random distributed new carbon fiber compound material. It sticks the leftovers into mixture, cutting the mixtures into small blocks, dipping the mixture into the resin, blending evenly for a while, distracting carbon fiber inversion for dipped mixture, selecting the pinched material to dry for a while, picking out a portion of dried material to compress to get the compound material.

Owner:陈锦松

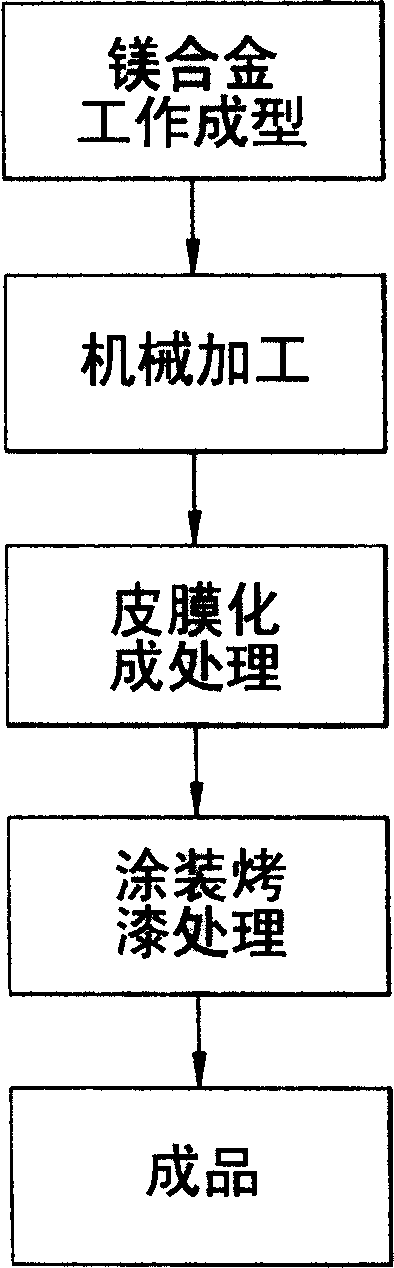

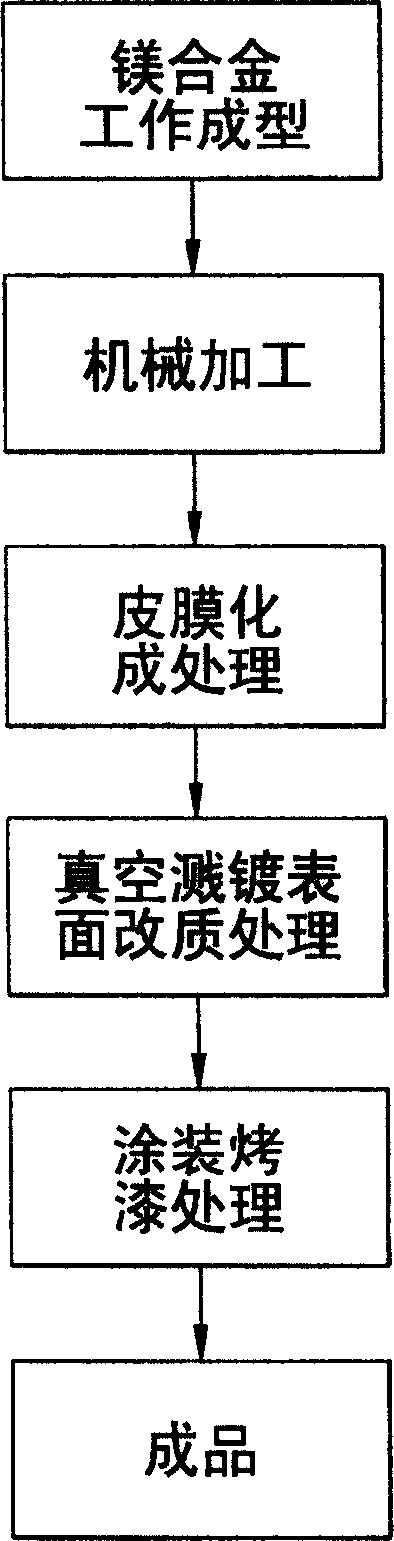

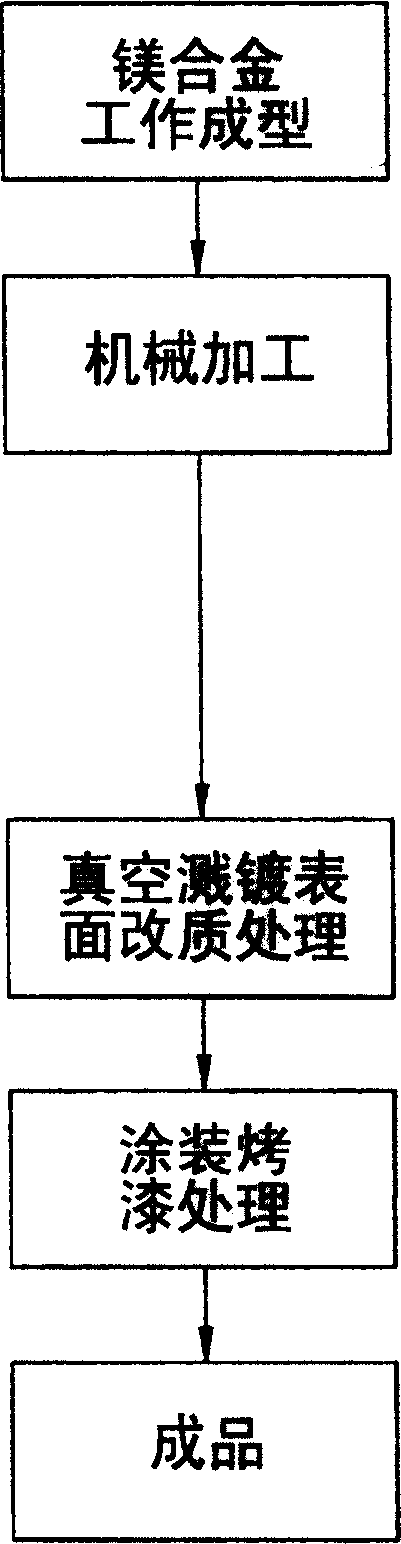

Method for manufacturing metallic products and production

InactiveCN1660510AReduced burst defectsImprove the excellent rateVacuum evaporation coatingPretreated surfacesSputteringMaterials science

A method for preparing the product of the soft metal difficult to machine, such as Mg-alloy or MgAl-alloy, features a vacuum sputtering method is used for modifying the surface of said product. Said Mg-alloy product has high surface quality.

Owner:SILITECH TECH CORP

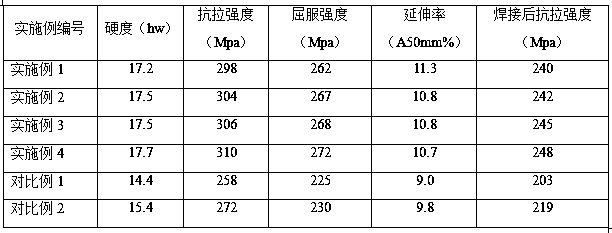

6-series aluminum alloy sectional material for new energy battery tray and machining method of 6-series aluminum alloy sectional material

ActiveCN109355537AImprove strength and toughnessImprove welding effectChemical compositionNew energy

The invention discloses a 6-series aluminum alloy sectional material for a new energy battery tray and a machining method of the 6-series aluminum alloy sectional material. According to the total weight of the 6-series aluminum alloy sectional material, the 6-series aluminum alloy sectional material comprises following chemical components including 0.65%-0.70% of Si, 0.90%-0.95% of Mg, 0.18%-22% of Cu, smaller than or equal to 0.20% of Fe, smaller than 0.1% of Mn, 0.09%-0.12% of Cr, smaller than 0.01% of Zn, smaller than 0.1% of Ti and the balance Al. The machining method of the 6-series aluminum alloy sectional material for the new energy battery tray is further included. The 6-series aluminum alloy sectional material for the new energy battery tray combines the characteristics of high strength and tenacity, high welding performance, corrosion resistance and fatigue resistance, and is suitable for the new energy battery tray machining process. The experiment shows that the hardness ofthe 6-series aluminum alloy sectional material can reach 16.2-17.5 hw, the tensile strength is larger than or equal to 290 Mpa, the yield strength is larger than or equal to 260 Mpa, and ductility islarger than or equal to 10 A50 mm%.

Owner:湖南海铝汽车工业有限公司

Parcel shelf guard board and base board material for automobile interior decoration and manufacturing process thereof

InactiveCN101275337AAvoid harmful substancesHigh heat resistanceNon-woven fabricsPolyesterPolypropylene fiber

A vehicle inner decoration package support guard board substrate material and manufacturing technology thereof are disclosed. The substrate material is composed of polypropylene fibers, fibrilia and polyester fibres. The manufacturing technology include: making a synthetic fabric felt; putting the synthetic fabric felt into an open-type oil heating mold; heating it in the mold; taking out the fabric felt in the melted state and putting it in the mold on the hydraulic machine; maintaining the fabric felt in the mold on the hydraulic machine for 2.5-3.5 minutes; and taking out the molding substrate. The invention has advantages that: the backbone material adopts environment protection material, avoids deleterious substance; the present material improves the heat resisting temperature ( 130 EDG C ) of the material based on the original technique PP+ fibrilia series scheme, which satisfy the requirement of the vehicle package support guard board material; at the present, the present material overpasses the consent of the Germany Audi company corporation, which embodies on the vehicle type Audi A6L.

