Patents

Literature

165results about How to "High temperature oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

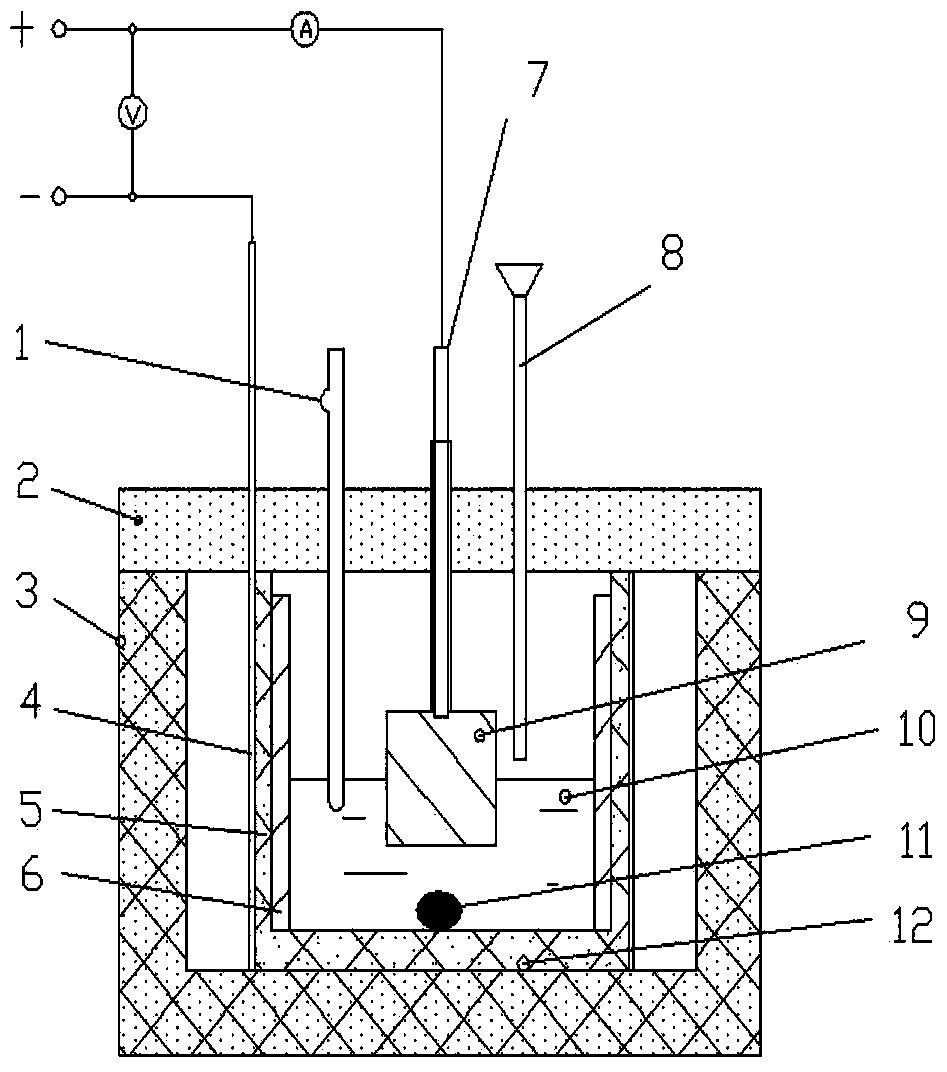

Aluminum electrolysis inert anode

InactiveCN103757661AAvoid consumptionWith energy saving and emission reductionElectrolysisHigh entropy alloys

The invention provides an aluminum electrolysis inert anode of which the material is a high-entropy alloy. The high-entropy alloy contains 5-10 alloy elements of which the mole ratio can be identical or different; and the atomic percent of each main element is 5-35%. The high-entropy alloy inert anode has the characteristics of favorable high-temperature oxidation resistance, high aluminum electrolysis salt corrosion resistance, high electric conductivity and the like. The high-entropy alloy prepared by the smelting method has the advantages of simple technique and low cost, and is easy for connection. When being used for aluminum electrolysis, the high-entropy alloy can avoid the consumption of the carbon anode and the emission of the CO2 gas, and has the advantages of energy saving and emission reduction.

