Preparation method of double layer electrochemical working electrode with shielding outer layer

A working electrode and electrochemical technology, applied in the field of preparation of double-layer electrochemical working electrodes, can solve problems such as inability to meet the development requirements of electrochemical experiments, inconvenient experimental operation, etc., and achieve wide practical value and application prospects, good stability, The effect of strong electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

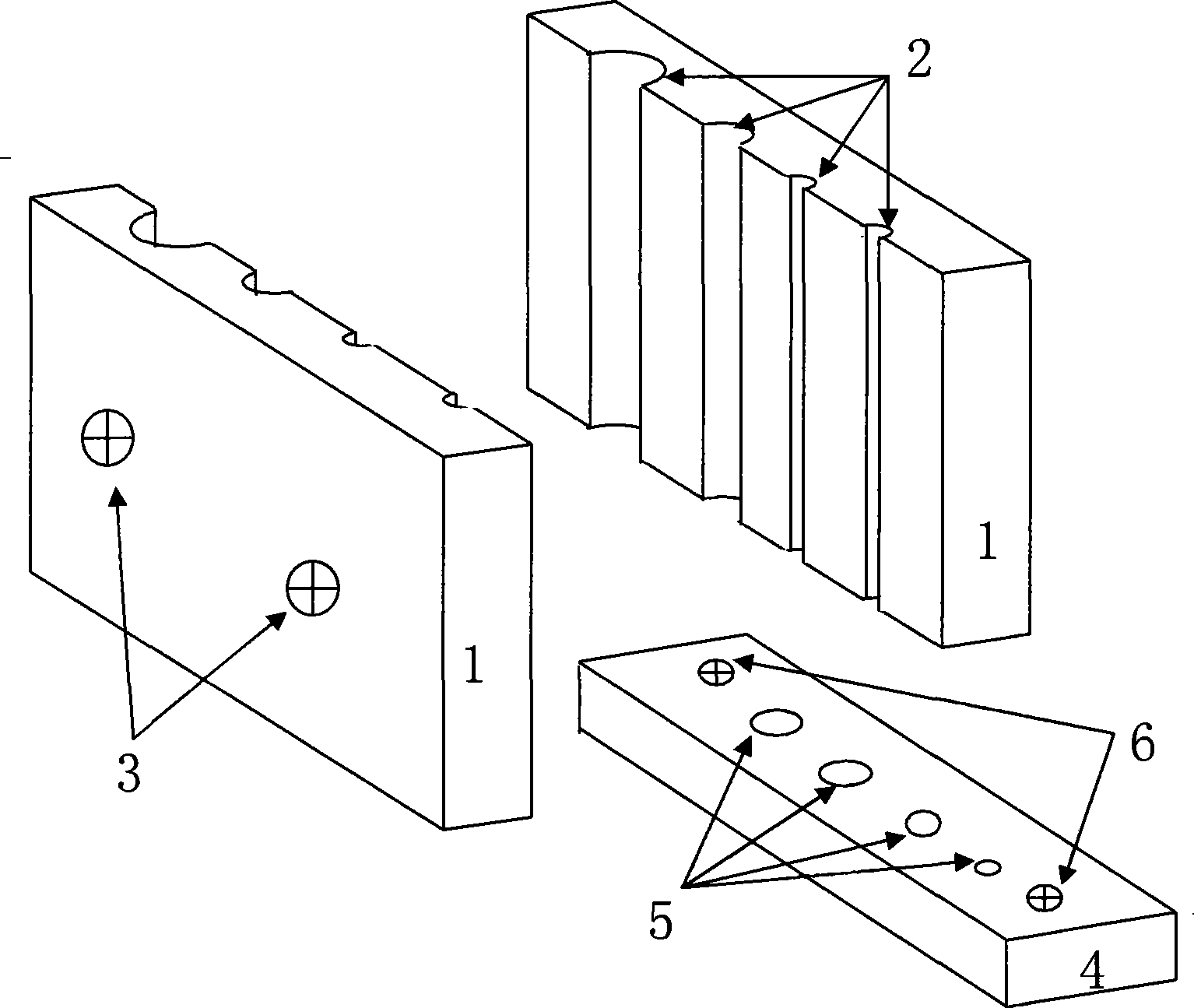

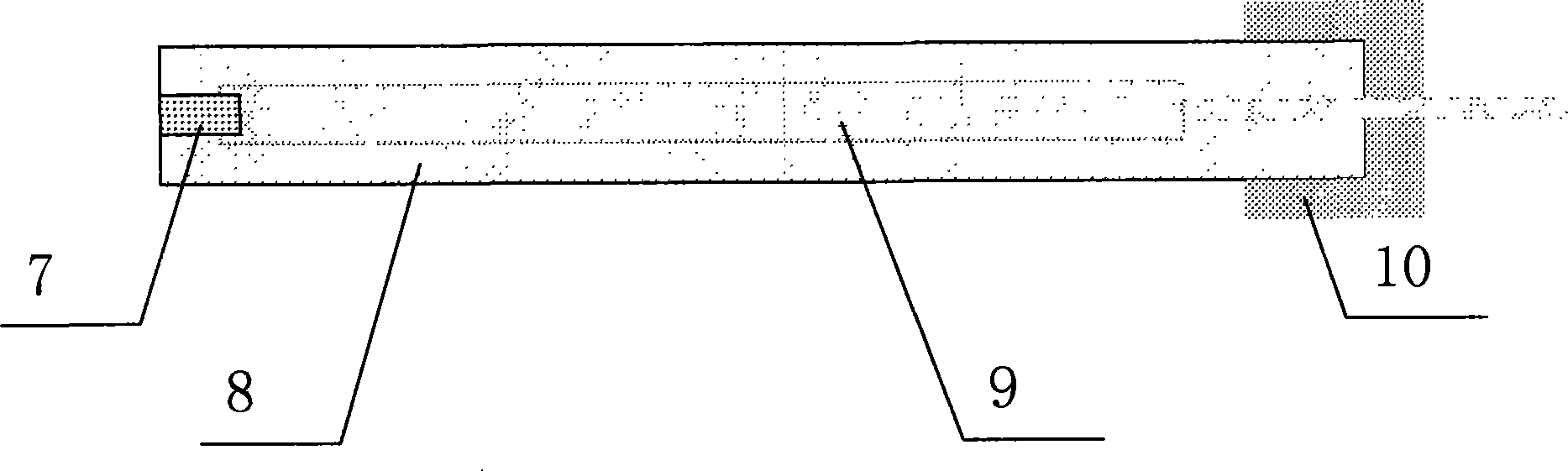

[0012] according to figure 1 As shown, firstly, the silicone oil release agent is applied to the electrode round hole 2, and the mold body 1 is tightly connected by the screw 3, and the mold body 1 and the bottom frame 4 are tightly connected by the screw 6, and the conductive material 7 embedded in the electrode base material 7 is tightly connected. The copper metal rod 9 is placed in the polished electrode hole 2 on the mold, and the bottom end of the electrode base material is placed in the positioning hole 5 on the chassis 4, so that the metal rod 9 is always in the casting process. Concentric with the outer edge of the electrode base material 7, cast, and complete the inner layer packaging; then place the electrode inner layer in the polished electrode hole 2 on the mold, and place the bottom end of the electrode inner layer base material on the chassis 4 In the positioning hole 5, the electrode inner layer material is always concentric with the outer edge of the electrod...

Embodiment 2

[0019] The mold was fixed as in Example 1.

[0020] Preparation of inner layer:

