Patents

Literature

35results about How to "Slow ascent rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

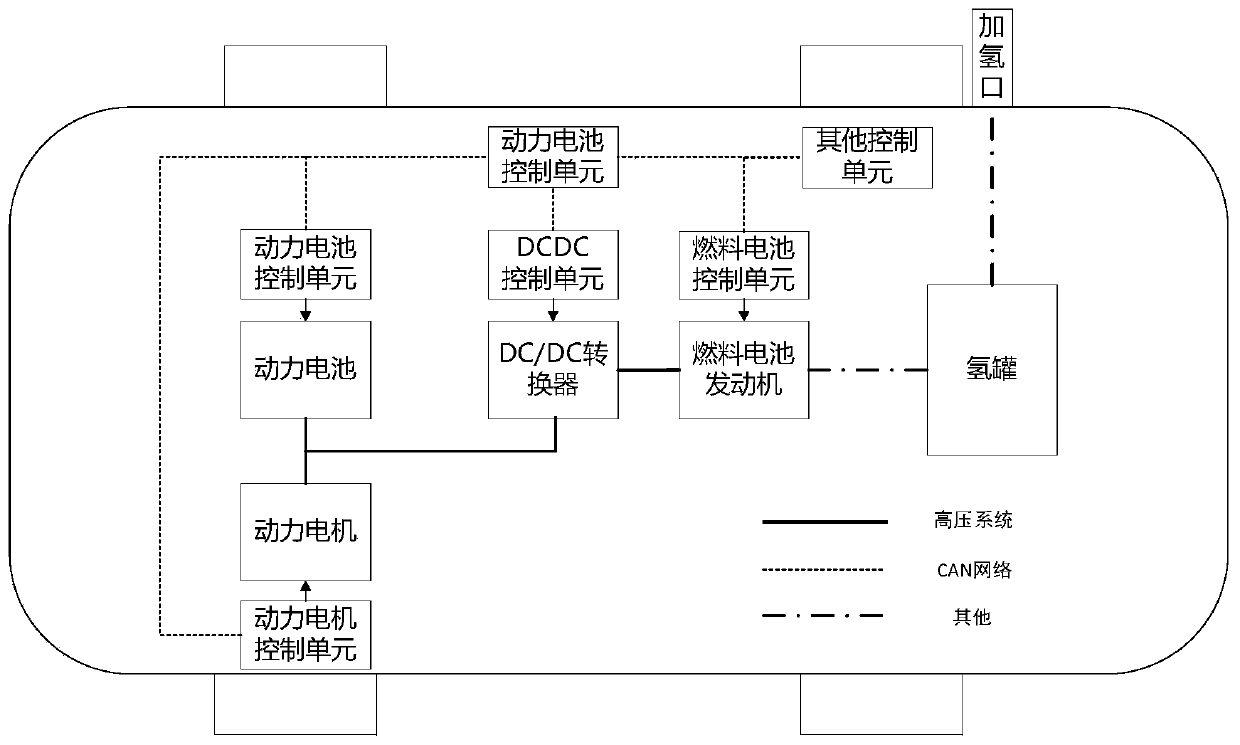

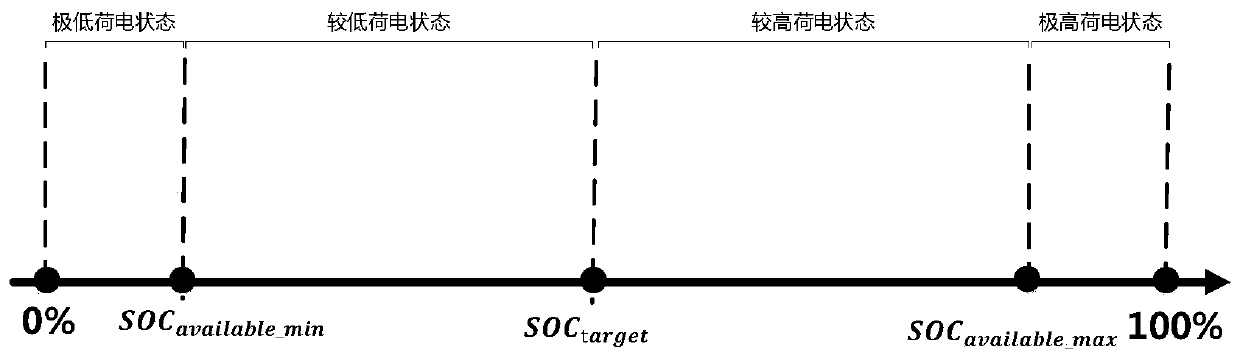

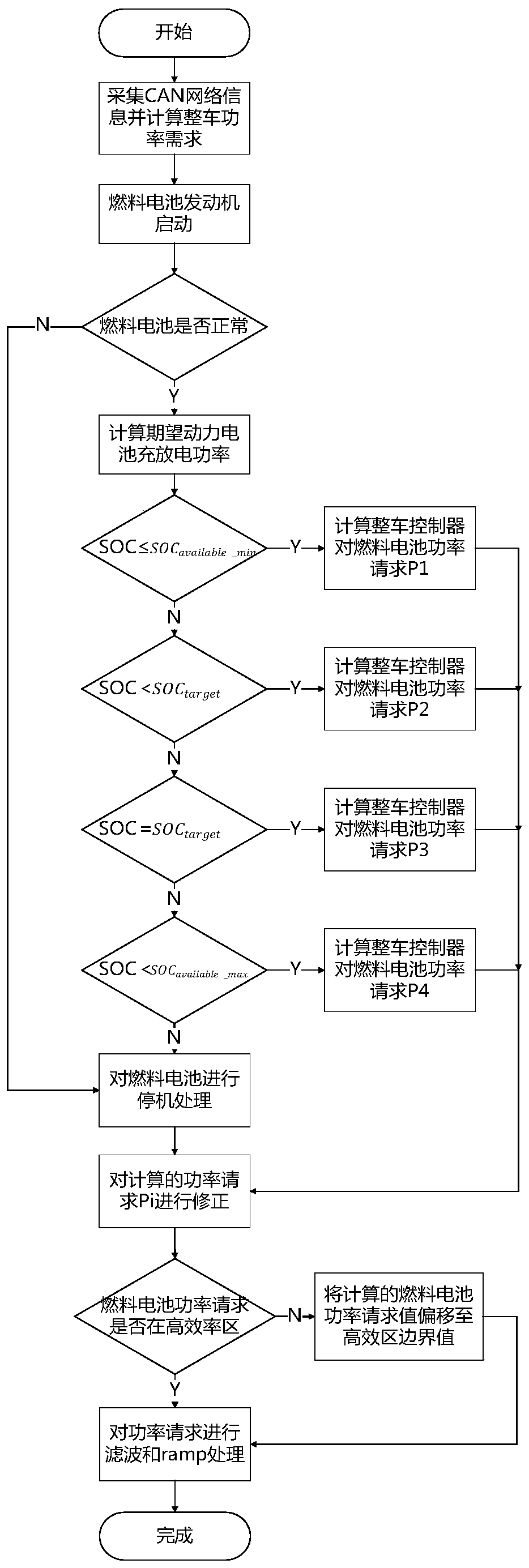

Power-following type fuel cell whole vehicle energy management and control method

ActiveCN110182071AFrequent fluctuationsIncrease powerPropulsion by batteries/cellsBattery/fuel cell control arrangementReal-time chargingElectricity

The invention discloses a power-following type fuel cell whole vehicle energy management and control method, and belongs to the technical field of fuel cell hybrid electrical automobiles. The power-following type fuel cell whole vehicle energy management and control method aims to solve the problem that in the case of an existing fuel cell whole vehicle energy management and control method, a power cell and a fuel cell can not be controlled to work within an optimal efficiency interval according to a power cell SOC and the power requirement of a driver, so that the service life and economicalefficiency of each cell are influenced. According to the power-following type fuel cell whole vehicle energy management and control method, the characteristics of the fuel cell and the power cell arefully utilized, the actual output power of the fuel cell is correspondingly controlled according to the whole vehicle power demand and the power cell real-time charge state so as to guarantee that both the fuel cell and power cell to work in the optimal interval, filtering and slope limiting are performed on the power of the fuel cell in different charge state intervals of the power cell, so thatin the whole working condition, multi-charge or multi-discharge of the power cell is guaranteed, the large-amplitude-value frequent fluctuation of the output power of the fuel cell is avoided, and thedurability of the fuel cell is also improved.

Owner:CHINA FIRST AUTOMOBILE

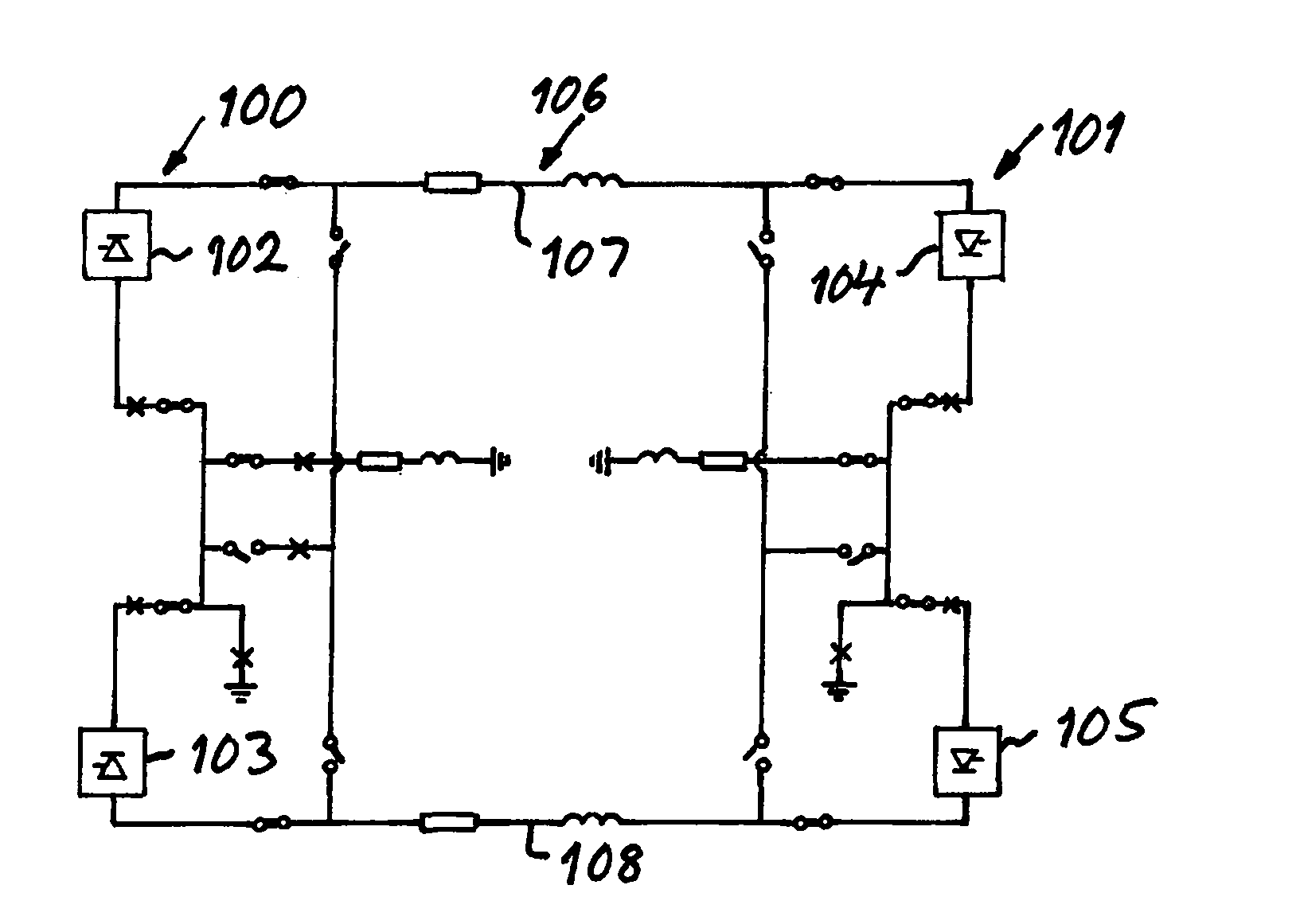

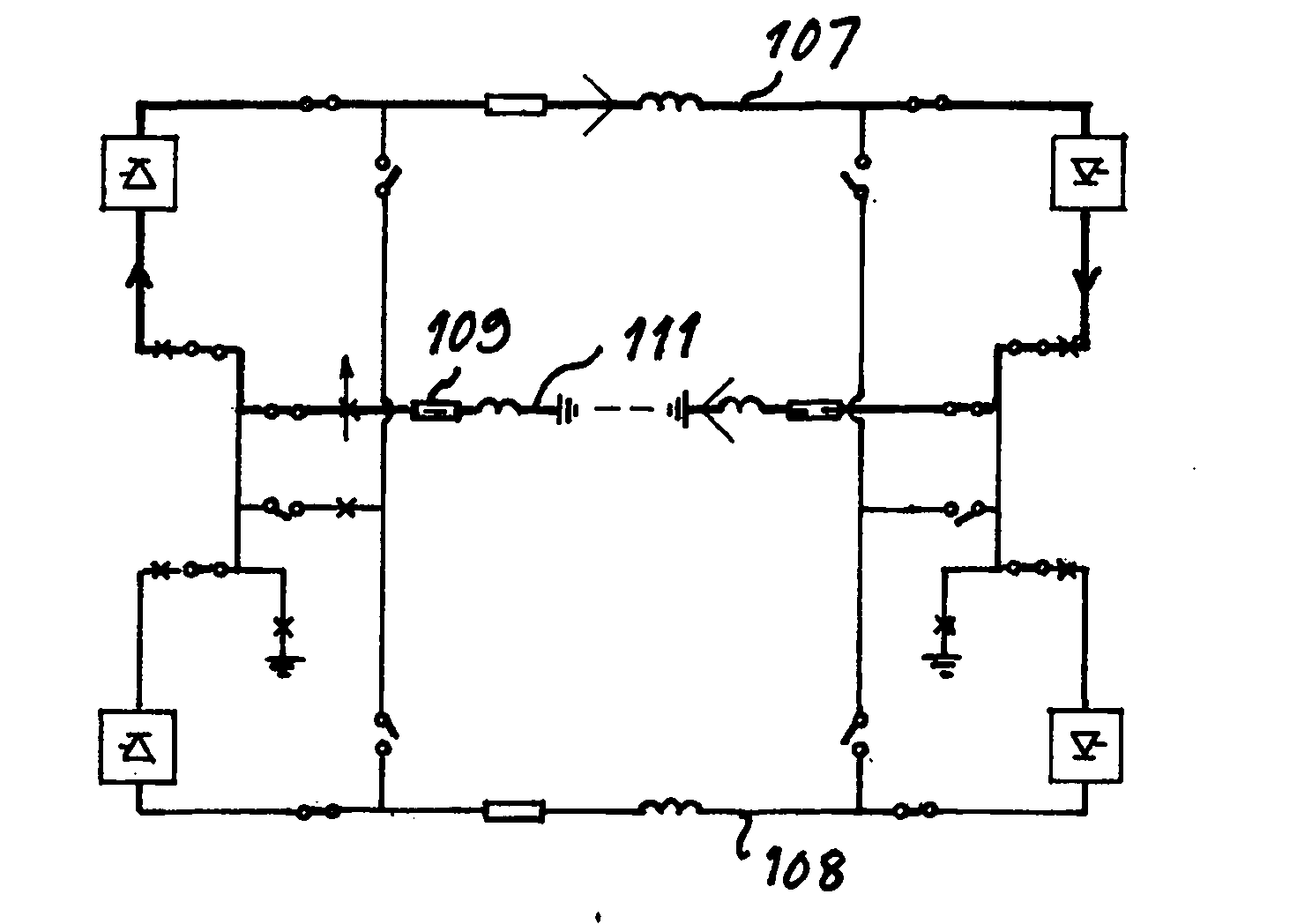

A DC current breaker

ActiveCN102132370ASlow ascent rateIncrease rate of ascentHigh-tension/heavy-dress switchesAir-break switchesCapacitanceDc current

A device for breaking DC currents exceeding 2500 A has a resonance circuit (2) connected in parallel with an interrupter (1) and a surge arrester (7) connected in parallel with the resonance circuit. The resonance circuit has a series connection of a capacitor (3) and an inductance (4). The specific value relationship of the capacitance in microfarad to the inductance in microhenry of the resonance circuit is not less than 1.