Owner:FUJIAN UNIV OF TECH

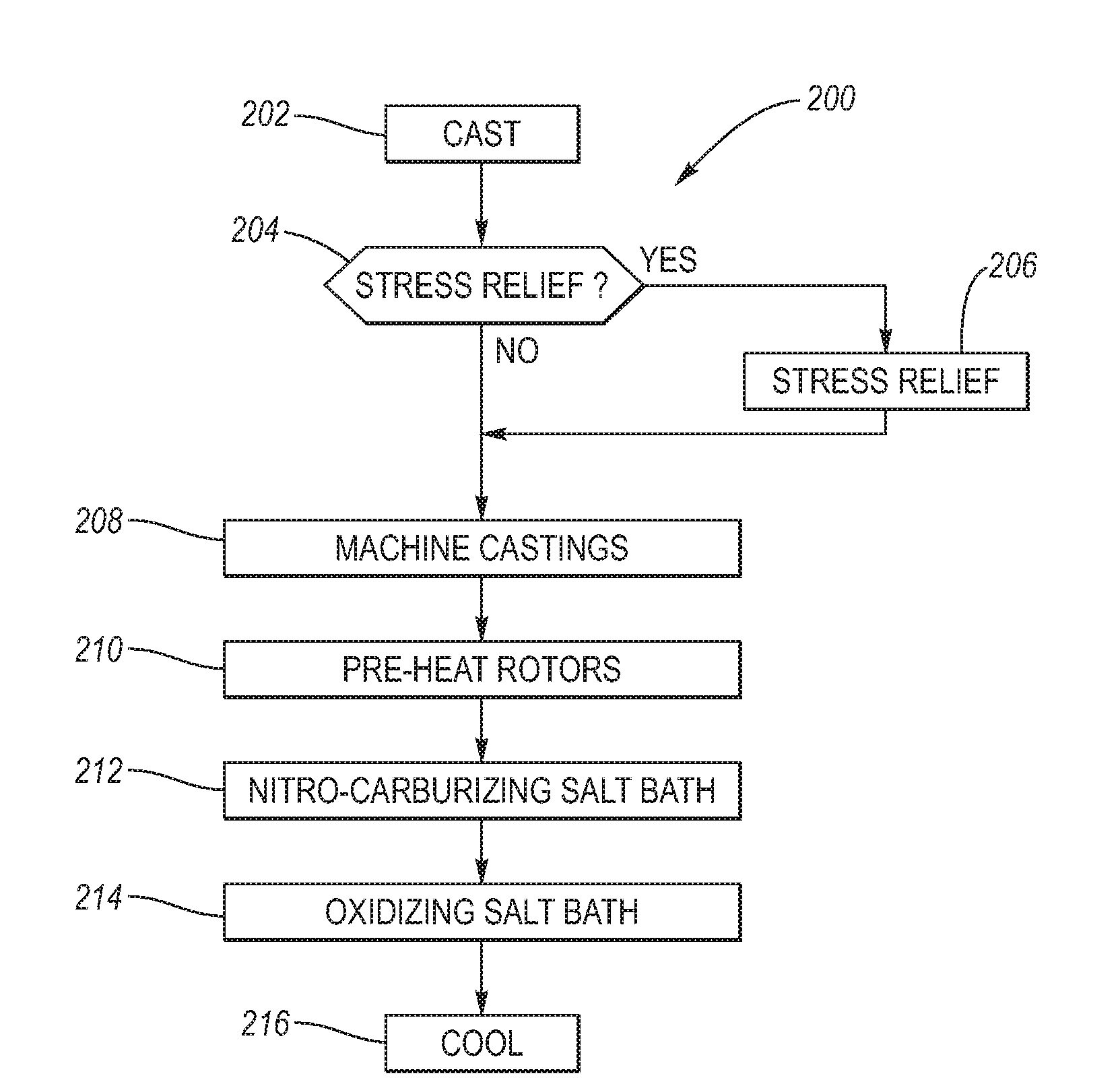

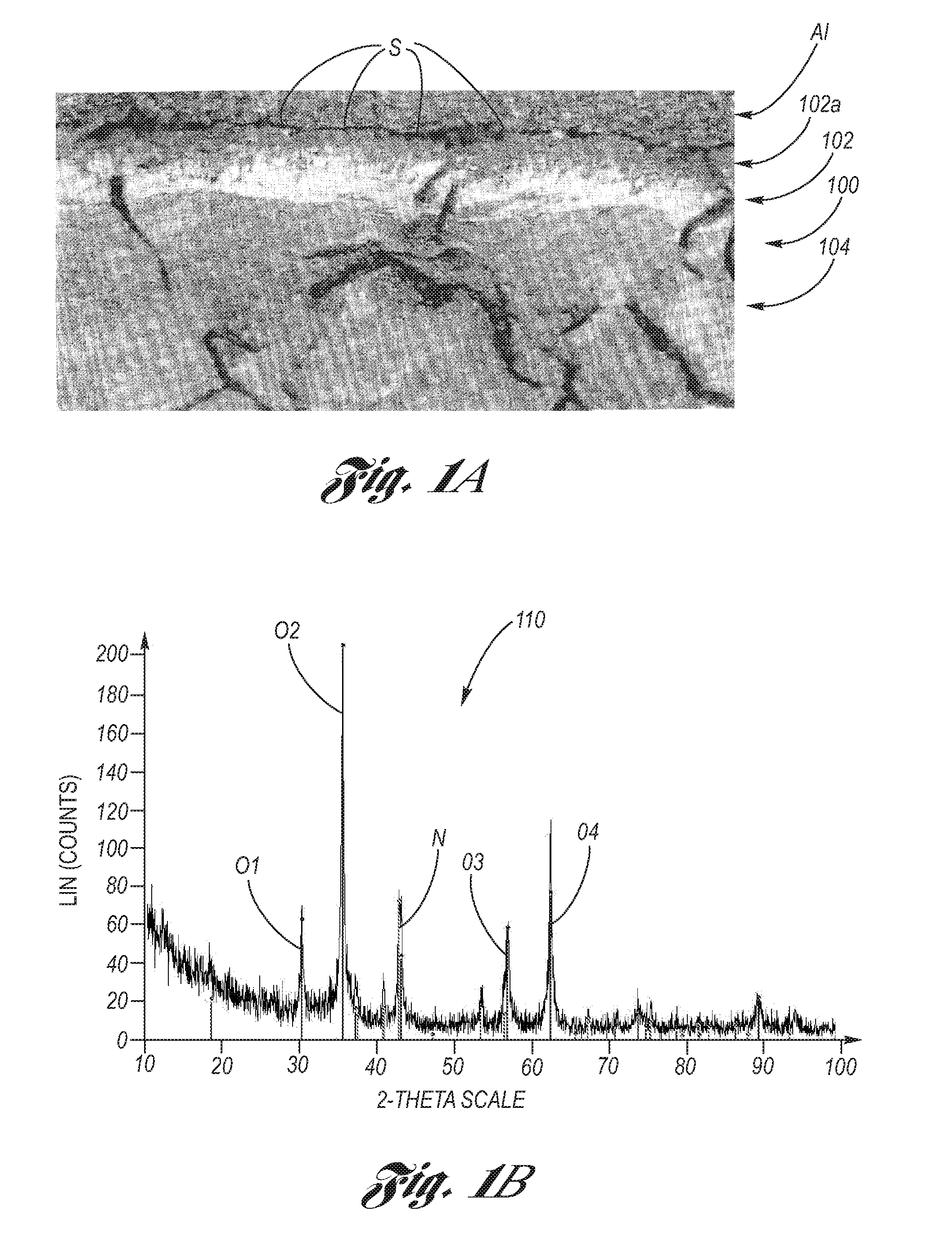

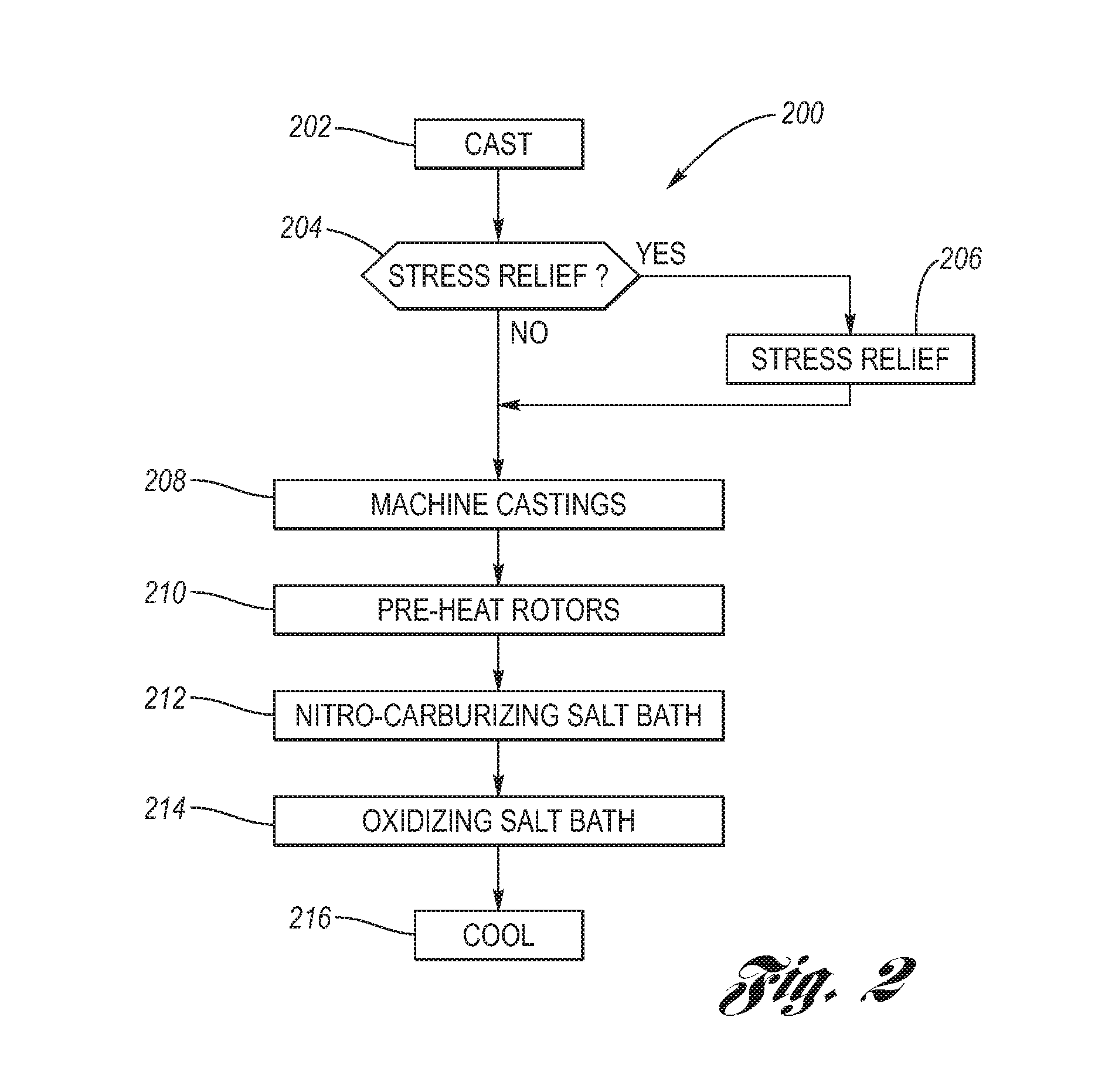

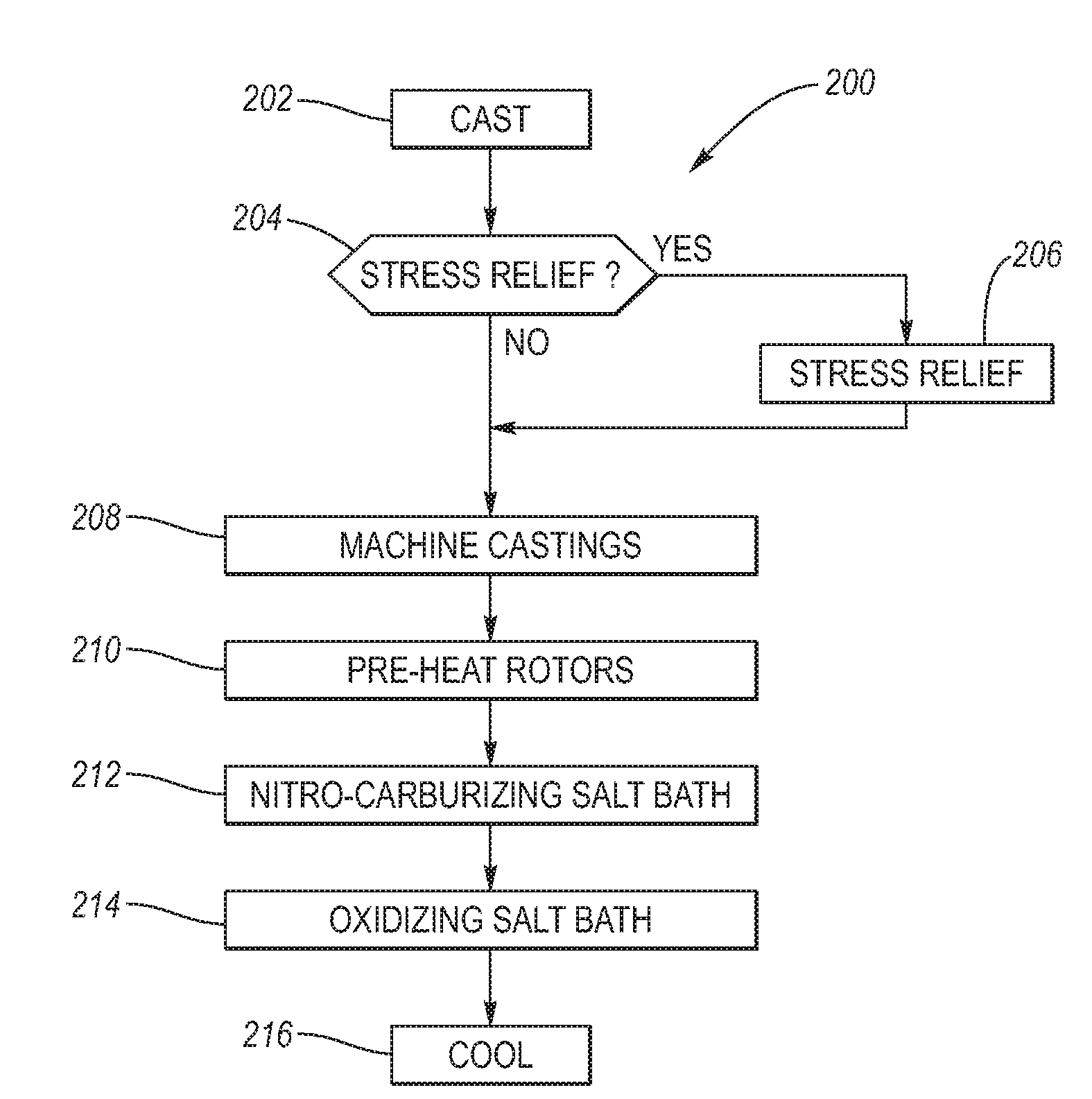

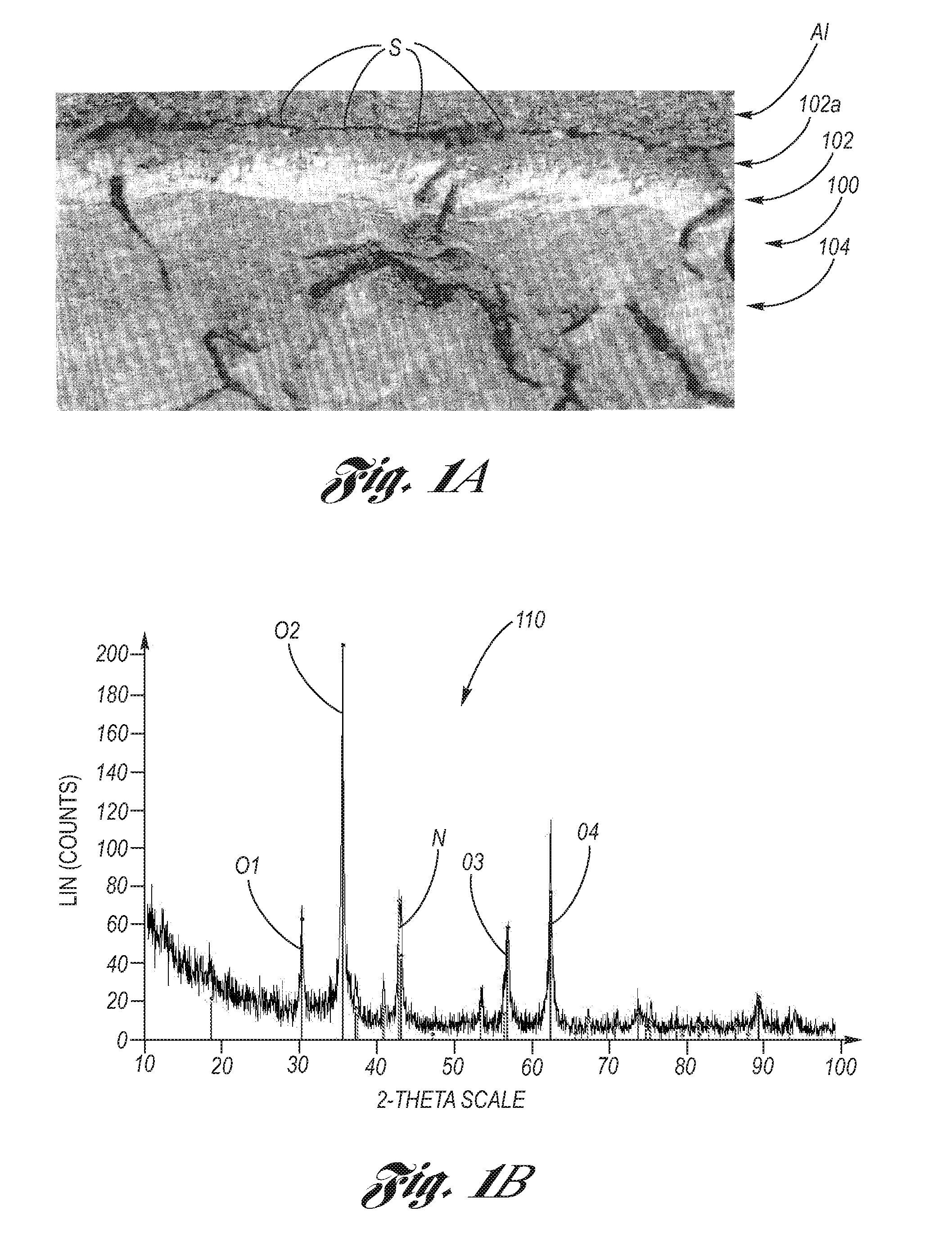

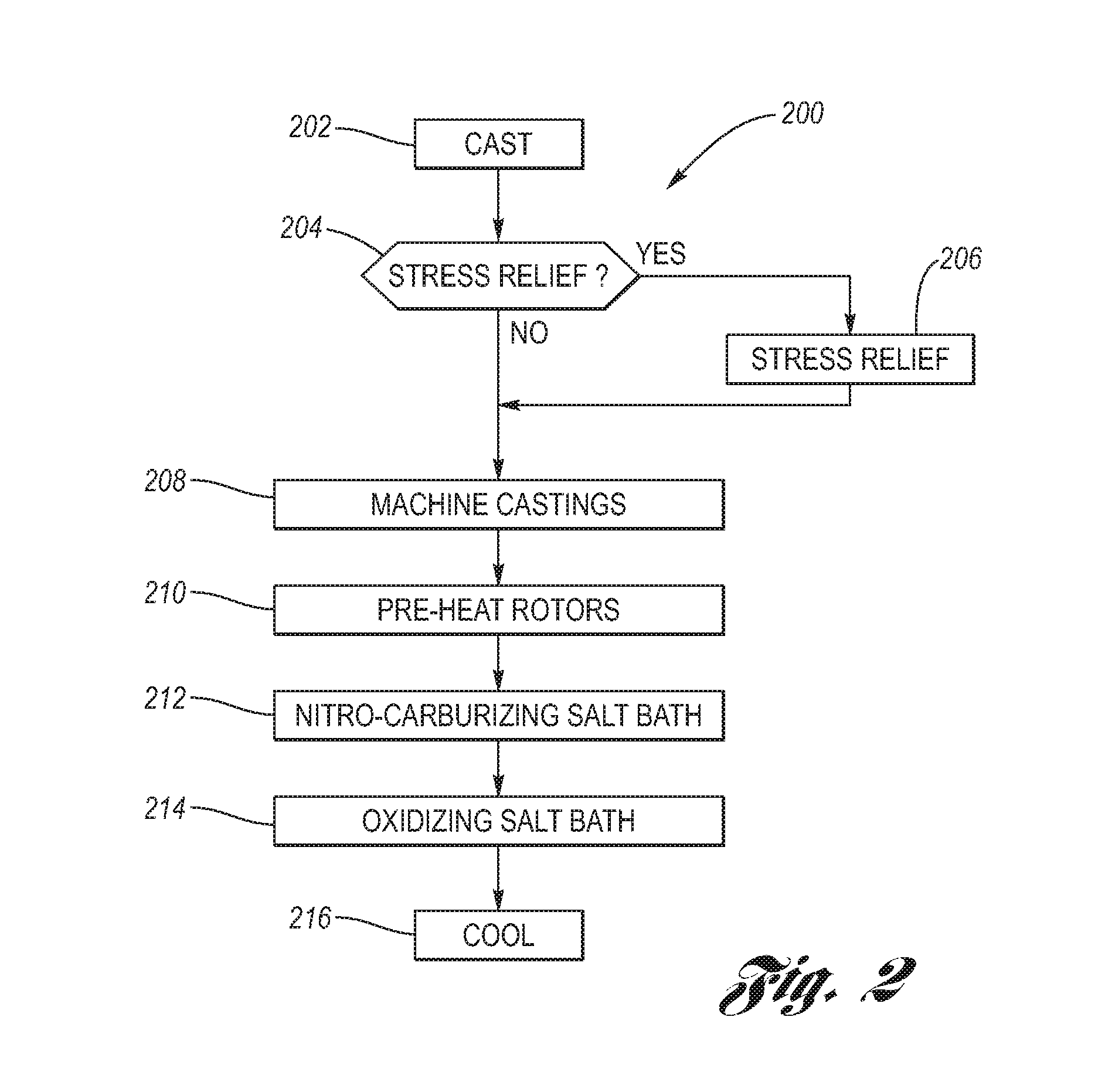

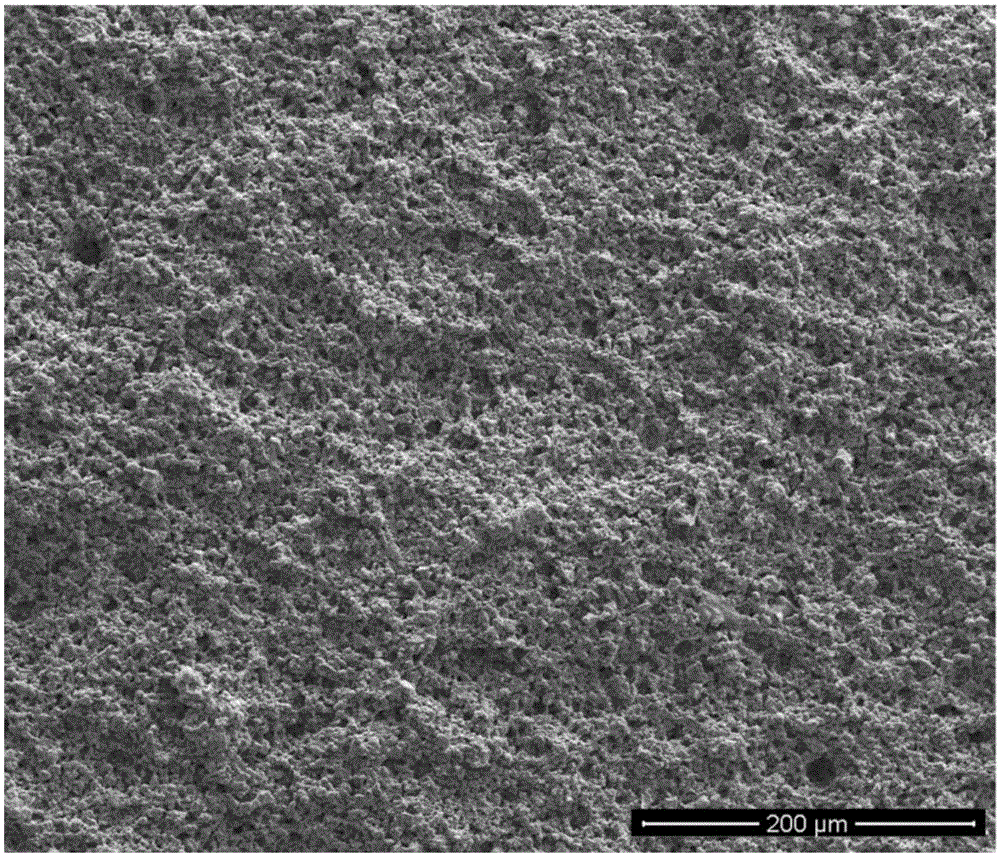

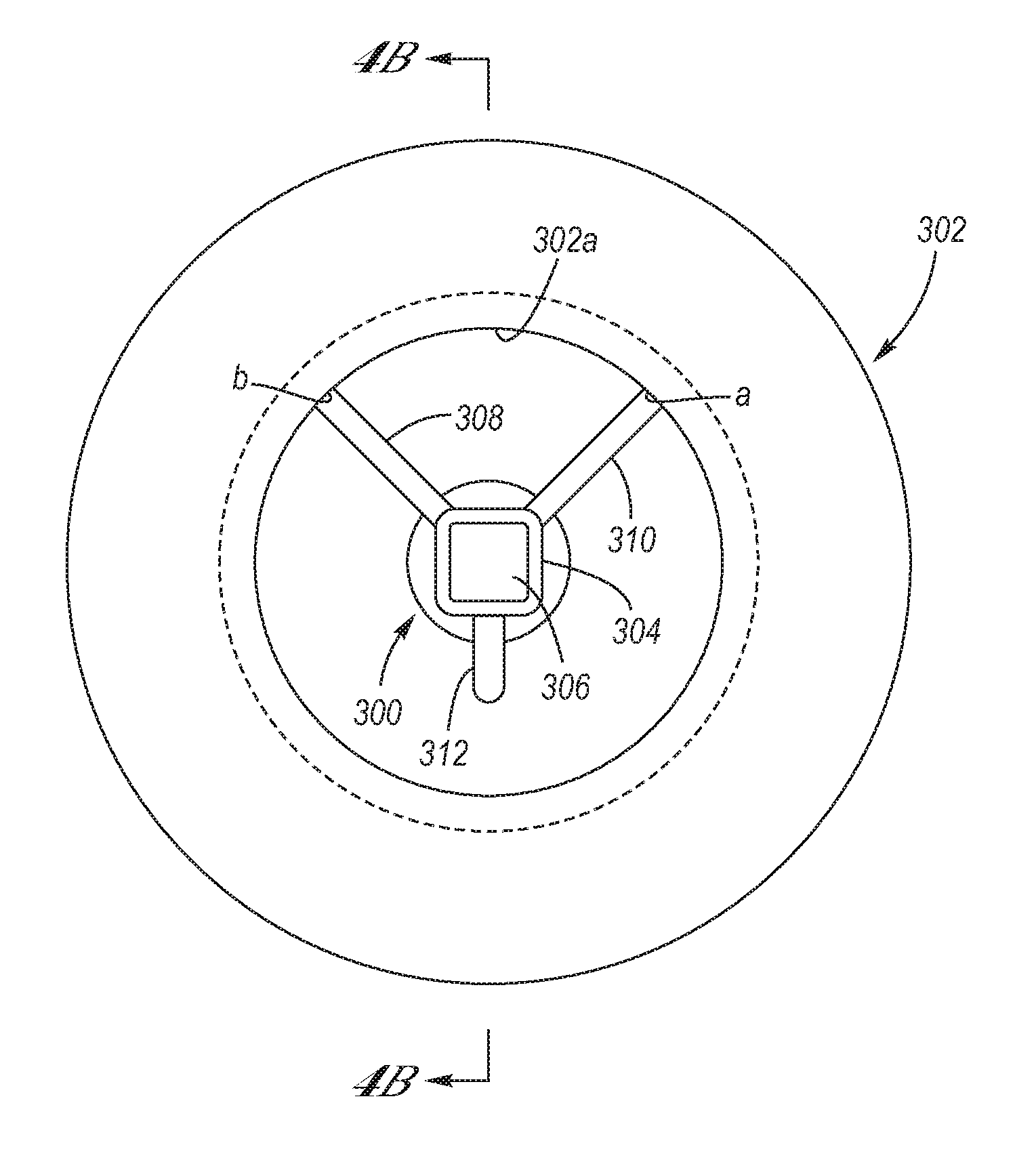

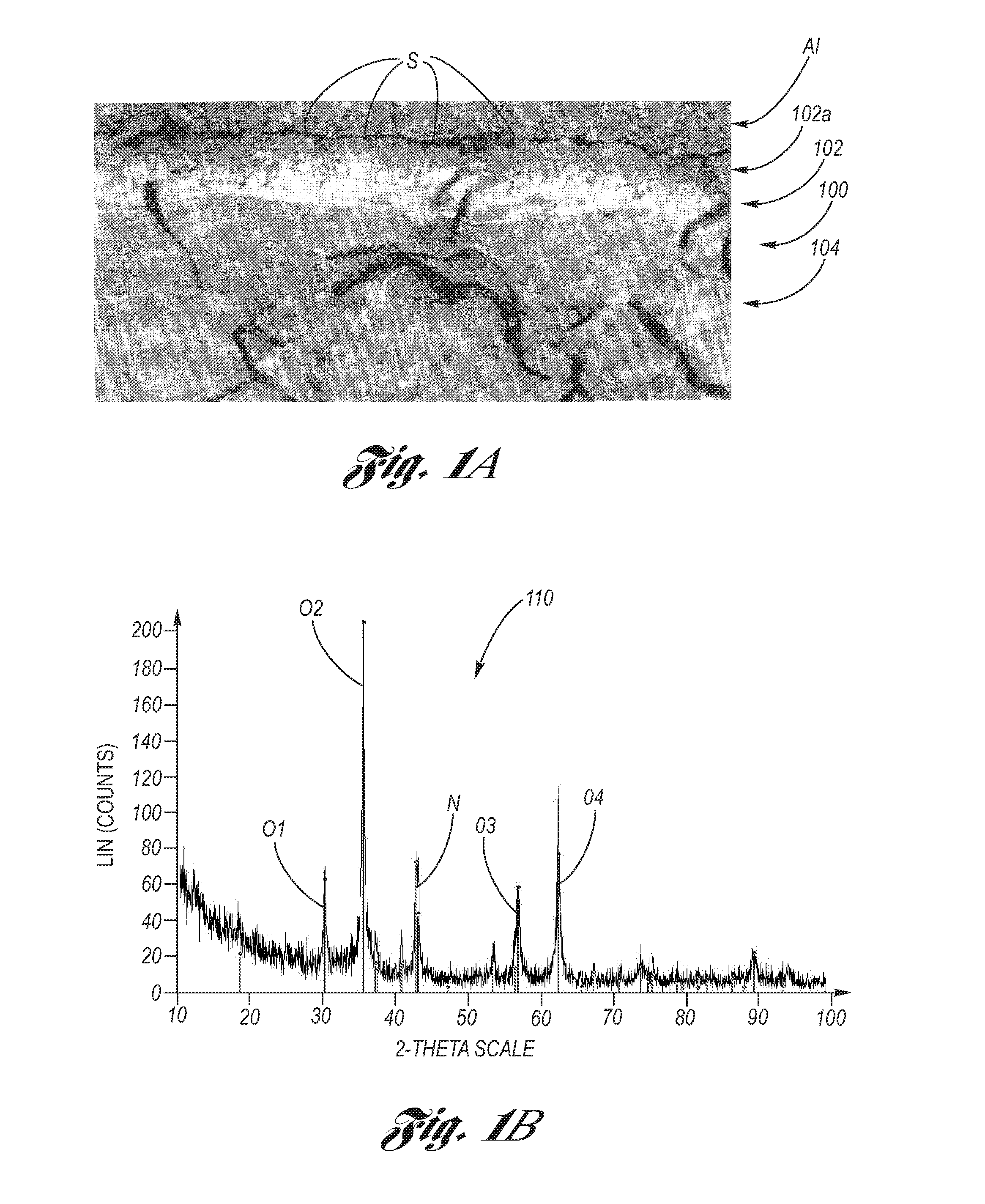

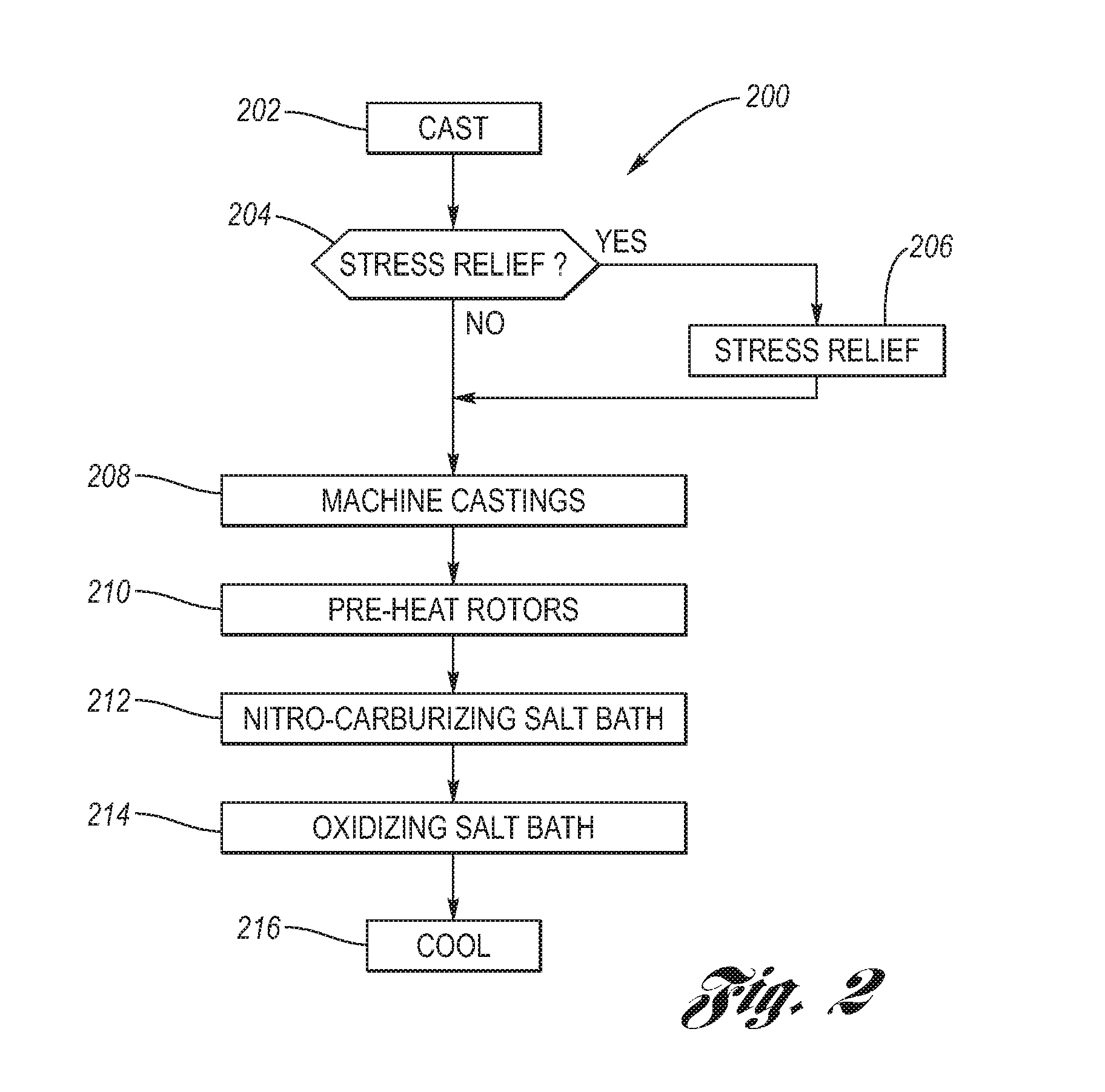

Salt Bath Ferritic Nitrocarburizing of Brake Rotors

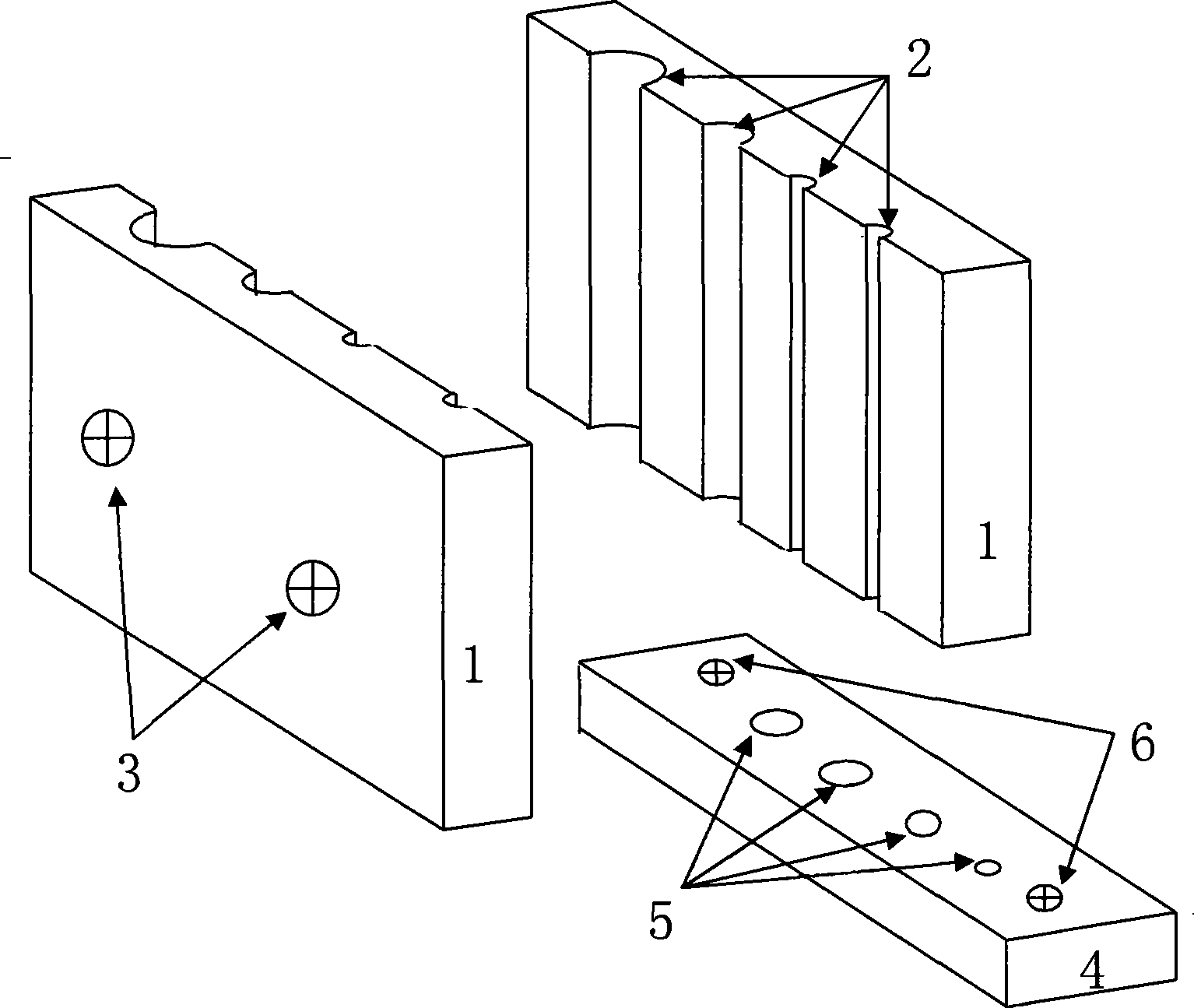

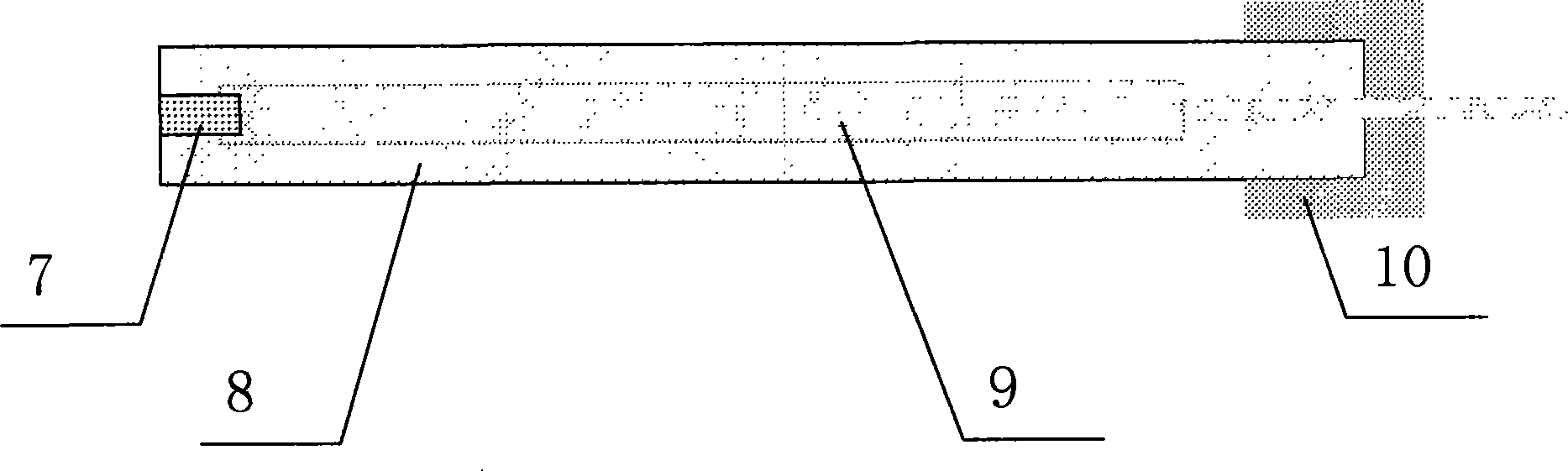

ActiveUS20080000550A1Absence of distortionProvide resistanceBraking discsSolid state diffusion coatingRoom temperatureNitrogen

