Manganese oxide/nickel micro-sphere with porous structure, and preparation and application thereof

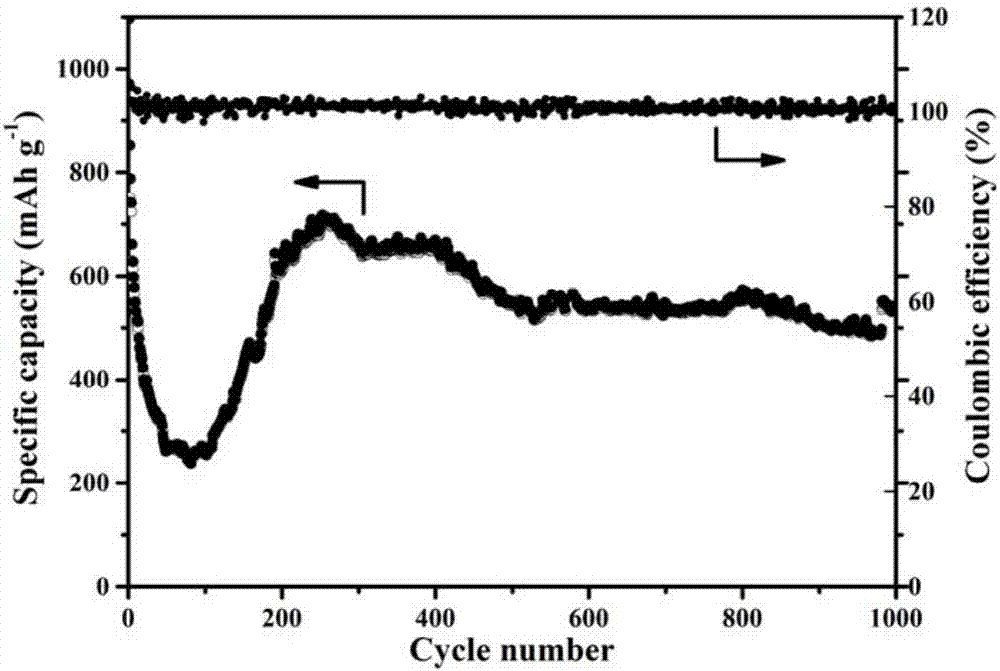

A porous structure, manganese oxide technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problems of poor conductivity, poor actual capacity and cycle stability of materials, and easily damaged structures, and achieves less impurities, The effect of controllable product morphology, enhanced specific capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