Owner:HITACHI ENERGY SWITZERLAND AG

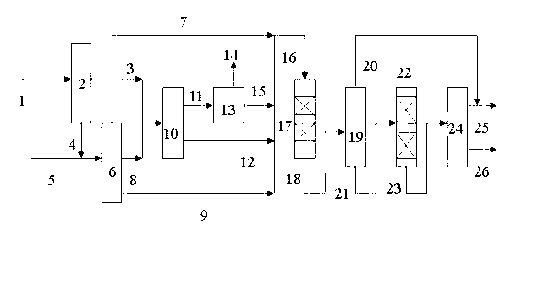

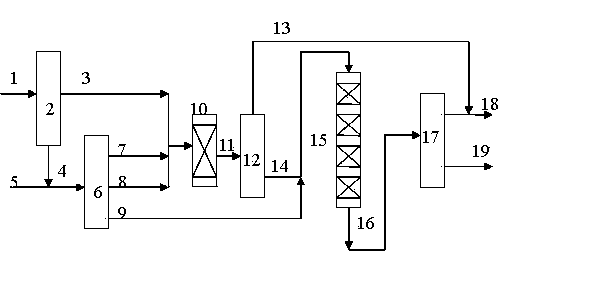

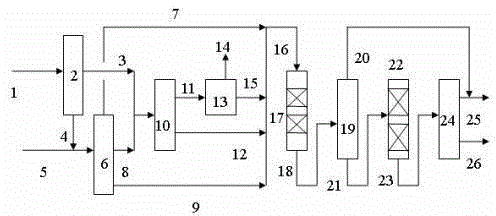

Treatment method of ethylene tar

ActiveCN103102976AImprove economic efficiencyAvoid concentrated heatDistillation purification/separationTreatment with hydrotreatment processesCrystallization PurificationGasoline

The invention discloses a treatment method of ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil and coker gas oil, mixing the coker diesel oil with the ethylene tar light fraction, performing rectification / crystallization purification to obtain naphthalene, mixing the naphthalene removed oil, naphthalene after-cut oil, with the coker gasoline and the coker gas oil, taking the obtained mixture as a hydrotreating raw material, leaving the material to undergo a hydrofining reaction, separating gasoline fraction I, subjecting the obtained fraction heavier than gasoline to hydrocracking so as to obtain gasoline fraction II and a diesel oil product, and mixing the gasoline fraction II with the gasoline fraction I so as to obtain a final gasoline product. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes, thus increasing the added value of ethylene tar. While generating the chemical raw material naphthalene, the method also improves the product quality of light fuel oil, and also enables the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

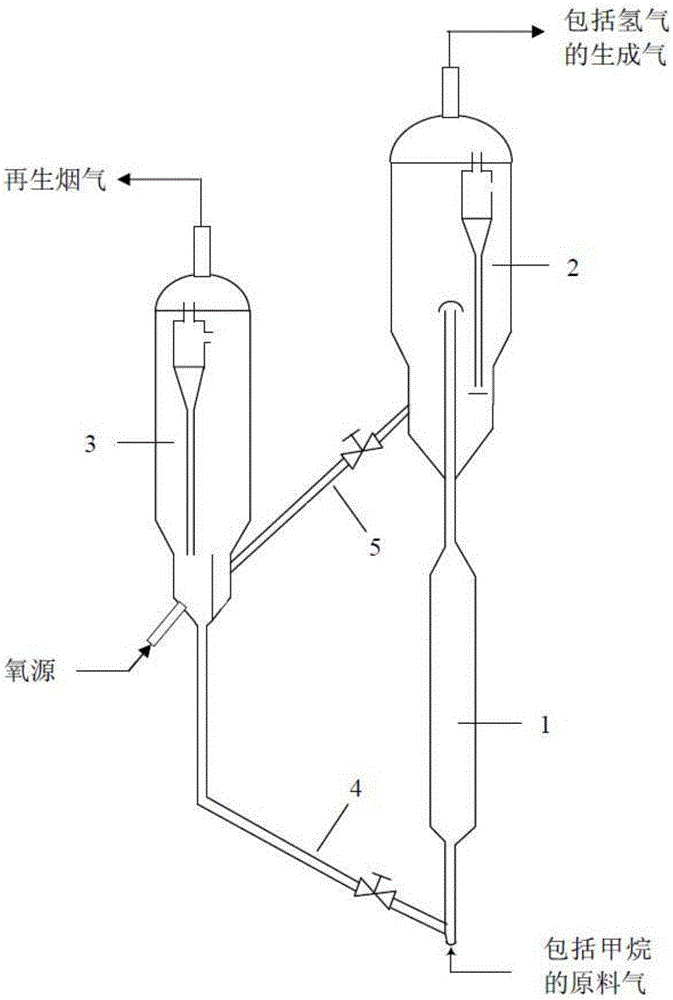

Nickel-based catalyst, preparation method thereof and method for catalyzing methane cracking to produce hydrogen

ActiveCN104998654AAchieving self-heating operationSlow ascent rateHydrogenChemical recyclingCarbon depositCracking reaction

The invention provides a nickel-based catalyst, a preparation method thereof and a method for catalyzing methane cracking to produce hydrogen. The catalyst includes a nickel-based composite metal oxide with a general formula shown as xX.yA.zB.(100-x-y-z)M, wherein X is Ni and / or its oxide, A is an auxiliary metal component, B is an assistant metal component, and M is a carrier. The method for catalyzing methane cracking to produce hydrogen includes: contacting methane-containing feed gas with the catalyst in a high density circulating fluidized bed reactor, and carrying out catalytic cracking reaction to obtain hydrogen containing product-gas and a deactivated catalyst, performing separation in a settler, letting the catalyst carry carbon deposit to enter a regenerator for regeneration, thus obtaining regenerated flue gas containing CO or synthetic gas, and letting the regenerated catalyst enter the reactor again. The heat generated by regeneration supplies the energy need of the whole system to realize self-heating operation. The method provided by the invention can realize large-scale continuous production of hydrogen at low price, and can effectively reduce energy consumption and save the production cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

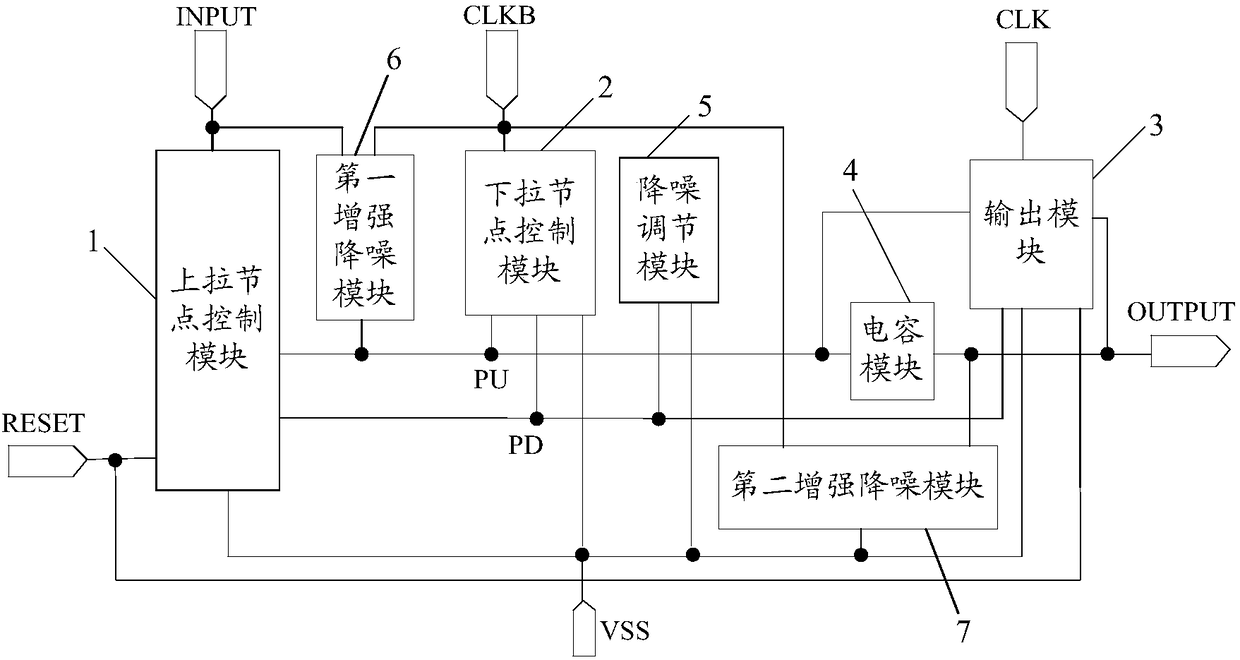

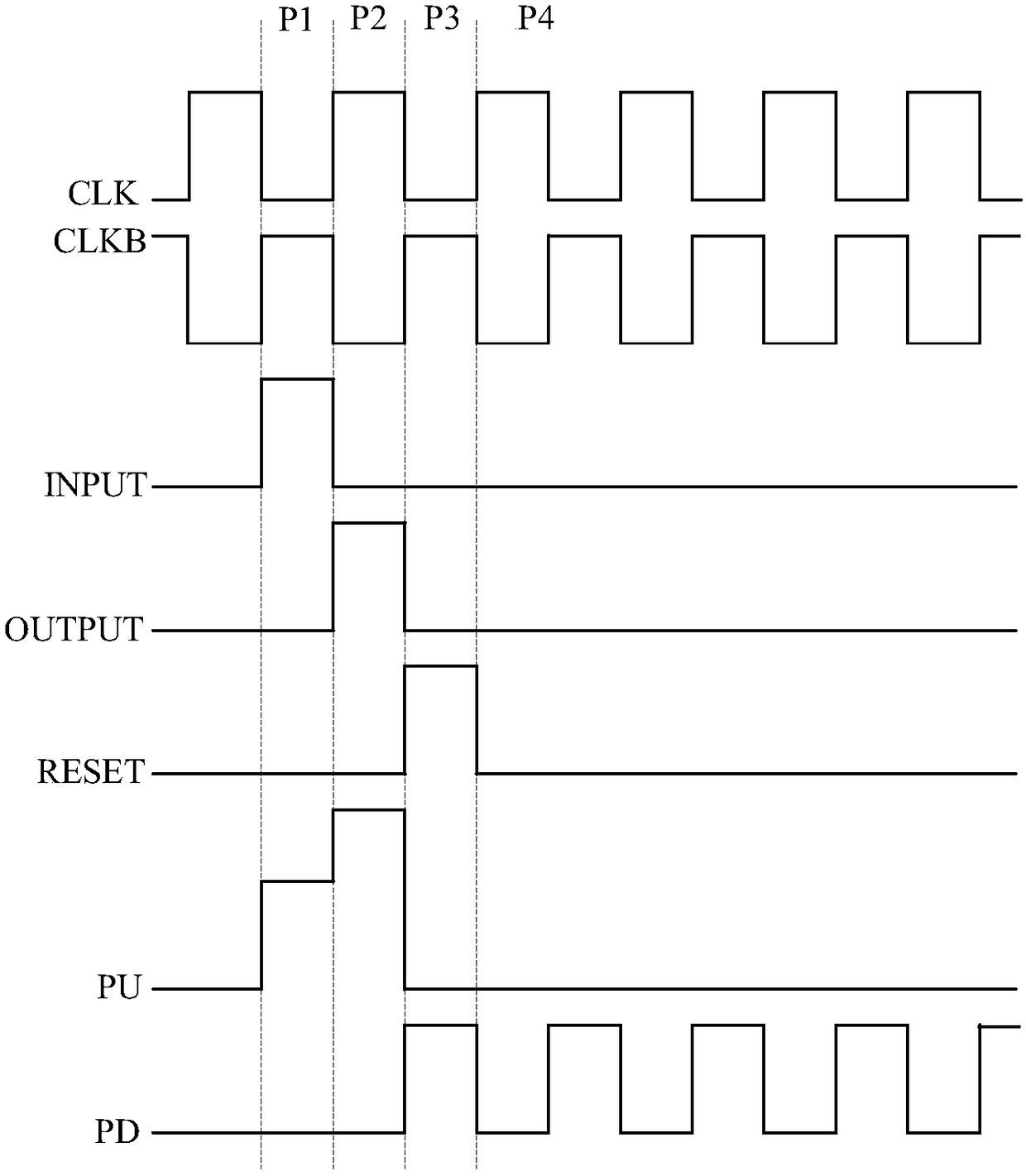

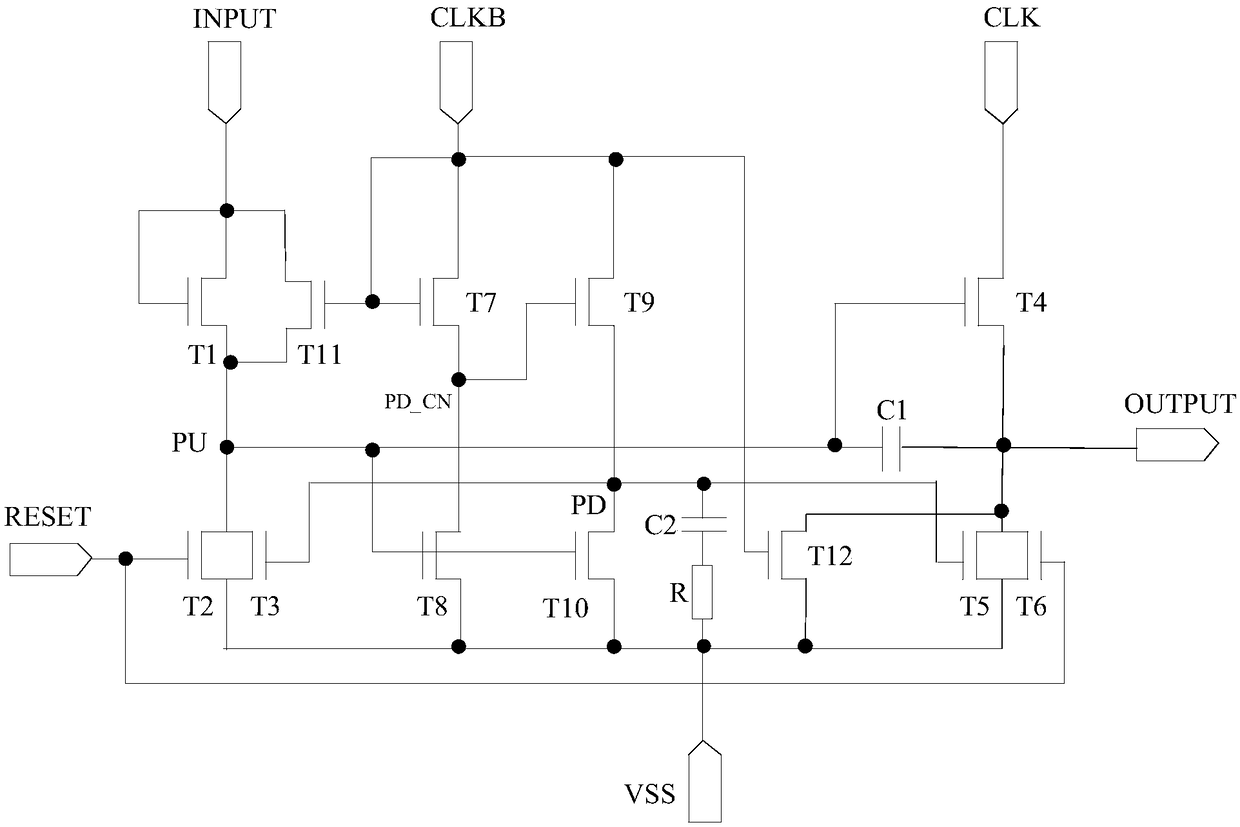

Shift register unit and driving method thereof and gate driving circuit

ActiveCN108389542AControl rate of ascentControlled rate of ascentStatic indicating devicesDigital storageCapacitanceShift register

The invention discloses a shift register unit and a driving method thereof and a gate driving circuit, which relate to the technical field of display and aim at solving the problems that the existingshift register unit is likely to meet electric leakage increase and lose noise reduction capability in a retaining time period. The shift register unit comprises a pull-up node control module, a pull-down node control module, a capacitor module, an output module and a noise reduction adjustment module, wherein the noise reduction adjustment module is connected with a pull-down node and a first level input terminal respectively; and the noise reduction adjustment module is used for controlling to reduce the rising rate of potential of the pull-down node in a noise reduction time period in the retaining time period and controlling to reduce the falling rate of potential of the pull-down node in a non-noise reduction time period in the retaining time period. The shift register unit provided in the invention is used for providing gate driving signals.