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:KOLENE +1

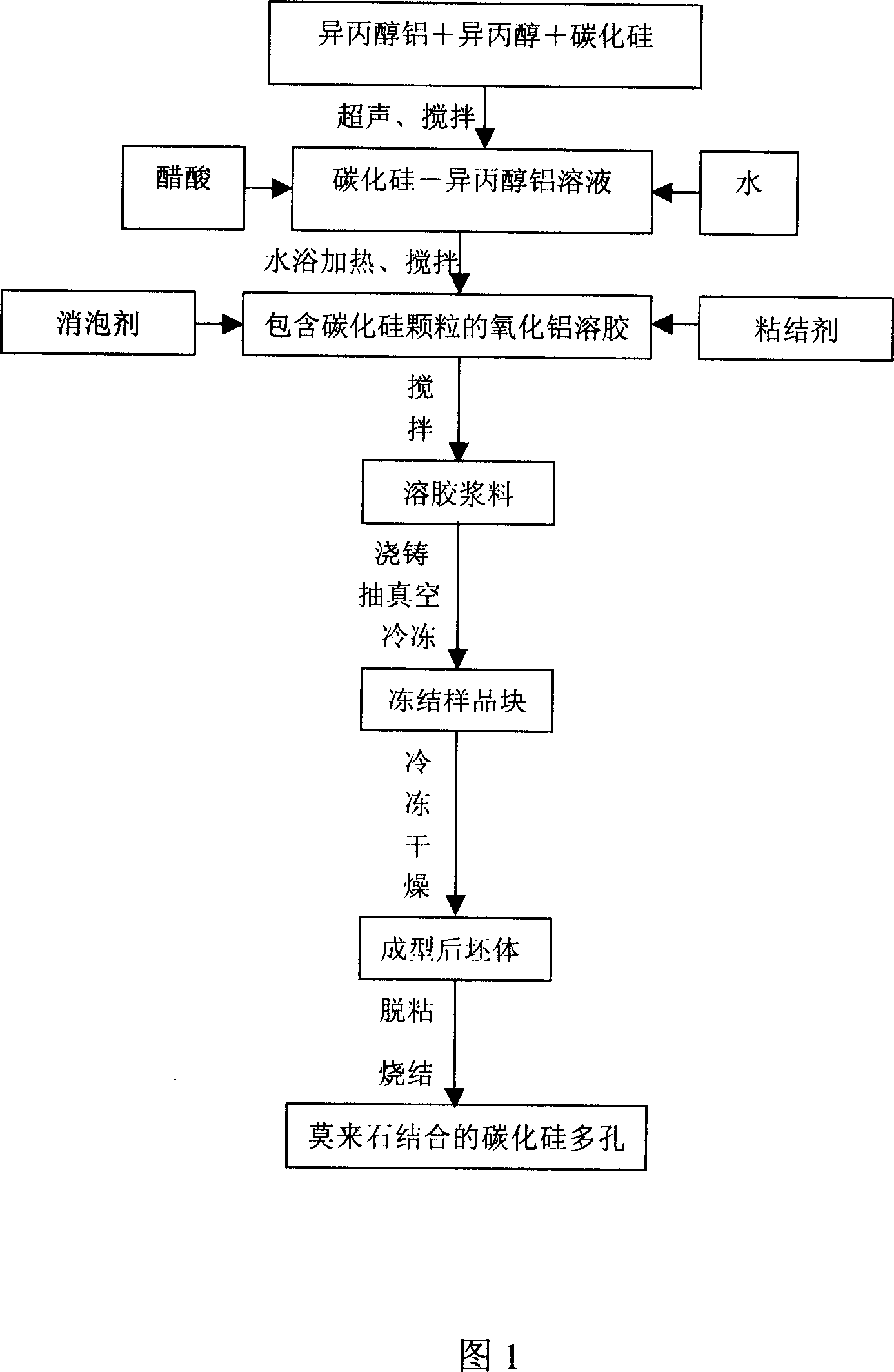

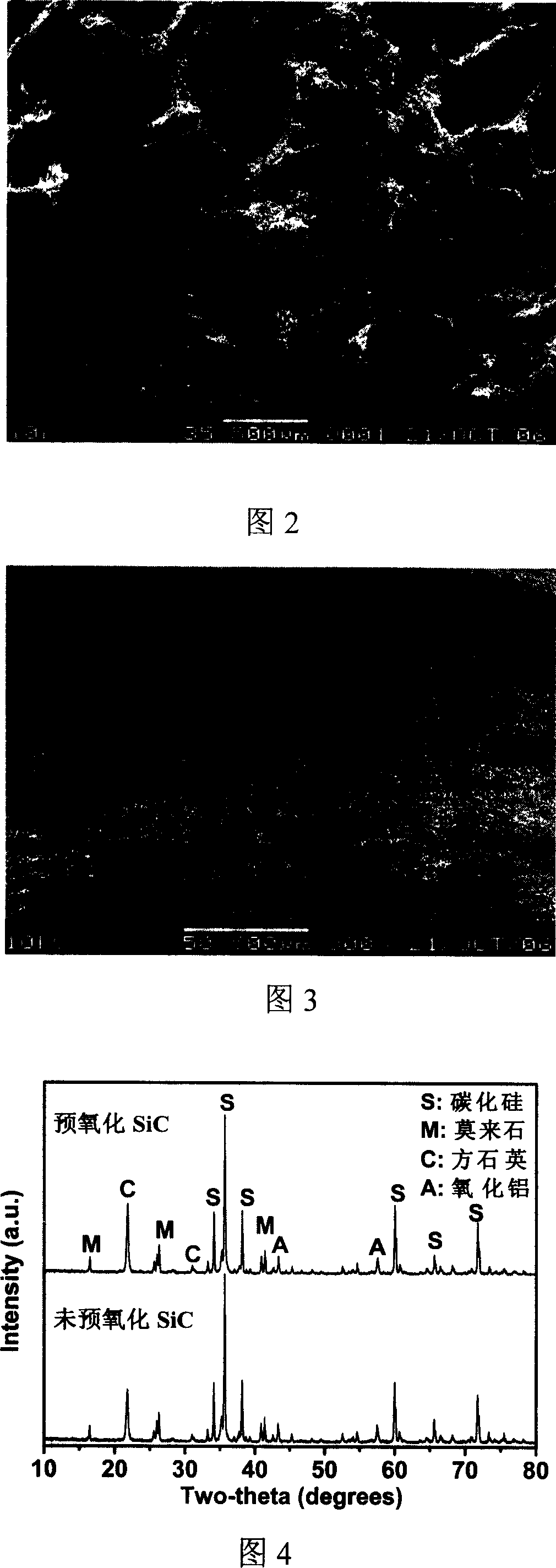

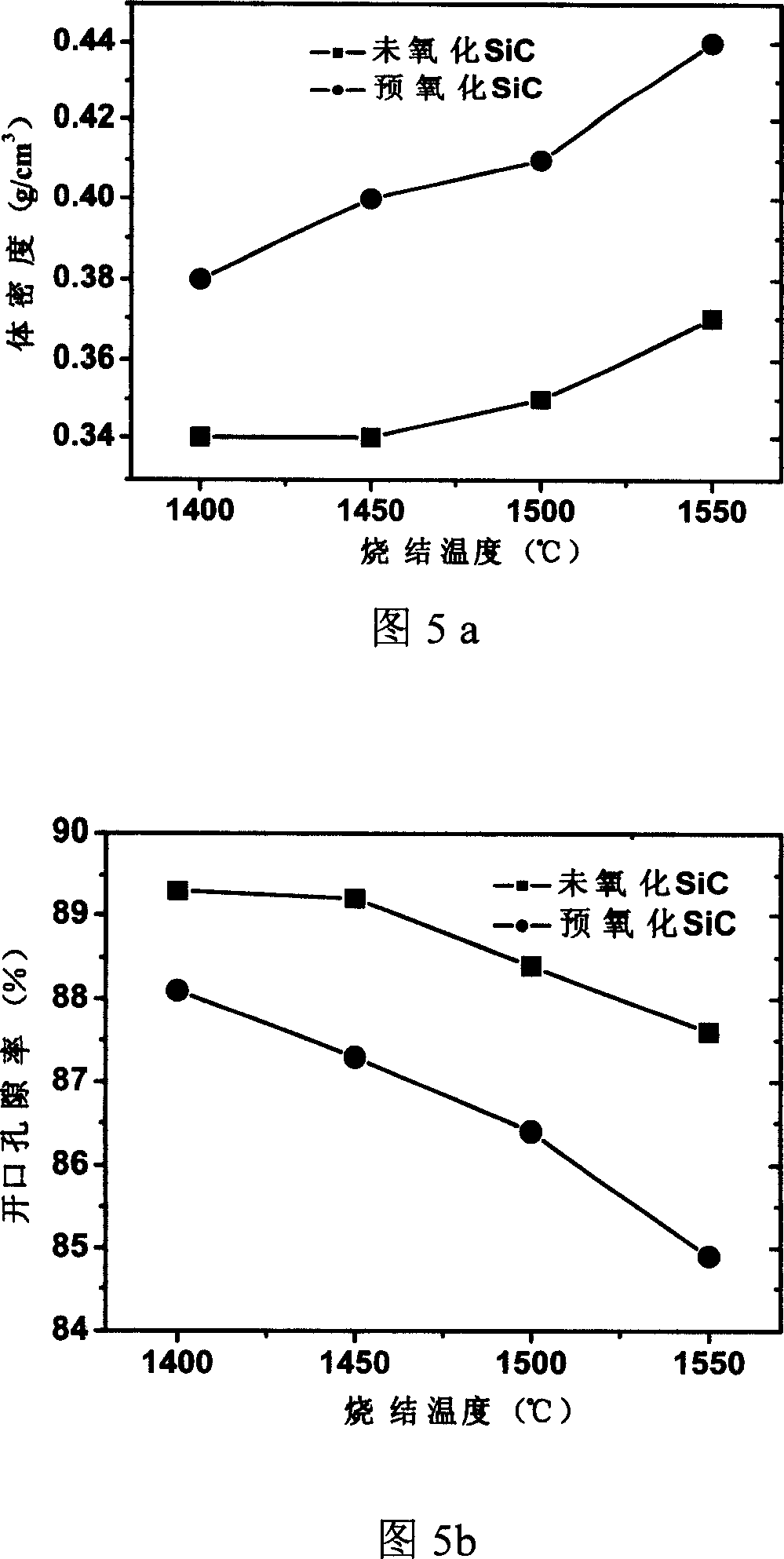

Method for preparing silicon carbide porous ceramic using gelatin wrapping-freeze drying process

The invention discloses a preparing method of carborundum porous ceramic through gel parcel-freezing drying technique, which comprises the following steps: preparing alumina sol; using alumina sol to parcel the carborundum particle; controlling the solid sol content; freezing sol slurry; drying; moulding; sintering; possessing oriental and mutual connecting pore with hole opening rate at 40-90% and aperture at 1-500 um; connecting carborundum through mullite; dispersing aluminium isopropoxide and carborundum particle in the isopropanol; hydrolyzing aluminium isopropoxide to form alumina sol slurry; adding adhesive and defoamer; casting; moulding; removing air to form vacuum; freezing to dry; forming porous blank; detackifying; sintering in the air; oxidizing carborundum particle surface into silica and alumina to obtain mullite; combining carborundum particle to obtain the porous carborundum ceramics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

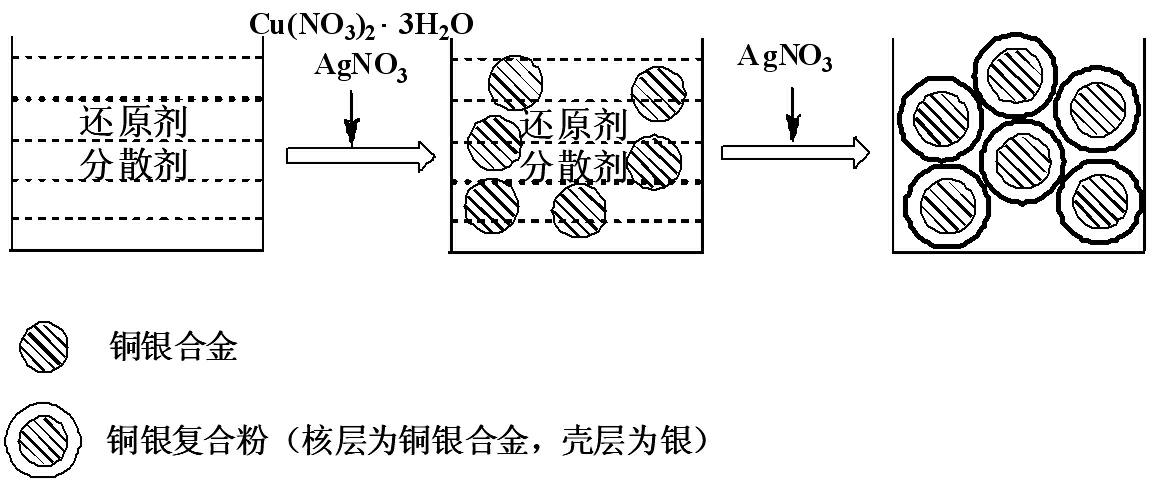

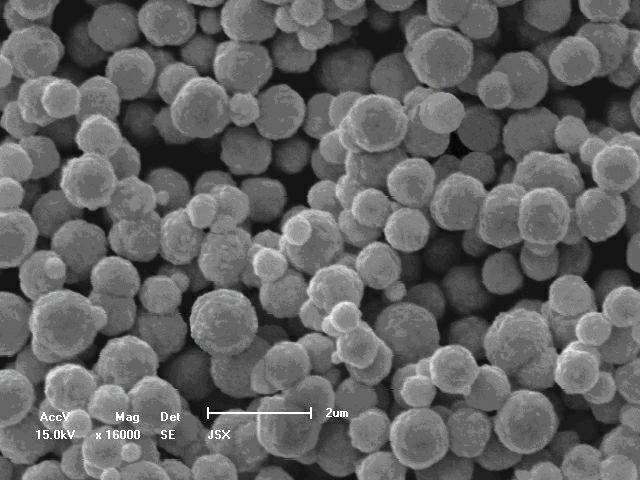

Preparation method of copper-silver composite powder

InactiveCN102161104AInhibition of spontaneous nucleation growthImprove efficiencyAqueous solutionReducing agent

The invention relates to a preparation method of copper-silver composite powder. The copper-silver composite powder has a coated nuclear-shell structure; a nuclear layer is made of copper-silver alloy, and the shell layer is made of silver. The preparation method comprises the steps: firstly, adding a mixed aqueous solution of AgNO3 and Cu(NO3)2.3H2O into a mixed aqueous solution consisting of a reducing agent and a dispersing agent to obtain a copper-silver alloy solution containing the reducing agent; then adding an AgNO3 aqueous solution into the copper-silver alloy solution containing the reducing agent, and leading silver to be deposited and coated on the surface of the copper-silver alloy; and then obtaining the 0.3-3mum copper-silver composite powder after filtering, cleaning, drying and surface densified treatment. In the obtained copper-silver composite powder, the coating of the outer-layer silver is uniform, the compact density is high, the conductivity is good, and the high-temperature oxidation resistance is strong.

Owner:SOUTHEAST UNIV

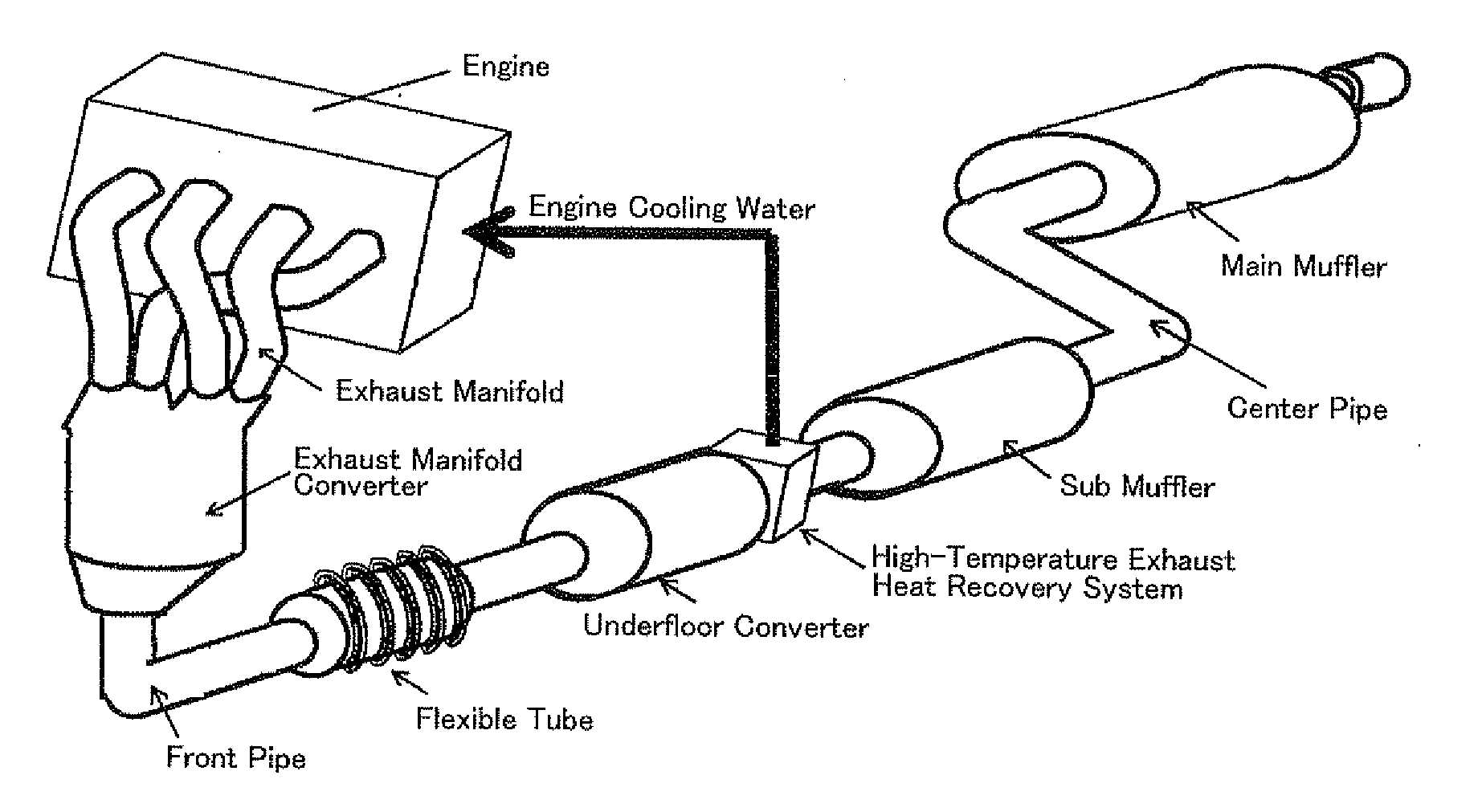

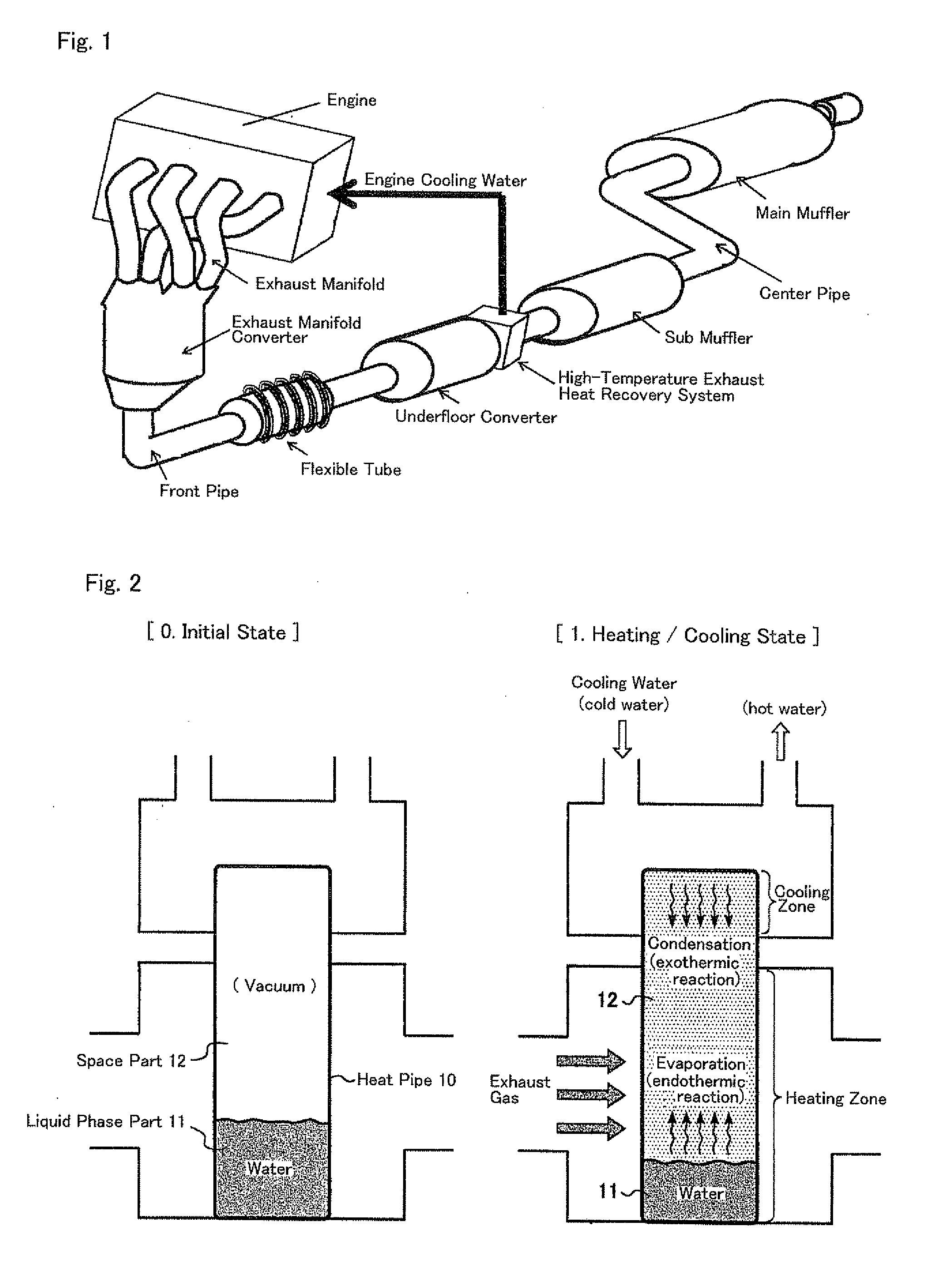

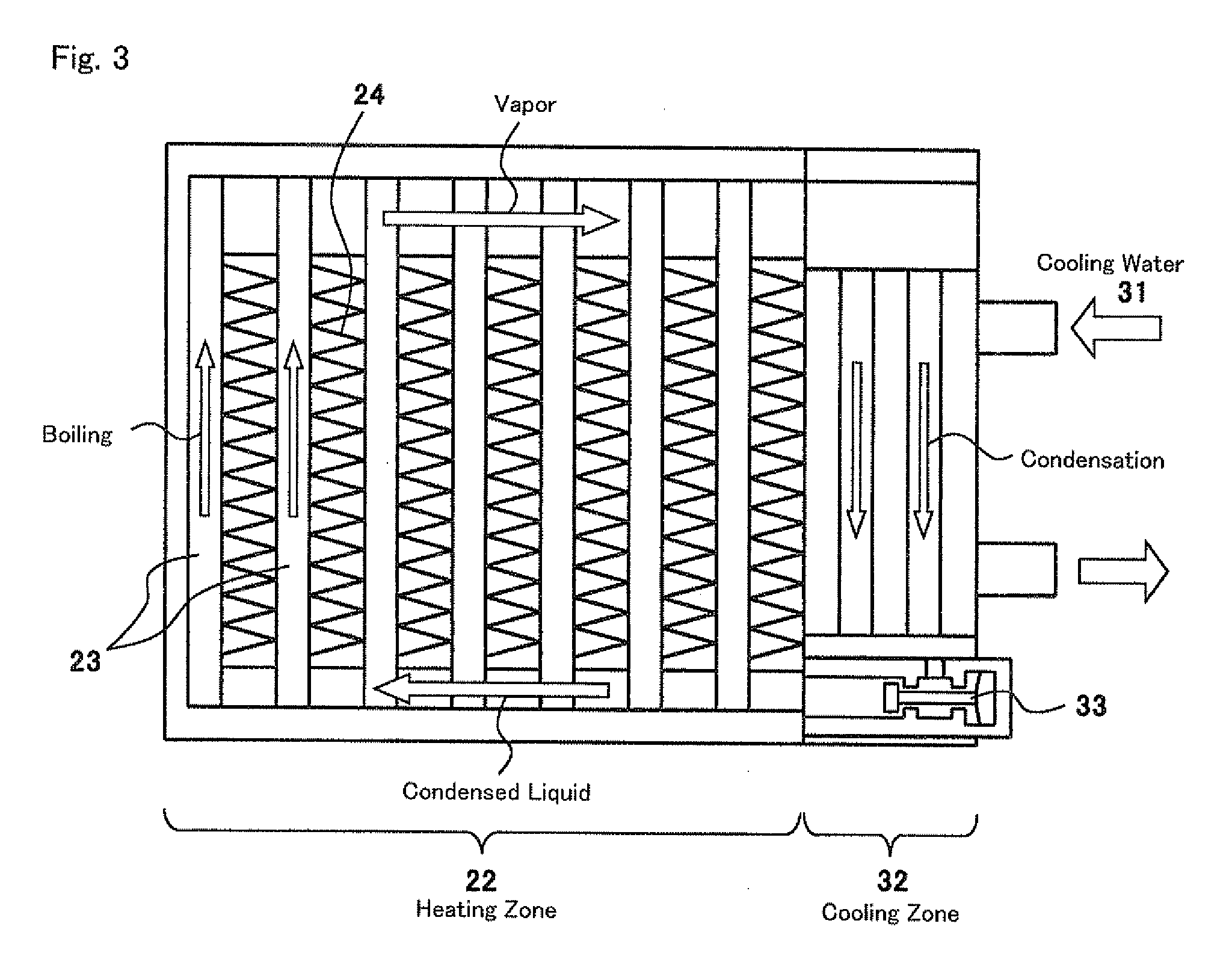

Ferritic stainless steel and steel sheet for heat pipes, and heat pipe and high-temperature exhaust heat recovery system

Provided is a ferritic stainless steel for heat pipes of high-temperature exhaust heat recovery systems, which comprises, in terms of % by mass, from 16 to 32% of Cr, at most 0.03% of C, at most 0.03% of N, at most 3% of Si, at most 2% of Mn, at most 0.008% of S, from 0 to 0.3% of Al, and at least one of at most 0.7% of Nb, at most 0.3% of Ti, at most 0.5% of Zr and at most 1% of V, and optionally at least one of at most 3% of Mo, at most 3% of W, at most 3% of Cu, at most 0.1% of Y, at most 0.1% of REM (rare earth metal) and at most 0.01% of Ca, with a balance of Fe and inevitable impurities, and which satisfies at least the following formula (1), formula (2) and formula (5):Cr+3(Mo+Cu)≧20 (1)Cr+3(Si+Mn+Al−Ti)≧20 (2)0.037{(C+N) / (V+Ti+0.5Nb+0.5Zr)}+0.001≦0.01 (5).

Owner:DENSO CORP +1

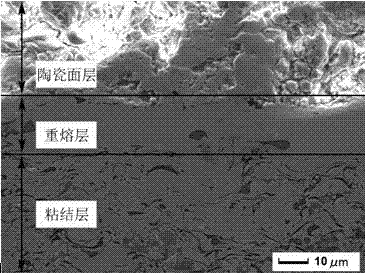

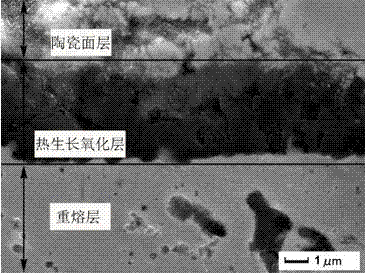

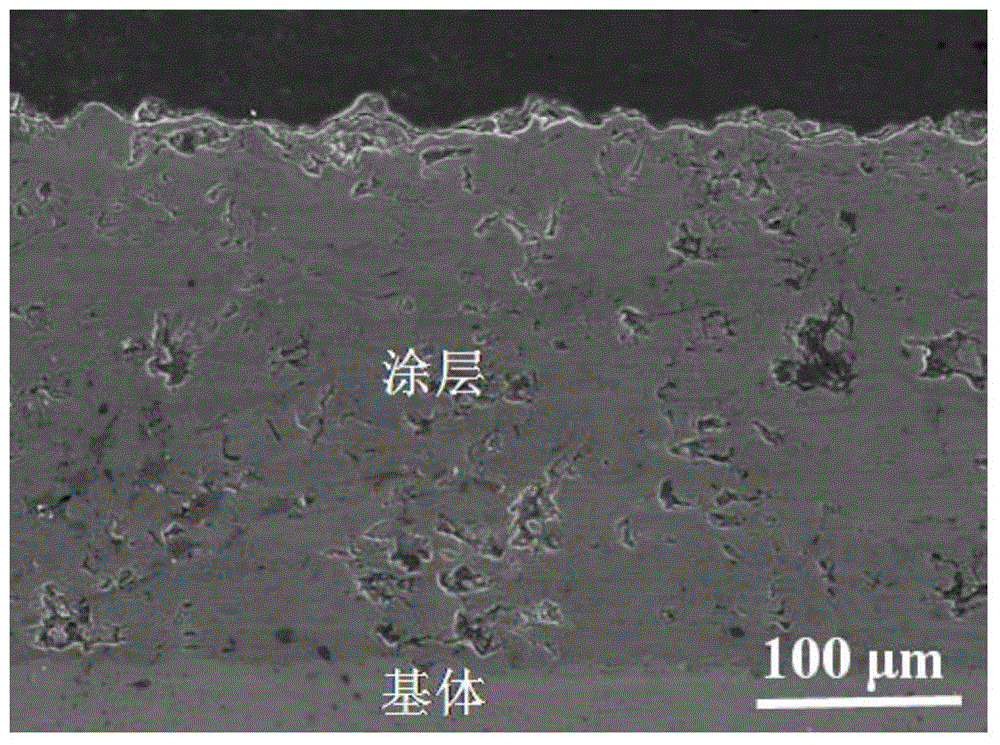

Anti-oxidization thermal barrier coating material with long service life and preparation method thereof

InactiveCN103789715AHigh temperature oxidation resistanceHigh thermal efficiencyMolten spray coatingAdhesiveSand blasting

The invention belongs to the technical field of thermal barrier coating surface treatment and modification, and in particular relates to an anti-oxidization thermal barrier coating material with long service life and a preparation method thereof. The coating material comprises a high-temperature alloy substrate, a metal adhesive layer, a fine-grain remelted layer and a ceramic surface layer. The invention also discloses the preparation method of the anti-oxidization thermal barrier coating material with long service life; the preparation method comprises the steps of depositing the metal adhesive layer on the surface layer of the high-temperature alloy substrate by a plasma spraying method after pre-grinding, cleaning and sand-blasting roughening treatment, and then performing remelting treatment on the metal adhesive layer with a high-current pulse electron beam device, performing sand-blasting treatment on the outmost surface layer of the remelted layer, and finally, depositing the ceramic surface layer on the surface layer of the remelted layer by the plasma spraying method. The anti-oxidization thermal barrier coating material with long service life prepared by the preparation method is high in interface bonding force and even in structural constituents, and has stable oxidization resistance and long coating service life in high-temperature service environment.