Owner:TIANJIN JIACHENG AUTOMOBILE PARTS MFG

Method for improving carbon nano tube parallel array density

ActiveCN103964413ARaise Parallel ArrayOvercoming the problem of not being able to slide directly on the substrateMaterial nanotechnologyCarbon compoundsPolyesterHigh density

The invention discloses a method for improving the density in the process of carbon nano tube transfer. The method comprises the following steps: firstly, transferring the carbon nano tube parallel array growing on a substrate to a retractable membrane capable of shrinking in a single direction, such as the retractable materials of silicone rubber, polyester, a shape memory alloy and the like; secondly, shrinking the membrane in the direction perpendicular to the extension direction of the carbon nano tube to improve the density of the carbon nano tube parallel array; finally, transferring the carbon nano tube parallel array to a target substrate through the adoption of chemical methods. According to the method provided by the invention, the efficiency is high, the cost is low, the high-quality high-density carbon nano tube parallel array can be obtained, and the difficulty of transferring the conventional carbon nano tube can be solved successfully.

Owner:PEKING UNIV

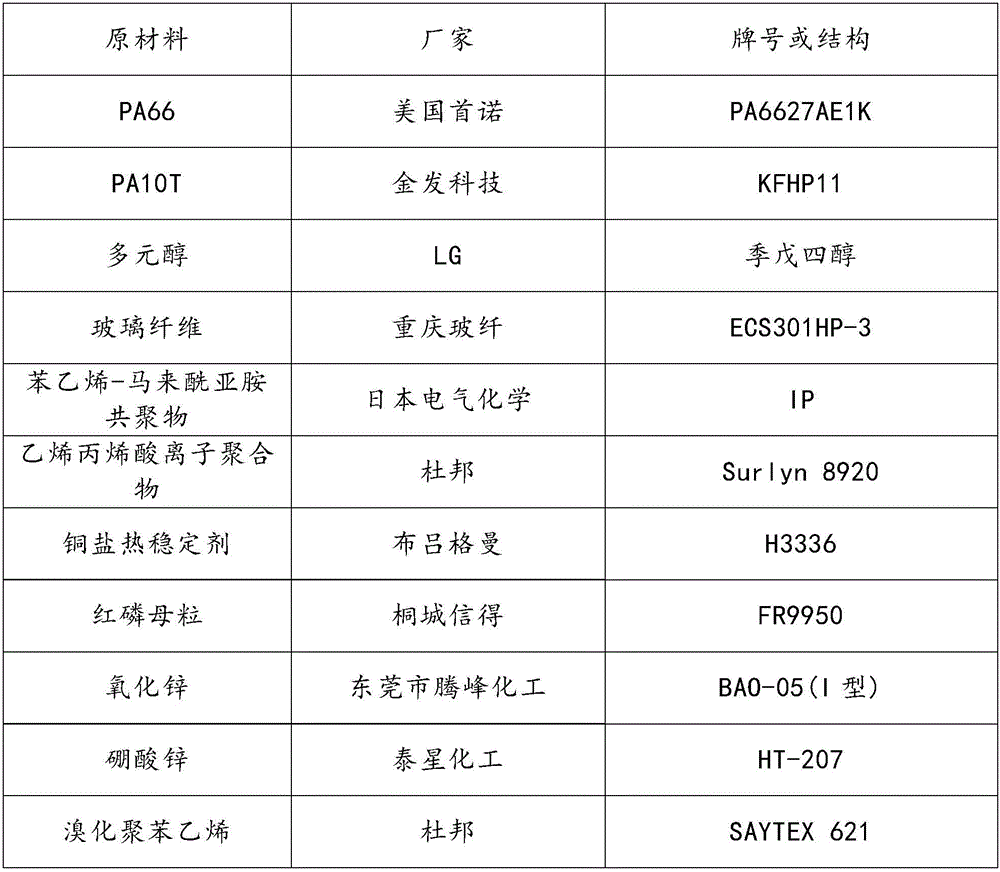

Flame-retardant and high temperature-resistant polyimide compound and preparation method thereof

InactiveCN106519663AImprove flame retardant performanceMeet material requirementsPolyesterHigh humidity

The invention discloses a flame-retardant and high temperature-resistant polyimide compound and a preparation method thereof. The compound comprises, by weight, 40-70 parts of polyimide, 0.1-30 parts of polyol, 0-10 parts of an anti-impact modifier, 0-60 parts of a filler, 5-20 parts of a flame retardant, and 0.2-1 part of a heat stabilizer. The polyol and the polyimide are blended and modified, so the high temperature ageing resistance and the flame retardation performance are effectively improved; and the carbon formation ability of the polyimide is improved, so the burning time is shortened, and the flame retardation performance of the polyimide is improved. The use amount of the flame retardant is effectively reduced, so influences of the flame retardant on the the high temperature ageing resistance of the polyamide are reduced. The anti-impact modifier regulates the anti-impact strength of alloy and plays a great role in enhancement of the compatibility of polyester and polyamide. The compound is suitable for being applied to high-temperature and high-humidity application environment of precise electronic and electric parts and automobile engine compartments and the most advanced fields of aerospace.

Owner:SHANGHAI KINGFA SCI & TECH +2

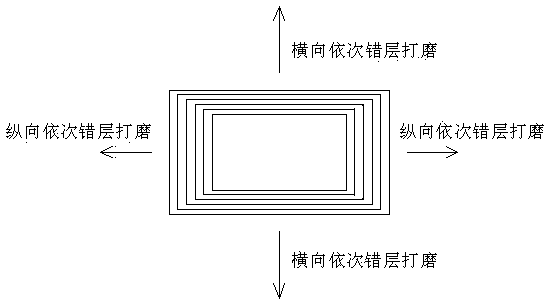

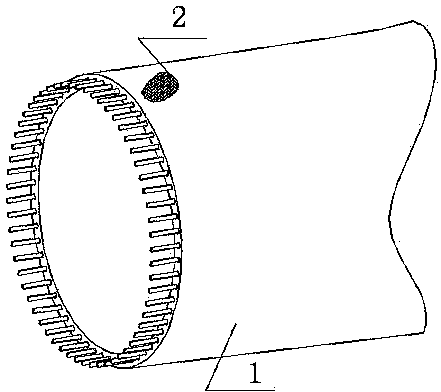

Maintaining method of dry fibers at roots of glass fiber reinforced plastic blades

The invention discloses a maintaining method of dry fibers at roots of glass fiber reinforced plastic blades. The dry fibers belong to a major quality defect easily generated when glass fiber reinforced plastic blades are formed, and can seriously impact the intensity of the glass fiber reinforced plastic blades. The maintaining method of the dry fibers at roots of the glass fiber reinforced plastic blades comprises the following ten steps: step 1, detecting the dry fibers at the roots of the blades; step 2, grinding the dry fibers at the roots; step 3, reinforcing and strengthening the annular inner parts of the blade roots; step 4, staggering and grinding the dry fibers at the blade roots; step 5, trimming the dry fibers at the blade roots and laying glass fiber cloth; step 6, trimming the dry fibers at the blade roots and carrying out vacuum laying by auxiliary materials; step 7, trimming the dry fibers at the blade roots and carrying out vacuum guide injection; step 8, trimming and precuring the dry fibers at the blade roots; step 9, trimming the dry fibers at the blade roots and uncovering a mold; and step 10, trimming the dry fibers at the blade roots and post curing. The maintaining method provided by the invention is suitable for maintaining the dry fibers at the roots of the glass fiber reinforced plastic blades.

Owner:HEILONGJIANG TIANHUA WIND POWER EQUIP MFG

Pearl embroidery design system

InactiveCN101393655AGuaranteed accuracyDrawing skills are not requiredSpecial data processing applications3D modellingPersonalizationDesign pattern

The invention provides a pearl embroidery designing system which is characterized in that the system comprises a free designing module used for designing patterns, materials and face fabric, and a product database module used for storing the information on the patterns, the materials and the face fabric. Further, the free designing module is mutually butted with the product database module for completing the virtual design of pearl embroidery products. The writing of the classes and functions required for the system is performed through a 'Visual C++ 2005' development platform and on the basis of the class library provided by 'Rhino 4.0 C++ SDK', thereby realizing the functions of all the modules of the system. The invention has the advantages that the working efficiency is improved, and the requirement on the materials for personalized pearl embroidery production can be met.

