Ti3SiC2-based composite material coating and plasma spray in-situ reaction preparation method thereof

A composite material and plasma technology, applied in the field of ion spraying in-situ preparation, can solve the problem of less coating research, and achieve the effect of flexible control of coating thickness, improvement of poor wear resistance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

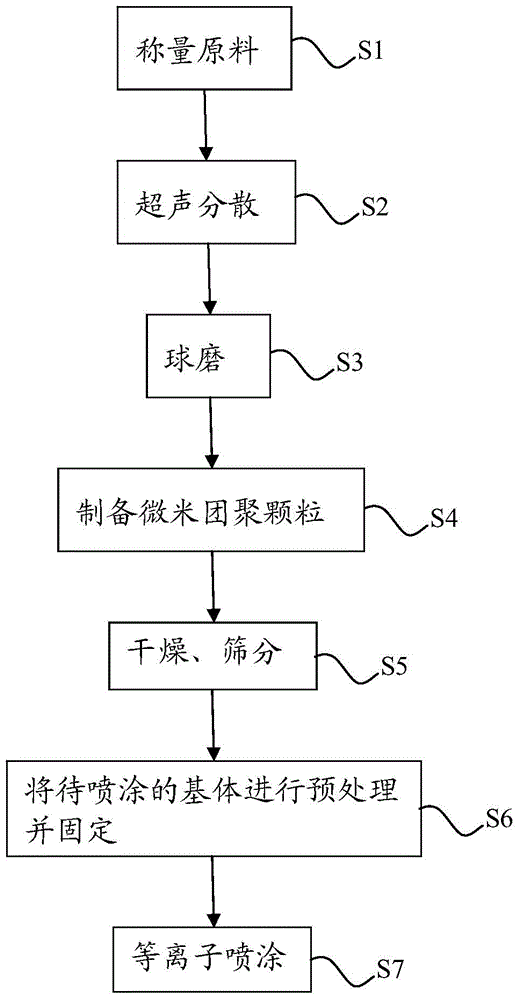

[0032] like figure 1 Shown, Ti of the present invention 3 SiC 2 The preparation method of matrix composite material coating comprises the steps:

[0033] S1. By weight percentage, weigh 65-80wt.% Ti powder, 15-25wt.% SiC powder, 5-10wt.% C powder;

[0034] S2. ultrasonically disperse the weighed Ti powder, SiC powder, and C powder in absolute ethanol respectively;

[0035] S3. The Ti powder, SiC powder, and C powder after ultrasonic dispersion are ball-milled to form a mixed slurry;

[0036] S4. Micron aggregated particles prepared by spray drying the mixed slurry;

[0037] S5. Dry the prepared micron aggregated particles, and use the sieved micron aggregated particles as plasma spraying feed;

[0038] S6. carrying out surface pretreatment and fixing the substrate to be sprayed;

[0039]S7. Spray the feed material sieved in step S5 on the substrate in step S6 by plasma spraying technology.

[0040] In step S1, high-purity 65-80wt.% Ti powder, 15-25wt.% SiC powder, and 5...