Owner:JIANGSU UNIV

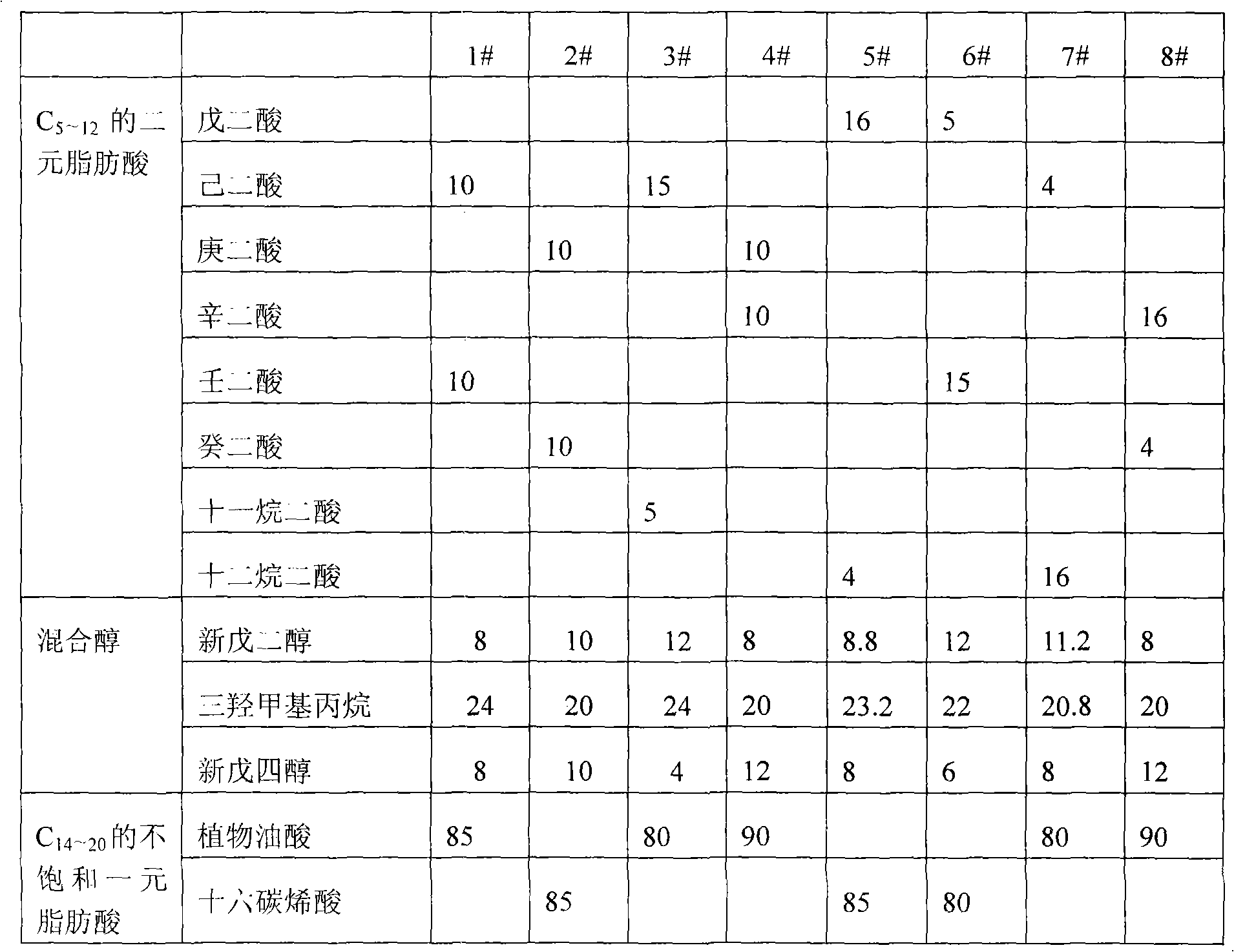

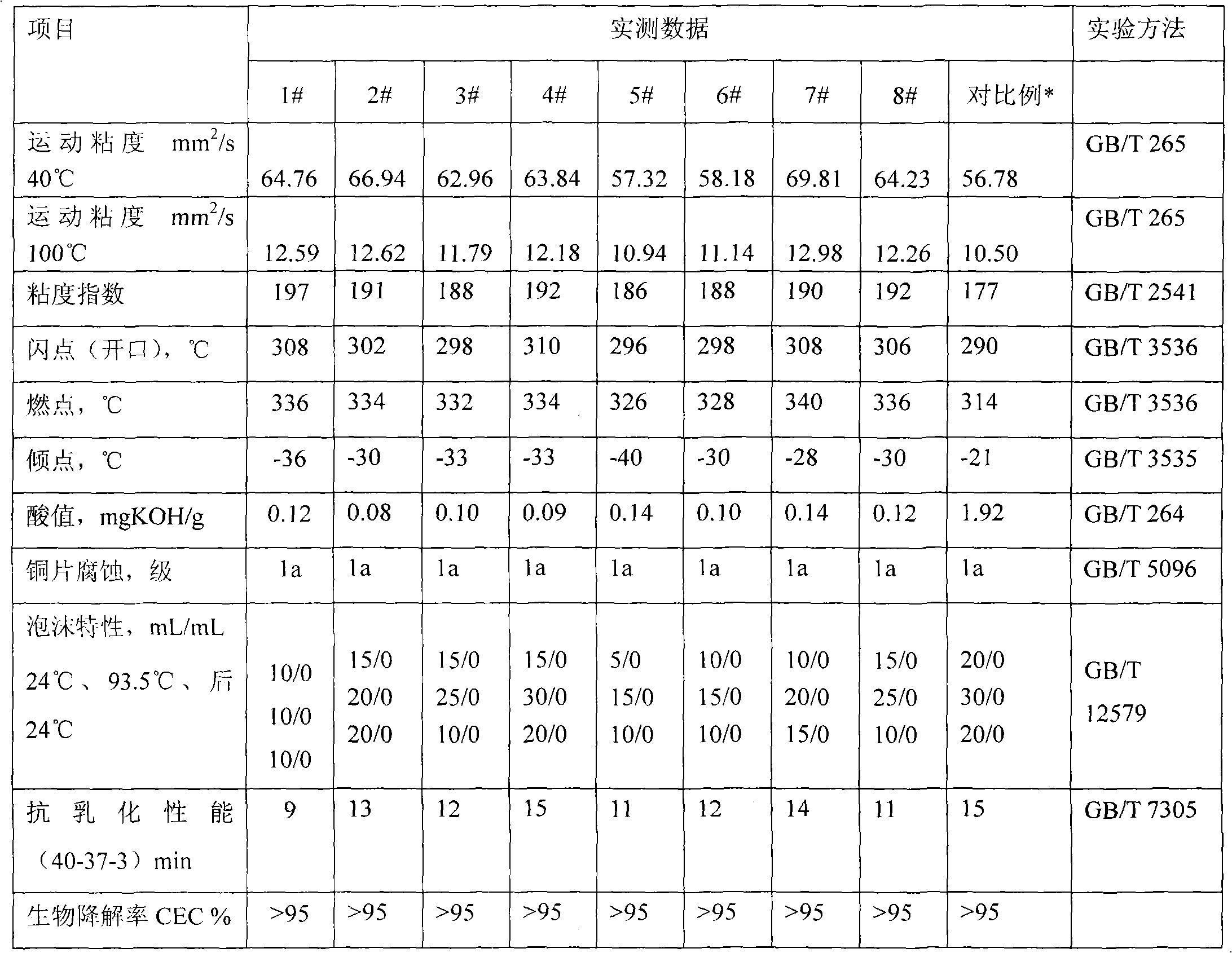

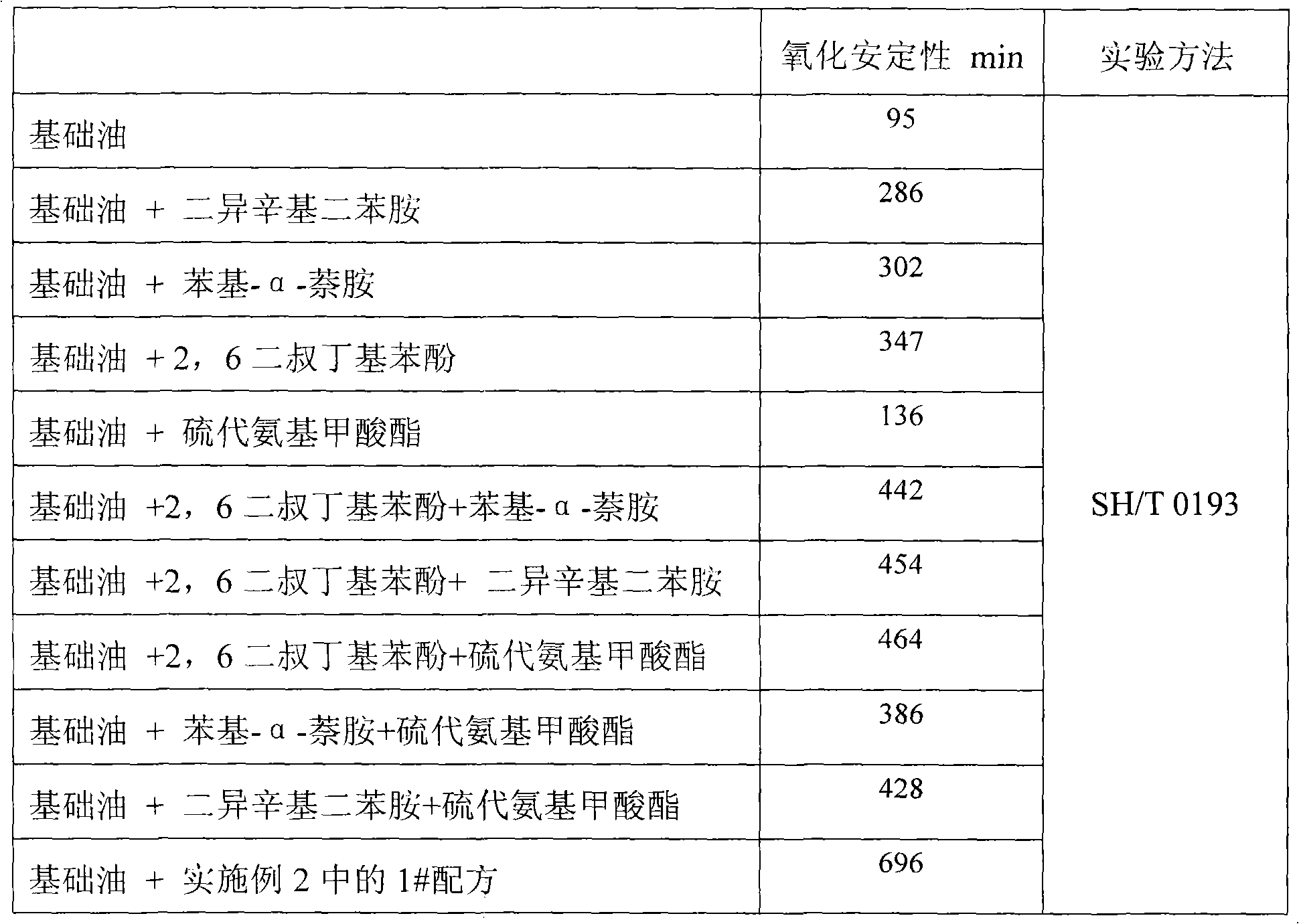

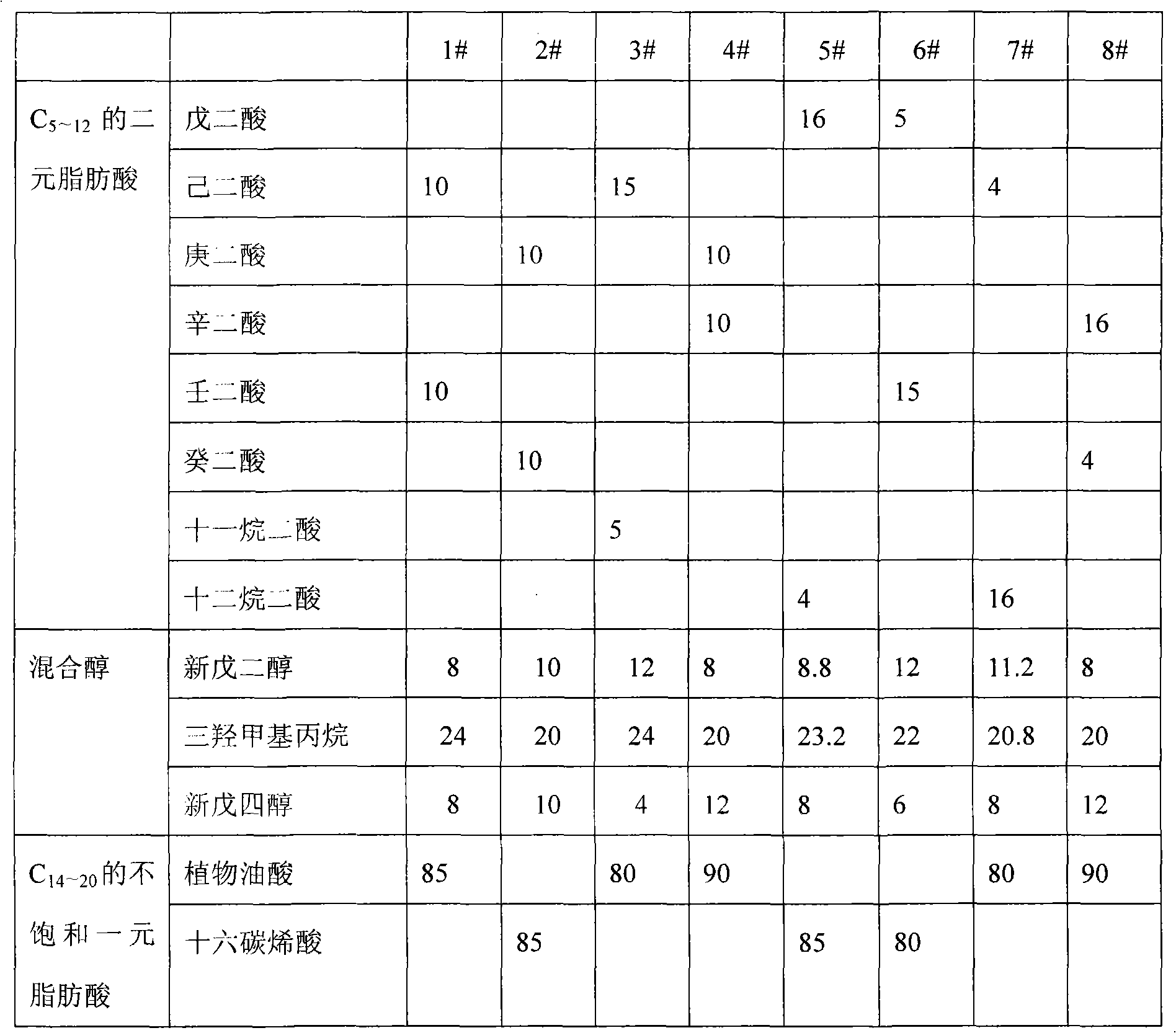

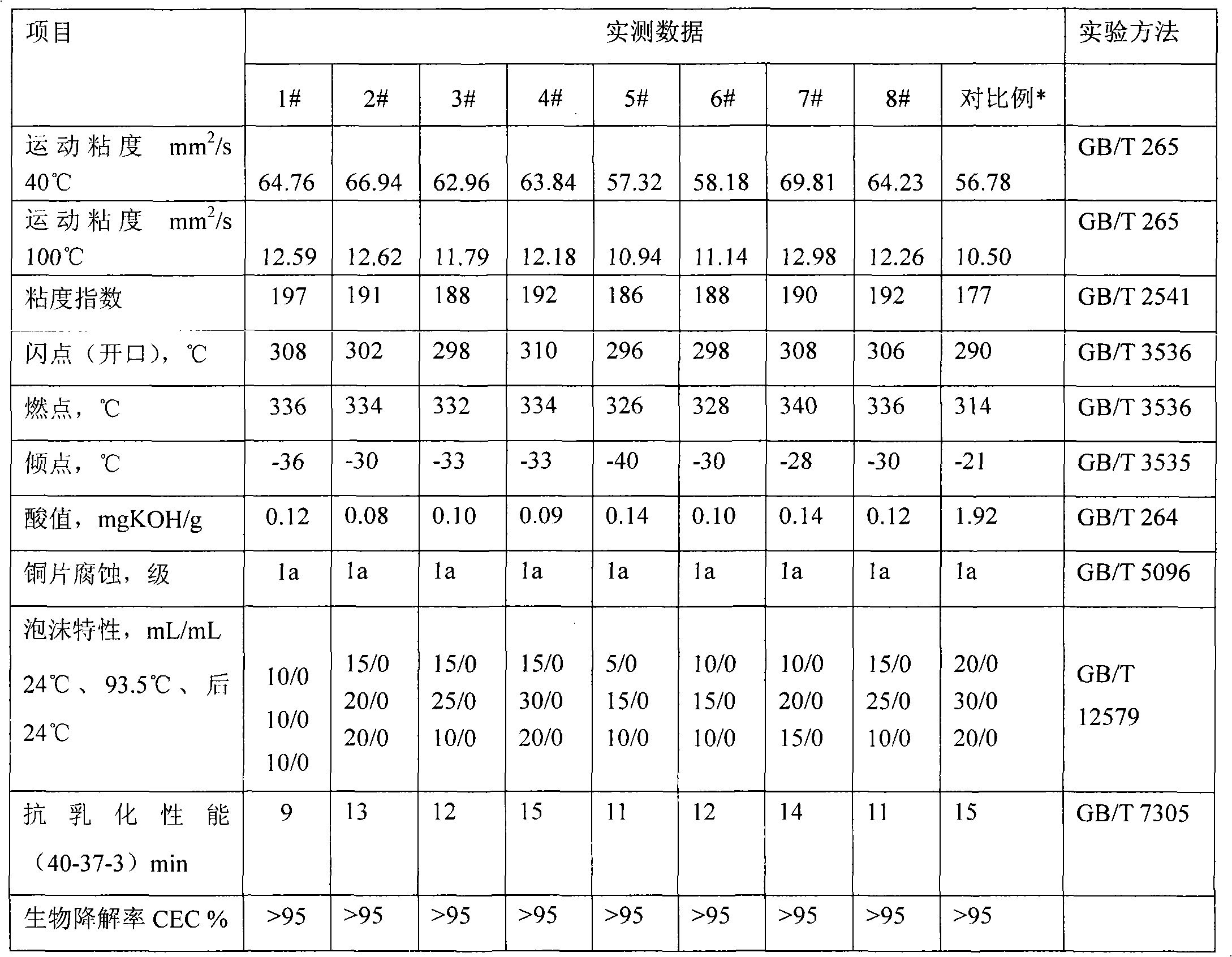

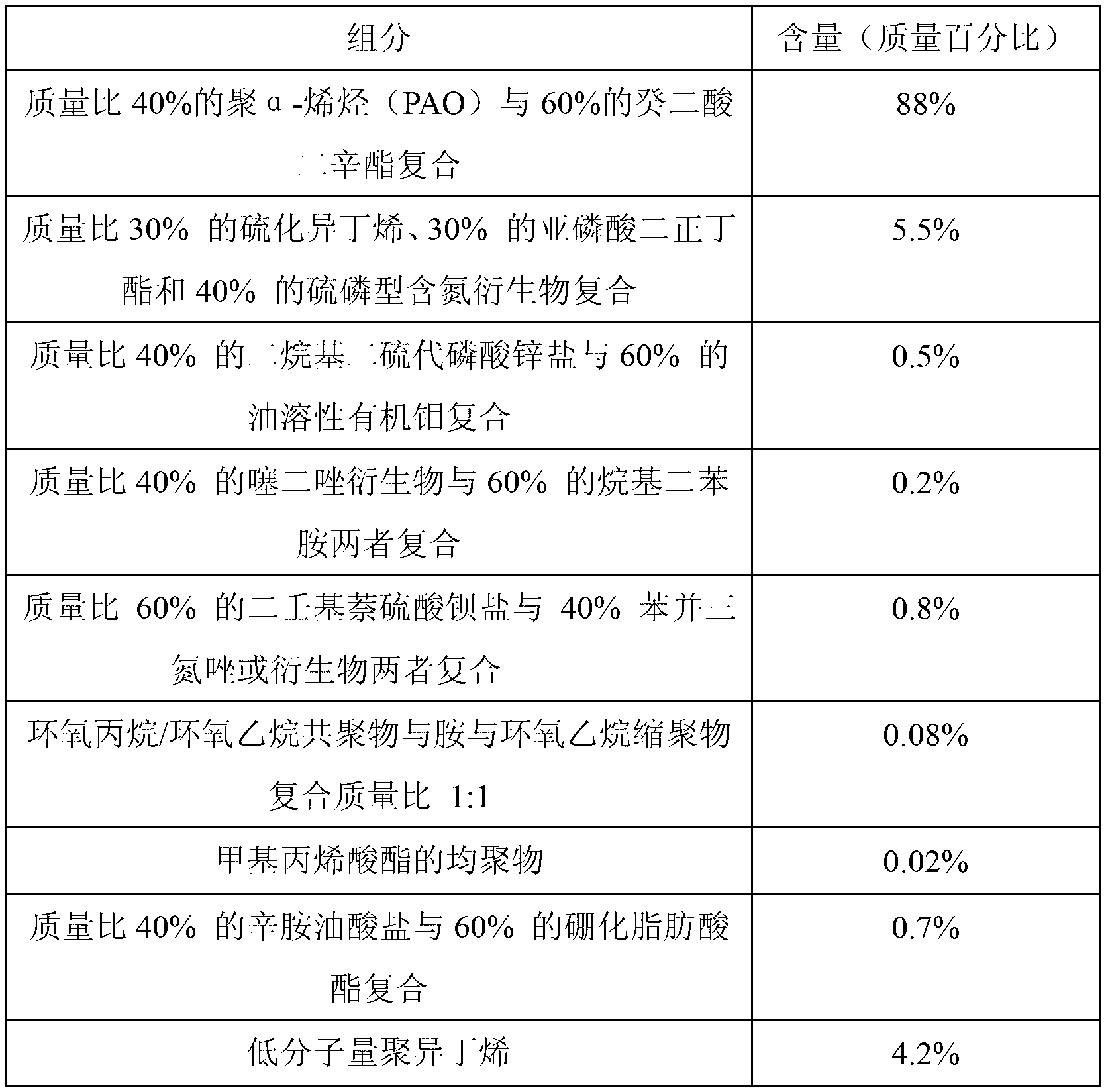

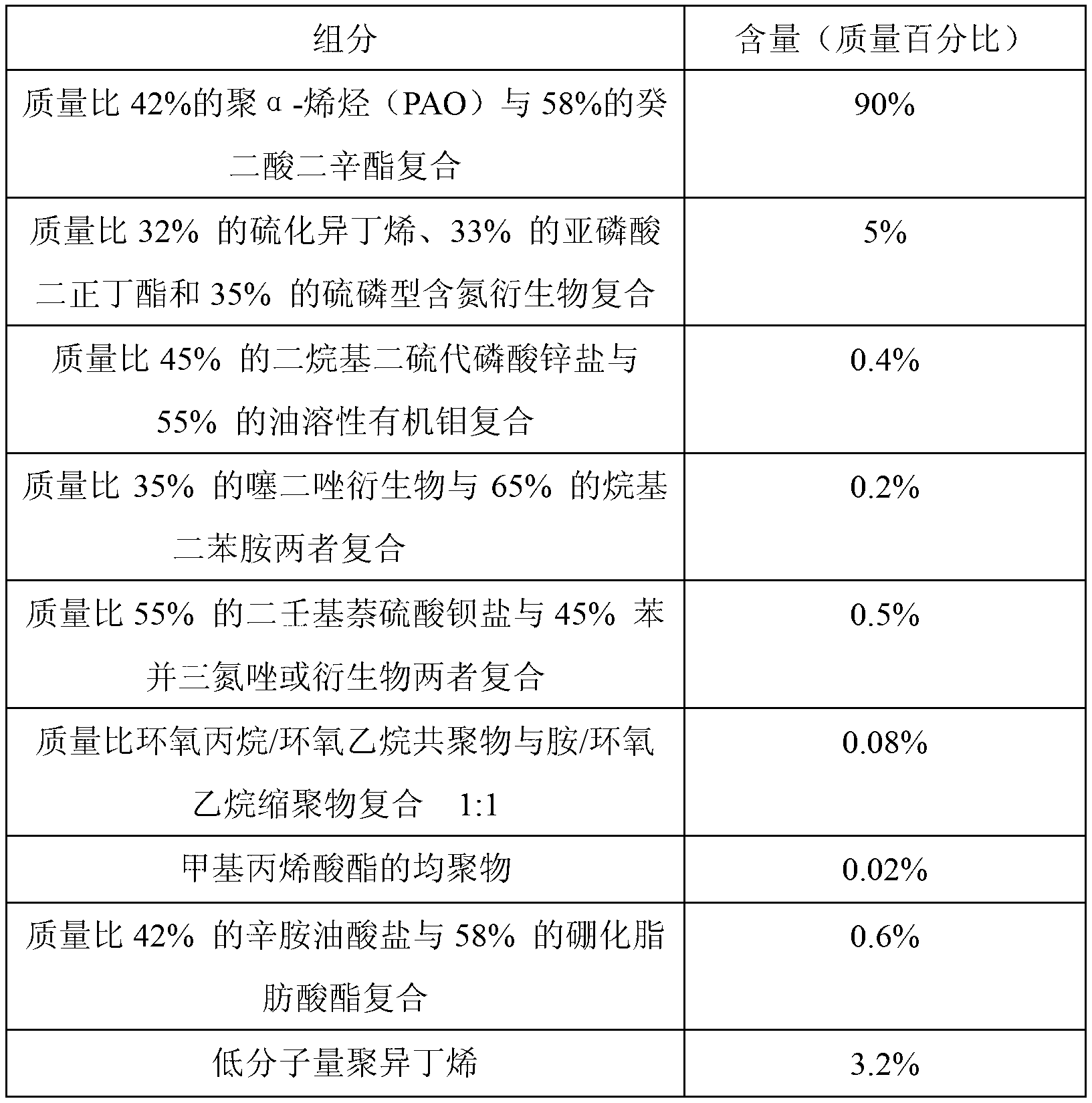

Flame-retardant hydraulic oil and preparation and application thereof

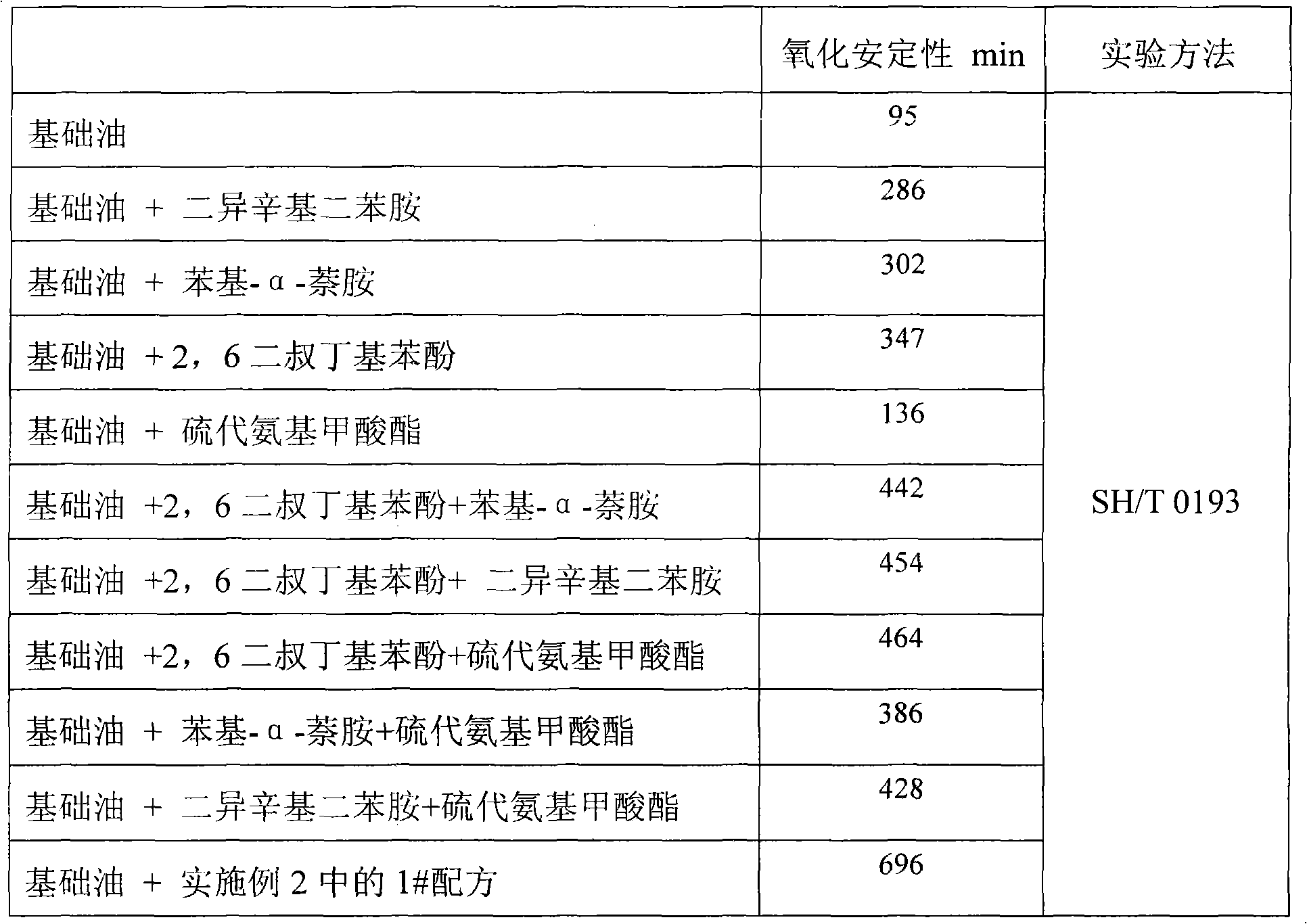

ActiveCN101831346AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceLubricant compositionAntioxidantHigh pressure

The invention provides flame-retardant hydraulic oil, which comprises the following components in percentage by weight: 1.9 to 4.5 percent of antioxidant, 1.5 to 3.5 percent of extreme-pressure abrasion resistant agent, 5 to 50ppm of antifoaming agent, 0.1 to 0.4 percent of anti-rusting agent and 92 to 97 percent of base oil, wherein the base oil is neopentyl polyol diacid composite ester which is prepared by fully esterifying carboxyl of aliphatic dibasic acid of C5-12 with mixed alcohol consisting of neopentyl glycol, trimethylolpropane and pentaerythritol and terminating the esterified product with unsaturated unitary fatty acid of C14-20. The flame-retardant hydraulic oil provided by the invention can be applied to various high-temperature and high-pressure hydraulic systems easy to contact naked flame. Compared with mineral-based (compressor) hydraulic oil, the flame-retardant hydraulic oil has the advantages of energy conservation, reduced oil consumption, reduced environmental pollution and prolonged service life, and can fully meet the working requirements of the high-temperature and high-pressure hydraulic systems easy to contact naked flame.