Owner:DONGHUA UNIV

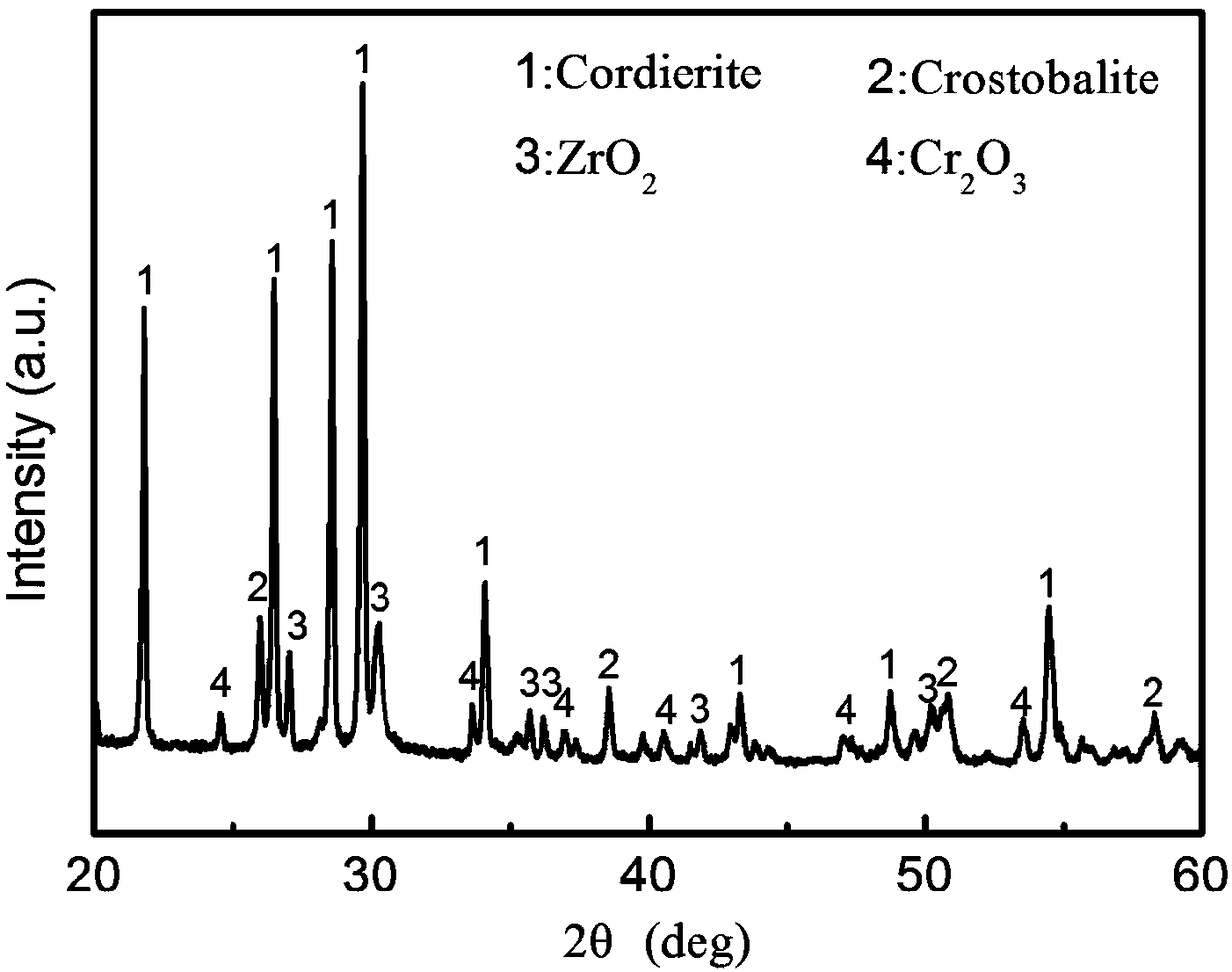

Magnesium-aluminum-silicon low-thermal-expansion-coefficient microcrystalline glass material and preparation method thereof

InactiveCN108585517ASmall coefficient of thermal expansionImprove flexural strengthDielectric lossMagnesium

The invention belongs to the field of electronic ceramic materials, and particularly provides a magnesium-aluminum-silicon low-thermal-expansion-coefficient microcrystalline glass material and a preparation method thereof which are used for overcoming the problems of high sintering temperature, large thermal expansion coefficient, low bending strength, high dielectric constant, high dielectric loss and the like of an existing ceramic material. The magnesium-aluminum-silicon low-thermal-expansion-coefficient microcrystalline glass material and the preparation method thereof have the advantagesthat the prepared low-thermal-expansion-coefficient microcrystalline glass has low thermal expansion coefficient (1.0-2.0*10<-6> per DEG C), high bending strength (150-200 MPa), low dielectric constant (5.0-5.5 @1 MHz), low dielectric loss (1.5-3.5*10<-3> @1 MHz) and reliable insulation, thereby satisfying the requirements of an LTCC electronic package substrate material; the magnesium-aluminum-silicon low-thermal-expansion-coefficient microcrystalline glass material can achieve low-temperature sintering at 900-950 DEG C, the process is simple, the stability is high, the production cost is low, and the magnesium-aluminum-silicon low-thermal-expansion-coefficient microcrystalline glass material is suitable for industrial mass production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