Owner:BOE TECH GRP CO LTD +1

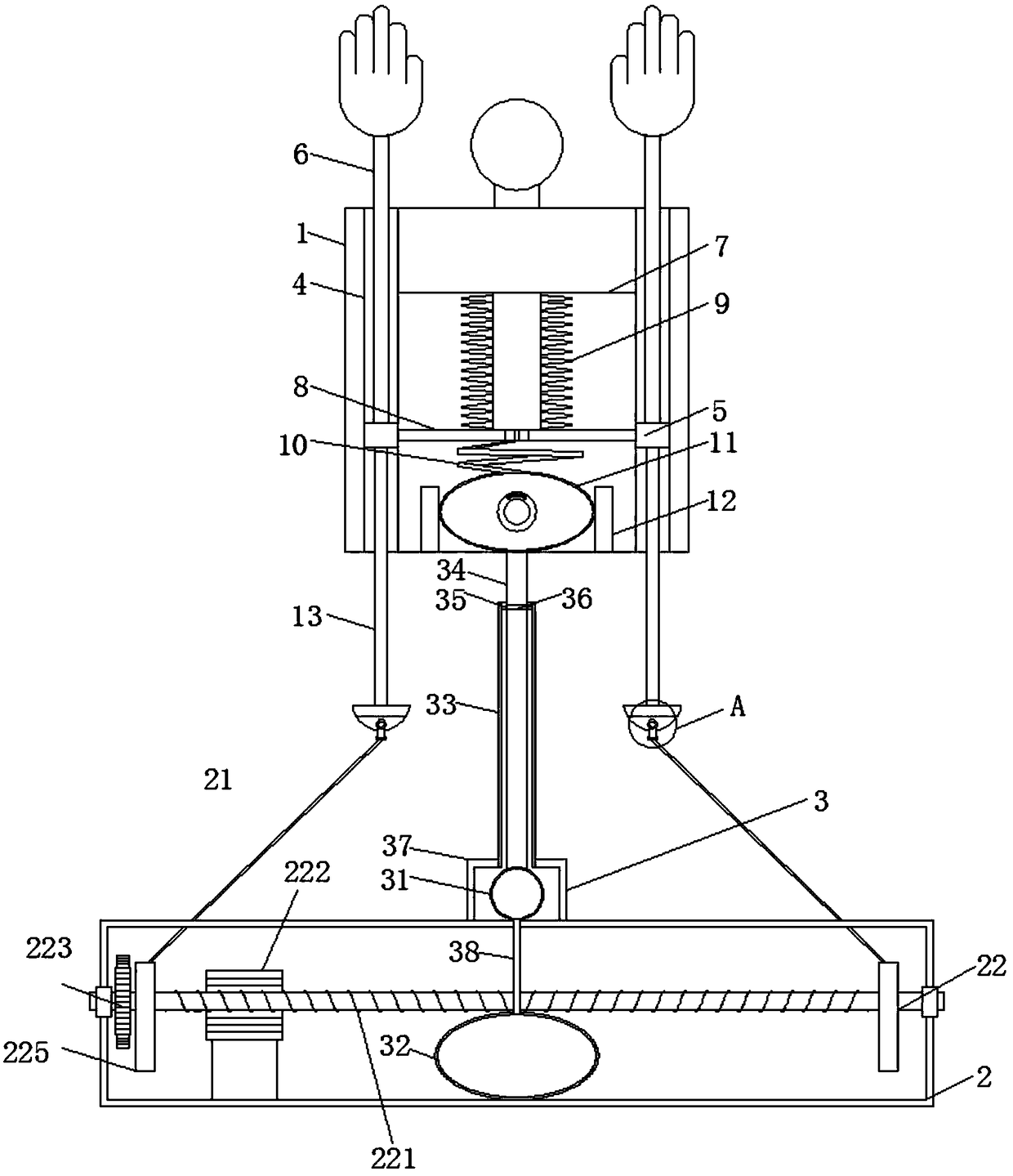

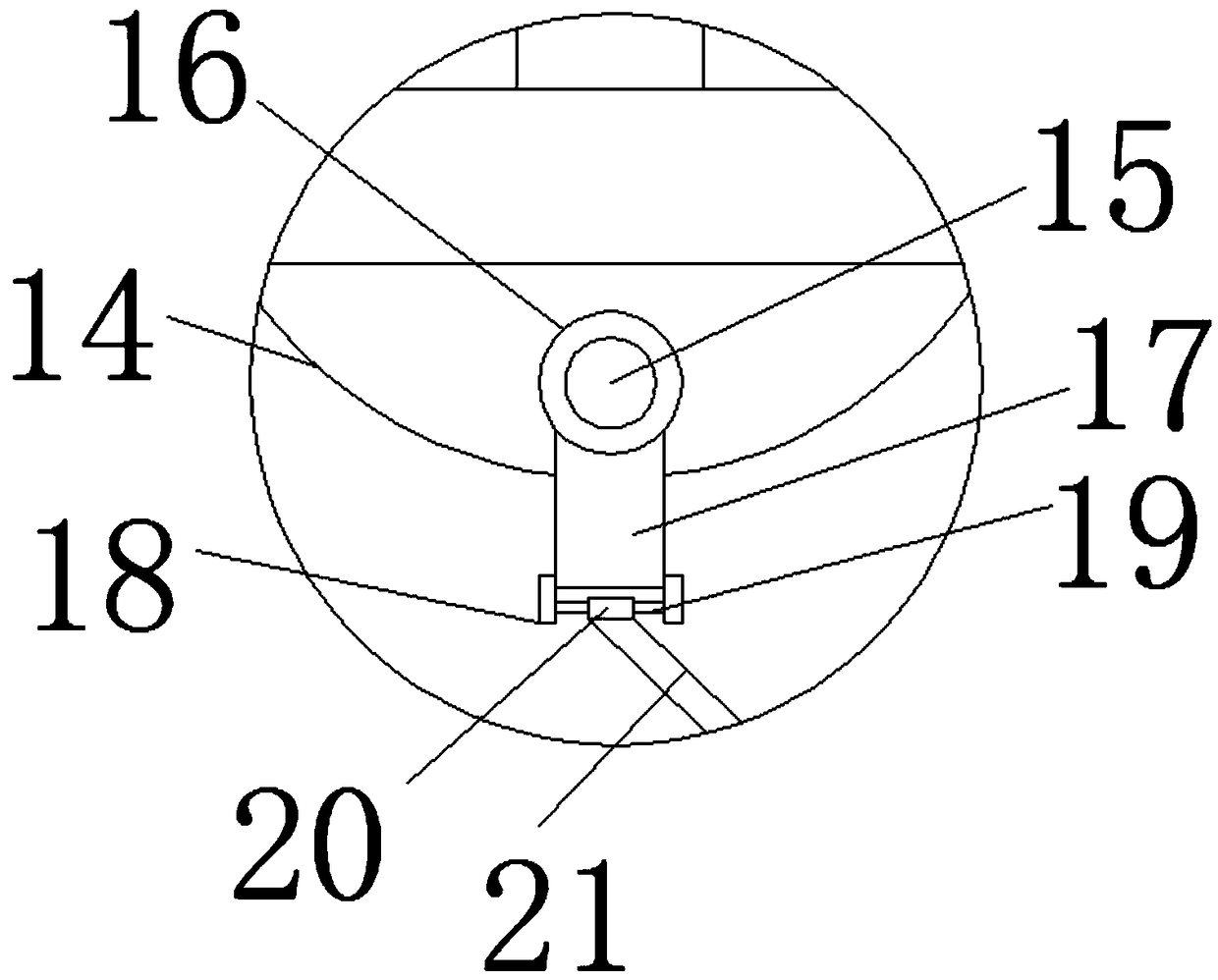

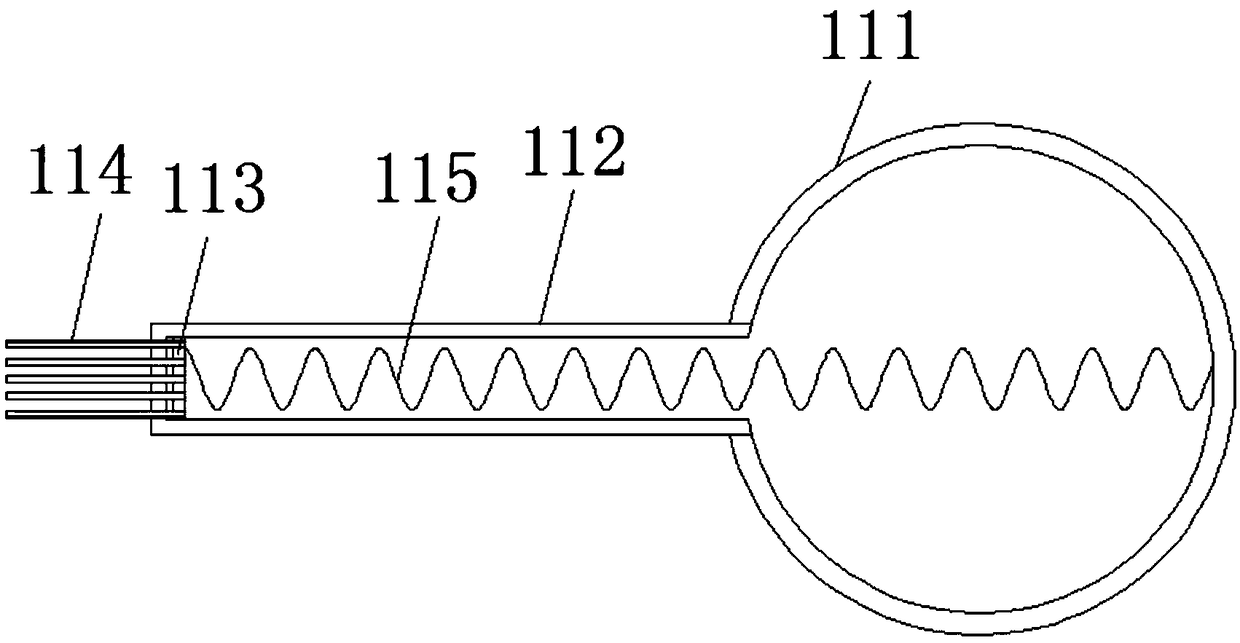

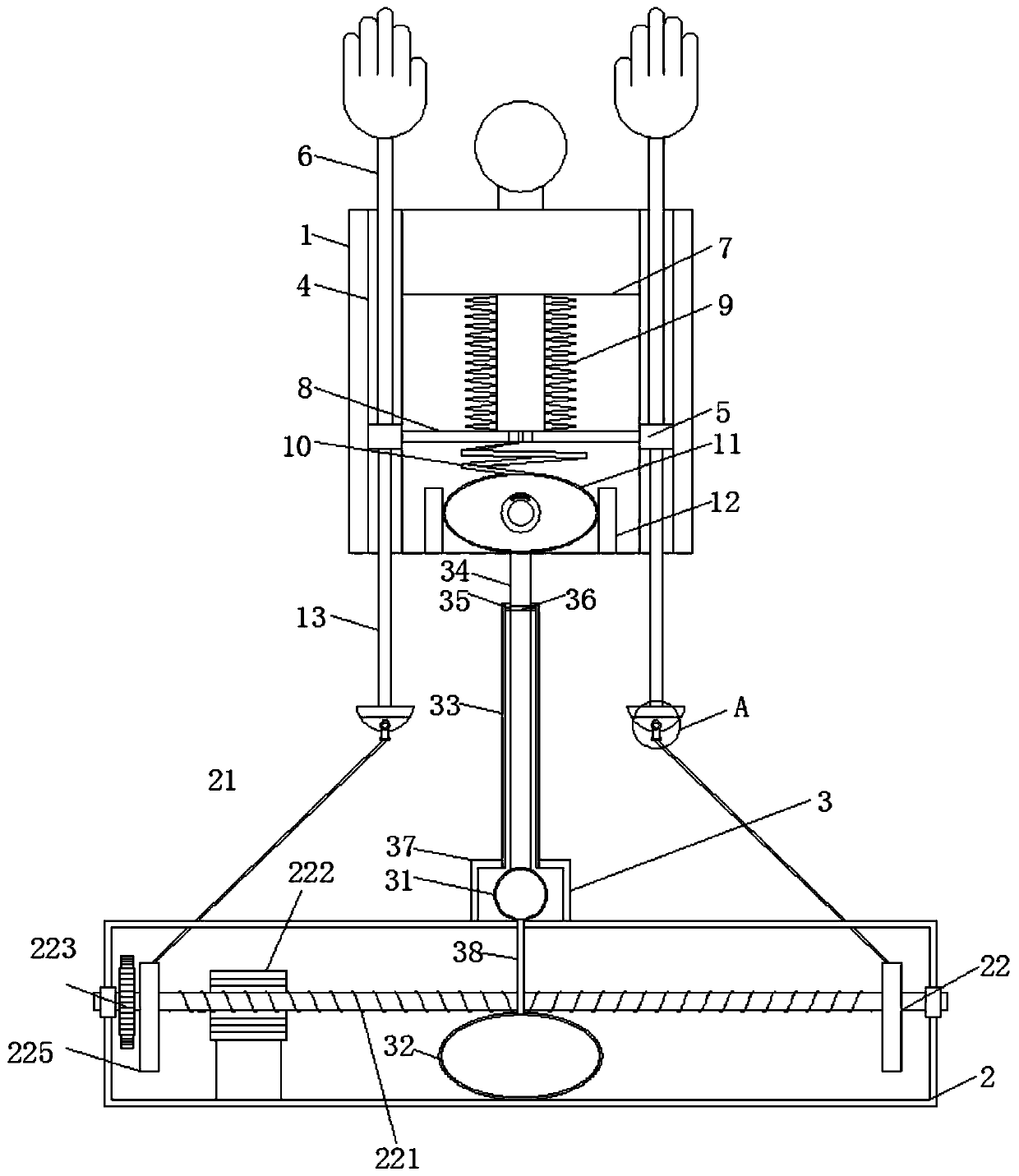

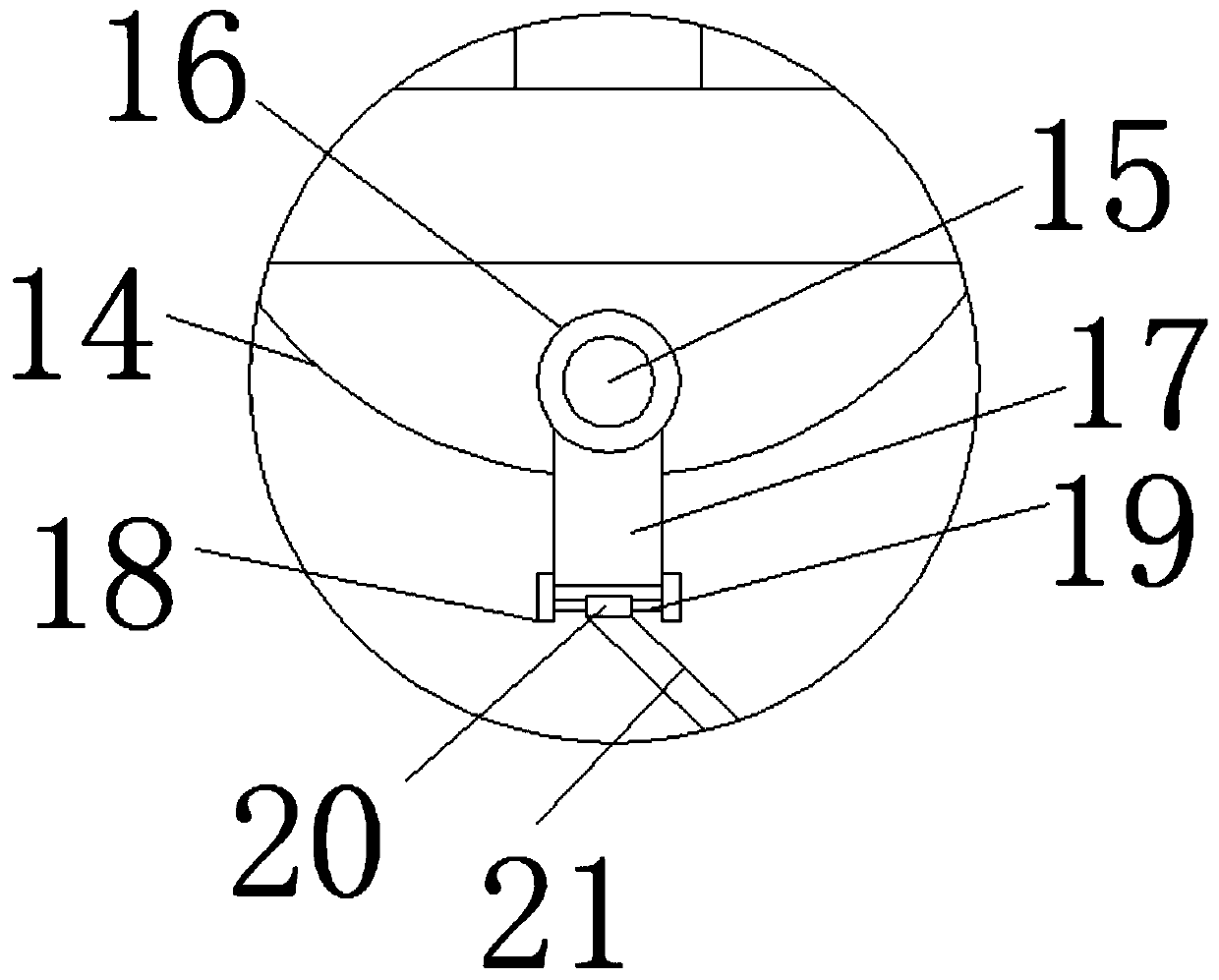

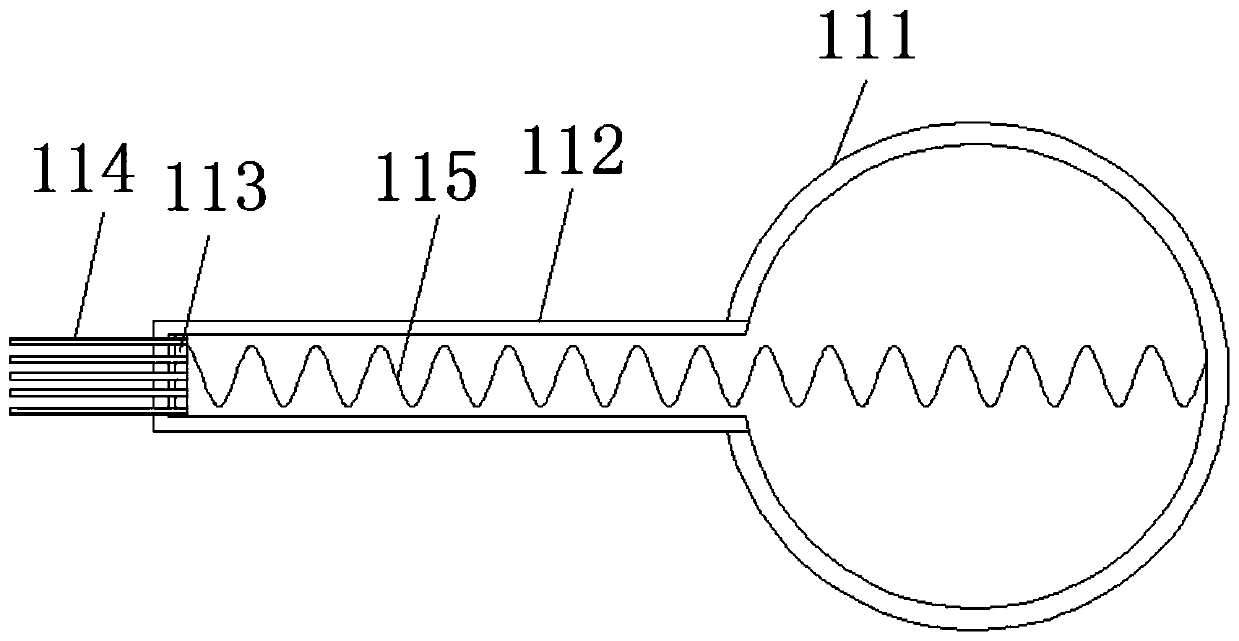

Training auxiliary jamming device for basketball shooting

The invention provides a training auxiliary jamming device for basketball shooting, which relates to the field of sports equipment. The invention relates to a training auxiliary jamming device for basketball shooting, the top of the mounting plate is fixedly connected with the top of the lifting lever through an inclination adjusting mechanism and the middle of the top of the mounting base and a rubber bellows hose is fixedly connected with the top of the lifting lever, the top of the rubber corrugated hose is fixedly connected with the top of the cavity inner wall, a lifting hand interferencemechanism is fixedly bonded to that middle part of the bottom of the inn wall of the cavity, a support rod is fixedly connected to the bottom of the movable sleeve B, a through groove is arranged onthe top of the mounting seat, a shrinking mechanism is installed in the inner cavity of the mounting seat, and two sides of the top of the shrinking mechanism are respectively connected with two support rods. So that the rated air in the airbag C is introduced into the airbag B and the airbag B is inflated, the inflated airbag B drives the fixed rod to be pressurized, the pressurized fixed rod isinclined, and the interference rod interfered by ascending is slightly leaned forward after ascending.