Owner:上海海都化学科技有限公司 +1

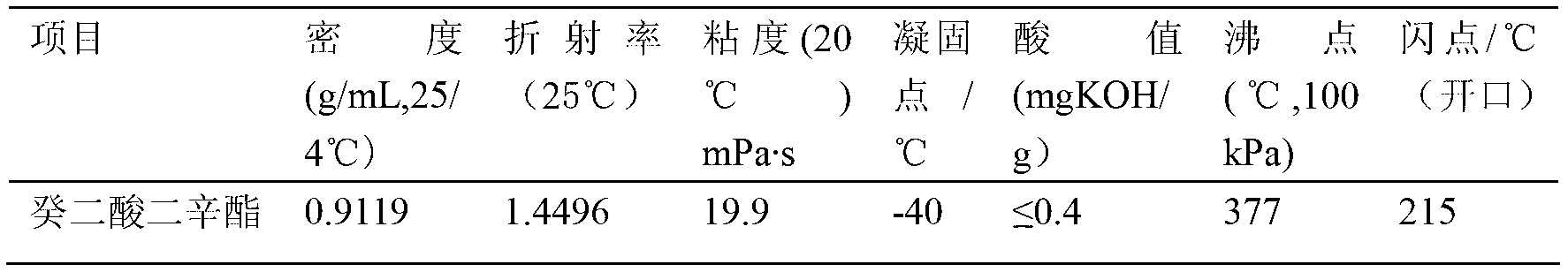

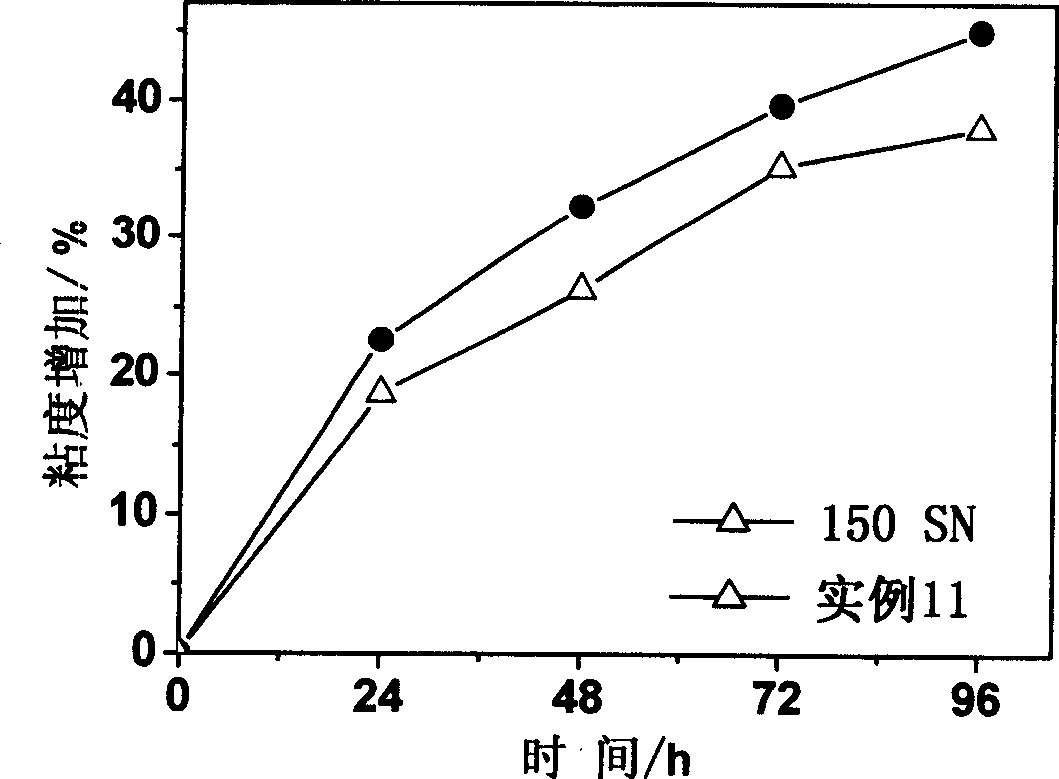

Lubricating oil and grease base oil, and preparation method and applications thereof

ActiveCN101812349AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceBase-materialsOil and greaseEvaporation

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Owner:上海海都化学科技有限公司 +1

Environment-friendly type oil for heavy-duty industrial gear

ActiveCN103215114AImprove the lubrication effectEmission reductionBase-materialsFriction reductionHigh torque

The invention discloses environment-friendly type oil for a heavy-duty industrial gear. The oil comprises base oil, an anti-wear reagent at extreme pressure, an antioxidant corrosion-resistant agent, a metal passivator, an antirust agent, a demulsifier, an antifoaming agent, an oiliness agent, and a viscosity index improver. The oil for the heavy-duty industrial gear is good in comprehensive property, not only has good antioxidant and corrosion-resistant properties, antirust property, anti-wear and corrosion-resistant properties, friction reduction, bearing, high torque, high-temperature stability, demulsibility, antifoaming property and the like, and is capable of reducing emission, good in biodegradability, and lower in cost, but also can be used for enabling an industrial gear to form an anti-wear, high temperature-resistant and extrusion-resistant boundary lubricating oil film under the high torque or impact load, so as to ensure that the gear is well lubricated. Additives are selected by adopting an artificial neural network algorithm, the optimal formula can be selected by a genetic algorithm, and the environment-friendly type oil for the heavy-duty industrial gear can meet the performance requirements of the GB5903-1995 heavy-duty industrial gear on the oil with the viscosity grades of 100, 150, 220, 320, 460 and 680.

Owner:GUANGXI UNIV

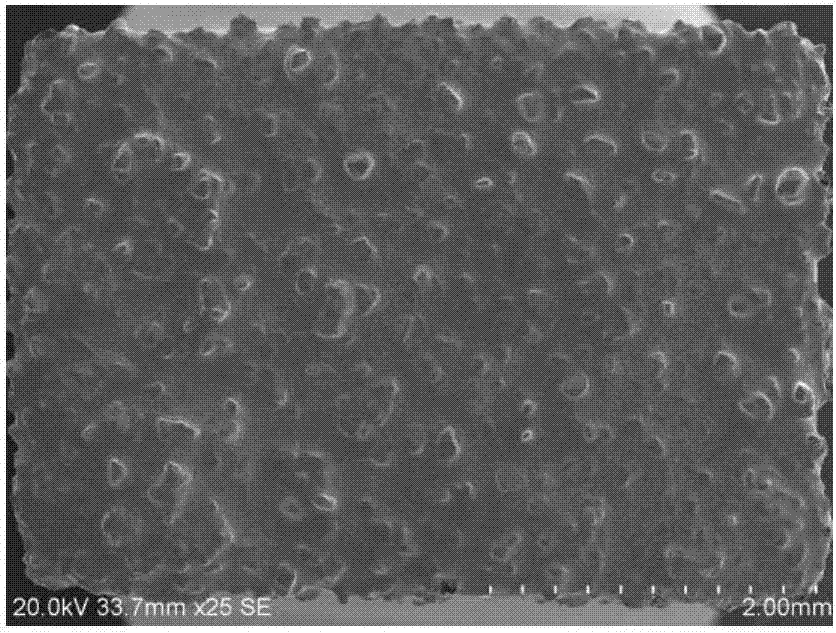

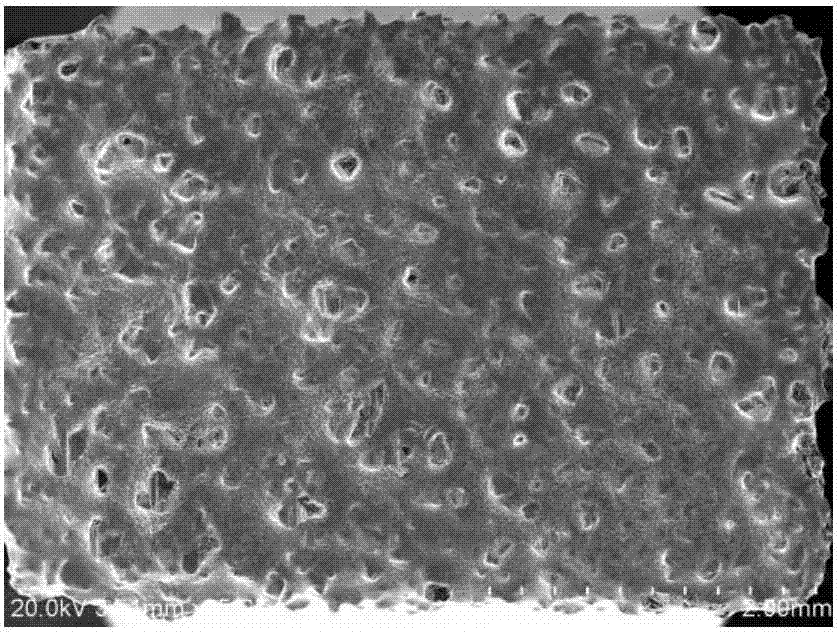

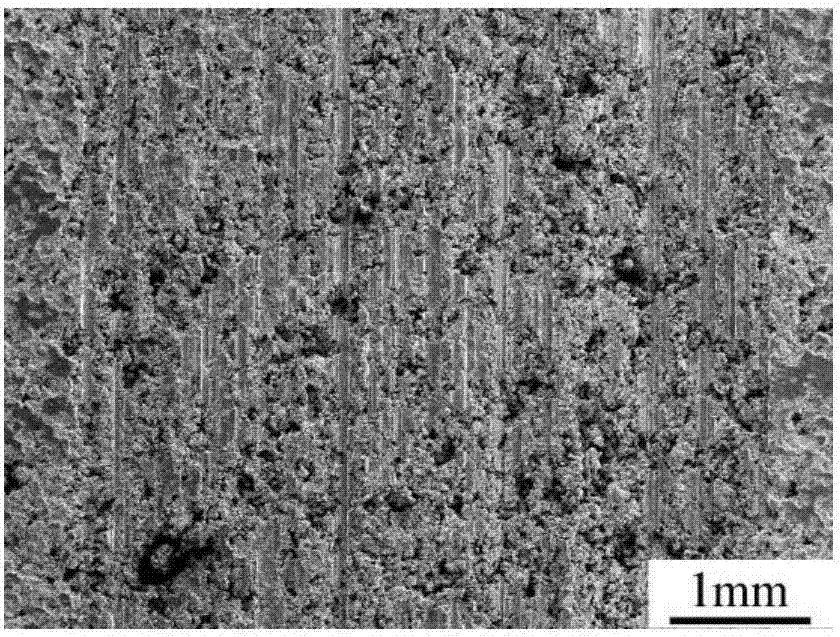

Salt bath ferritic nitrocarburizing of brake rotors

ActiveUS8287667B2Absence of distortionAccelerated corrosionBraking discsSolid state diffusion coatingNitrogenRoom temperature

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:KOLENE +1

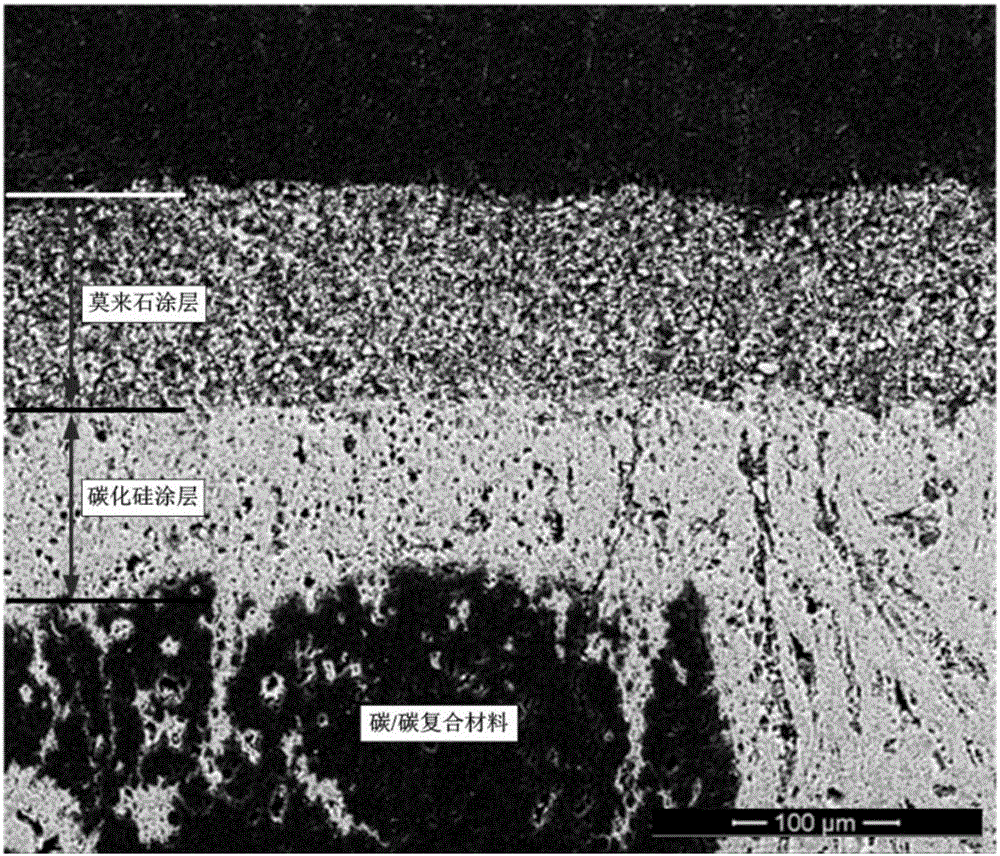

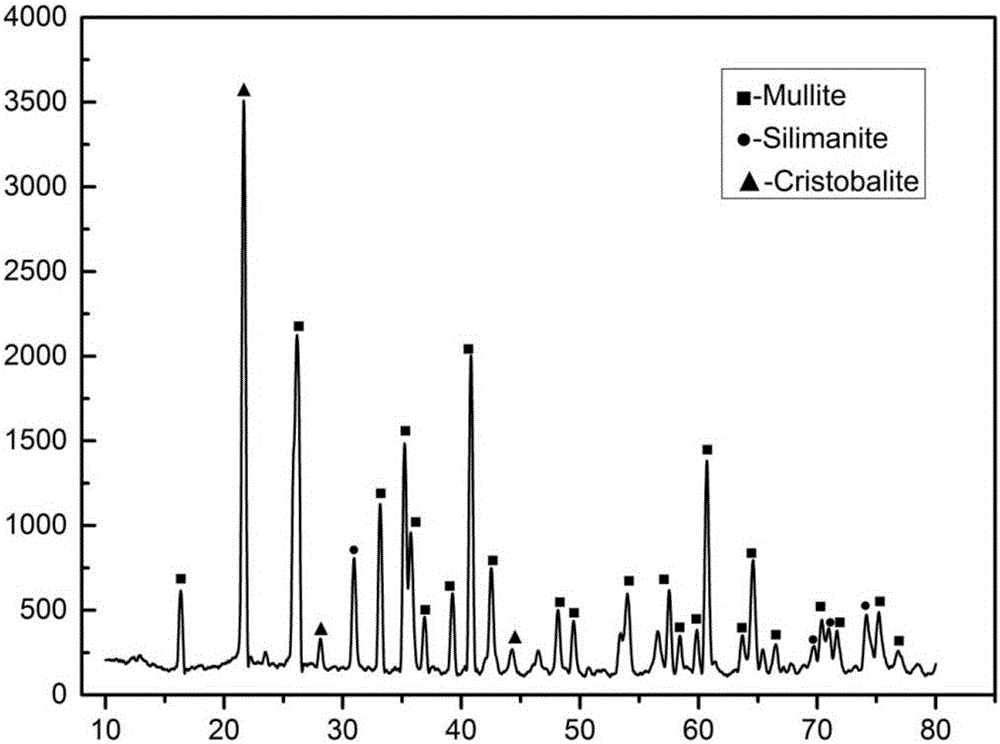

Preparation method of mullite oxidation resistant coating

The invention relates to a preparation method of a mullite oxidation resistant coating, particularly to a method for preparing a mullite / SiC bilayer-structure oxidation resistant coating on the surface of a carbon / carbon composite material. The preparation method comprises the following steps: pre-calcining mullite powder A and mullite precursor powder B according to the mass ratio of (4-6):1 to prepare pre-calcined mullite powder A and mullite precursor powder B, preparing a coalescing agent and a drying inhibitor according to certain ratio, uniformly mixing the pre-calcined mullite powder A, the pre-calcined mullite precursor powder B, the coalescing agent and the drying inhibitor to obtain a sizing agent, dipping a matrix in the sizing agent, performing sizing agent coating by adopting the dip-coating technology, and after the sizing agent coating, calcining at 1480-1515 DEG C to obtain the mullite oxidation resistant coating. According to the invention, the technology is simple, the raw material is cheap and available, the industrial production is facilitated, and the obtained coating has the advantages of high uniformity and compactness, excellent binding property, and high high-temperature oxidation resistant capacity.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Technology for preparing metal surface coating through compounding multiple processes

InactiveCN101962768AImprove compactnessHigh strengthSuperimposed coating processThermal sprayingHeat resistance

The invention relates to a technology for preparing a metal surface coating through compounding multiple processes, which is characterized by preparing a coating on the surface of a metal substrate by simultaneously using three coating preparation processes of thermal spraying, cold spraying and laser remelting. The technology comprises the following steps of: (1) pretreating the surface of the metal substrate; (2) spraying by using electric arcs; (3) remelting by using a laser; and (4) spraying coldly. By simultaneously utilizing the three coating preparation processes, combining the advantages of the three processes and overcoming the defects of the three processes, the technology can be used for preparing the high-performance coating with the functions of abrasion resistance, corrosion resistance, heat resistance, high-temperature oxidation resistance and fatigue spalling resistance in low cost and high efficiency.

Owner:黄锦

Scaling powder for lead-free solder paste

InactiveCN103111773AActiveHalogen freeWelding/cutting media/materialsSoldering mediaInsulation resistanceSolvent

The invention discloses scaling powder for lead-free solder paste. The scaling powder for the lead-free solder paste comprises, by weight, 35.0%-45.0% of colophony, 2.0%-5.0% of activating agent, 3.0%-8.0% of thixotropic agent, 1.5%-3.0% of surface active agent and 0.1%-1.5% of corrosion inhibitor, the other part is solvent. The scaling powder for the lead-free solder paste is wide in viscosity range, good in activity and strong in high temperature oxidation resistance, no halogen residues exist on a welded base plate, washing is not needed, insulation resistance is beyond 108 ohms, and the scaling powder for the lead-free solder paste can be widely applied to the field of welding of electronic materials.

Owner:郴州金箭焊料有限公司

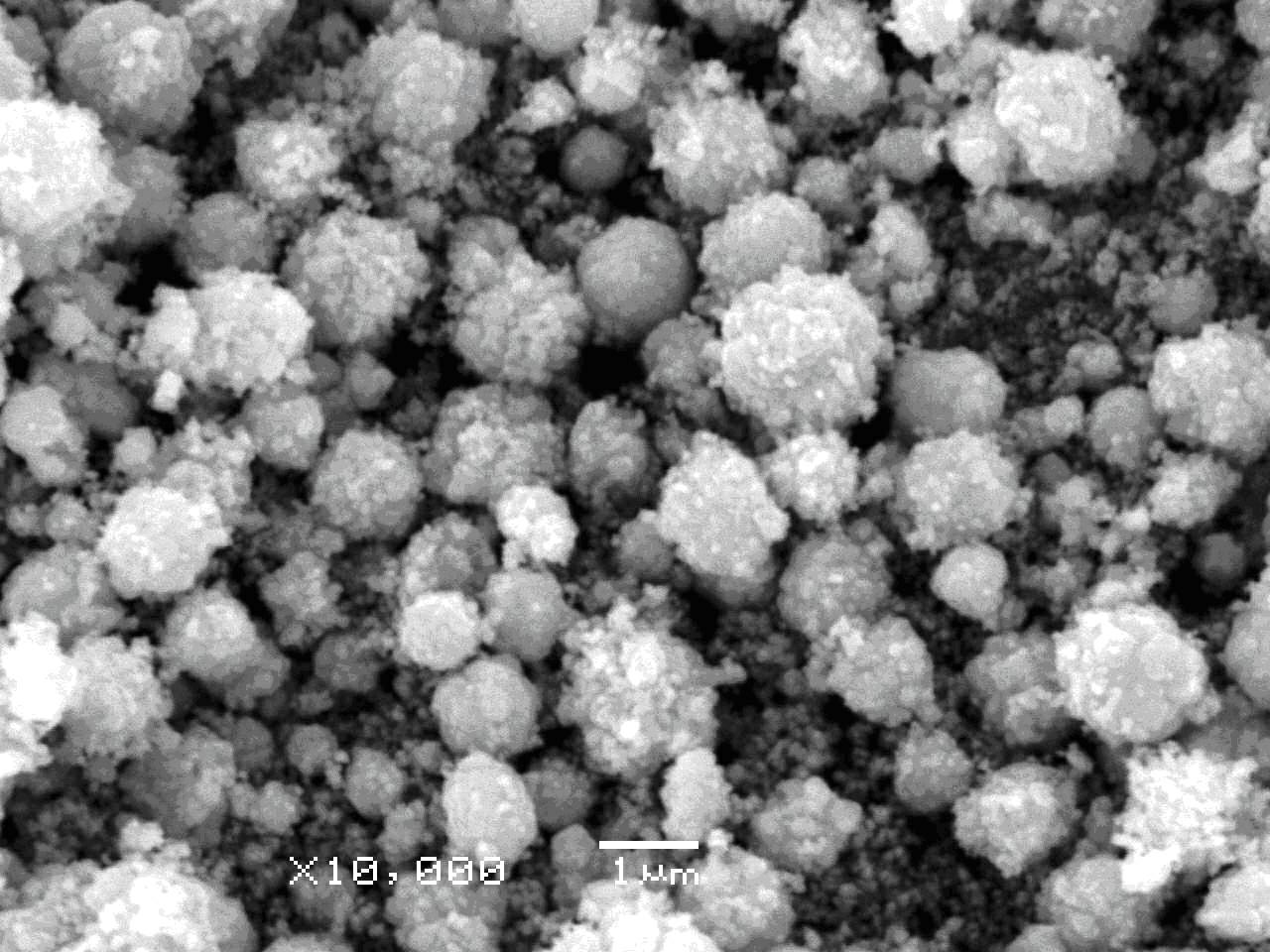

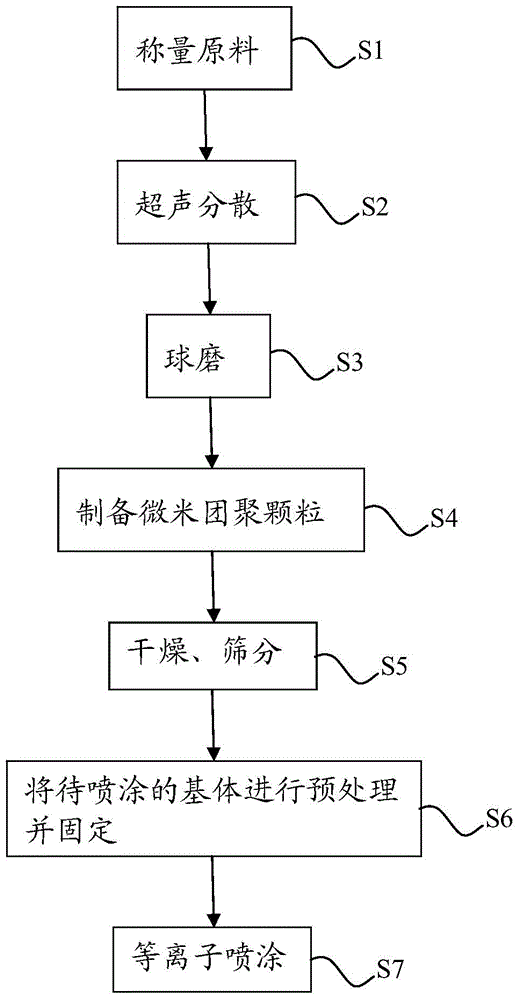

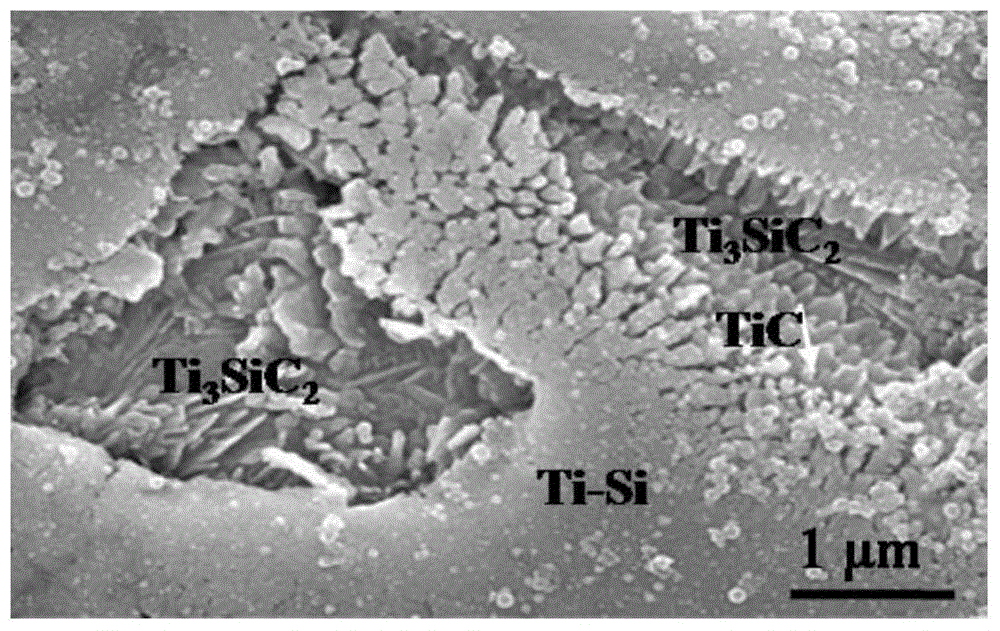

Ti3SiC2-based composite material coating and plasma spray in-situ reaction preparation method thereof