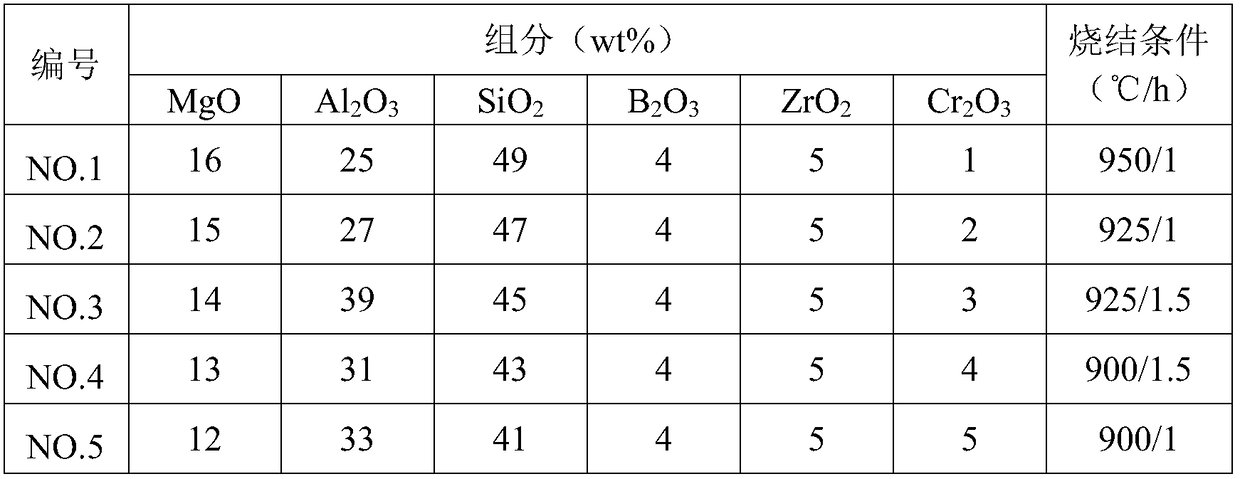

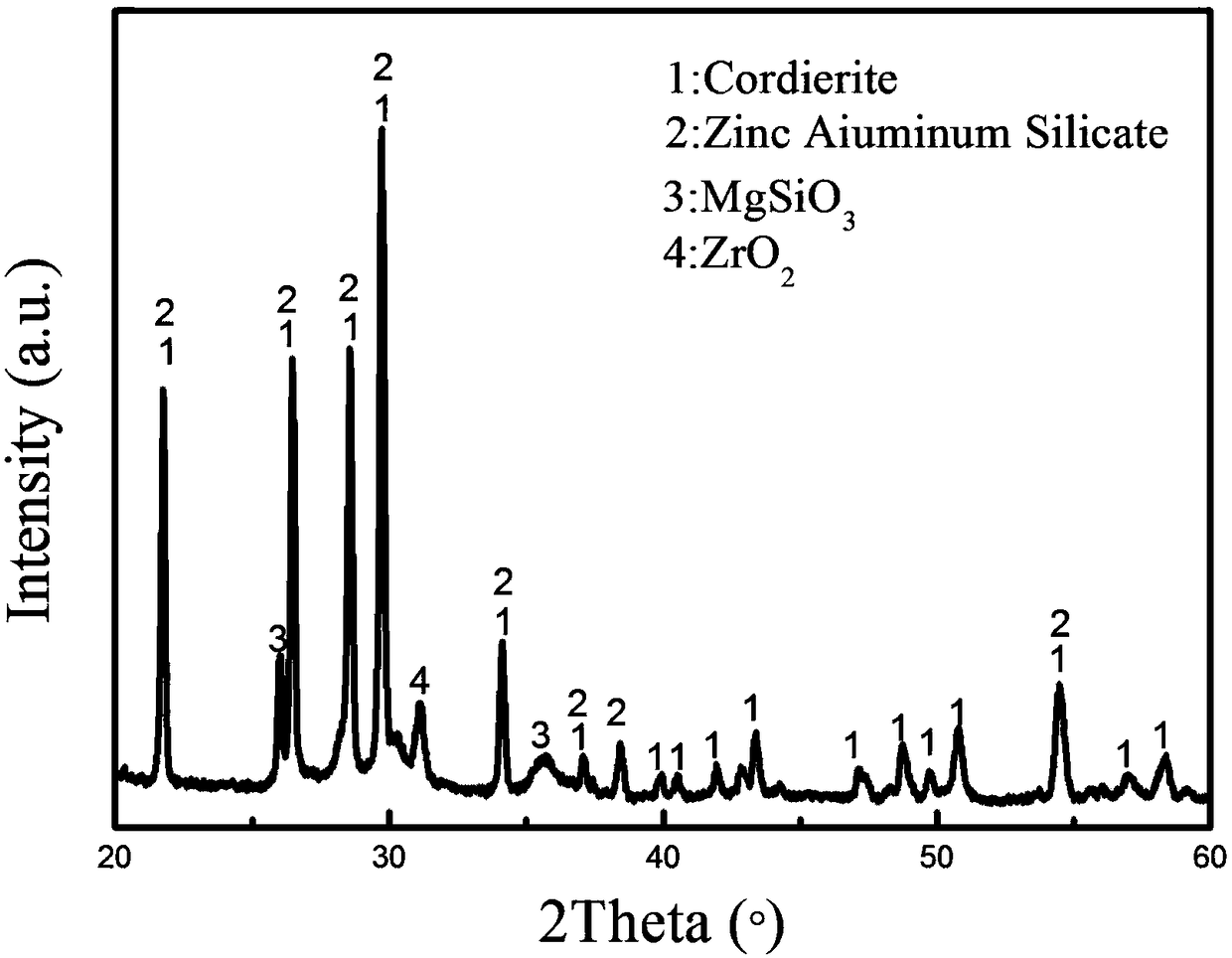

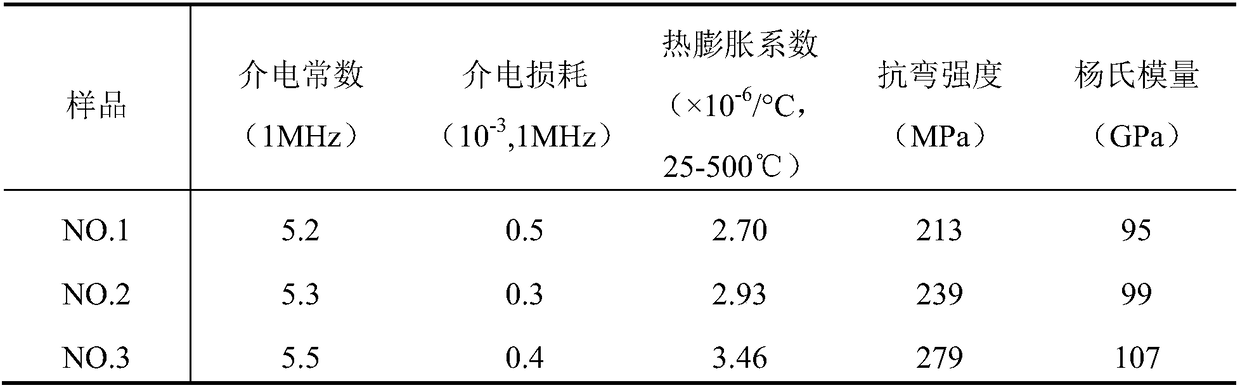

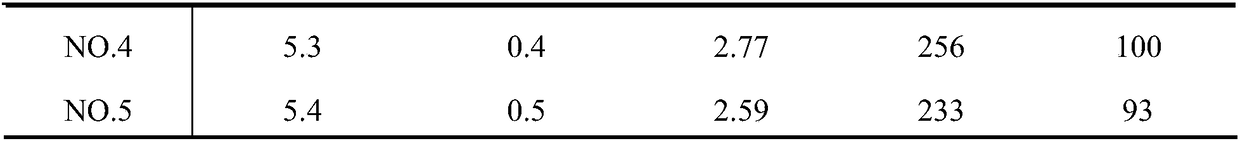

High-strength low-thermal-expansion-coefficient microcrystalline glass and preparation method thereof

InactiveCN108558215AMeet material requirementsImprove flexural strengthGlass shaping apparatusDielectric lossYoung's modulus

The invention belongs to the field of electronic ceramic materials, and particularly provides high-strength low-thermal-expansion-coefficient microcrystalline glass and a preparation method thereof. The microcrystalline glass is used for solving the problems that an existing ceramic material is high in thermal expansion coefficient (poor in matching degree with a silicon chip), low in bending strength, high in dielectric constant, large in dielectric loss and the like. The high-strength low-thermal-expansion-coefficient microcrystalline glass which is low in thermal expansion coefficient (2.5-3.5*10<-6> / DEG C), high in bending strength (200-280 MPa), high in Young modulus (90-110 GPa), low in dielectric constant (5.0-5.5@1MHz), low in dielectric loss (0.3-0.5*10<-3>@1MHz), insulating and reliable can be prepared from the components and through the preparation technology, and requirements of LTCC electronic packaging substrate materials are met; meanwhile, the microcrystalline glass issimple in process, high in stability, low in production cost and suitable for industrial batch production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing low-oxygen high-pure metal hafnium powder

ActiveCN104646659ALow content of interstitial elementsGuaranteed complete deoxygenationCrucibleMolten salt

The invention relates to a method for preparing low-oxygen high-pure metal hafnium powder; the low-oxygen high-pure metal hafnium powder has the purity of greater than 99.5wt% and the oxygen content being smaller than 0.15 wt%. The preparation method comprises the following steps: a. filling metal hafnium powder, a deoxidizing agent and a molten salt into a crucible; b, putting the crucible into a reaction tank, sealing the equipment, vacuumizing and inflating argon gas to wash the crucible, heating and deoxidizing, then performing constant-temperature and thermal-insulating deoxidization, cooling and discharging at the end of the deoxidization; c, pickling the discharged product, then washing with de-ionized water, sieving and drying the obtained product, namely, the product of the low-oxygen high-pure metal hafnium powder. The molten salt system is capable of effectively removing impurities in the metal hafnium powder, in particular, remarkably reducing the oxygen content in the hafnium powder; and the prepared low-oxygen high-pure metal hafnium powder satisfies the material requirement of high-end products.

Owner:有研资源环境技术研究院(北京)有限公司

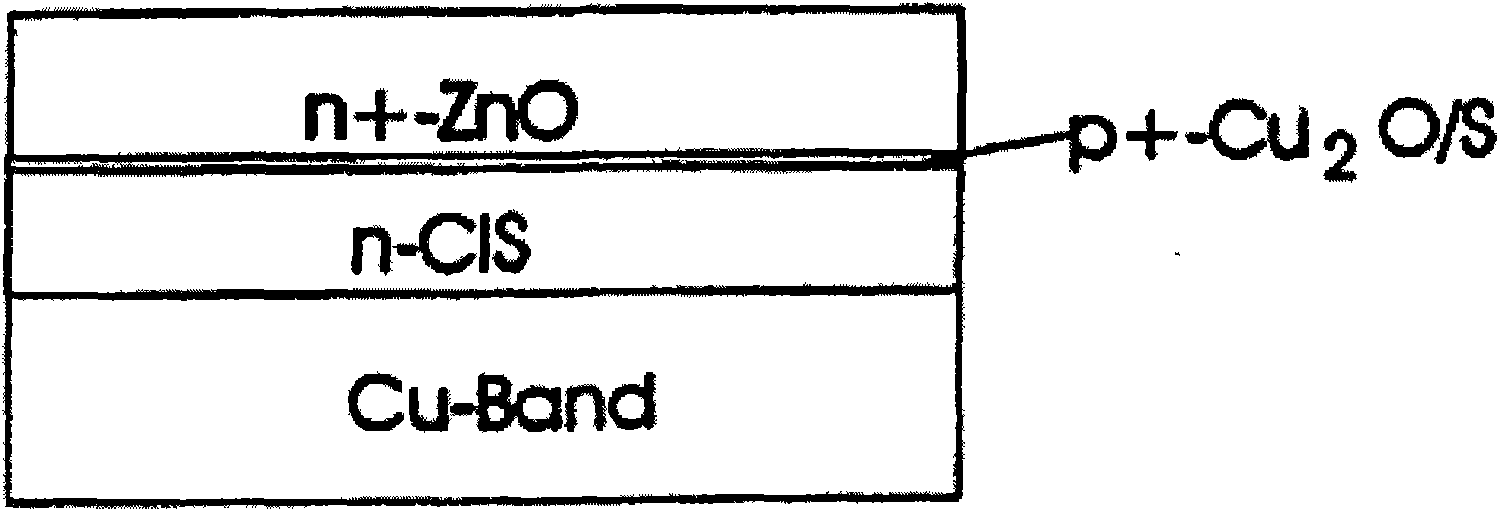

Thin film solar cell as well as base band and preparation method thereof

InactiveCN101931011AReduce thicknessAvoid pollutionFinal product manufacturePhotovoltaic energy generationAlloyDiffusion barrier

The invention relates to a thin film solar cell as well as a base band and a preparation method thereof, in particular to a thin film solar cell base band. The thin film solar cell base band comprises a substrate layer, a diffusion impervious layer and a pure copper layer, wherein the substrate layer is made of alloy materials; the diffusion impervious layer is formed on the substrate layer; and the pure copper layer is formed on the diffusion impervious layer. The invention also relates to application of the thin film solar cell base band in preparing a solar cell, a thin film solar cell comprising the thin film solar cell base band, the thin film solar base band and a preparation method of the thin film solar cell. The thin film solar cell and the base band thereof have the advantages of thin thickness and good mechanical property without polluting functional layers.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method of polycarbonate used for blow molding

The invention relates to the technical field of polycarbonate (PC), in particular to the polycarbonate used for blow molding and a preparation method thereof. The raw material in the preparation method comprises the following components in percentage by mass: 98 to 100 percent of the polycarbonate, 0.1 to 0.5 percent of chain extender, 0.1 to 1.0 percent of antioxidant, 0.01 to 0.5 percent of toner, and 0.01 to 0.5 percent of ultraviolet absorber. The polycarbonate used for the blow molding not only can be prepared simply and conveniently but also can greatly improve the yield of bottle blowing grade polycarbonate and reduce the cost; besides, blow molding uses prove that the performance of the polycarbonate for the blow molding can completely replace the bottle blowing grade polycarbonate of companies such as American GE, Germany Bayer and the like, and the polycarbonate for the blow molding meets requirements on materials for preparing drinking water buckets.

