6-series aluminum alloy sectional material for new energy battery tray and machining method of 6-series aluminum alloy sectional material

A technology of aluminum alloy profiles and battery trays, which is applied in the field of aluminum alloy processing, can solve the problems of lack of special alloys, etc., and achieve high welding performance, good heat conduction and welding performance, and good heat conduction and welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

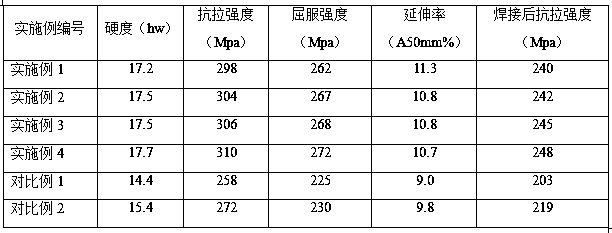

Examples

Embodiment 1

[0032] A processing method for 6-series aluminum alloy profiles for new energy battery trays includes the following steps:

[0033] (1) Heat the raw material aluminum ingot to 730°C to melt to obtain molten aluminum;

[0034] (2) Remove scum on the surface of molten aluminum, according to the chemical composition of 6 series aluminum alloy profiles: Si 0.65%, Mg 0.92%, Cu 0.20%, Fe 0.15%, Mn 0.05%, Cr 0.10%, Zn 0.003%, Ti 0.05 %, the balance is the standard of Al to adjust the content of alloying elements in the molten aluminum, and refining and standing;

[0035] (3) Filter the aluminum liquid after standing, and then cast it while cooling with water at a temperature of 23°C for 60 minutes to obtain an aluminum rod with a diameter of 152mm;

[0036] (4) After preheating the aluminum rod at a temperature of 510°C for 3 hours, extrude it at an extrusion speed of 10m / min and at a temperature of 520°C at the discharge port. Utilizing the high-temperature solid solution effect in...

Embodiment 2

[0039] A processing method for 6-series aluminum alloy profiles for new energy battery trays includes the following steps:

[0040] (1) Heat the raw material aluminum ingot to 720°C to melt to obtain molten aluminum;

[0041] (2) Remove scum on the surface of molten aluminum, according to the chemical composition of 6 series aluminum alloy profiles: Si 0.68%, Mg 0.90%, Cu 0.22%, Fe 0.20%, Mn 0.03%, Cr 0.09%, Zn 0.008%, Ti 0.03 %, the balance is the standard of Al to adjust the content of alloying elements in the molten aluminum, and refining and standing;

[0042] (3) Filter the molten aluminum after standing, and then cast it while cooling with water at a temperature of 26°C for 62 minutes to obtain an aluminum rod with a diameter of 152mm;

[0043] (4) After preheating the aluminum rod at a temperature of 520°C for 2.5 hours, extrude it at an extrusion speed of 8m / min and at a temperature of 530°C at the discharge port. Utilizing the high temperature solid solution effect d...

Embodiment 3

[0046] A processing method for 6-series aluminum alloy profiles for new energy battery trays includes the following steps:

[0047] (1) Heat the raw material aluminum ingot to 740°C to melt to obtain molten aluminum;

[0048] (2) Remove scum on the surface of molten aluminum, according to the chemical composition of 6 series aluminum alloy profiles: Si 0.66%, Mg 0.94%, Cu 0.21%, Fe 0.18%, Mn 0.08%, Cr 0.11%, Zn 0.001%, Ti 0.08 %, the balance is the standard of Al to adjust the content of alloying elements in the molten aluminum, and refining and standing;

[0049](3) Filter the molten aluminum after standing, and then cast it while cooling with water at a temperature of 24°C for 60 minutes to obtain an aluminum rod with a diameter of 152mm;

[0050] (4) After preheating the aluminum rod at a temperature of 500°C for 4 hours, extrude it at an extrusion speed of 5m / min and at a temperature of 520°C at the discharge port. Utilizing the high-temperature solid-solution effect in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com