InactiveCN104451517AEasy to operateImprove efficiencyMolten spray coatingIn situ reactionPre treatment

The invention discloses a Ti3SiC2-based composite material coating and a preparation method thereof, wherein the preparation method of the Ti3SiC2-based composite material coating comprises the following steps: S1, weighing raw materials; S2, carrying out ultrasonic dispersion; S3, ball-milling Ti powder, SiC powder and C powder after ultrasonic dispersion, so as to form mixed slurry; S4, spray drying the mixed slurry to prepare micronmeter agglomerated particles; S5, drying the prepared micronmeter agglomerated particles and sieving the dried micronmeter agglomerated particles; S6, carrying out surface pre-treatment on a to-be-sprayed substrate and fixing the substrate; and S7, spraying the micronmeter agglomerated particles dried in the step S4 onto the substrate treated in the S6 by virtue of a plasma spray method. The preparation method is simple to operate, convenient and controllable and high in efficiency and the thickness of the coating is flexibly controlled, and the prepared Ti3SiC2-based composite material coating has the performances of wear resistance, corrosion resistance, high-temperature oxidization resistance and the like and has a wide application prospect.

Owner:SUZHOU UNIV

Preparing method of titanium fire resistance coating

ActiveCN107138878AHigh hardnessHigh temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaAlloyFire resistance

The invention discloses a preparing method of a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal can be completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Preparation method of double layer electrochemical working electrode with shielding outer layer

InactiveCN101241098ASpecial structureImprove electromagnetic shielding performanceMaterial electrochemical variablesEpoxyCarbon nanotube

The present invention provides a preparation method of double electrochemistry working electrode structure with shielding crust. Epoxy on outside is used as substrate based on the inner layer as preparation working electrode, and carbon nano-tube is used as conductive filler to process a choiceness Hertzian waves shielding layer. The said working electrode has special structure, dielectric property and strong electromagnetic shielding effectiveness, at the same time, has merits of light quality, adjustable conductivity, strong high temperature oxidation resistance and good stability. In addition, the said working electrode is a working electrode with electromagnetic shielding technique, which is convenient for operation of electrochemistry test and is a promising electromagnetic shielding technique, and has widely use value and application prospect in electrochemistry field.

Owner:佛山中科先创电子科技有限公司

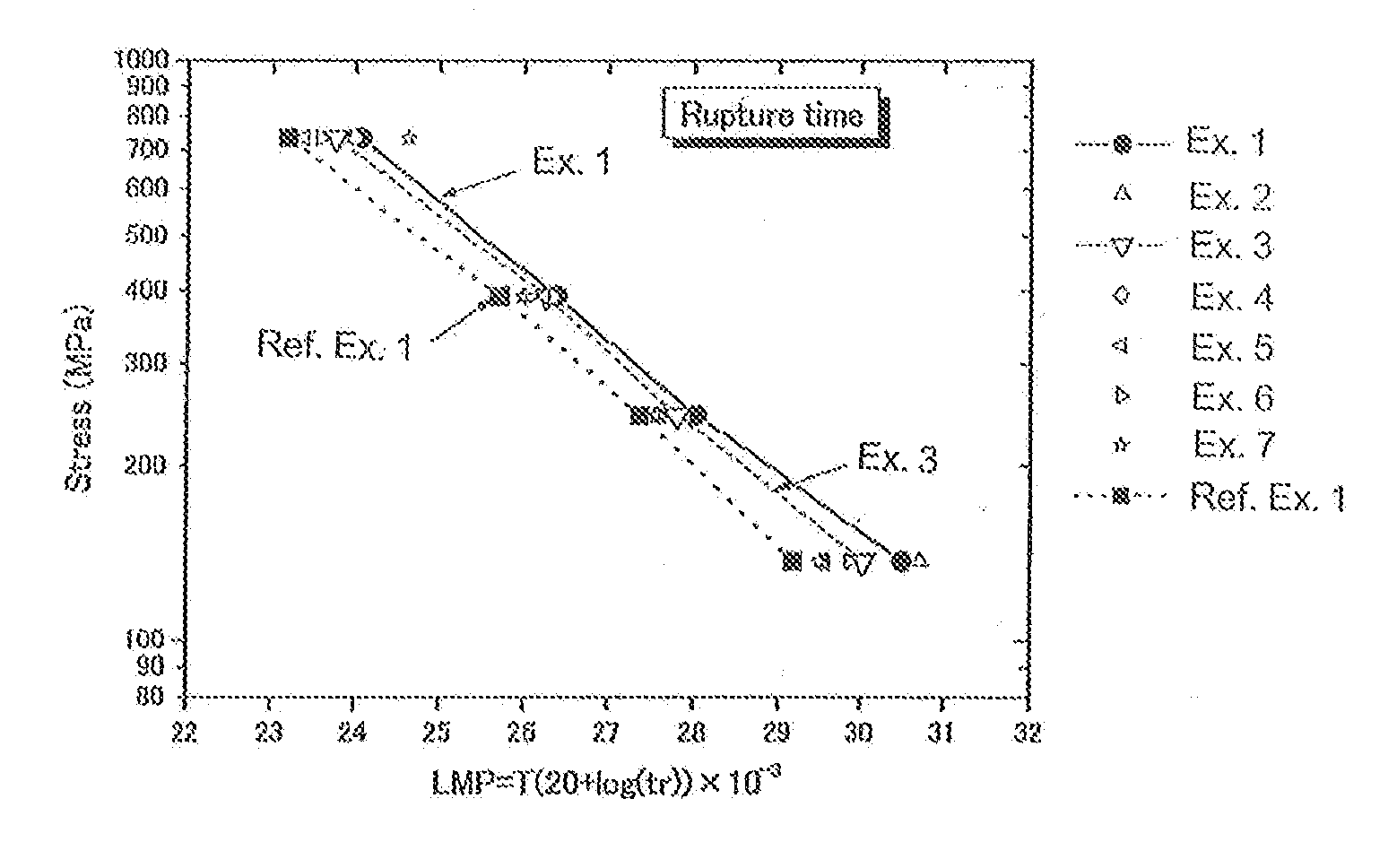

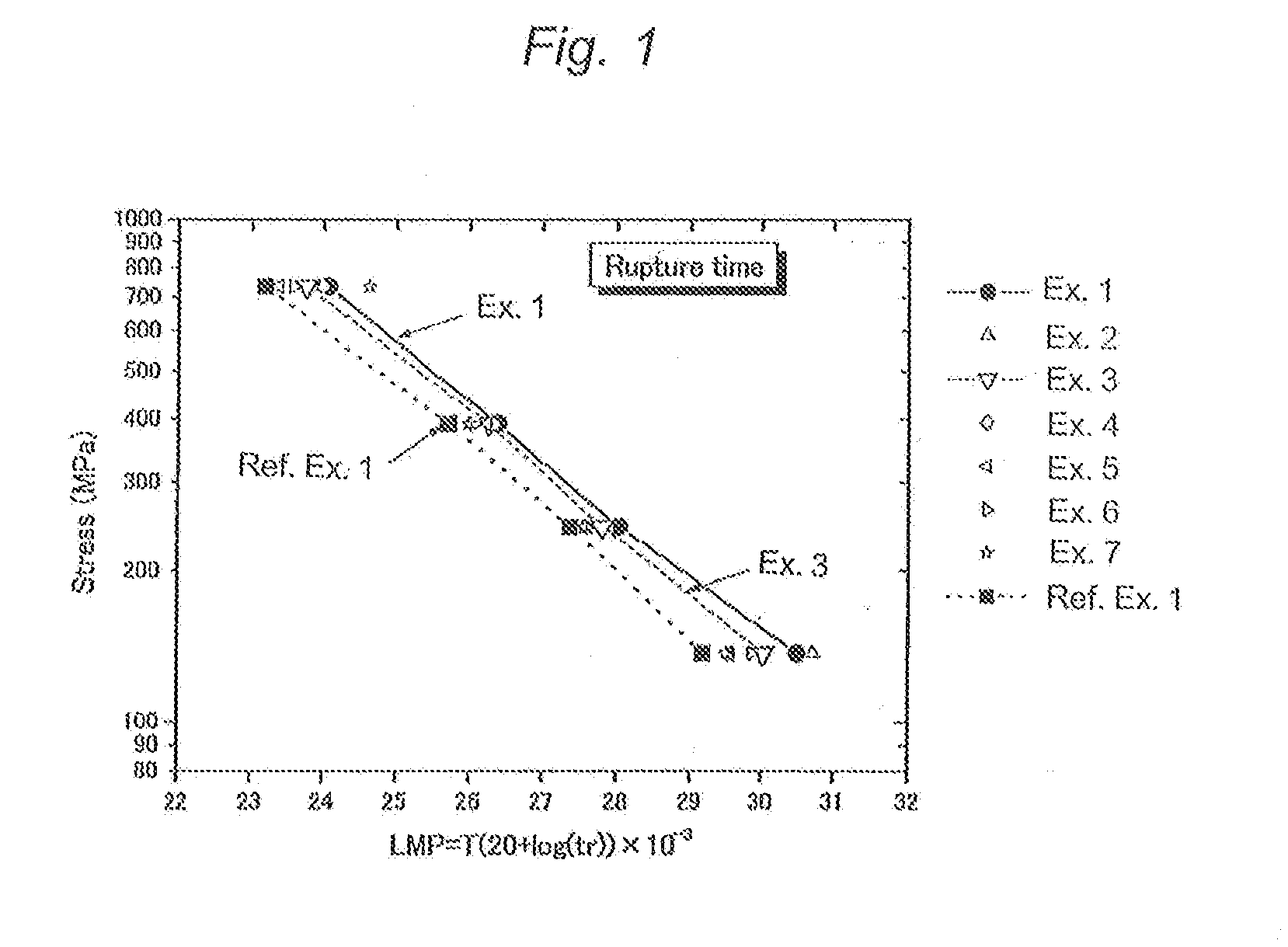

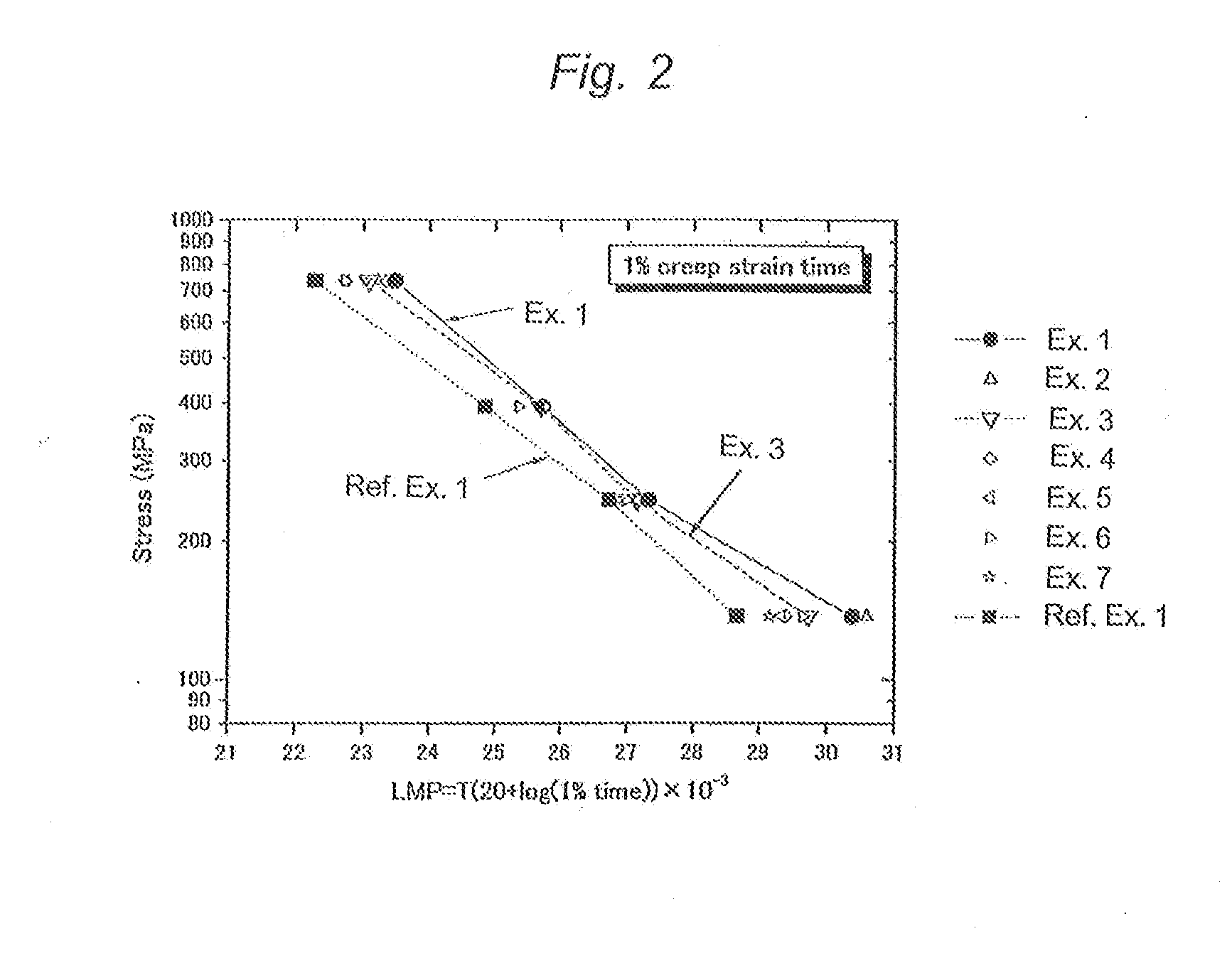

Ni-BASED SINGLE CRYSTAL SUPERALLOY

ActiveUS20150197833A1Improve featuresLittle dependencePolycrystalline material growthAfter-treatment detailsSingle crystal superalloyMaterials science

Provided is a Ni-based single crystal superalloy containing6% by mass or more and 12% by mass or less of Cr,0.4% by mass or more and 3.0% by mass or less of Mo,6% by mass or more and 10% by mass or less of W,4.0% by mass or more and 6.5% by mass or less of Al,0% by mass or more and 1% by mass or less of Nb,8% by mass or more and 12% by mass or less of Ta,0% by mass or more and 0.15% by mass or less of Hf,0.01% by mass or more and 0.2% by mass or less of Si, and0% by mass or more and 0.04% by mass or less of Zr, andoptionally containing at least one element selected from B, C, Y, La, Ce, and V,with a balance being Ni and inevitable impurities.

Owner:NAT INST FOR MATERIALS SCI +1

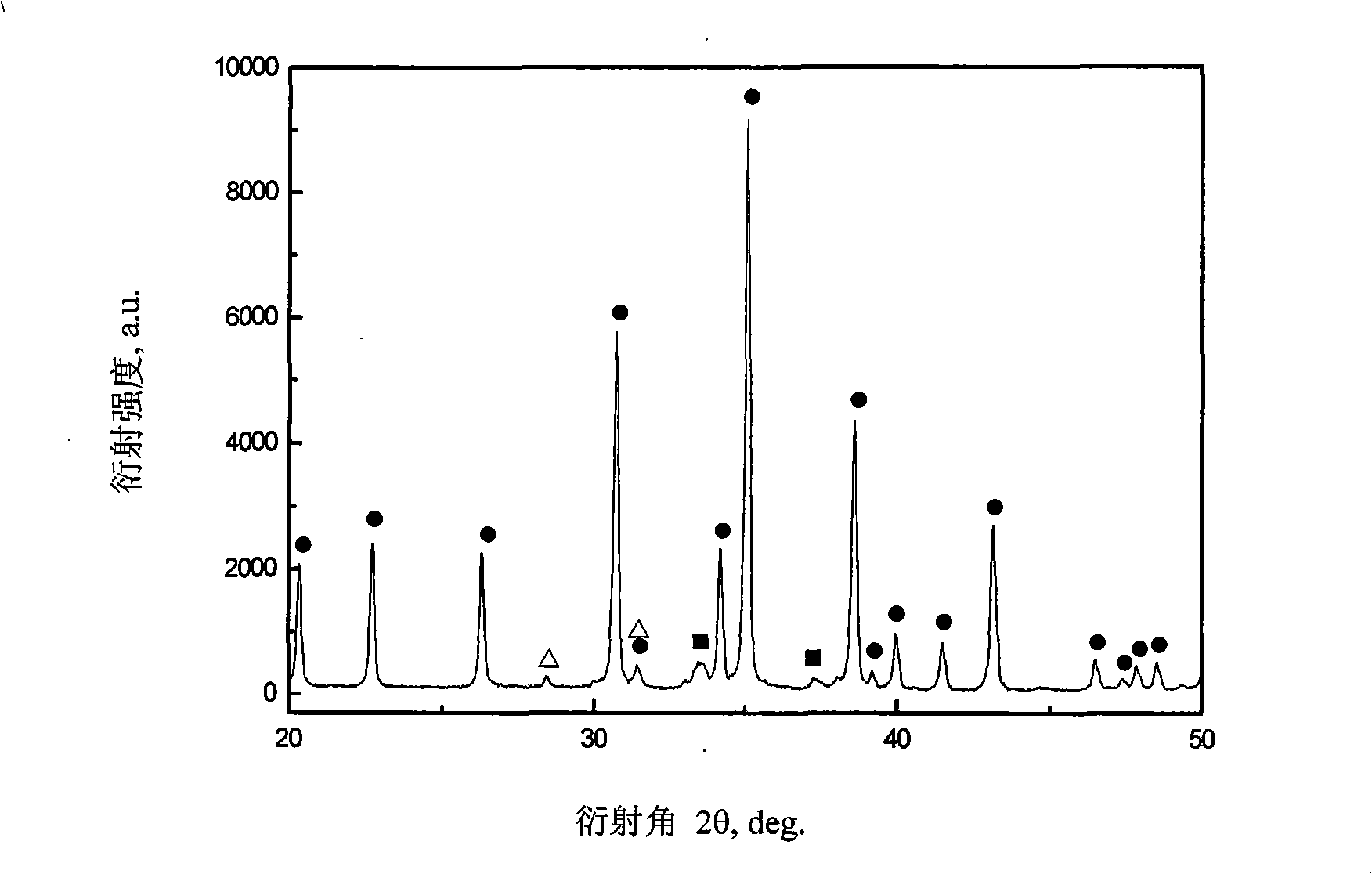

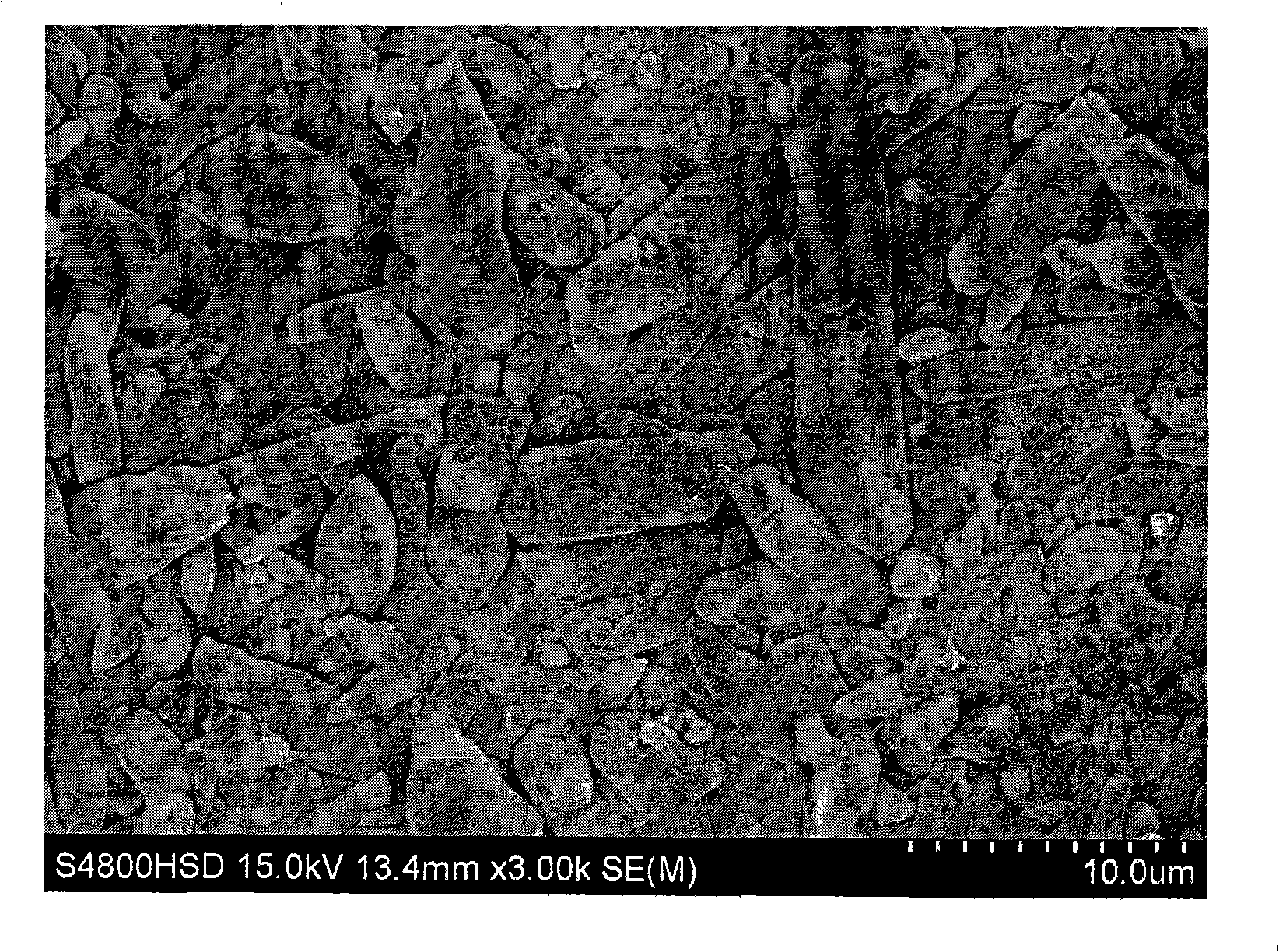

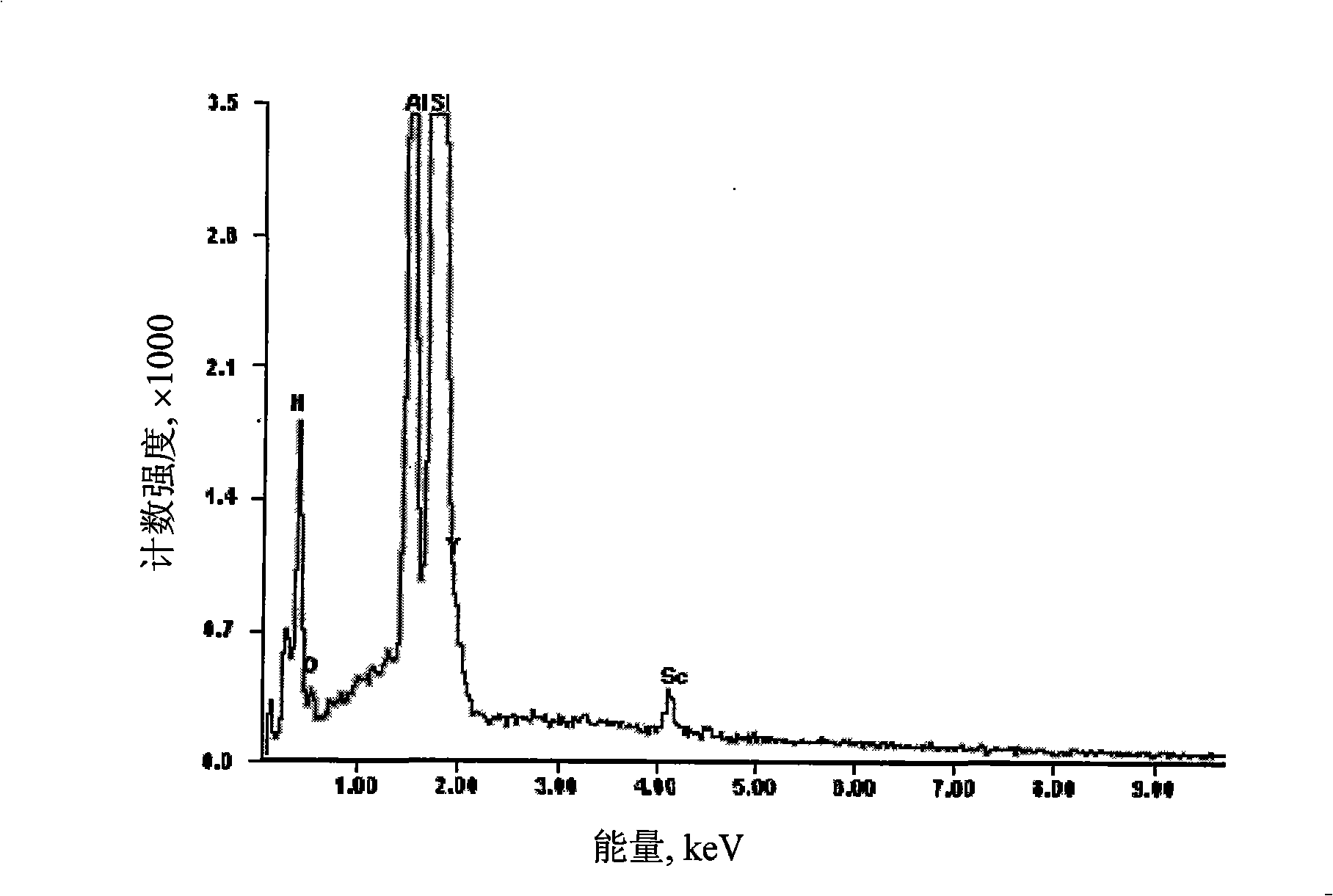

Alpha--sialon ceramic doping composite rare earth and preparation method thereof

The present invention provides alpha-sialon ceramics doped with composite rare earth and a preparation method thereof, and relates to the alpha-sialon ceramics and the preparation method. The present invention solves the problem that the hot pressing and no pressure can not easily prepare Sc-alpha-sialon phase in the existing sintering method, thus restricting the application of scandium oxide. The ceramics has a formula (ScxRy)Si<12-(m+n)>AlOnN<16-n>. The preparation method comprises the following steps: raw materials are mixed in wet environment, dried and then arranged in a mould; under the conditions of protective nitrogen and pressure of 30MPa, the temperature is raised and maintained; thus the ceramics can be prepared. With the common influence of Y<3+>, the preparation method adopts Sc<3+> in the alpha-sialon structure and makes full use of the scandium oxide. The prepared ceramic material has the hardness of 21GPa; and the formation of alpha-sialon grains, which are shaped like a long rod, results in excellent toughness of the ceramic material, which is about 5.3MPm<1 / 2>.