Owner:东莞市沃捷塑胶原料有限公司

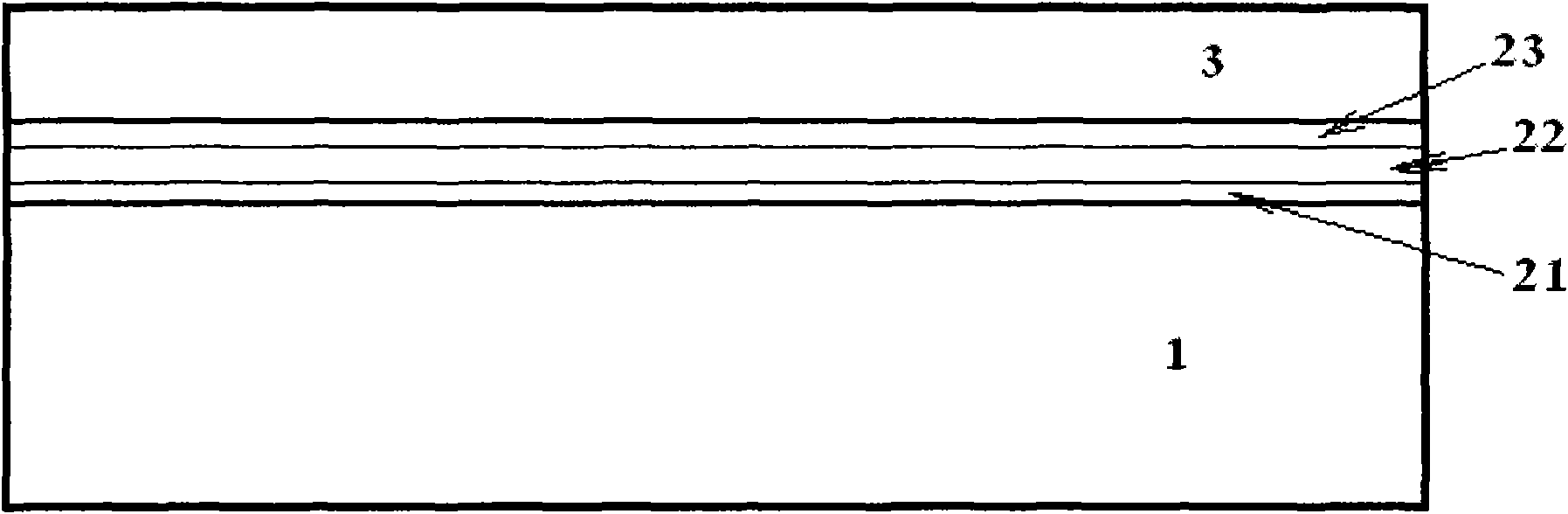

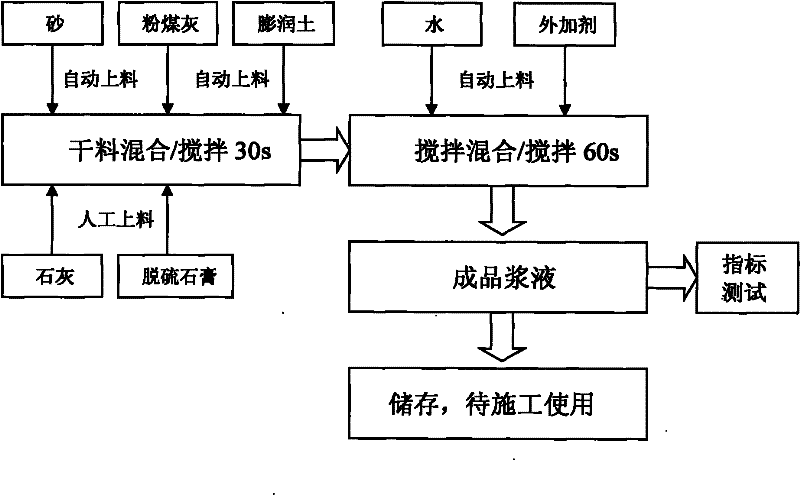

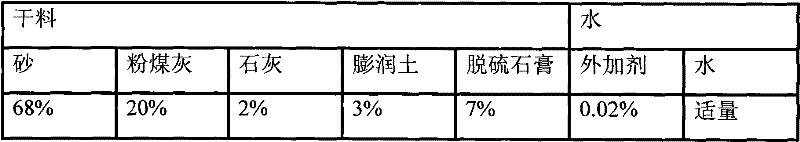

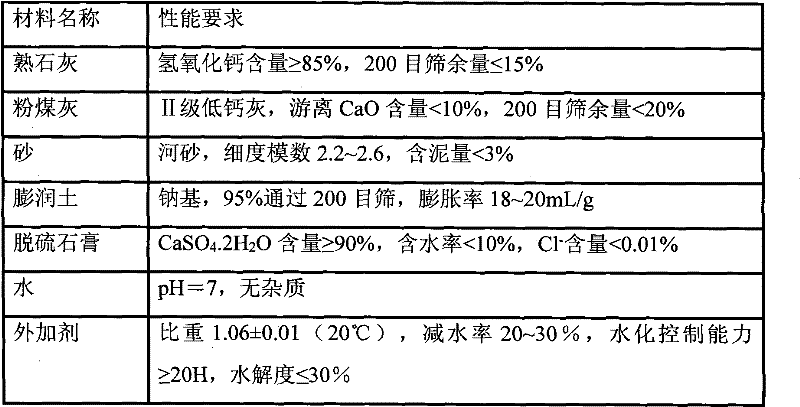

Synchronous grouting slurry for shield tunneling and preparation method thereof

InactiveCN102173699AAvoid adverse effectsReduce material costsSolid waste managementSpecific gravityIndustrial waste

The invention discloses synchronous grouting slurry for shield tunneling, which is prepared from materials including desulfurization gypsum generated in a smoke desulfurizing process of a thermal power plant. The slurry comprises the following dry material components in percentage by weight: 68 percent of sands, 20 percent of coal ash, 3 percent of bentonite, 2 percent of lime, and 7 percent of the desulfurization gypsum. The invention also provides a method for preparing the synchronous grouting slurry for field tunneling, which comprises the following steps of: weighing the sands, the coal ash, the bentonite, the lime and the desulfurization gypsum which form the dry materials; uniformly mixing and stirring the dry materials; adding proper water and additives; uniformly mixing and stirring; sampling an index of detection performance; and preparing to grout the finished product. By the method, industrial wastes of the thermal power plant are sufficiently utilized to achieve the effects of reducing slurry cost and reducing environmental pollution, the developing orientation of energy conservation and emission reduction is fulfilled, and the slurry has the advantages of high proportion, low denseness, high shearing resistance, good flow filling performance, improved later strength of slurry and the like and can be used as synchronous grouting slurry for shield tunneling.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +1

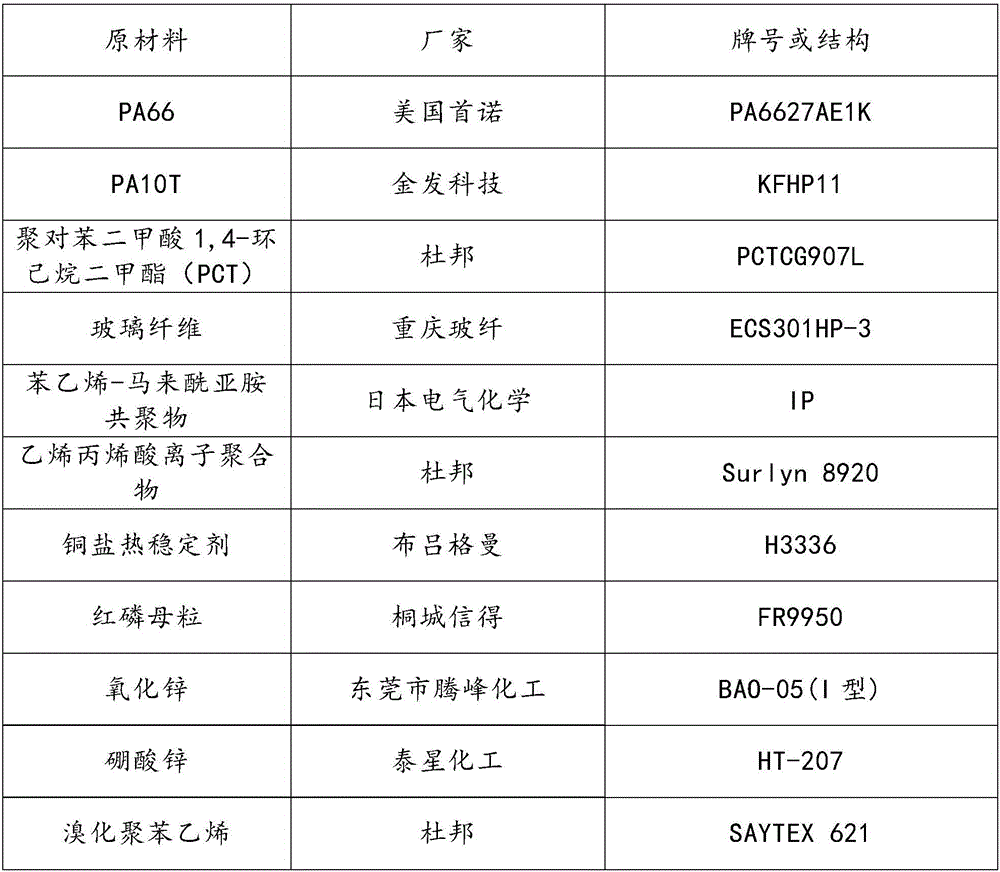

Flame-retardant high-temperature-resistance polyamide composition and preparation method thereof