Owner:嘉兴市瑞鑫塑业有限公司

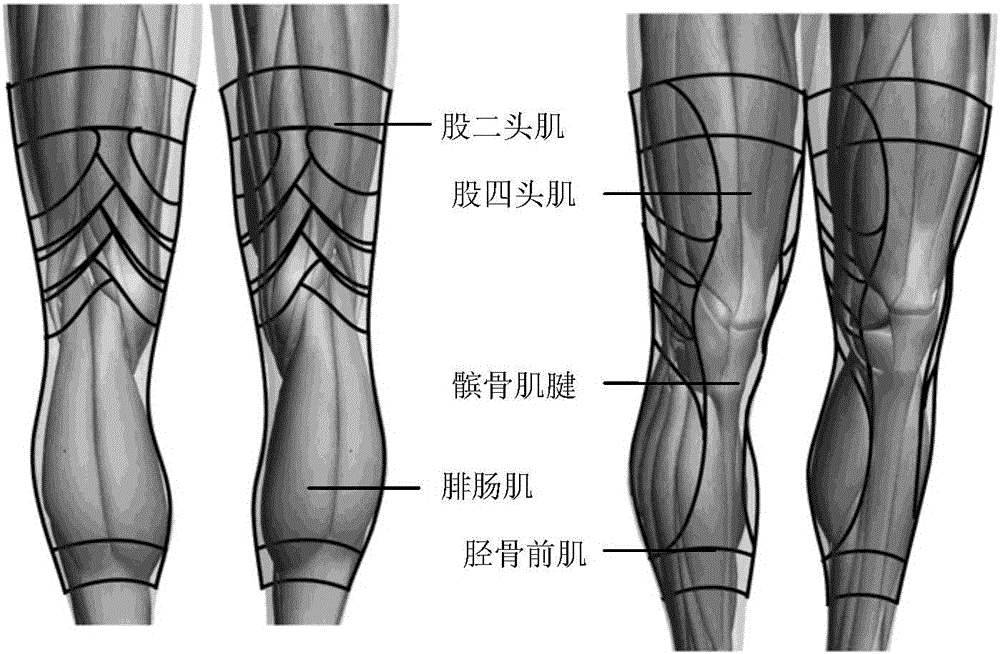

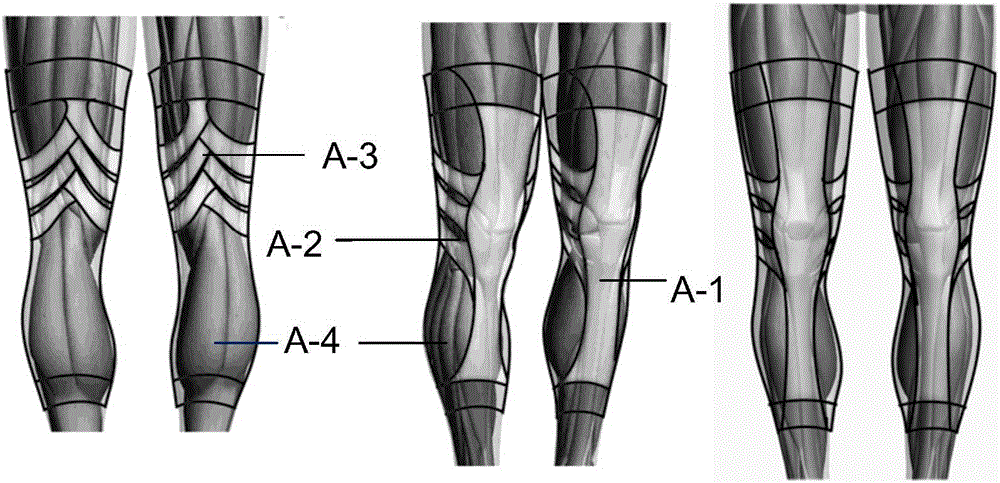

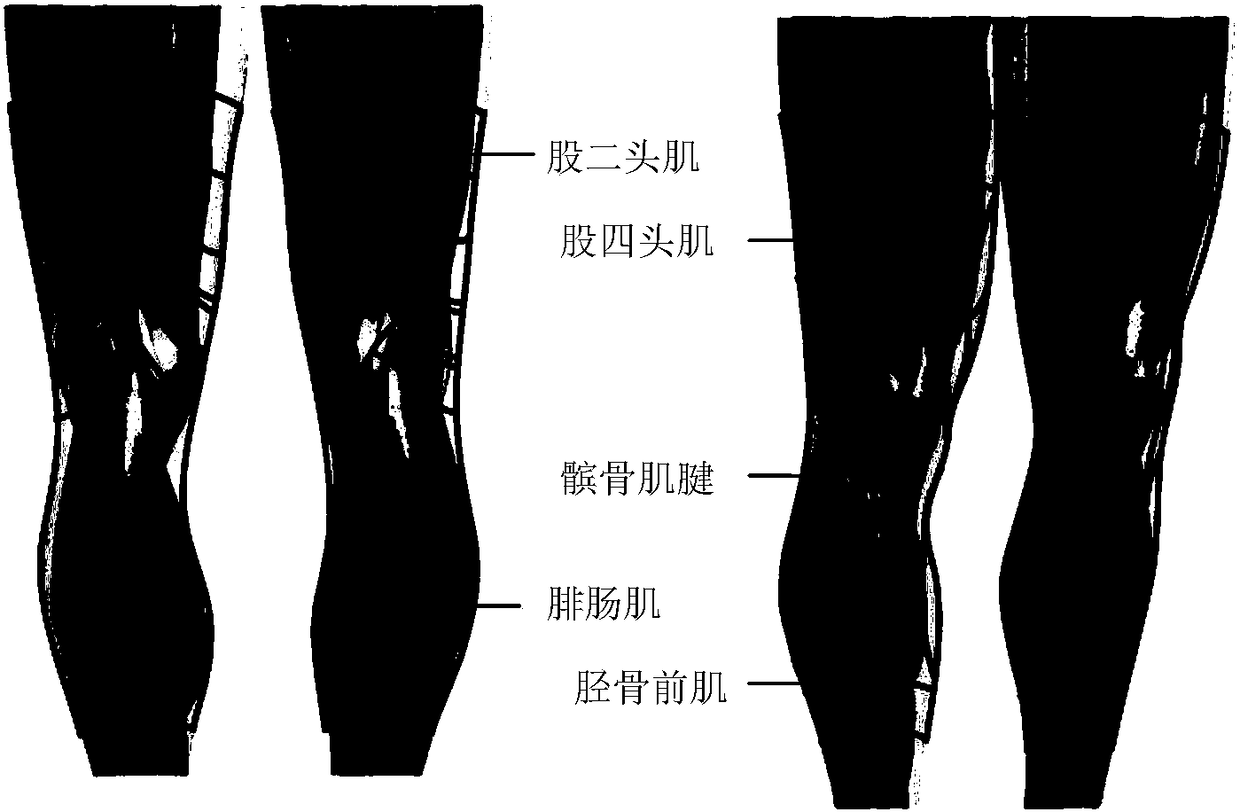

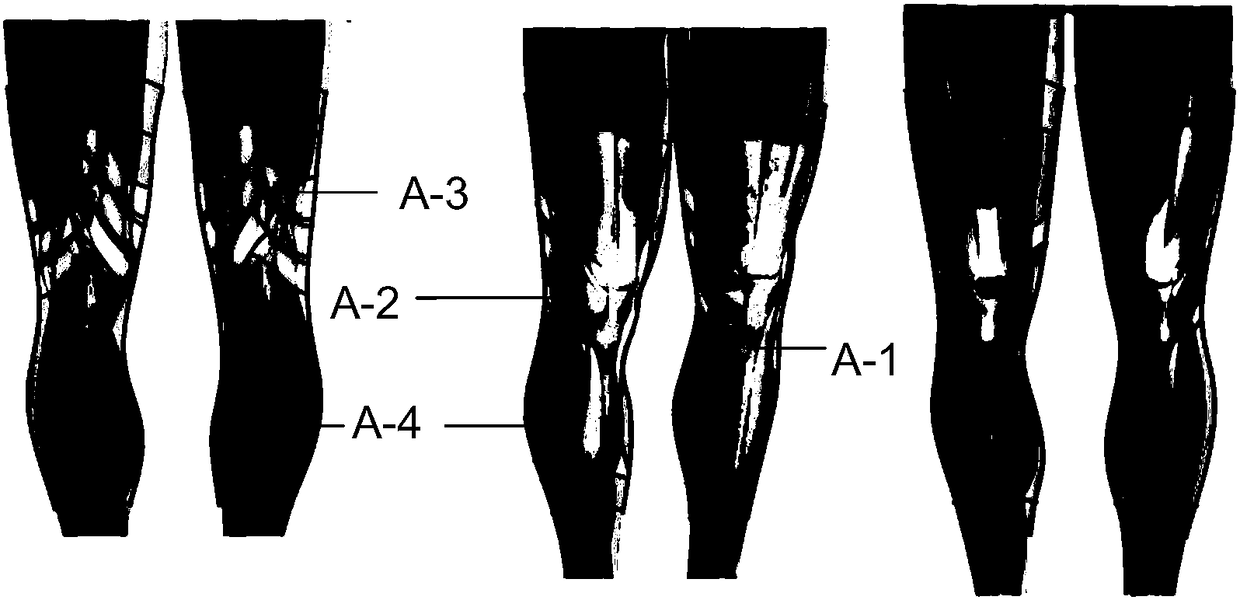

Dynamic biological-function leg protective tool

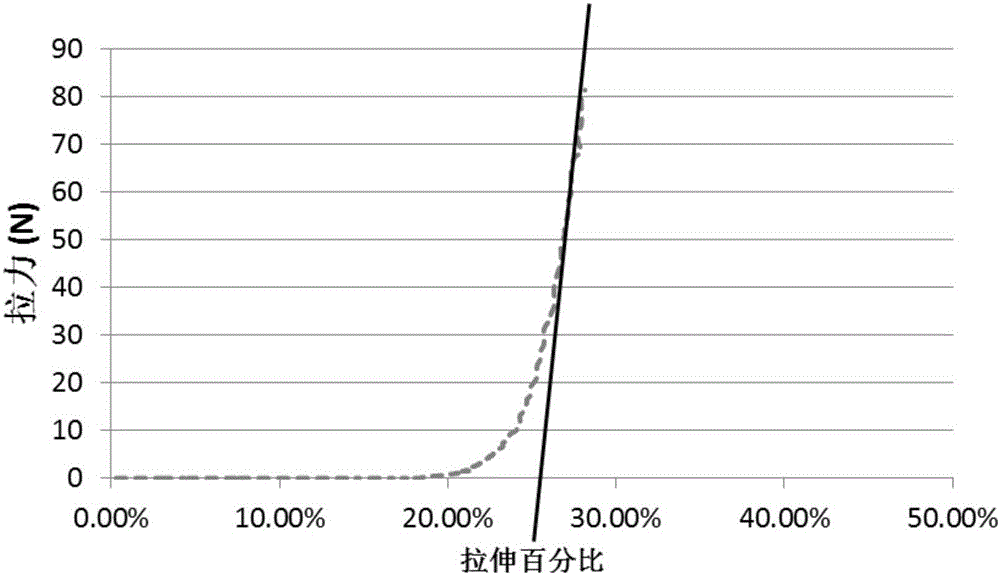

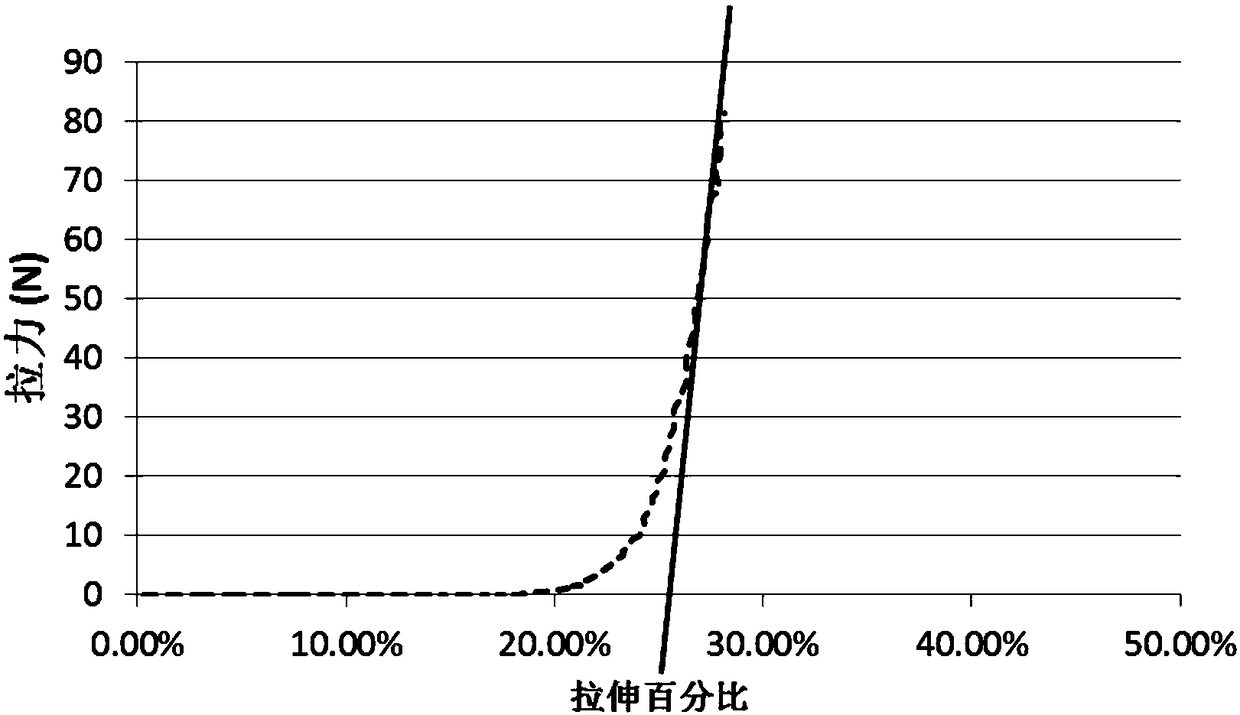

ActiveCN106267784AReduce movement hindranceEnhance the sense of movementSport apparatusProtective garmentLow modulusElastic modulus

The invention discloses a dynamic biological-function leg protective tool. The dynamic biological-function leg protective tool comprises a biomechanics protective belt arranged based on the structure positions and the directions of tendon ligaments and muscles of the knee and the biomechanics characteristics in the human-body exercise process. The biomechanics protective belt comprises a cruciate ligament protective belt, a patellar tendon protective belt, a thigh muscle group protective belt and a shank muscle group protective belt; periodical changes of the elasticity modulus of the cruciate ligament protective belt and the elasticity modulus of the patellar tendon protective belt are generated based on the fabric stretching ratio caused by knee bending, and the change stages include the initial stretching low-modulus stage, the stretching suddenly-changing stage and the stretching high-modulus stage which are gradually transited along with the reduction of the knee angle. According to the dynamic biological-function leg protective tool, comfortable elastic protection is provided for the knee bending action of a sportsman, the elasticity modulus of a knee material is correspondingly and automatically adjusted according to different knee angles caused by different exercise knee bending ranges, healthy and comfortable elastic protection can be provided under the small knee angle and the high exercise amount, perspiring can be achieved through heat comfortable areas, and the protective tool can be prevented from sliding through the strengthened anti-sliding belt.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