Owner:HARBIN INST OF TECH

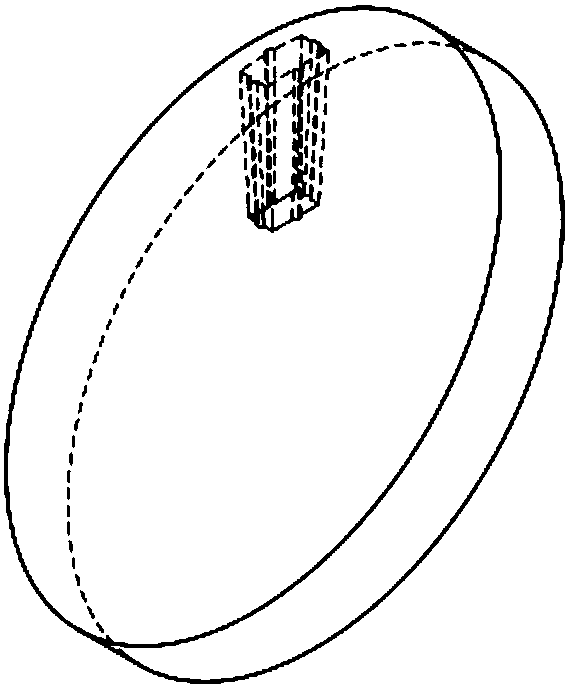

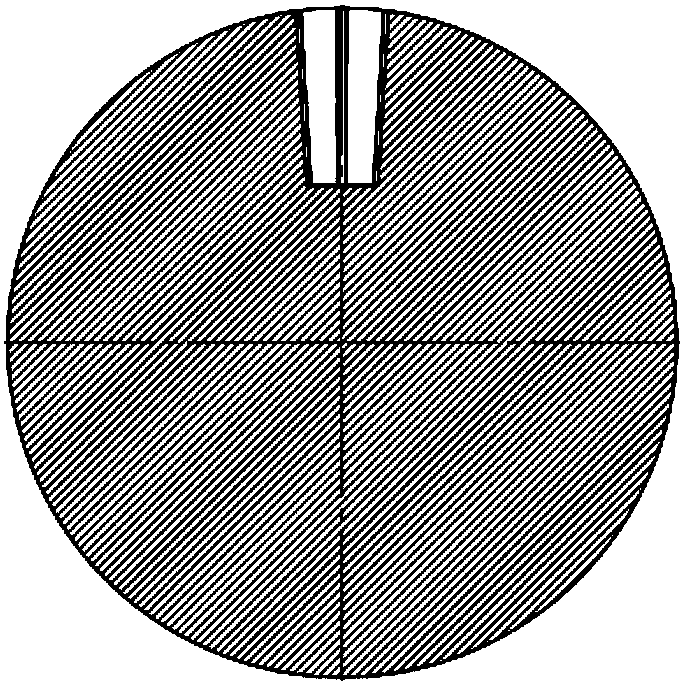

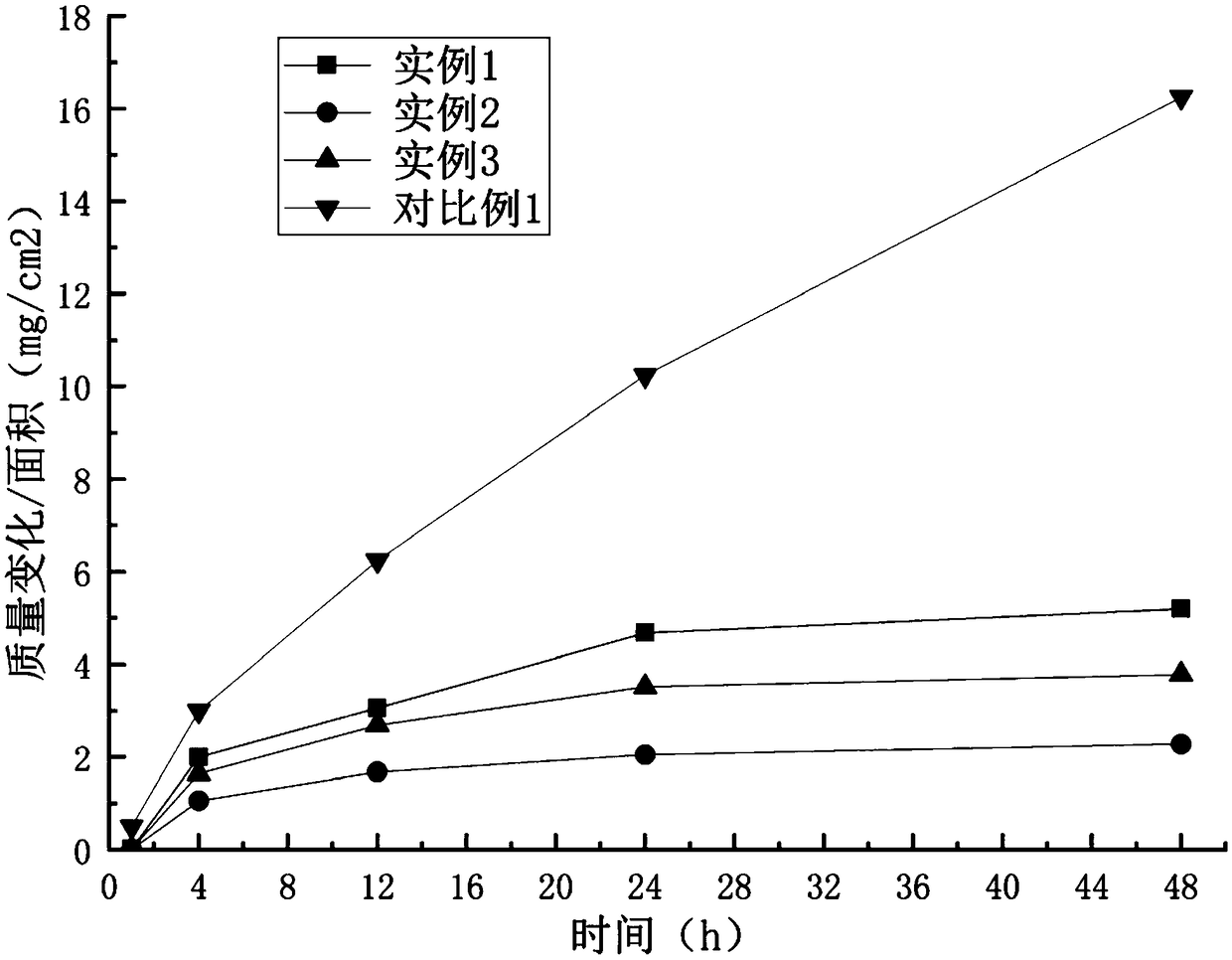

Laser forming method of TiC-Ti composite component

InactiveCN105344994AHigh temperature oxidation resistanceWear-resistantAdditive manufacturing apparatusMetallic materialsGraphite

The invention relates to a laser forming method of a TiC-Ti metallic composite structural component. The adopted formula of raw material powder comprises 2.36-4.55wt% of graphite, 0.11-0.22wt% of rare earth oxide and the balance of Ti. Quantitative powder distribution and mixing, required by laser forming are finished by a multi-hopper spiral powder conveying and mixing system, and coaxial discontinuous powder sprayers are used as laser forming nozzles. The forming of the inner and outer layered structure of the composite component is realized by using the system to control powder conveying and laser, and the dynamic performance of the composite can reach more than 70% of a base metal material.

Owner:HUBEI UNIV OF TECH

Preparation methods of carbon-carbon composite material and carbon-ceramic composite material with inner holes

The invention relates to preparation methods of a carbon-carbon composite material and a carbon-ceramic composite material with inner holes. According to the preparation methods, by a method of embedding a plastic mould or a graphite mould with a predetermined shape and a predetermined size and coating the surface thereof with graphite paper with a special structure and special functions, or pretreated graphite paper or carbon fiber paper, a carbon fiber needle-punched preform is woven and moulded, then the carbon fiber needle-punched preform is degummed at high temperature in a protective atmosphere, then CVI densification and / or resin impregnation-cracking densification is performed, and finally after high-temperature graphitization or siliconizing treatment, the embedded plastic mould is removed or the graphite mould is taken out to obtain the carbon-carbon composite material and the carbon-ceramic composite material with special internal pore structures and functions. The preparation methods are simple and controllable, and are particularly suitable for preparing the carbon-carbon composite material and the carbon-ceramic composite material which have special functional requirements on the inner holes, such as heat dissipation, heat conduction and electricity conduction, and have very complicated inner holes.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

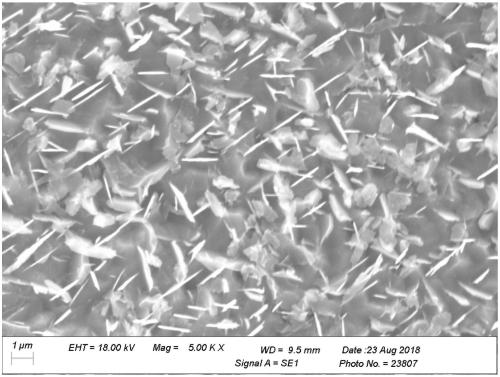

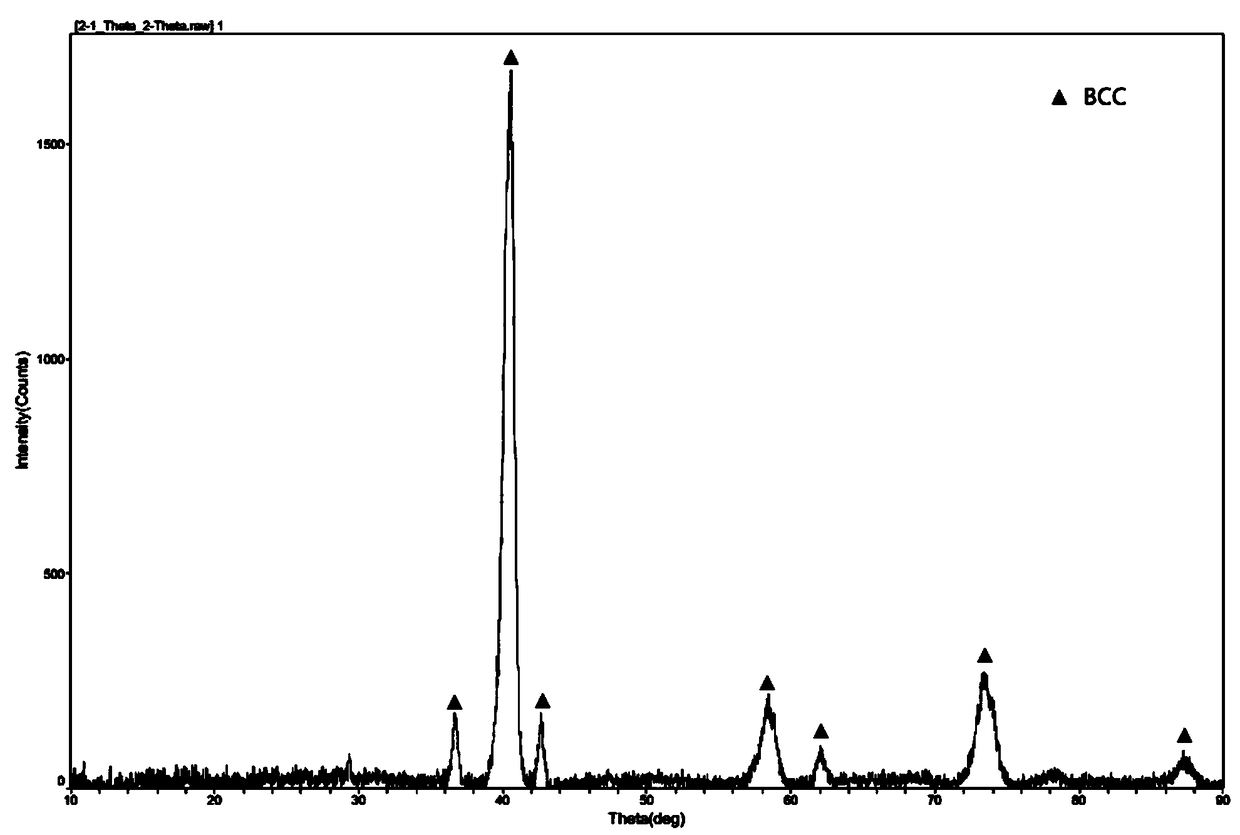

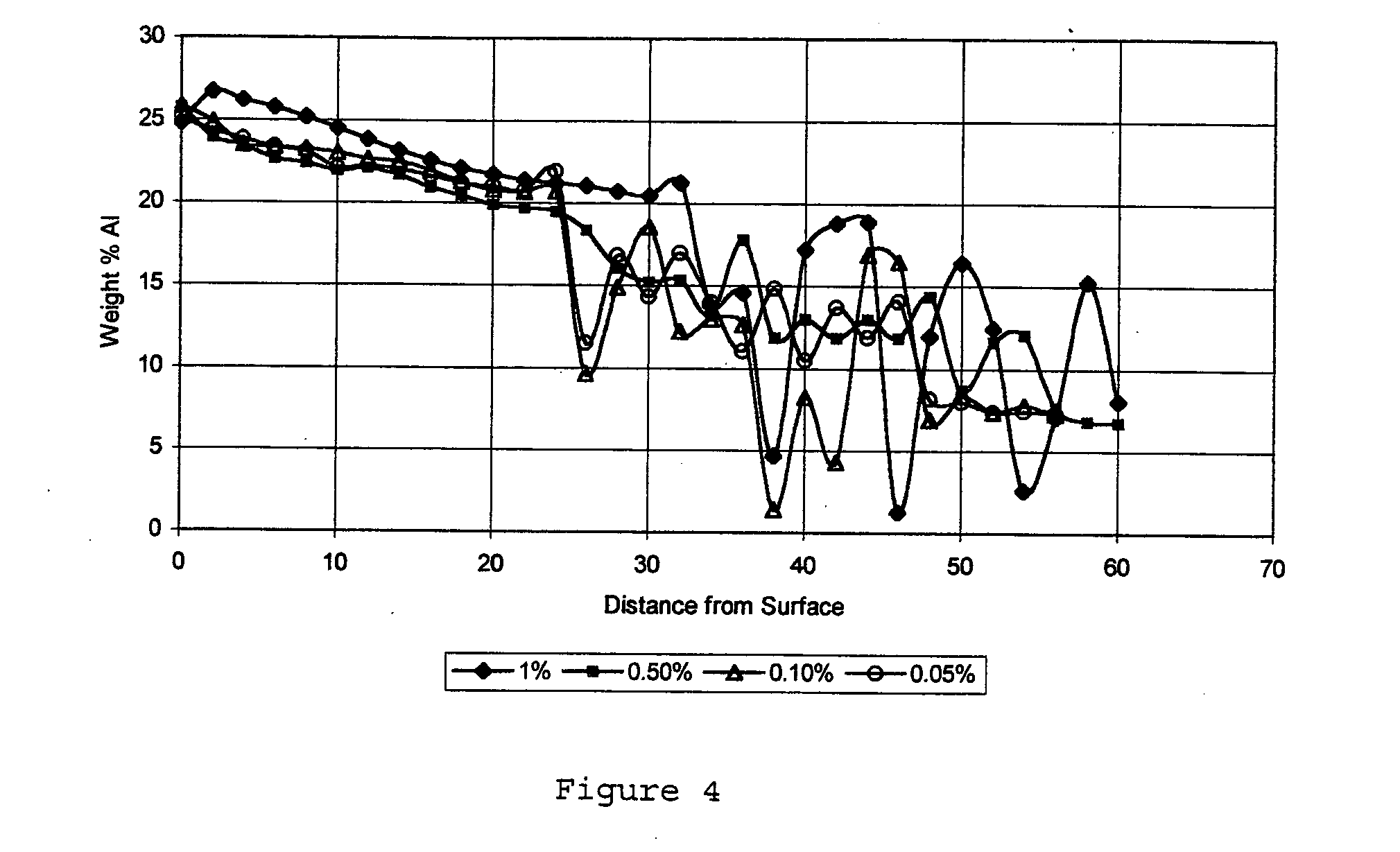

Ultrafine-grained Al-bearing multiple-principal-element high-entropy alloy and preparation method thereof

ActiveCN109136715AImprove high temperature creep resistancePromote formationHigh entropy alloysEqual channel angular extrusion

The invention discloses ultrafine-grained Al-bearing multiple-principal-element high-entropy alloy and a preparation method thereof. The ultrafine-grained Al-bearing multiple-principal-element high-entropy alloy is composed of Al, Co, Cr, Fe, Ni, Ti and Nb, marked in an atomic ratio as Al20-xCo20Cr20Fe20Ni20(TiyNb1-y)x, wherein 0<x<20, and 0<y<1. The ultrafine-grained Al-bearing multiple-principal-element high-entropy alloy is prepared by the combination of vacuum arc melting and equal channel angular extrusion; firstly, an alloy rod is made by vacuum arc melting; a super-large block of ultrafine-grained high-entropy alloy is prepared via equal channel angular extrusion; secondly, subsequent annealing is performed to adjust strength and plasticity of the alloy. By adding certain Ti and Nbto replace Al, high-temperature creep resistance of the alloy herein is improved; BCC (body center cubic) solid solution is formed, so that antioxidant property is improved; equal channel angular extrusion and annealing help improve strength, plasticity and antioxidant property.

Owner:BAISE UNIV

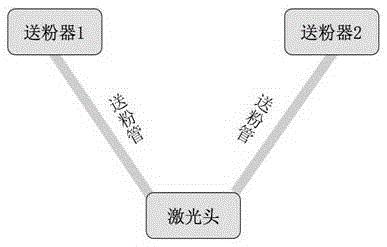

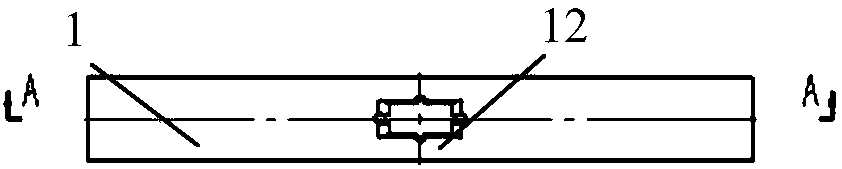

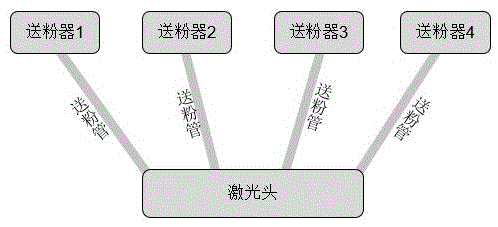

Laser forming method of Cr3C2-NiCr composite material component

InactiveCN105458259AEliminate uneven distributionTunable Laser ShapingAdditive manufacturing apparatusIncreasing energy efficiencyGraphiteAlloy

The invention relates to a laser forming method of a Cr3C2-NiCr composite material component. Selected raw material powder comprises, by weight percent, 3.28% to 4.80% of graphite, 30.25% to 38.53% of Cr, 1.56% to 3.85% of Mo, 0.38% to 0.71% of rare earth oxide and the balance Ni. The laser forming powder is conveyed quantitatively through a multi-hopper conveying system, four powder feeding devices of the multi-hopper conveying system are all connected with one common laser head through powder feeding pipes; a four-pipe coaxial laser head is adopted in laser forming, and through control over the powder conveying system and the laser head, the inner and outer gradient layered structure of the Cr3C2-NiCr component can be achieved, and the breaking toughness of the Cr3C2-NiCr component can reach more than 70% of a Ni-based alloy.

Owner:HUBEI UNIV OF TECH

Salt Bath Ferritic Nitrocarburizing of Brake Rotors

ActiveUS20130000787A1Absence of distortionAccelerated corrosionBraking discsSolid state diffusion coatingNitrogenRoom temperature

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

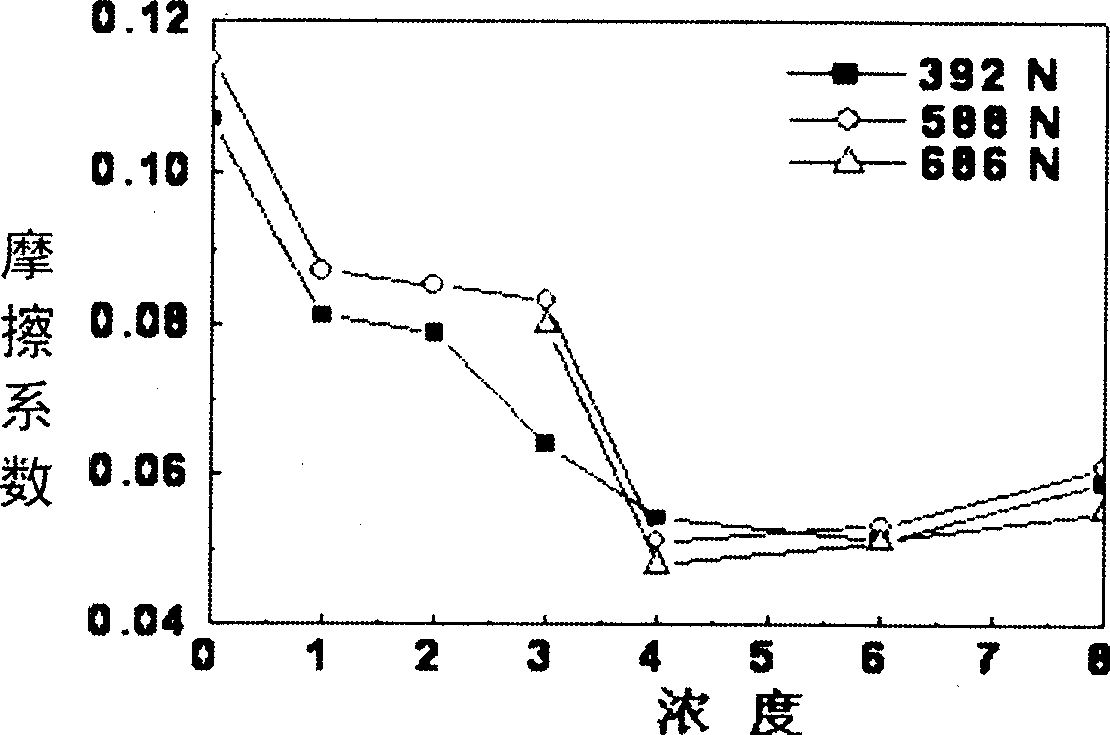

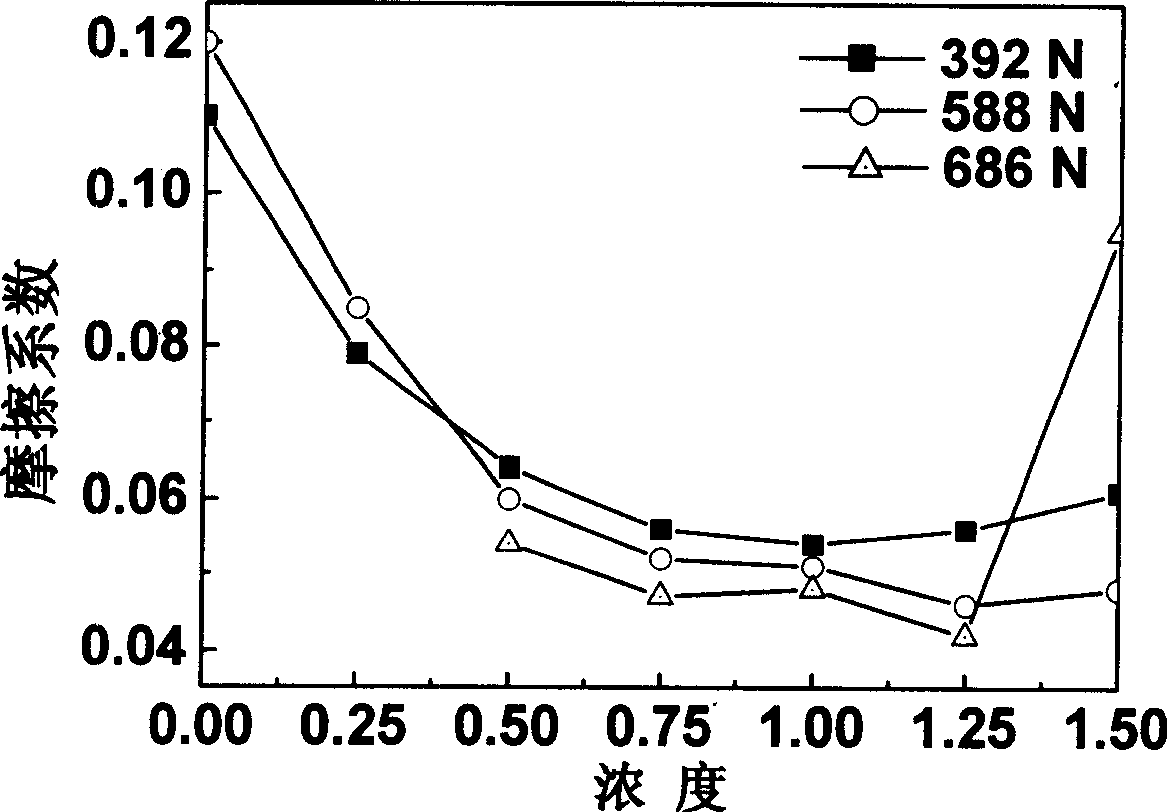

Non-sulphur and phosphorus antiwear and friction reducing multifunctional additive agent and preparation method

InactiveCN101381649ARaise the initial oxidation temperatureProlonged oxidation induction timeAdditivesAntioxidantInternal combustion engine

The invention belongs to the technical field of lubricating oil and discloses a non-sulfur non-phosphorus anti-wear and antifrictional multifunctional additive and a preparation method thereof. The compositions of the additive comprise a friction modifier, an antiwear agent, an antioxidant, a detergent dispersant, and an antirusting agent. Firstly, the friction modifier is synthesized, then the friction modifier, the antiwear agent, the detergent dispersant, the antioxidant, and the antirusting agent with the needed amount are orderly mixed according to the proportion, and the mixture is heated to between 50 and 70 DEG C under the stirring and then is stirred evenly. The additive can be widely applied to various lubricating oil products including lubricant base oil or lubricant oil finished products, such as internal combustion engine oil, gear oil and so on, and is added into lubricating oil of an internal combustion engine with 3 to 20 weight percentage during the use. The additive can greatly improve the abrasion resistance and the antifriction performance of oil products, can also apparently improve the initial oxidation temperature and the oxidation induction time of the oil products, effectively suppress the viscosity of the oil products from increasing, and ensure that the high-temperature antioxidation performance of the internal combustion engine oil is greatly improved.