The invention discloses a flame-retardant high-temperature-resistance polyamide composition and a preparation method thereof. The composition is characterized by being prepared from the following components in parts by weight: 40-70 parts of polyamide, 5-15 parts of polyester, 0-10 parts of an impact-resistant modifier, 15-60 parts of a filler, 5-200 parts of a fire retardant and 0.2-1 part of a thermal stabilizing agent. According to the method, polyester and polyamide are mixed and modified, the polyamide carbonizing capability can be improved by means of polyester, the flame retarding performance of polyamide can be improved, the usage amount of flame retardant can be reduced, and further the attenuation of high-temperature aging resistance caused by introducing massive flame retardant can be further reduced; the alloy fluidity is further improved by using polyester, and the mold filling capability in the material injection-molding process can be improved. The flame-retardant high-temperature-resistance polyamide composition is especially applicable to the most advanced fields of precise electronic appliance parts, automobile engine compartment high-temperature high-humidity application environment, aerospace and the like.

Owner:SHANGHAI KINGFA SCI & TECH +2

Preparation method of high-wear-resistance WC-based hard alloy

InactiveCN110735075AImprove corrosion resistanceImprove mixing uniformityChromium carbideWater jet cutter

The invention provides a preparation method of a high-wear-resistance WC-based hard alloy. A certain amount of molybdenum powder, chromium carbide powder and vanadium carbide powder are added before tungsten powder carbonization, and are mixed with carbon powder by a wet grinding mode, so that the powder mixing uniformity is greatly improved; the doped molybdenum powder, chromium carbide powder and vanadium carbide powder can achieve an effect of inhibiting growth of tungsten carbide grains in the tungsten powder carbonization process in the step 2 and the alloy sintering process in the step 4; and meanwhile, in the tungsten powder carbonization process, molybdenum, chromium and alum can be largely or slightly dissolved in tungsten carbide to form (W, Mo, Cr, V) C solid solution, so that guarantee is provided for formation of (W, Mo, Cr, V) C solid solution powder with fine and uniform particle size in the later tungsten powder carbonization process, and the purpose of reinforcing physical performances of the tungsten carbide grains and alloys thereof is achieved. The prepared non-bonded-phase WC-based hard alloy is high in hardness and excellent in wear resistance, and can satisfythe high wear resistance requirements of water jet sand pipes and fracturing nozzles on materials.

Owner:ZIGONG CEMENTED CARBIDE CORP

Corrosion-resistant and wear-resistant high-conductivity alloy for sockets

The invention discloses a corrosion-resistant and wear-resistant high-conductivity alloy for sockets. The alloy comprises the following components in percentage by weight: 21-23% of zinc, 2-3% of aluminum, 0.2-0.4% of phosphorous, 1.5-2.5% of silver, 0.1-0.5% of yttrium, 1.5-2.5% of chromium, 0.3-0.5% of nickel, 1-2% of vanadium, 0.1-0.3% of lead and the balance of copper. The invention also provides a preparation method of the corrosion-resistant and wear-resistant high-conductivity alloy for sockets. The preparation method comprises the steps such as smelting, draw casting, hot rolling, solid solution, finish rolling and aging treatment. The corrosion-resistant and wear-resistant high-conductivity alloy for sockets disclosed by the invention has relatively high conductivity and hardness, good corrosion resistance and good properties in elasticity, strength and the like, basically reaches or exceeds the properties of common tin-phosphorous bronze materials, can completely meet the material requirements of socket sleeves and is a very proper substitute material; due to low dosage of precious materials, the cost is greatly reduced; and meanwhile, the preparation method is simple in process and easy to implement and thus is suitable for industrial mass production.