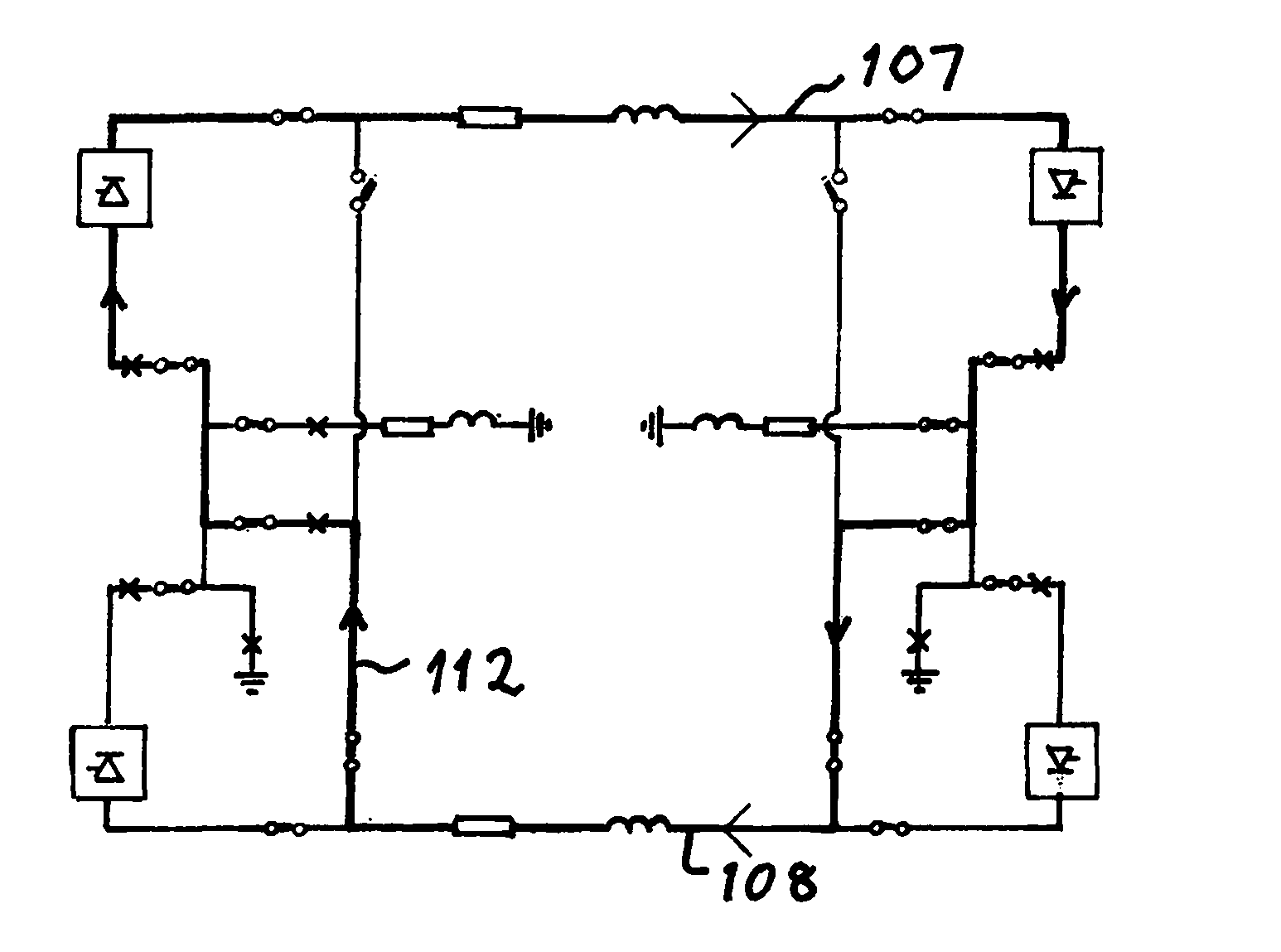

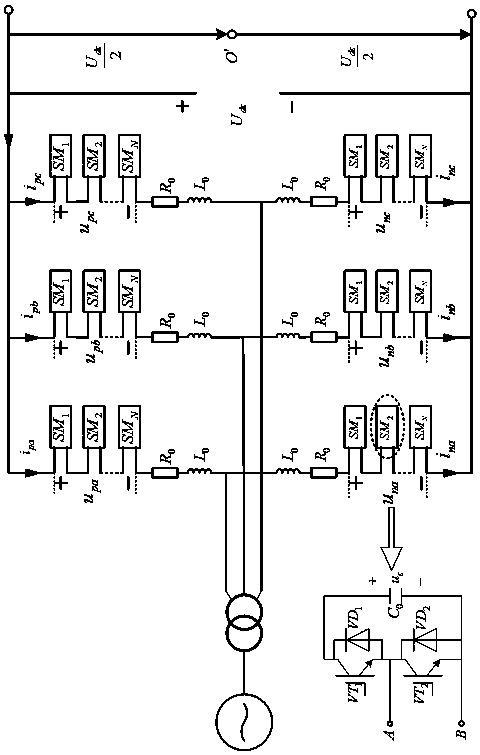

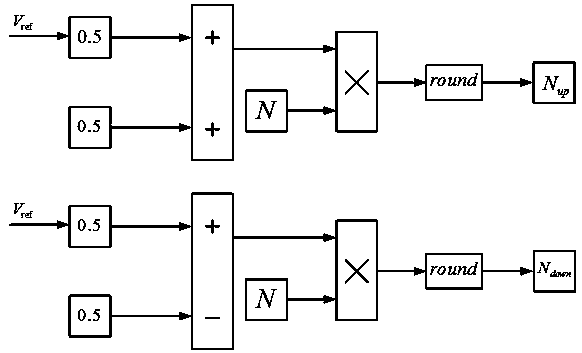

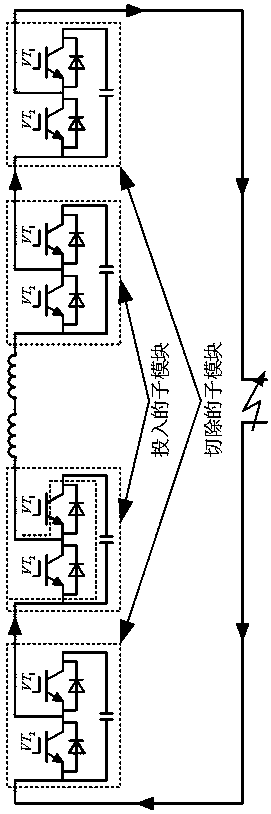

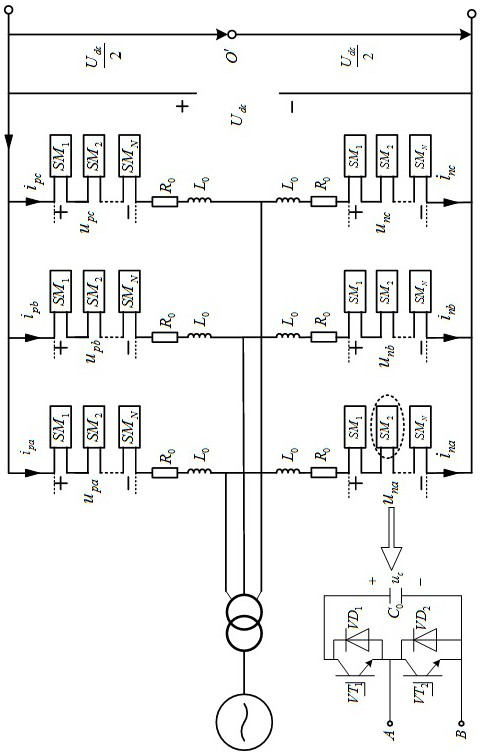

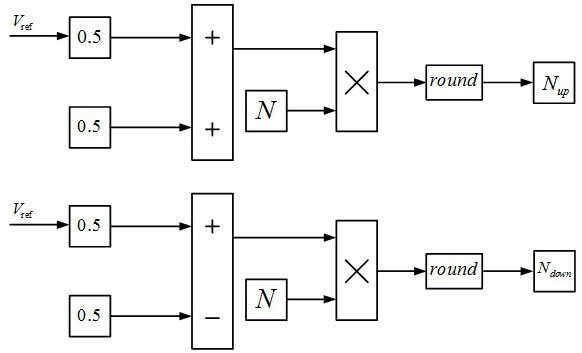

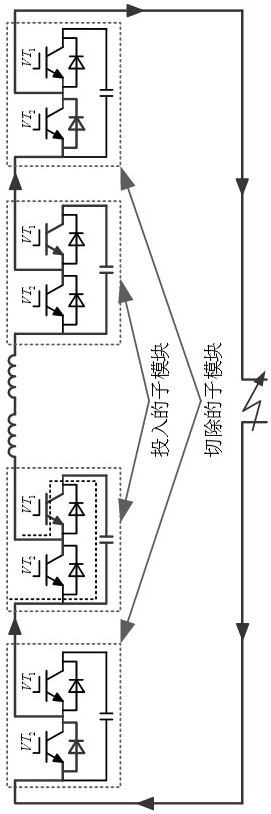

Transverter direct current side fault current suppression method based on additional virtual inductance coefficient

ActiveCN109787205ASlow ascent rateReduce overcurrent stressEmergency protective arrangements for limiting excess voltage/currentEngineeringAlternating current

The invention relates to a transverter direct current side fault current suppression method based on additional virtual inductance coefficient, belonging to the technical field of flexible direct current power transmission. Firstly, a calculation method of influence of partially cutting a submodule after short circuit fault of a transverter outlet on an alternating current system is put forward, discharge current capacity of an IGBT device and breaking capacity of a direct current breaker are considered comprehensively, a suppression method of transverter direct current side short circuit fault current is put forward, wherein the suppression method can reduce investment proportion of the submodule after fault happens, meanwhile, a fault current suppression method of changing investment proportion of the submodule after fault through mapping the virtual inductance coefficient into a control system is also put forward, and a setting method of the virtual inductance coefficient is also provided. The method, applied to a MMC transverter, can effectively reduce rising rate of the fault current, reduce overcurrent stress of the direct current breaker which cuts off the fault device, andhas good economic efficiency and practicability in comparison with a method of performing fault current suppression through an additional current limiting device.