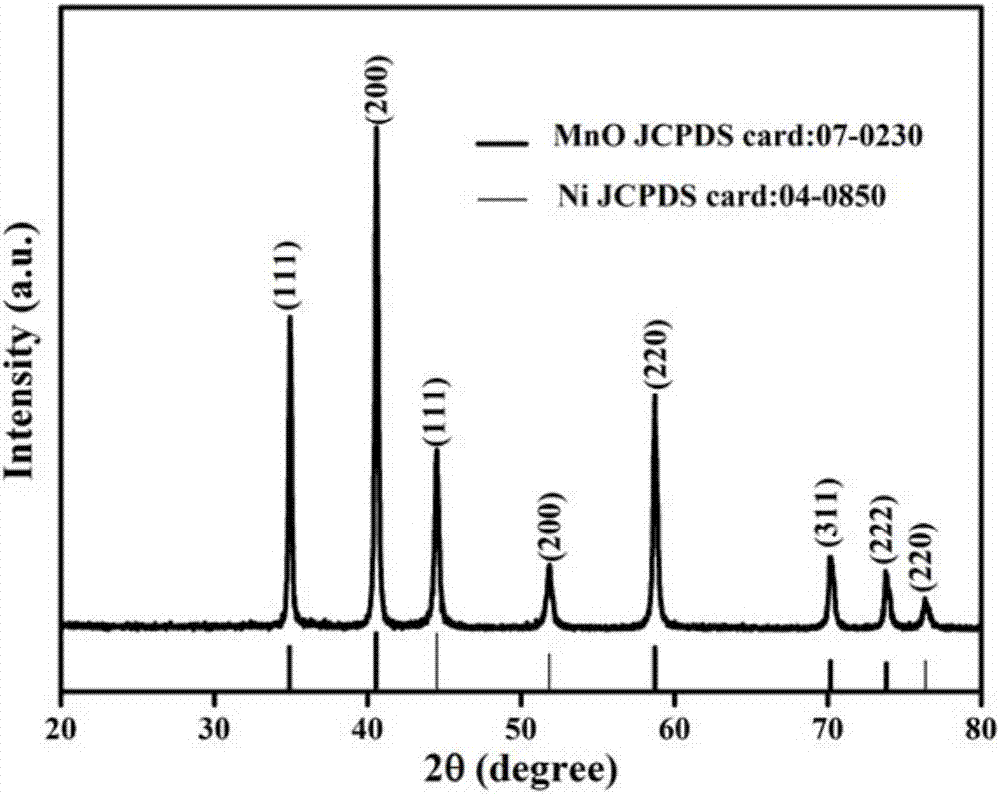

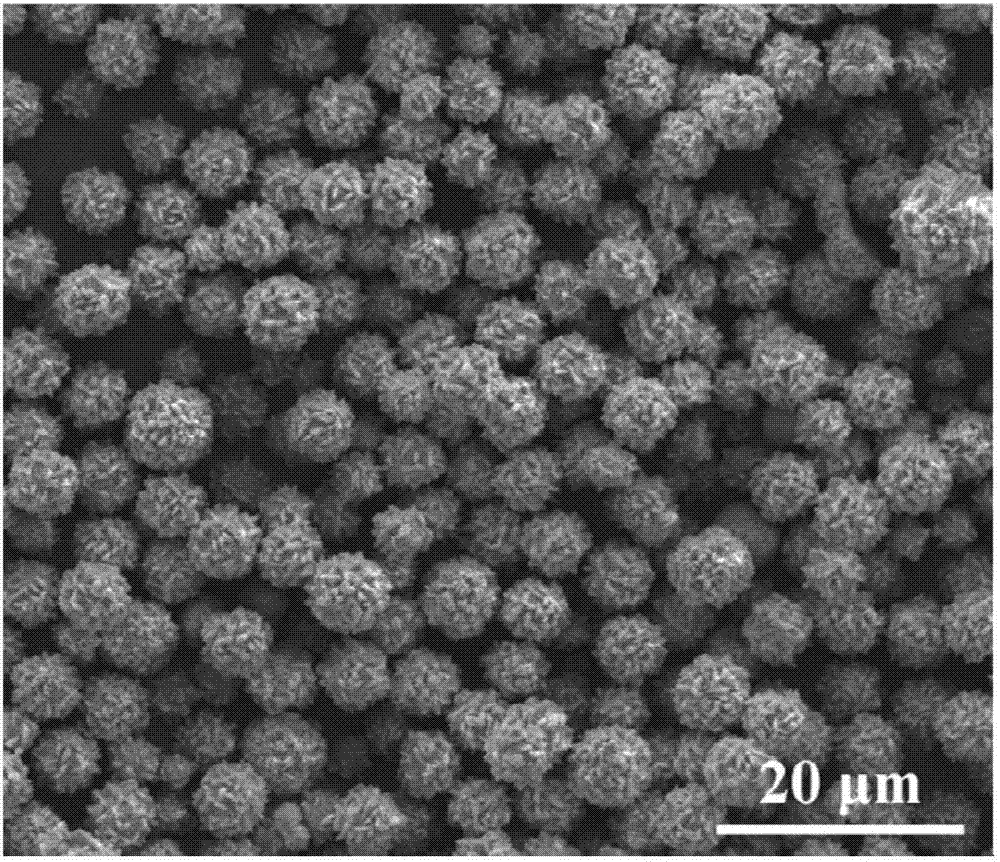

[0031] Add manganese acetate and nickel acetate into 10 mL of deionized water at a molar ratio of 2:1, the total ion concentration of manganese and nickel is 0.15 mol / L, and stir at room temperature until clear. Add urea to water at a molar ratio of 1.5:1 to metal ions, and stir until clear. Add 20mL of ethylene glycol into the prepared mixed solution, mix well, transfer to a 50mL hydrothermal reaction kettle, and heat at 180°C for 30h. The resulting product was centrifuged and washed several times with water and ethanol, then dried at 70°C. The obtained precursor was placed in a tube furnace to raise the temperature to 500°C at a rate of 5°C / min, and the protective atmosphere was argon. After holding for 2 hours, manganese oxide / nickel microspheres with a porous structure were obtained. Adopt Japanese science D / max-2500 type X-ray diffraction analyzer to analyze gained sample, obtained result is as follows figure 1 shown. Observing the sample with a Nova NanoSEM 230 scanni...

Embodiment 2

[0033] Add manganese acetate and nickel acetate into 10 mL of deionized water at a molar ratio of 4:1, the total ion concentration of manganese and nickel is 0.2 mol / L, and stir at room temperature until clear. Add urea to water in a molar ratio of 5:1 to metal ions, and stir until clear. Add 20 mL of isopropanol into the prepared mixed solution, mix well, transfer to a 50 mL hydrothermal reaction kettle, and heat at 200° C. for 20 h. The resulting product was centrifuged and washed several times with water and ethanol, then dried at 70°C. The obtained precursor was placed in a tube furnace to raise the temperature to 400°C at a rate of 8°C / min, and the protective atmosphere was argon. After holding for 7 hours, manganese oxide / nickel microspheres with a porous structure were obtained. Observing the sample with a Nova NanoSEM 230 scanning electron microscope from FEI Company in the United States, it was found that the spindle-shaped particles were uniformly distributed and th...

Embodiment 3

[0035] Add manganese acetate and nickel acetate into 10 mL of deionized water at a molar ratio of 8:1, the total ion concentration of manganese and nickel is 0.5 mol / L, and stir at room temperature until clear. Add urea to water in a molar ratio of 6:1 to metal ions, and stir until clear. Add 20mL of methanol into the prepared mixed solution, mix well, transfer to a 50mL hydrothermal reaction kettle, and heat at 100°C for 35h. The resulting product was centrifuged and washed several times with water and ethanol, then dried at 70°C. The obtained precursor was placed in a tube furnace at a heating rate of 3°C / min to 600°C, the protective atmosphere was argon, and after holding for 2 hours, porous manganese oxide / nickel microspheres were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com