Owner:天津市东宝润滑油脂有限公司

Nano composite plating paste material and its preparation and electroplating method

InactiveCN1414144ASpecial structureExtraordinary corrosion resistanceElectrolytic coatingsMischmetalAlkaline earth metal

A nano-class composite slurry for electroplating is prepared through mixing alpha-Al2O3 with the oxide is alkali-earth metal and / or transition metal and / or rare-earth metal by ball grinding for 6-10 hr transferring phase at 1200-1500 deg.C, proportionally mixing powder, water and cationic surfactant, and dispersing in ball grinder for 60-100 hr. It can be added to traditional plating liquid to obtain decorative-protective-functional plated layer.

Owner:重庆阿波罗机电技术有限公司

High conductivity solid oxide fuel cell connection part, preparation and application thereof

ActiveCN103887533AIncrease contactIncrease power generation capacityCell component detailsCollectors/separatorsFuel cellsAlloy

The present invention relates to a high conductivity solid oxide fuel cell high temperature oxidation resistance flexible connection part. According to the present invention, a coating material is coated on the surface of an alloy network body or foam-like body to form a high temperature oxidation resistance protection coating, and the good conductivity is provided, such that the prepared flexible connection part having high conductivity at a high temperature oxidation atmosphere has characteristics of high conductivity and high temperature oxidation resistance, wherein the coating coated on the surface contains one or more than two materials selected from an oxide having a perovskite structure, an oxide having a spinel structure, an oxide having a fluorite structure and an oxide having a rutile structure, and at least one of the oxides has the conductivity of more than 1 S / cm at a temperature of 500-900 DEG C; and the flexible connecting part can be provided for improving contact between the electrode or connector of the solid oxide fuel cell and the current collection part, eliminating high temperature expansion damage caused by rigid contact and improving the electricity generation performance of the fuel cell, and has advantages of high temperature oxidation resistance, good electrical conductivity, simple battery stack assembly and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

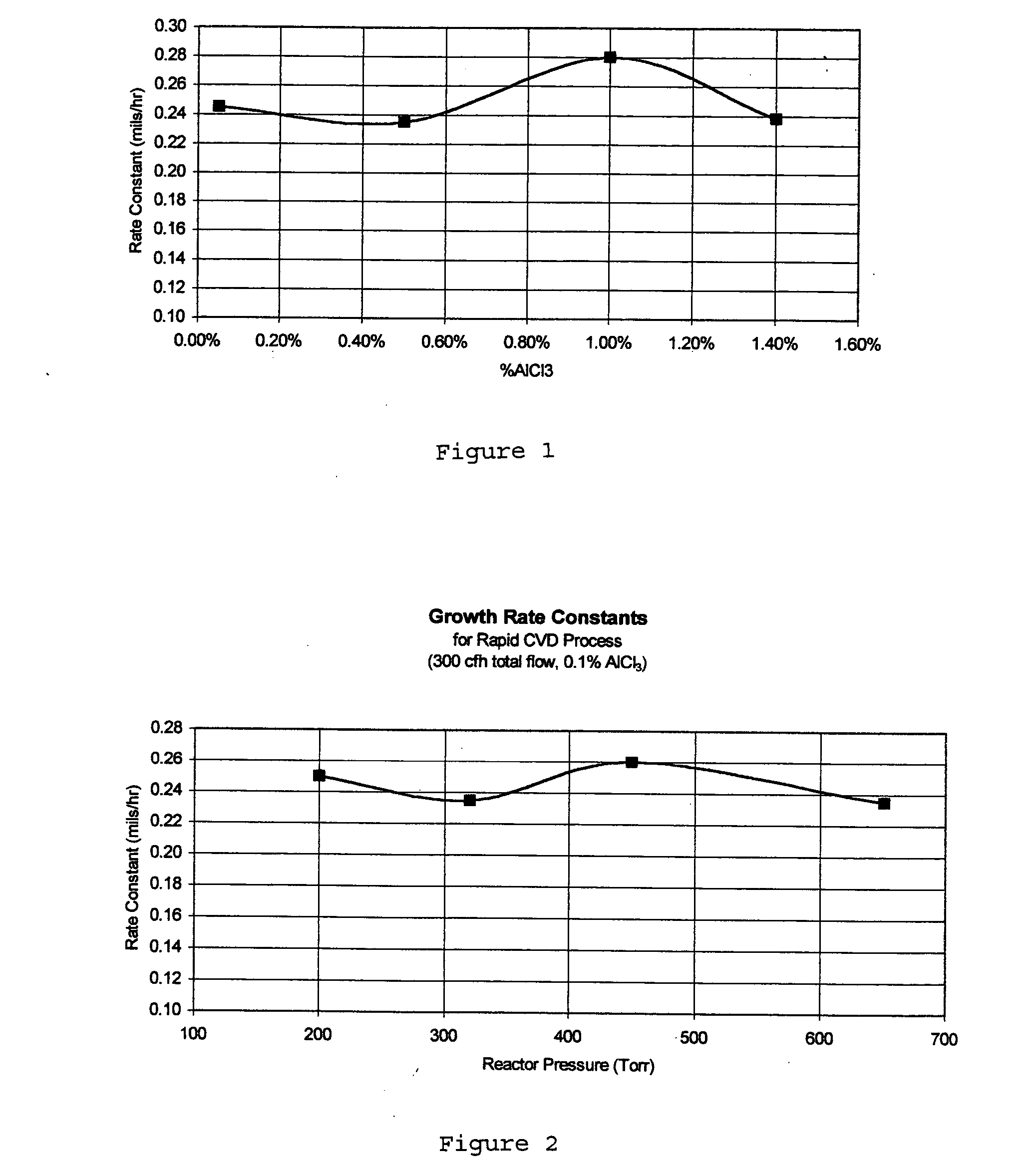

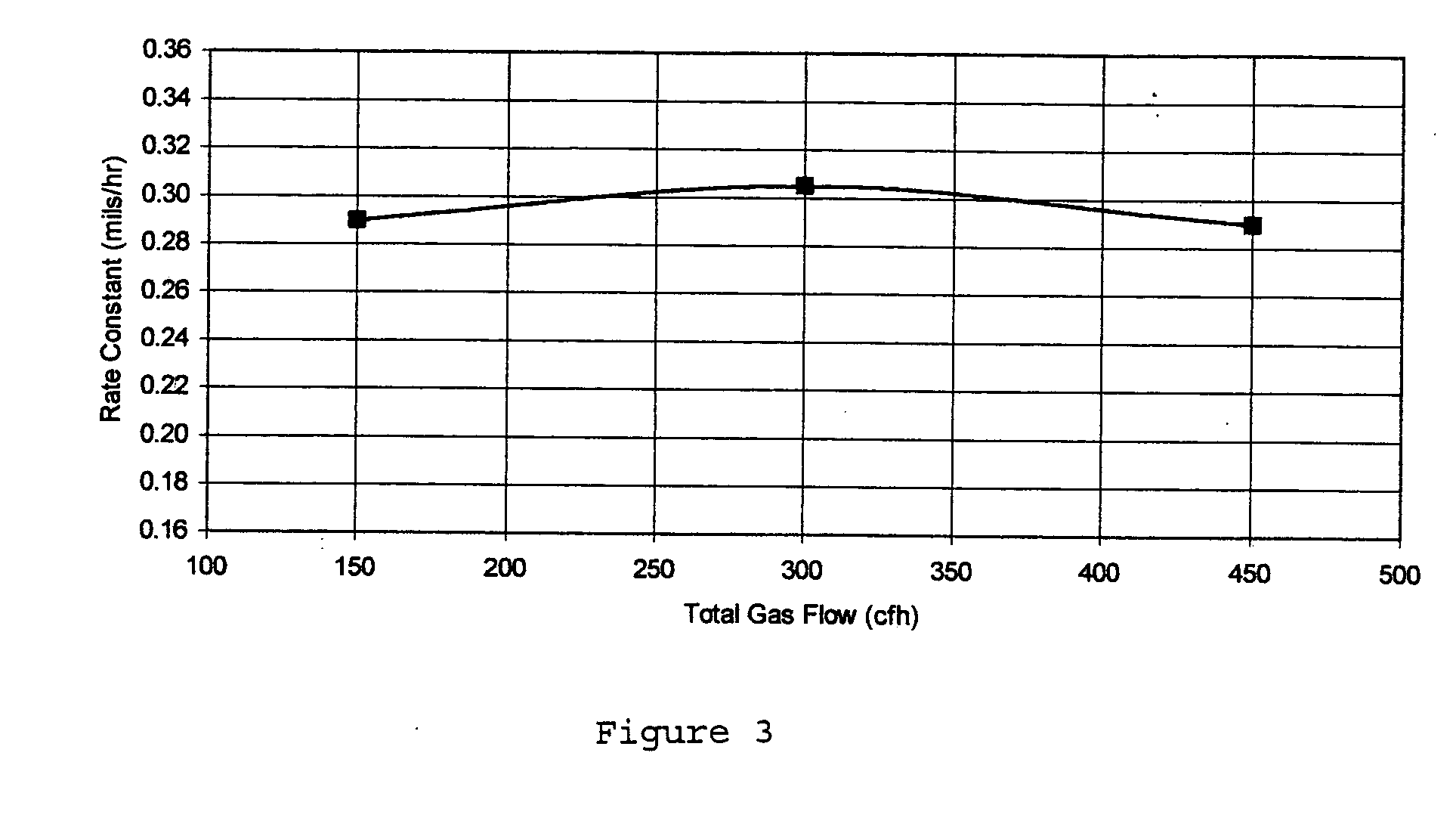

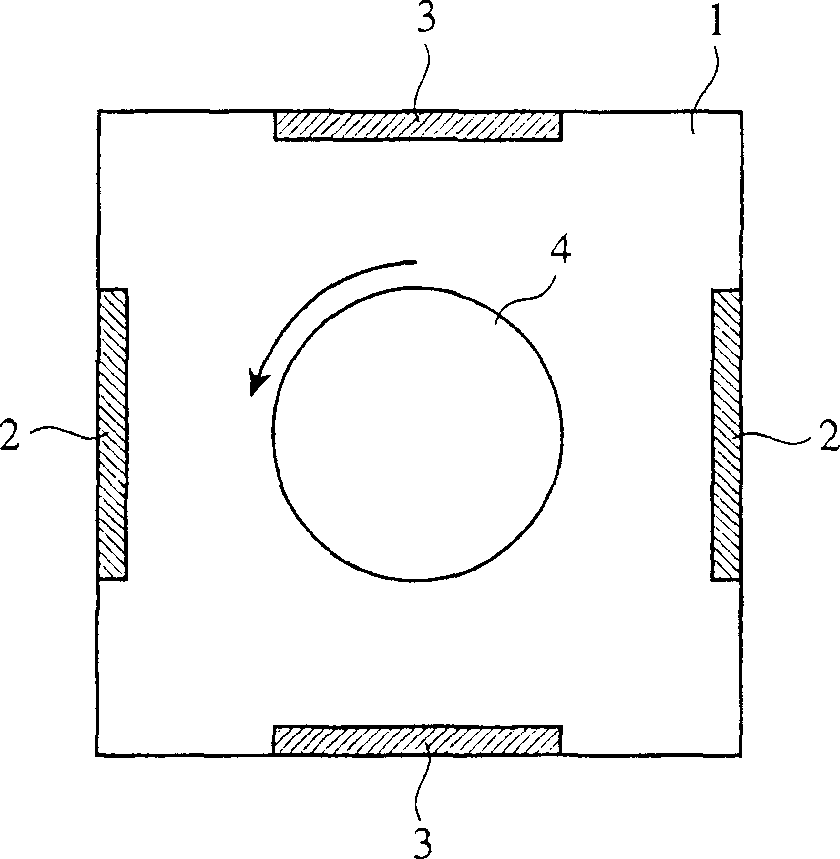

Method of forming aluminide diffusion coatings

ActiveUS20050069642A1Reduce timeIncreased growth rateSolid state diffusion coatingChemical vapor deposition coatingAluminum trichlorideAluminide

Method of forming an outwardly grown aluminide diffusion coating on a superalloy substrate disposed in a coating retort including the steps of heating the substrate to a temperature of 900 to 1200 degrees C., flowing a coating gas comprising aluminum trichloride and a carrier gas through the coating retort at a flow rate of the coating gas of about 100 to about 450 standard cubic feet per hour, providing a concentration of aluminum trichloride in the retort of less than 1.4% by volume of the coating gas, and providing a total pressure of the coating gas in the coating retort of about 100 to about 450 Torr.

Owner:HOWMET CORPORATION

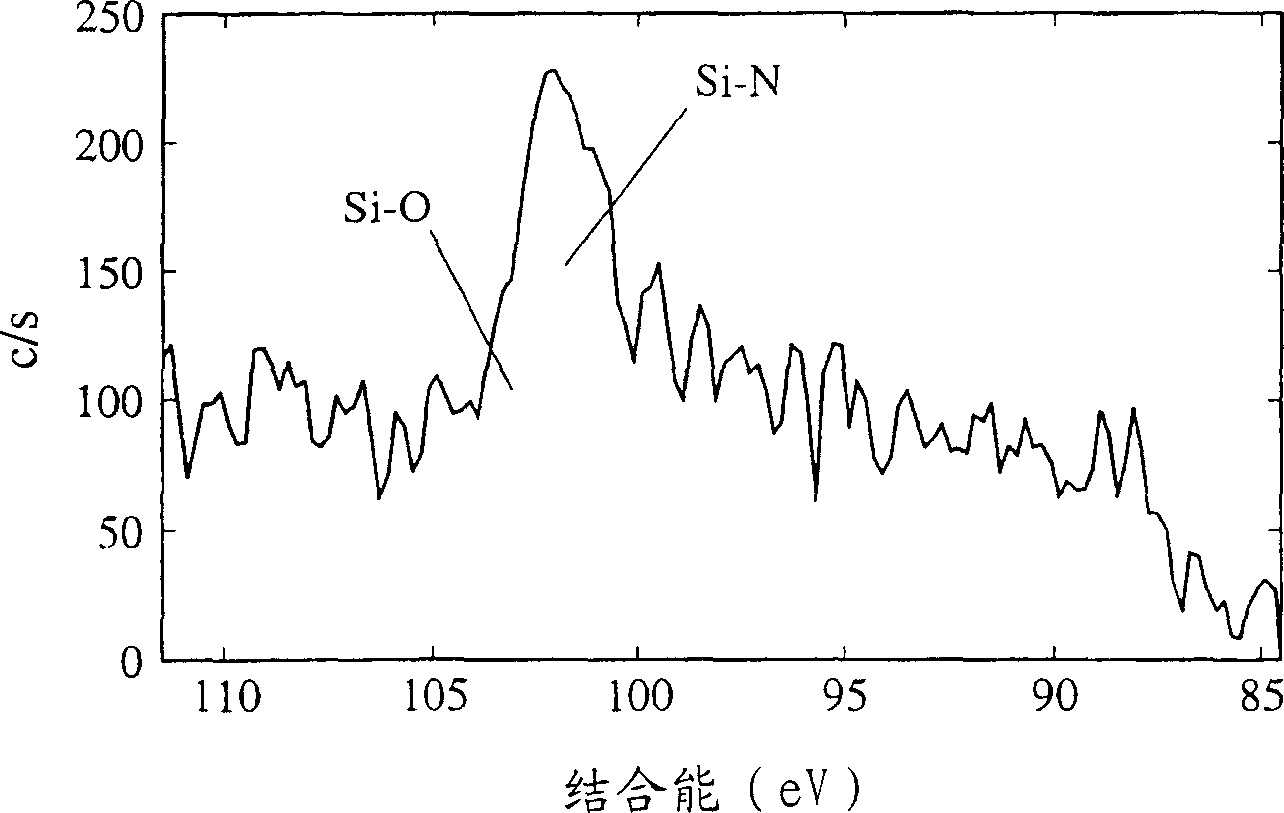

Hard coating and its production method

InactiveCN1710144AExcellent adhesionExcellent machinabilityVacuum evaporation coatingSputtering coatingTectorial membraneBoundary region

The present invention relates to a kind of hard protection film, and this hard protection film is the hard protection film that forms by physical vapor deposition method, is made of transition metal elements selected from Group 4a, 5a and 6a of the periodic table, Al and B At least one metal element of Si and at least one non-metallic element selected from C, N and O, the above-mentioned hard protective film has a columnar structure, and the columnar structure has a plurality of layers with different Si contents In the formed multi-layer structure, the lattice bands are continuous in the boundary region between the above-mentioned layers, and the thickness of each layer is 0.1-100 nm.

Owner:HITACHI TOOL ENG LTD

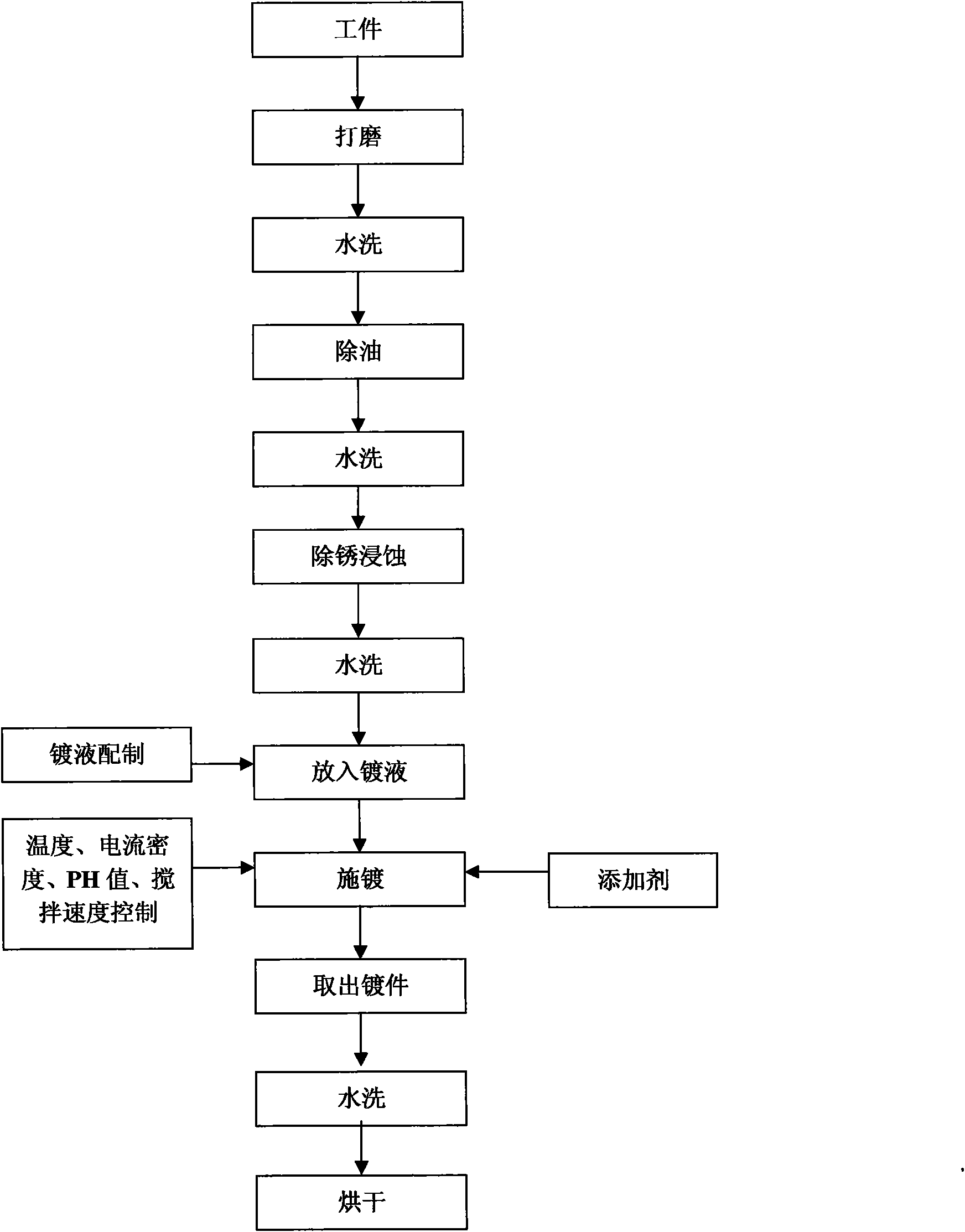

Electroplating method of zinc-nickel alloy nano multilayer film

The present invention discloses a method of plating a plating layer of zinc-nickel alloy nano multilayer film on surface of steel components, belongs to surface treatment technique of steel components and metallic materials field. The electroplating is using Ni and Zn as main salt, controlling content of Ni salt and Zn salt and pH value and current density to obtain plating layer of zinc-nickel alloy nano multilayer film. The invention has advantages of no post-processing after plating, low cost, high-efficiency and high-speed, convenient operation, simple process, safety, plating layer rigidity, corrosion resistance, wearing resistance, high-temperature resistance, compactness, decorative and excellent combination property.

Owner:KUNMING UNIV OF SCI & TECH

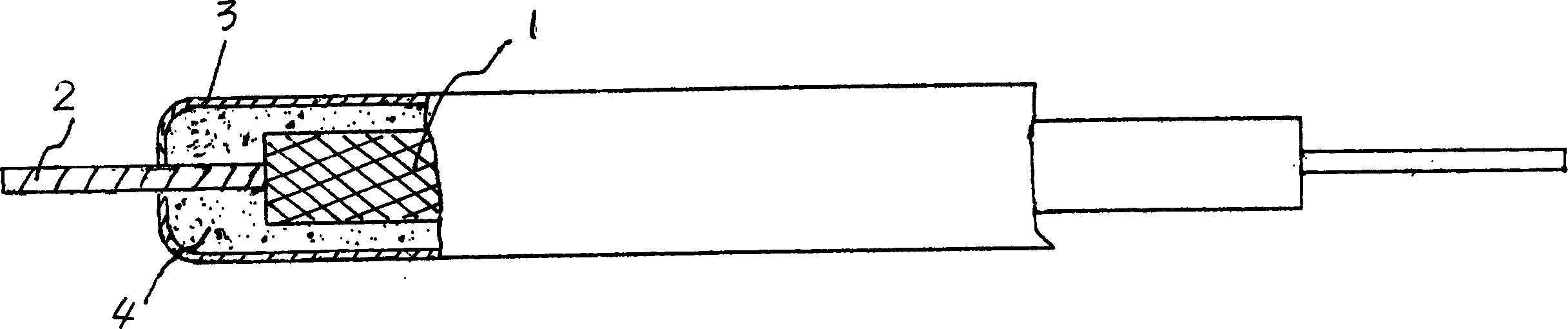

Carbon-ceramic heating tube and processing method

InactiveCN1555213ANo cracking will occurImprove thermal stabilityHeating element shapesHeating element materialsWorking lifeOxidation resistant

This invention discloses a ceramic-carbon heating pipe having a heating matrix, an electrode lead-out rod is connected with both ends of matrix sleeved with a protection pipe, insulation and heat conduction powder is filled between matrix and protection pipe. Its electric-heat transformation rate reaches as high as 99.6% and is oxidation resistant, not easy to be broken with a long work life to 50000 hours, 1.5 times higher than that of the national standard.

Owner:马放

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com