Owner:NORTHEAST DIANLI UNIVERSITY +1

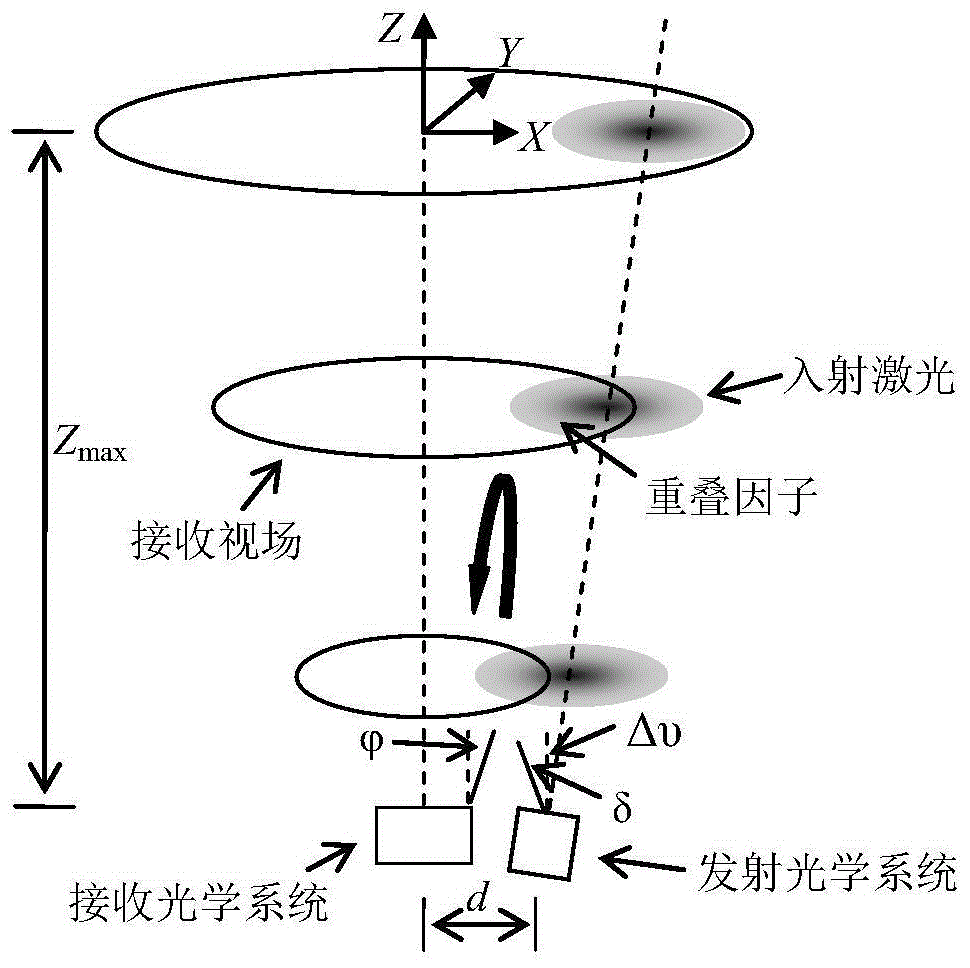

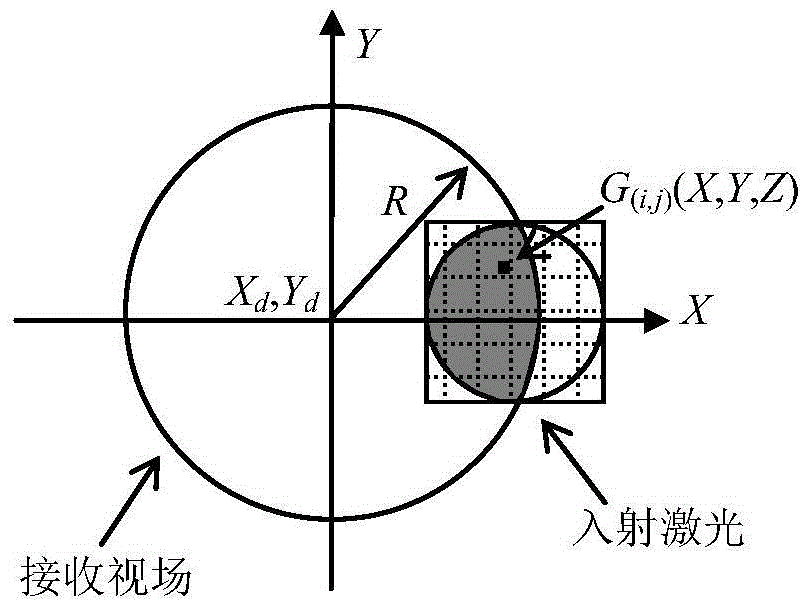

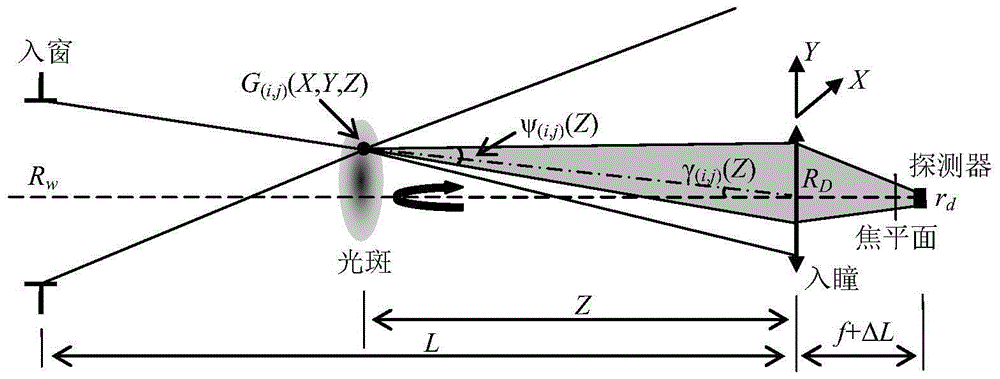

Compression Method of Echo Energy Dynamic Range of LiDAR System

InactiveCN104714221BSlow ascent rateGood for compressing dynamic rangeElectromagnetic wave reradiationRadar systemsDynamic range compression

The invention relates to a compression method for a dynamic range of echo energy of a laser radar system. The compression method is particularly suitable for a two-shaft structure. A certain negative included angle is formed between a light emission shaft and a light receiving shaft, so that the rising rate, which is increased with the detection distance, of an overlapping factor is reduced, and the dynamic range of the laser echo energy can be compressed favorably; furthermore, a detector is arranged at a position spaced from a focal plane of an optical system at a distance so as to obtain an optimal laser echo energy response. Due to an experimental formula and a conclusion which are provided by theoretical analysis and value calculation, the compression method has a guiding significance for the whole design and the performance estimation of the laser radar system.

