Current collection component of anode supporting tube type solid oxide fuel cell and application thereof

A solid oxide, fuel cell technology, used in fuel cell parts, solid electrolyte fuel cells, fuel cells, etc., can solve the problems of battery performance decline, large volume, and no solution to alloys, and achieve the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

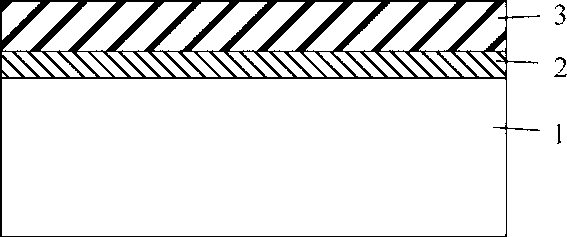

[0033] Such as figure 1 As shown, the tube-type SOFC collector component includes an alloy substrate 1 and a protective coating 3 coated on the surface of the collector. There is also a pre-oxidized layer 2 between the substrate and the protective coating.

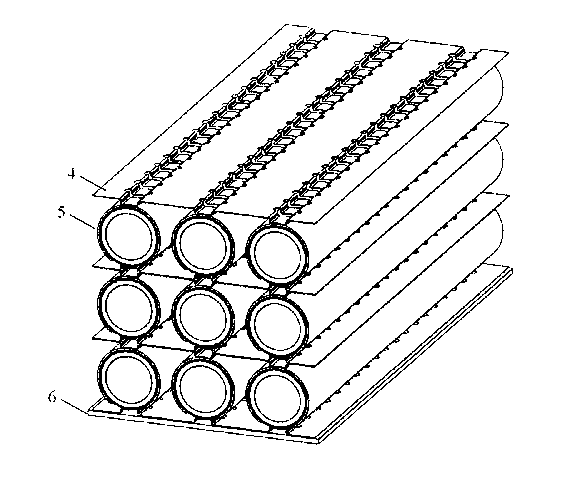

[0034] Fig. 2 is a perspective view showing an anode support tube type SOFC current collecting part of the present invention and a mode of its application, and Fig. 3 is a cross-sectional view of Fig. 2(a) and its enlarged view, and the battery pack includes 3 * 3 circular tubes Type battery cell array, the battery cells are parallel to each other along the tube axis, and the battery cells are arranged in a rectangular shape when viewed from a section perpendicular to the tube axis.

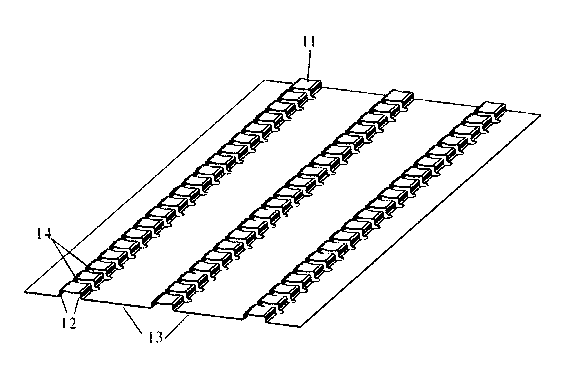

[0035] The current collecting part 4, as shown in FIG. 2(b), contains curved and undulating shape features on the cross-section of the plate-shaped alloy base material perpendicular to the axial direction of the tubular battery unit 5, and t...

Embodiment 2

[0039] Such as Figure 4 As shown, the difference from Embodiment 1 is that the side wall 12 is changed to an inclined type (12'), and a bend 15 is added in the middle of the arc connecting portion 13, and the shape of the bend can be V-shaped, S-shaped, Arcs or repetitions and combinations of the above shapes. The above changes can increase the elastic deformation capacity of the current collecting component 4, so that the current collecting component 4 can better absorb the strain caused by thermal expansion and reduce the influence of thermal stress.

Embodiment 3

[0041] The difference from Example 1 is that in this example, the plate-shaped alloy substrate 1 uses a Fe-Cr alloy with a brand name of SUS430, the thickness of the alloy substrate 1 is about 0.5 mm, and no pre-oxidation treatment is performed before coating.

[0042] In addition, the conductive composite oxide in the coating material is prepared by a solid-state reaction method with a composition of Cu 1.3 co 1.7 o 4 of powder. Will Cu 1.3 co 1.7 o 4 Powder, MnO 2 The powder is mixed in a molar ratio of 80:20, and n-butanol and PVB are added as an organic solvent and a binder, the weights of which are 200% and 10% of the total weight of the powder respectively, and a slurry with a solid phase content of 32% is formed after ball milling and dispersion , the slurry is evenly coated on the surface of the alloy substrate by dipping twice, and after drying, it is sintered at 800°C for 24h, and the thickness of the coating 3 is about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com