Owner:陈晓东

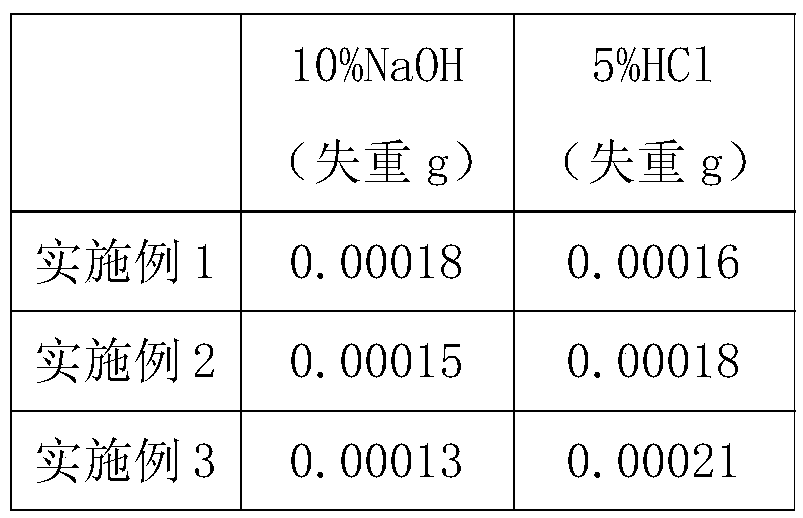

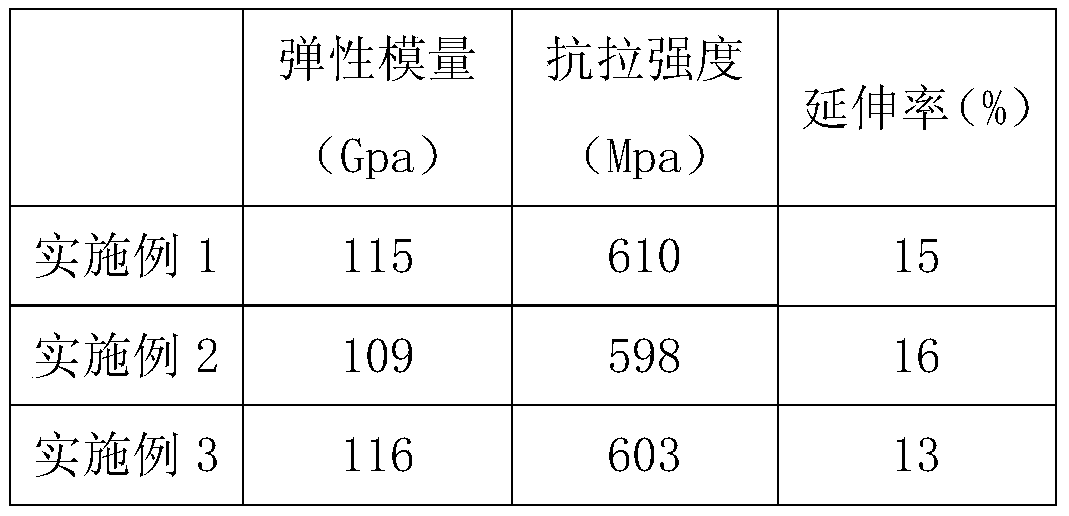

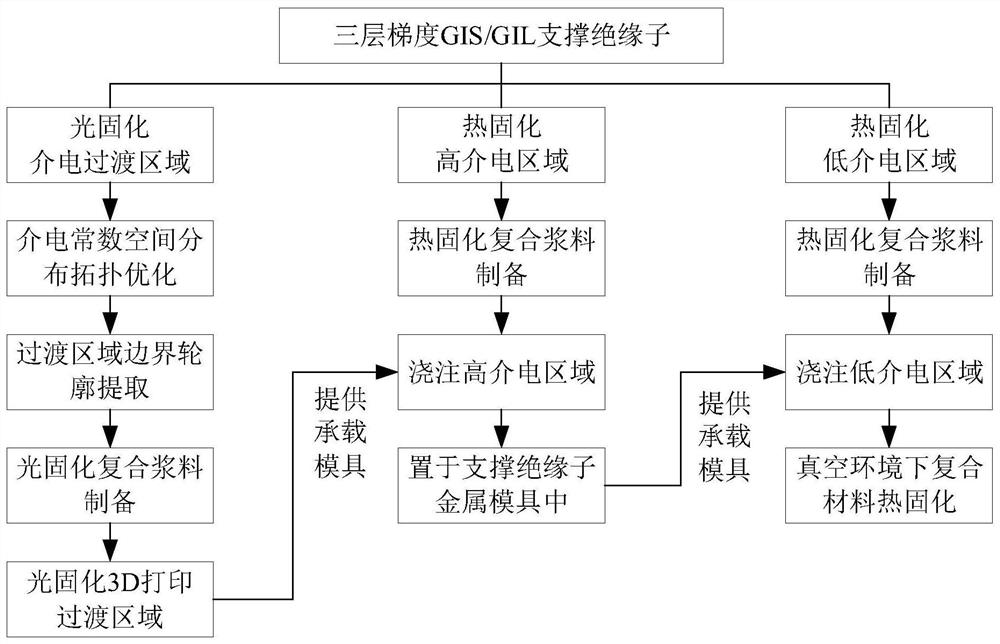

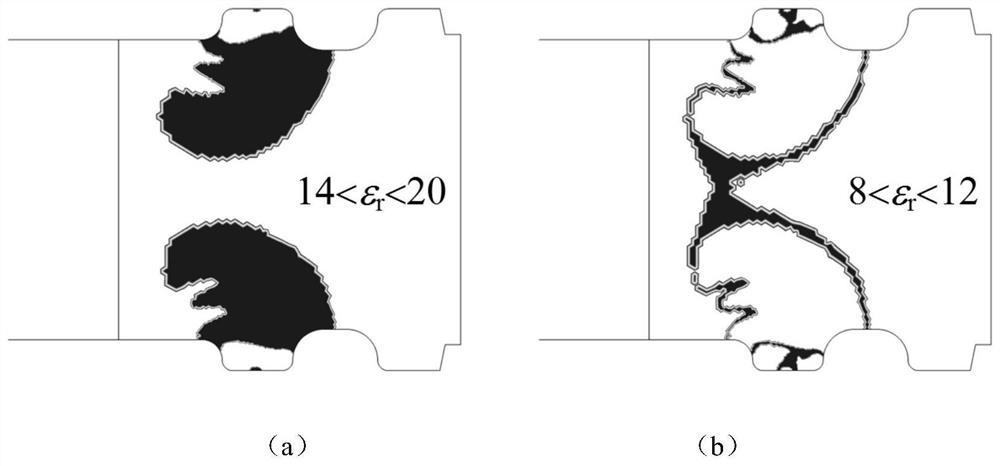

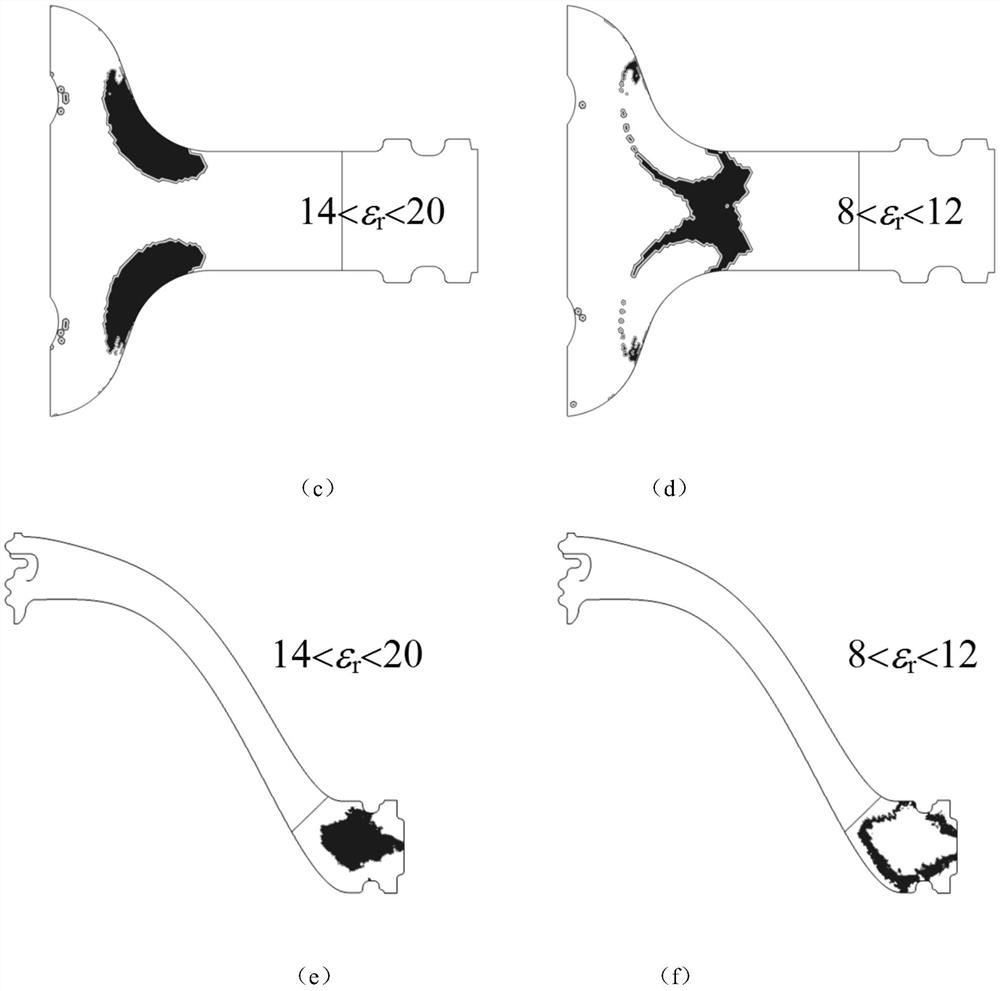

Preparation method of three-layer gradient GIS/GIL supporting insulator

ActiveCN113284684AGuaranteed mechanical strengthImprove electrical strengthAdditive manufacturing apparatusAdditive manufacturing with liquidsDielectricMetal mold

The invention discloses a preparation method of a three-layer gradient GIS / GIL supporting insulator, which aims at reducing the electric field intensity of an insulator along a surface or a local region as an optimization target, and solves the optimal spatial distribution of a dielectric constant in the supporting insulator by using a variable density algorithm. According to the optimization result, the dielectric constant change area is divided into a dielectric constant transition area and a high dielectric area, the combination contour of the dielectric constant transition area is extracted, and then a hollow dielectric constant transition area with a support and a resin sprue gate is generated through photocuring 3D printing; a thermocurable high-dielectric composite material is prepared by adopting a high-dielectric filler / polymer blending mode, and then the high-dielectric composite material is poured into the dielectric constant transition area and integrally put into a metal mold for fixing; and a thermocurable high-dielectric composite material is prepared in a low-dielectric filler / polymer blending mode, then the thermocurable high-dielectric composite material is poured into a metal mold, and the three-layer gradient GIS / GIL supporting insulator can be obtained after curing is completed in vacuum.

Owner:XI AN JIAOTONG UNIV

Mobile terminal component and preparation method thereof

ActiveCN110086898AImprove bindingImprove cohesionTelephone set constructionsHigh volume manufacturingMetallurgy

The invention discloses a mobile terminal component. The mobile terminal component comprises a ceramic component, a plastic component and a bonding layer; the bonding layer is used for connecting theceramic component and the plastic component; a gravel layer is arranged on the surface, making contact with the bonding layer, of the ceramic component, and the particle size D50 of gravel in the gravel layer ranges from 20 m to 400 m. According to the component, the binding force of the ceramic component and the plastic mold is high after injection molding, no offset or gap exists at the joint ofthe ceramic component and the plastic component, the problem that fine substances such as dust and scurf are adsorbed and embedded can be effectively avoided, and the texture and the aesthetic feeling of the ceramic-plastic composite component can be improved. The invention further provides a preparation method of the mobile terminal component, and the preparation method is simple in technological process, high in operability and suitable for mass production of the injection molding ceramic components in the mobile terminal mold.