Owner:WUHAN UNIV

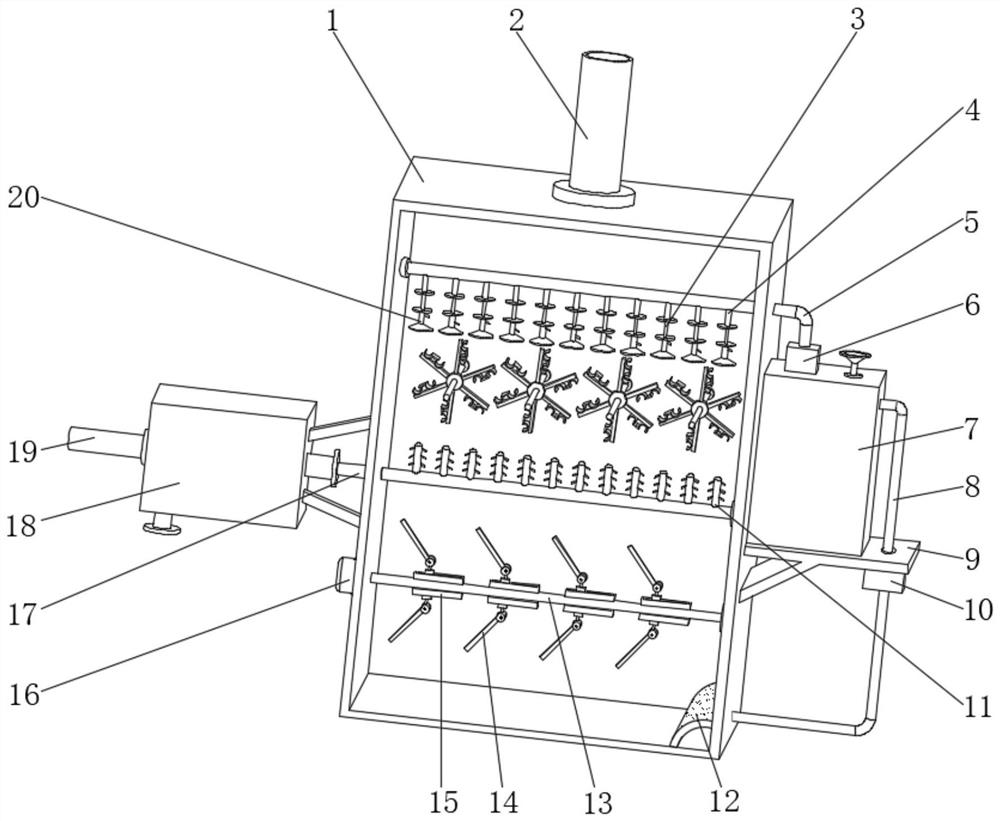

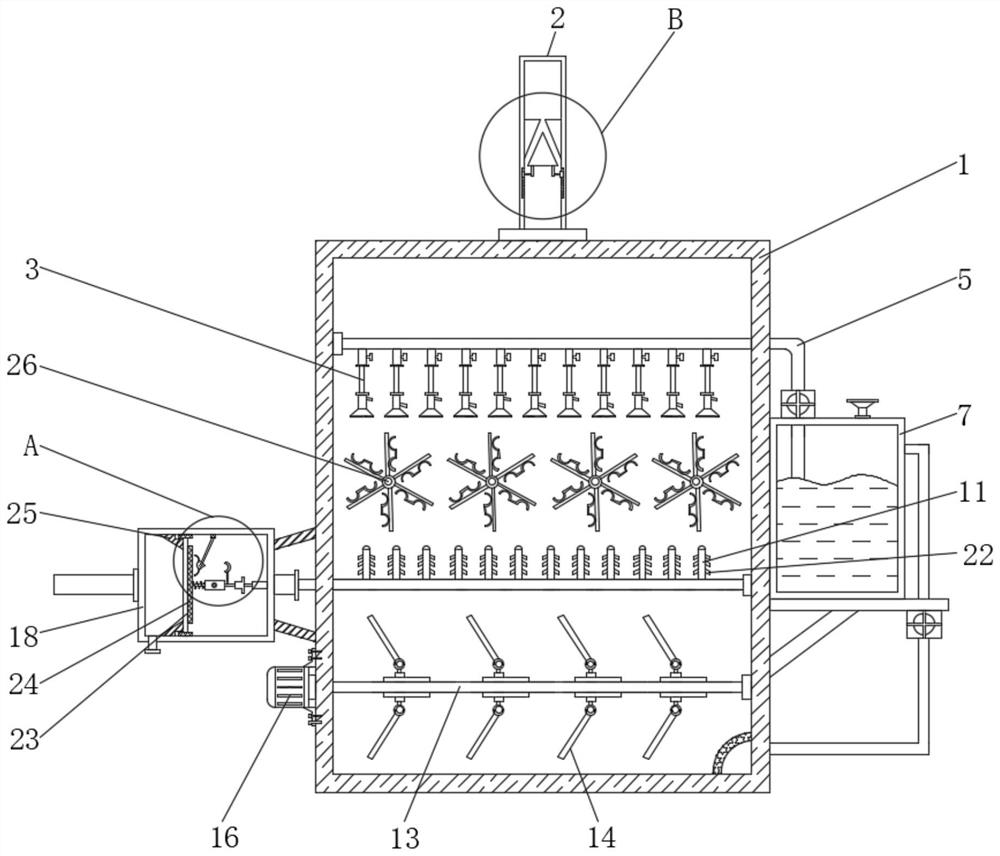

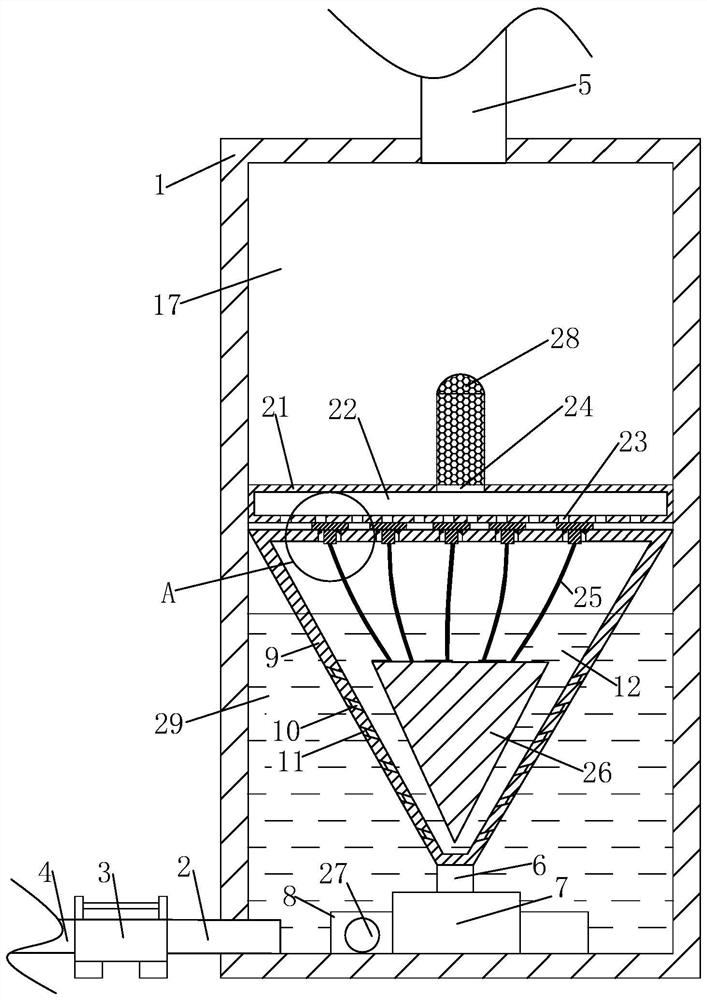

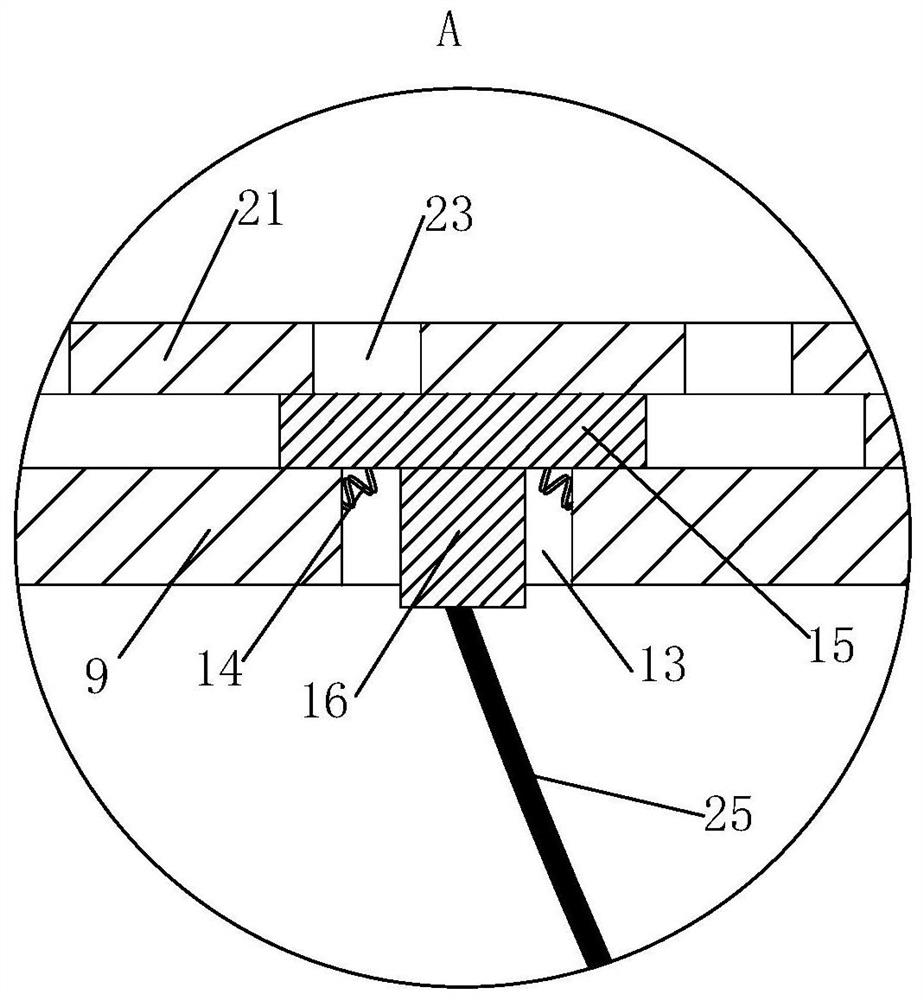

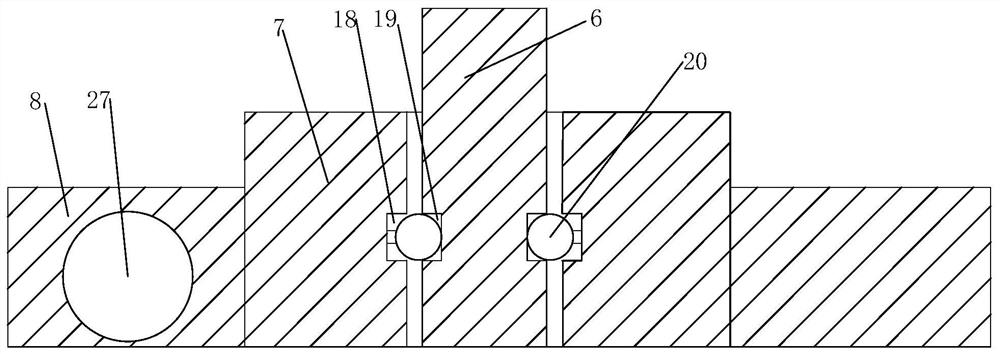

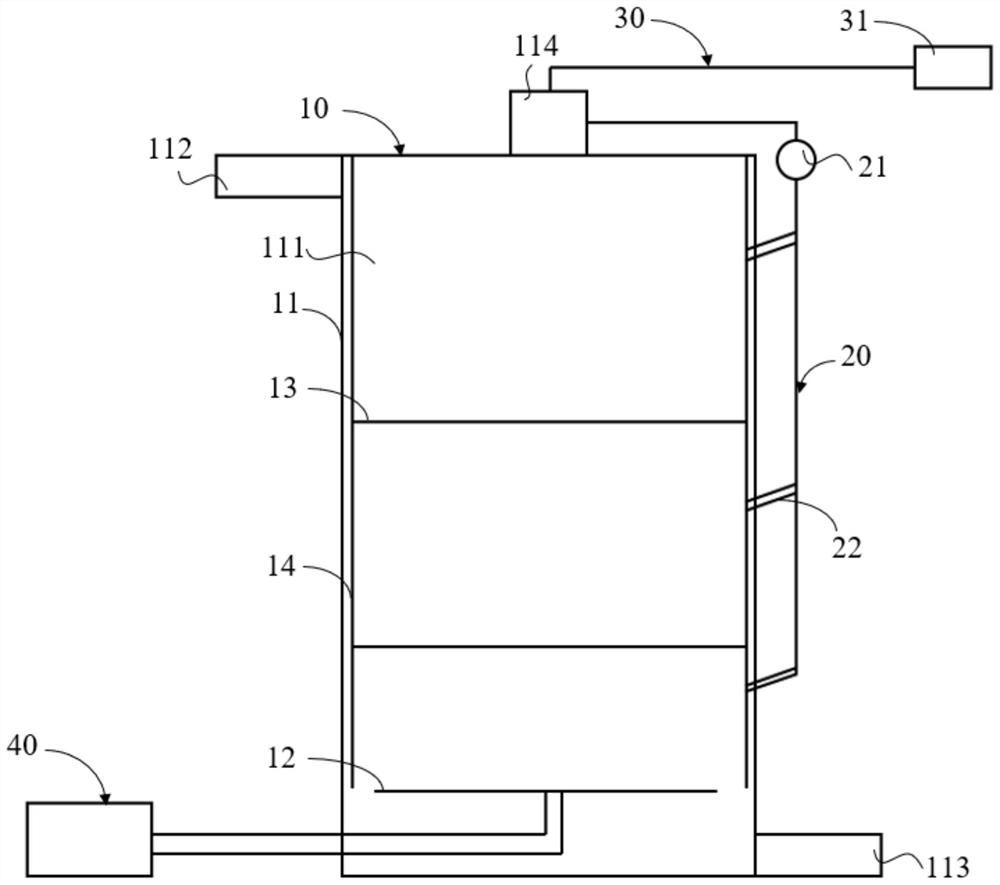

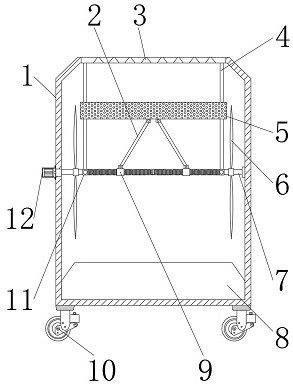

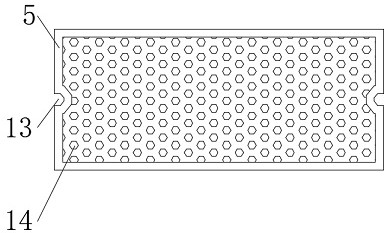

Odor removal device and method for plastic film processing

InactiveCN114425232AEasy to handleImprove purification effectCombination devicesDispersed particle filtrationLiquid storage tankProcess engineering

The invention discloses a plastic film processing peculiar smell removing device and method.The plastic film processing peculiar smell removing device comprises a box body, a mounting rod is fixedly connected to the outer wall of one side of the box body, an impurity removing box is fixedly connected to one end of the mounting rod, air inlet pipes are inserted into the outer walls of the two sides of the impurity removing box, and a purifying assembly used for filtering waste gas is arranged in the impurity removing box; a connecting pipe is inserted into the inner wall of one end of the air inlet pipe, one end of the connecting pipe extends into the box body, exhaust pipes distributed at equal intervals are inserted into the outer wall of the top of the connecting pipe, a supporting frame is fixedly connected to the outer wall of one side of the box body, and a liquid storage box is fixedly connected to the outer wall of the top of the supporting frame; and the outer wall of the top of the liquid storage tank is fixedly connected with a first pump body. In the process of purifying the waste gas by the treatment liquid, the treatment liquid and the waste gas can be fully mixed through the stirring assembly, so that the purification effect and efficiency of the device on the waste gas are improved.

Owner:广州中创建筑科技有限公司

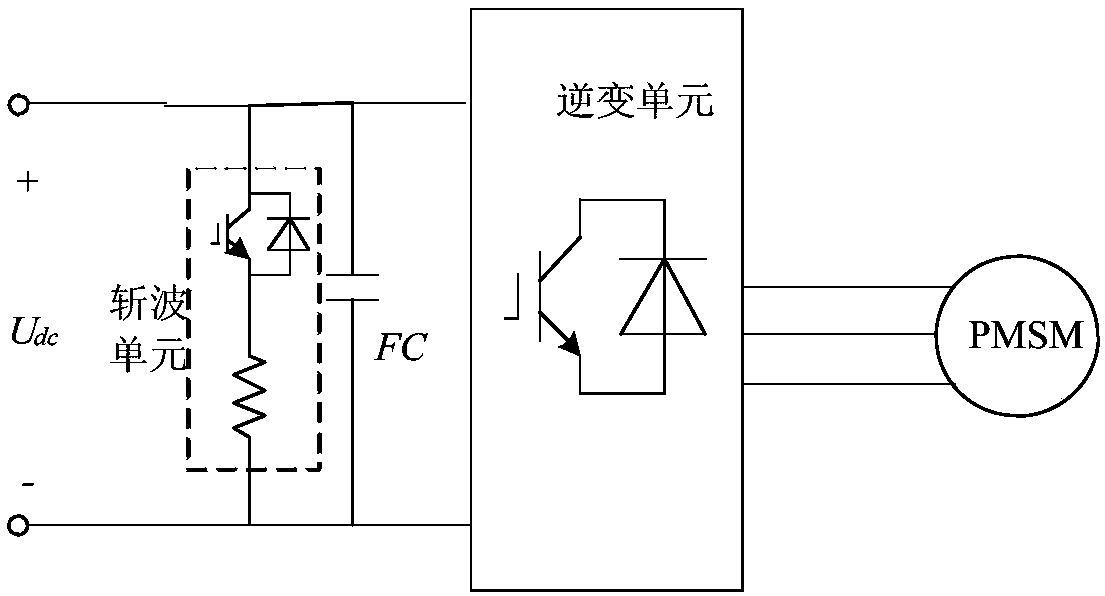

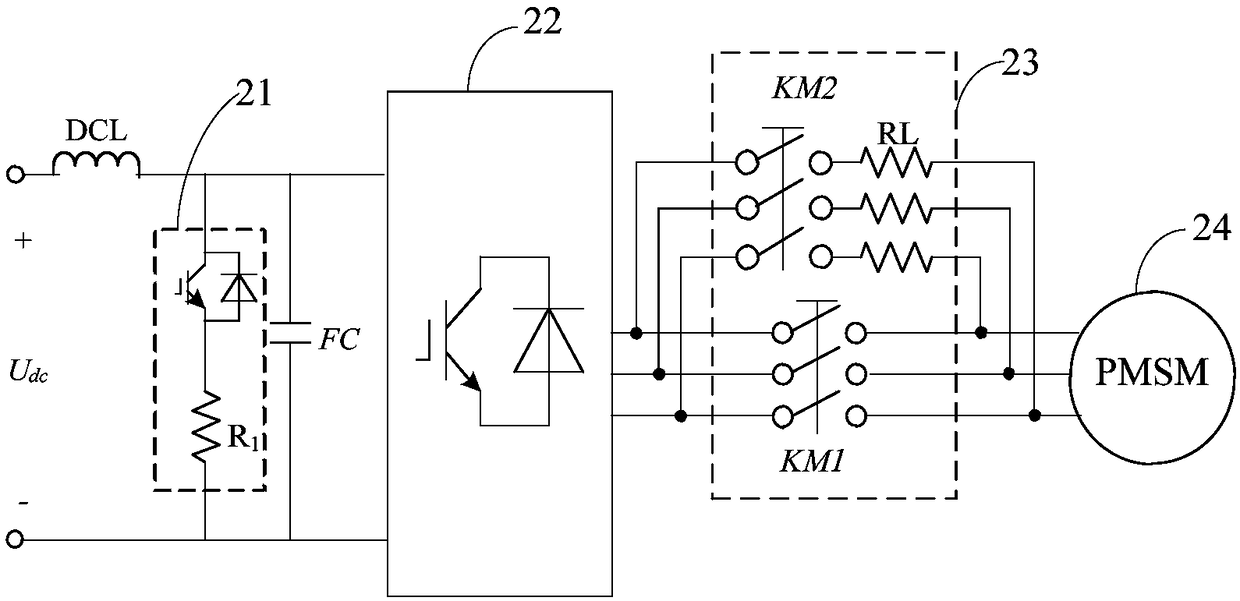

Permanent magnet synchronous motor traction system

PendingCN108964524ASlow down the rate of current riseIncrease the circuit time constantSpeed controllerAC motor controlContactorRise rate

The invention provides a permanent magnet synchronous motor traction system. During the application process in the rail transit field, when IGBT pulses need to be blocked and an inverter unit needs tobe powered off and enter idle running, a first three-phase contactor and a second three-phase contactor in a system reput-into-service unit are disconnected. When reput-into-service is required, thefirst three-phase contactor can be directly put into service if a permanent magnet synchronous motor is running at low speed, the reput-into-service is carried out, the second three-phase contactor does not operate, and a disconnecting state is maintained; and if the permanent magnet synchronous motor is running at a high speed, the second three-phase contactor can be directly put into service, amotor stator performs current limiting and voltage division by means of resistors serially connected with phases of the second three-phase contactor, or slow down the current rise rate by means of inductors serially connected with phases of the second three-phase contactor, and increases circuit time constant, thereby suppressing overcurrent or overvoltage faults caused by too fast rise of motor stator current and DC side bus voltage at the reput-into-service moment.