[0021] When encapsulating, use diaminophenyl ether ketone as a crosslinking agent to cure epoxy resin as an electrode packaging material to prepare a working electrode; the molar ratio of crosslinking agent diaminophenyl ether ketone to epoxy resin is 1:10, and the molecular weight of epoxy resin is 300-1500; first place a certain amount of epoxy resin and the mold in a constant temperature environment of 90°C, add the cross-linking agent to the epoxy resin, and stir well. After mixing evenly, cast it into the preset constant temperature mold electrode In the round hole, heat up to 40°C for 1.5 hours to make the reaction moderate and uniform, and release the air bubbles that may be trapped during the reaction process. Since the mixture is mixed under heating, the mixture has low viscosity and is not easy to produce air bubbles. Constant temperature Curing at 90°C for 10 hours to complete the cur...

Embodiment 3

[0026] The mold was fixed as in Example 1.

[0027] Preparation of inner layer:

[0028] When encapsulating, use diaminophenyl ether ketone as a crosslinking agent to cure epoxy resin as an electrode packaging material to prepare a working electrode; the molar ratio of crosslinking agent diaminophenyl ether ketone to epoxy resin is 1:15, and the molecular weight of epoxy resin is 300-1500; first place a certain amount of epoxy resin and the mold in a constant temperature environment of 100°C, add the cross-linking agent to the epoxy resin, and stir thoroughly. After mixing evenly, cast it into the preset constant temperature mold electrode In the round hole, heat up to 60°C for 1 hour to make the reaction moderate and uniform, and release the air bubbles that may be trapped during the reaction process. Since the mixture is mixed under heating, the viscosity of the mixture is low and it is not easy to generate air bubbles. Constant temperature 100 Cure for 15 hours at ℃ to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com