Embodiment 1

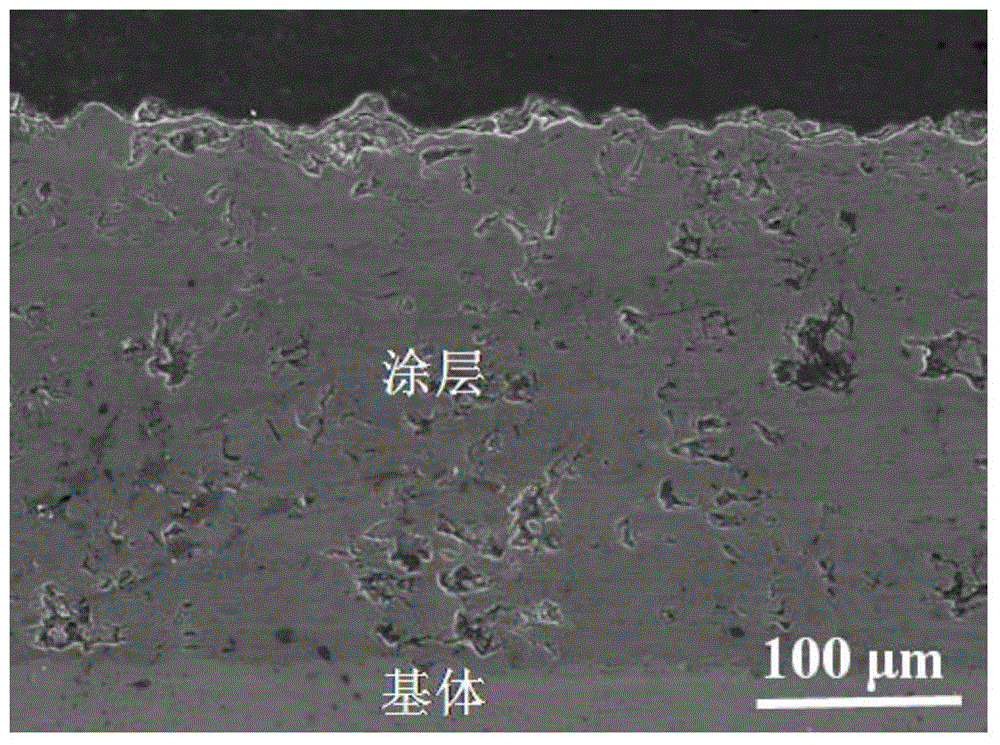

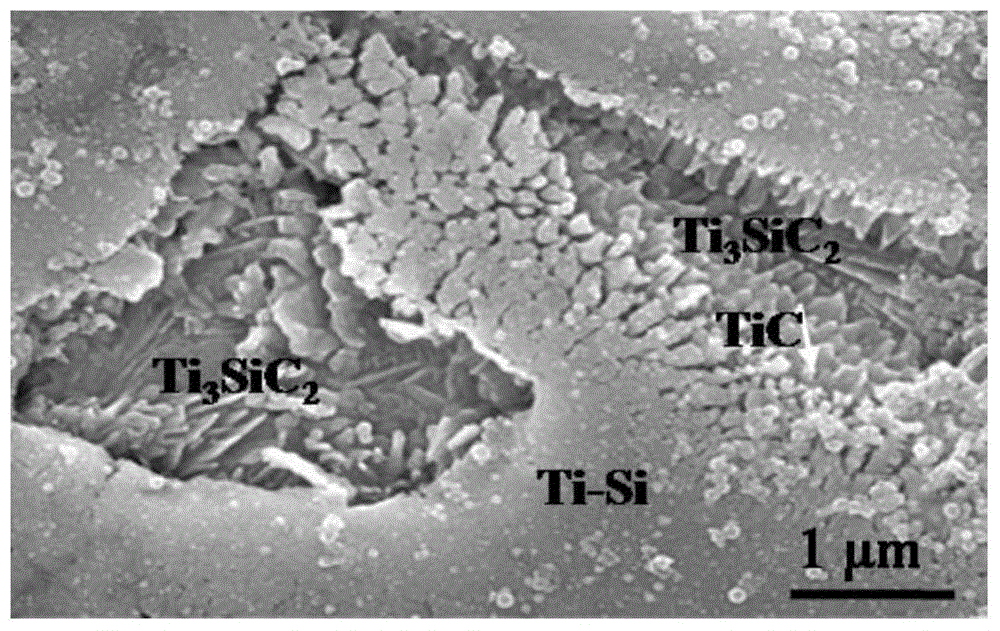

[0051] Weigh an appropriate amount of raw materials according to 75wt.% of Ti powder, 20wt.% of SiC powder, and 5wt.% of C powder; ultrasonically disperse them in absolute ethanol for 30 minutes; ball milling: put the Ti, SiC, and C powders after ultrasonic dispersion together Put it into a planetary ball mill tank for ball milling to make a uniformly mixed slurry. The ball-to-material ratio is 5:1, the rotating speed is 300r / min, and the ball milling time is 12h; spray granulation: the mixed slurry is sprayed into the drying chamber for atomization, and the droplets are dried rapidly in the hot air to form micron agglomerated particles. The dry atomization pressure is 0.5MPa, the indoor temperature is 200°C, and the outlet temperature is 100°C; after drying and screening, 40-60μm micron agglomerated particles are obtained as plasma spraying feed; the stainless steel substrate is polished with fine sandpaper and then the surface is sandblasted. , and fixed on the plasma sprayi...

Embodiment 2

[0053] Weigh an appropriate amount of raw materials according to 75wt.% of Ti powder, 20wt.% of SiC powder, and 5wt.% of C powder; ultrasonically disperse them in absolute ethanol for 30 minutes; ball milling: put the Ti, SiC, and C powders after ultrasonic dispersion together Put it into a planetary ball mill tank for ball milling to make a uniformly mixed slurry. The ball-to-material ratio is 5:1, the rotating speed is 300r / min, and the ball milling time is 12h; spray granulation: the mixed slurry is sprayed into the drying chamber for atomization, and the droplets are dried rapidly in the hot air to form micron agglomerated particles. The dry atomization pressure is 0.5MPa, the indoor temperature is 200°C, and the outlet temperature is 100°C; after drying and screening, 40-60μm micron agglomerated particles are obtained as plasma spraying feed; the stainless steel substrate is polished with fine sandpaper and then the surface is sandblasted. , and fixed on the plasma sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com