Owner:CHAOZHOU THREE CIRCLE GRP

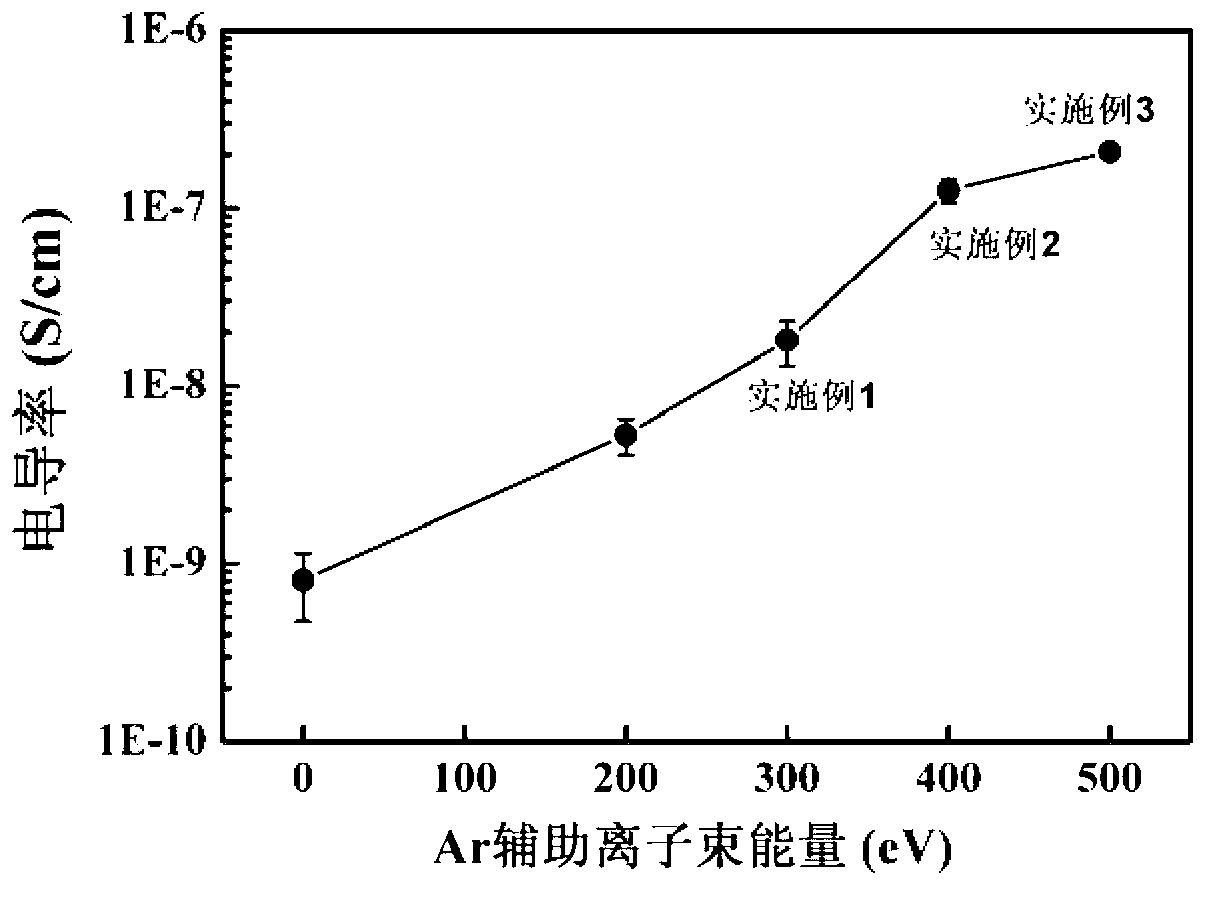

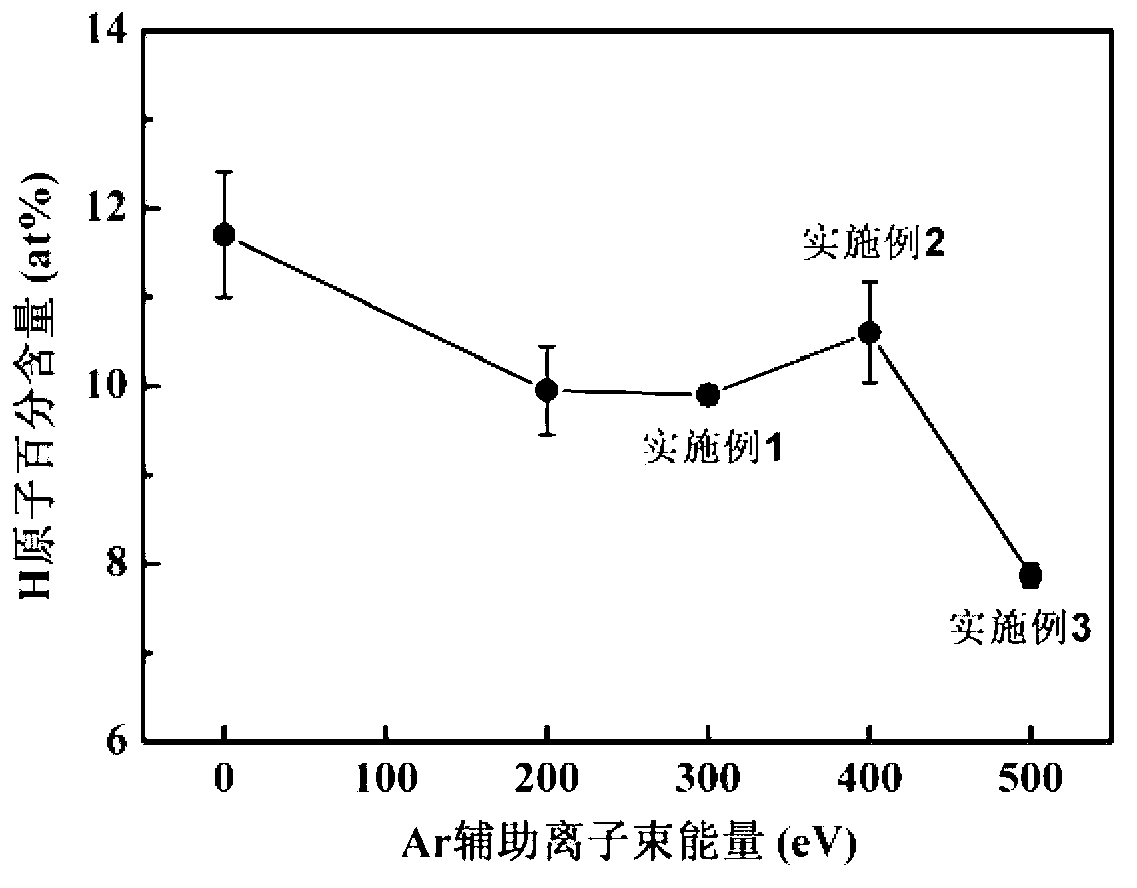

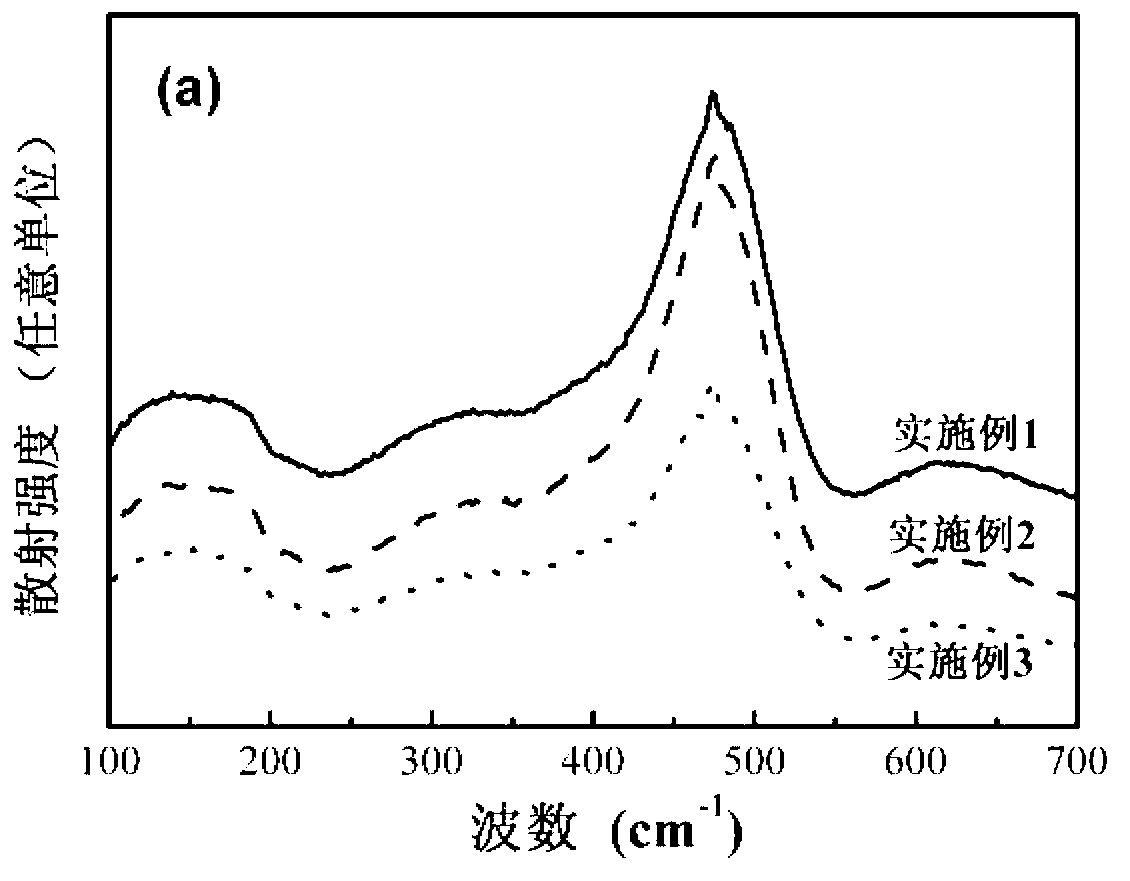

Method for preparing low-boron-doped high-conductivity hydrogenated amorphous silicon film

InactiveCN103346069ANo pollution in the processH content can be adjustedFinal product manufactureVacuum evaporation coatingBoron atomSolar cell

The invention discloses a method for preparing a low-boron-doped high-conductivity hydrogenated amorphous silicon film. An ion beam auxiliary magnetic control sputtering technology is adopted, boron-doped monocrystalline silicon doped with 0.02-0.2at% of boron atoms is used as magnetic control sputtering target materials for carrying out sputtering, the base pressure is 104-105Pa, the radio frequency power is 100-300W, the sputtering gas is mixed gas of argon and hydrogen, the total pressure of the sputtering gas is 0.1-0.5Pa, the temperature of a substrate is 100-400 DEG C, the high-purity argon is used as an auxiliary atom source for forming an argon auxiliary ion beam, the energy of the argon auxiliary ion beam is 100-800eV, the beam stream is 5-30mA, the film is formed and deposited on the surface of the substrate in a sputtering mode, meanwhile, the argon auxiliary ion beam strikes the surface of the film, and the low-boron-doped high-conductivity a-Si:H hydrogenated amorphous silicon film is obtained. The method is simple in preparation process, low in cost and suitable for large-scale industrial production. The a-Si:H film prepared by the method has high conductivity and good structural characteristics, the requirements of silicon-based film solar cell window layer materials are met, and the improvement of the performance of a solar cell is facilitated.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com