Owner:CRRC XIAN YONGEJIETONG ELECTRIC CO LTD

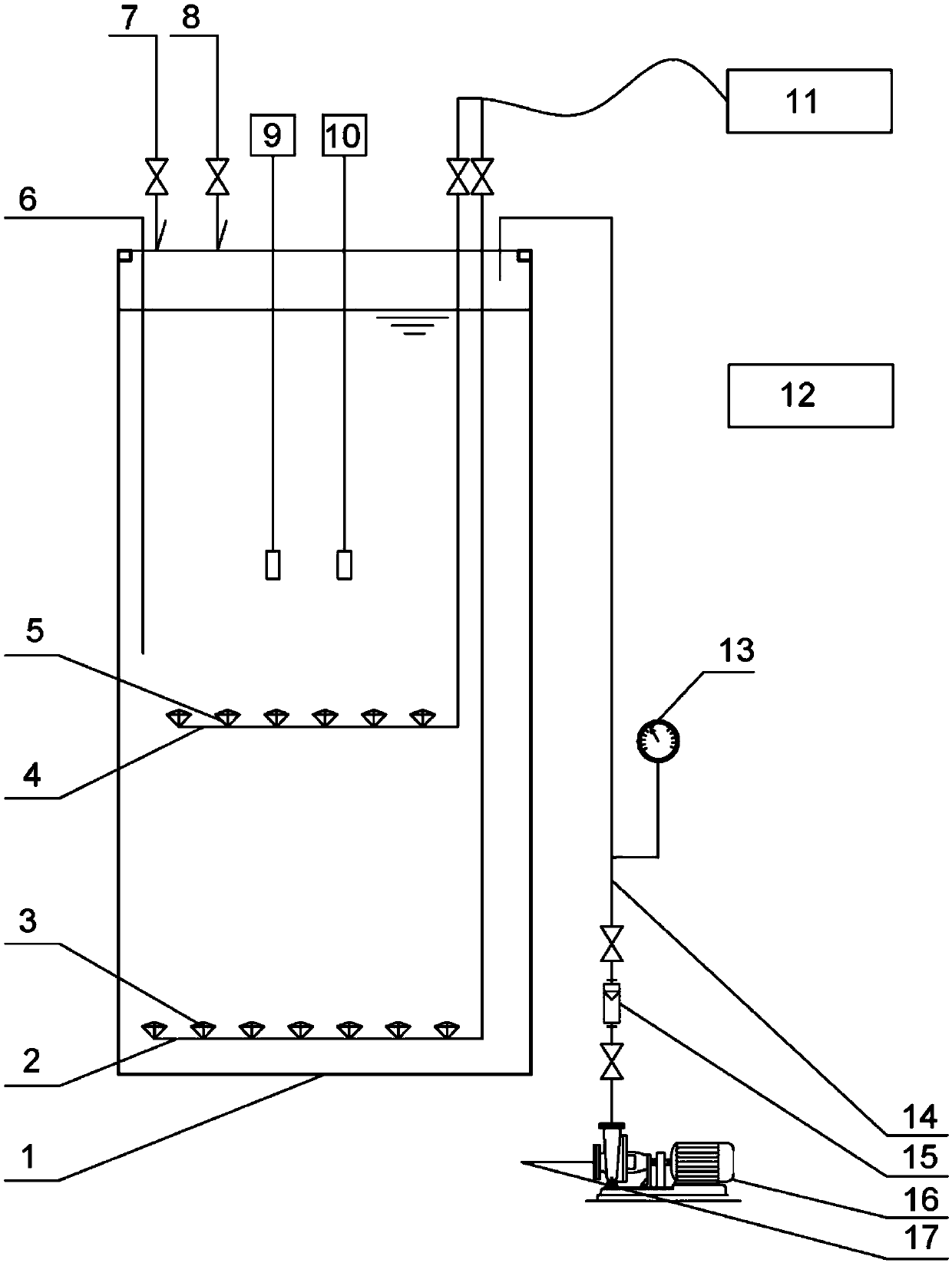

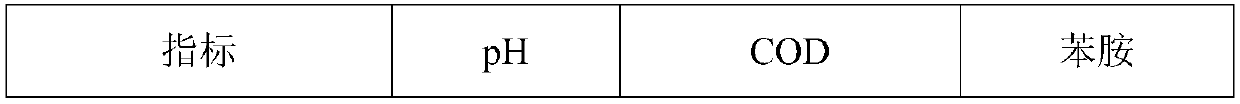

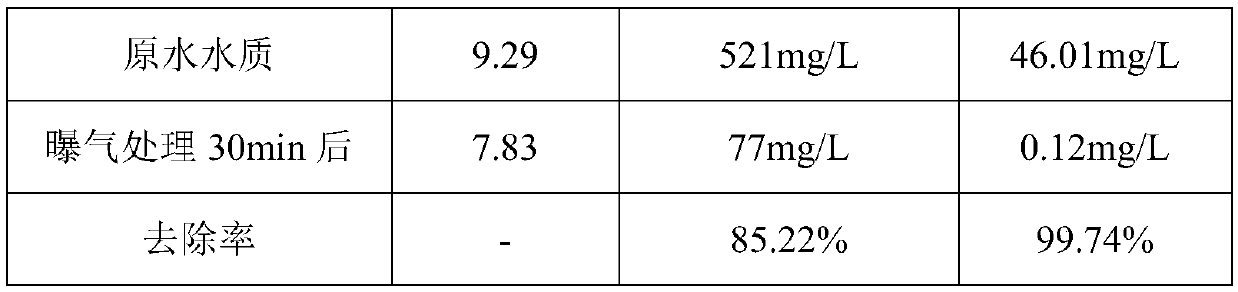

Device and method for treating phenylamine wastewater

PendingCN109574197AIncrease contact areaLow rate of ascentWater treatment parameter controlWater contaminantsContact timeAniline

Owner:GUANGZHOU GUANGSHEN ENVIRONMENTAL PROTECTION TECH

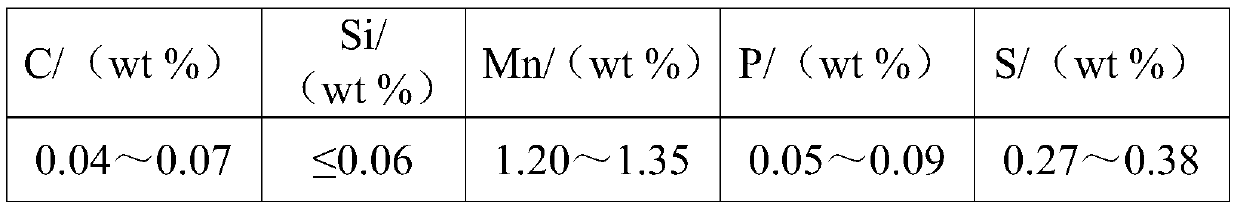

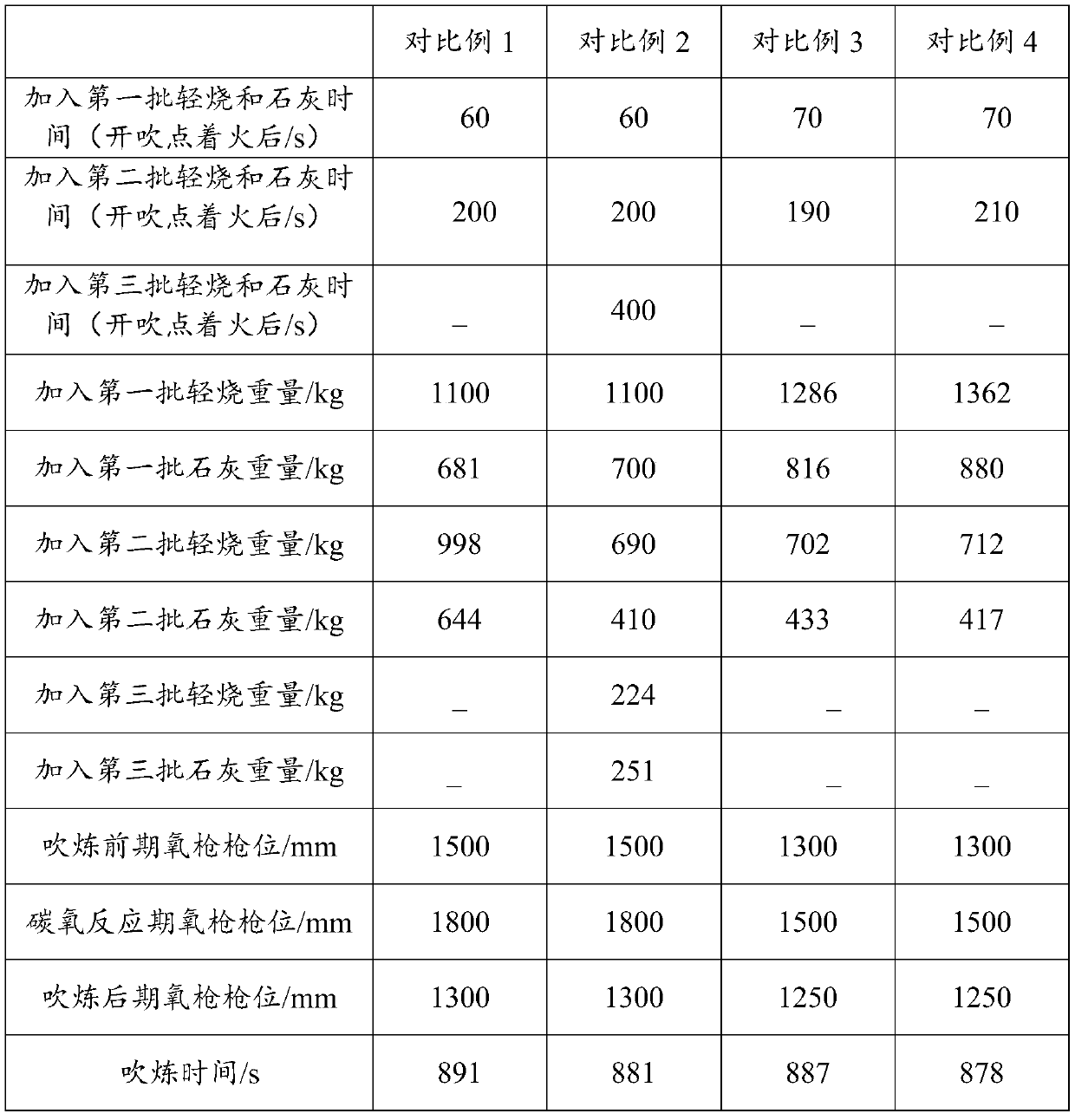

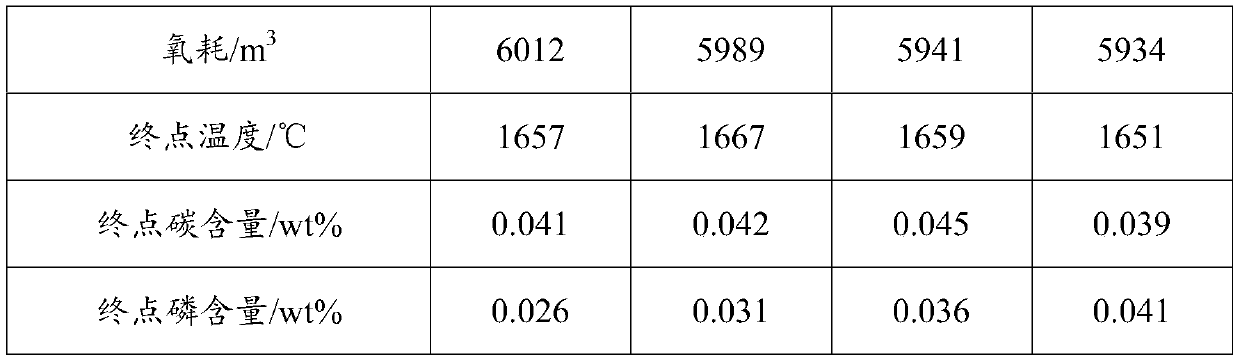

Smelting method of low-carbon high-phosphorus steel

The invention discloses a smelting method of low-carbon high-phosphorus steel and the low-carbon high-phosphorus steel, and belongs to the technical field of metallurgy. The smelting method of the low-carbon high-phosphorus steel comprises the steps of charge weight control, wherein the weight ratio of molten iron to waste steel is controlled to be (3.4-4.2):1; and blowing control, wherein a firstbatch of raw dolomite is added for slagging 30-60 s after blowing is started and ignition is carried out. The molten iron and the waste steel with the weight ratio of (3.4-4.2):1 are smelted, moltenpool heat balance is basically kept, and damage to furnace liner refractory materials can be reduced. The first batch of raw dolomite is added 30-60 s after blowing is started and ignition is carriedout, the raw dolomite is fast dissolved to fast slag, the utilization rate of oxygen is increased, and scouring of high-speed jet to the furnace liner refractory materials is relieved; and the raw dolomite is decomposed and absorbs heat, decomposed MgO can inhibit and relieve erosion of slag to furnace liner bricks, and the function of protecting a furnace body can be achieved well.

Owner:SGIS SONGSHAN CO LTD

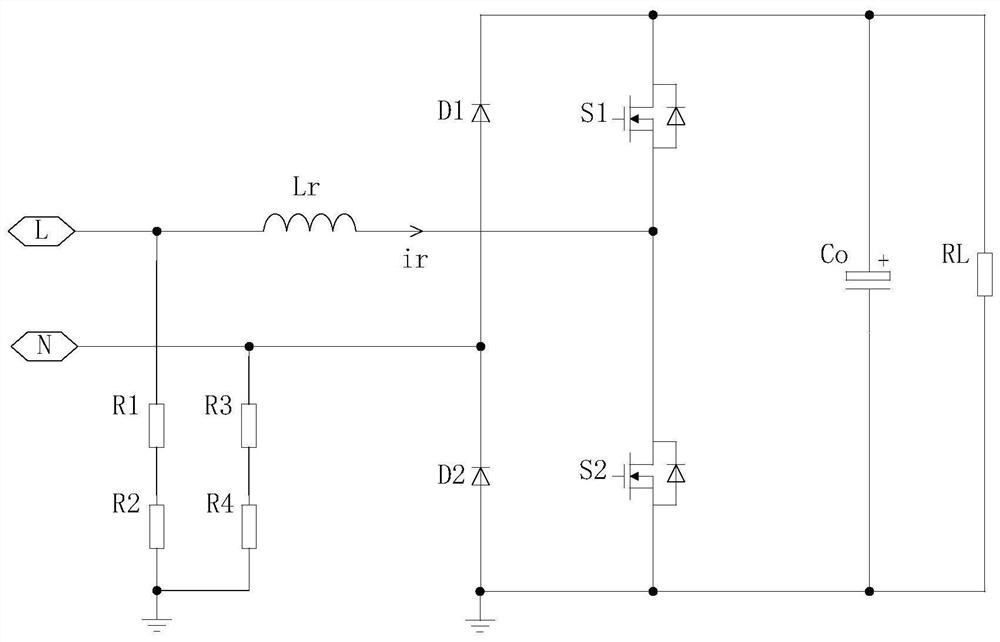

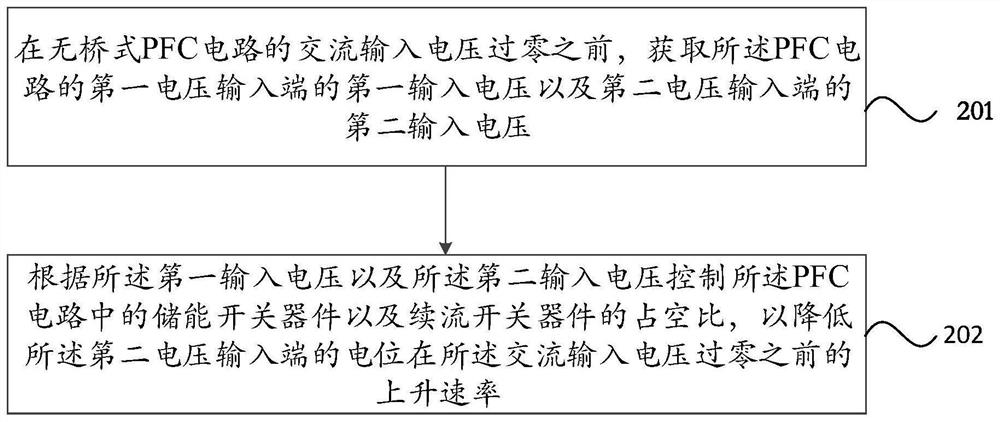

Bridgeless PFC circuit control method and device, electronic equipment and storage medium

InactiveCN113346733ADoes not affect manufacturing costsDoes not affect power densityEfficient power electronics conversionPower conversion systemsHemt circuitsPeak current

One or more embodiments of the invention disclose a bridgeless PFC circuit control method and device, a storage medium and an electronic device. The bridgeless PFC circuit control method comprises the following steps: acquiring a first input voltage of a first voltage input end of a PFC circuit and a second input voltage of a second voltage input end of the PFC circuit; and according to the first input voltage and the second input voltage, controlling the duty ratio of an energy storage switch device and a follow current switch device in the PFC circuit so as to reduce the rising rate of the potential of the second voltage input end before zero crossing of the alternating current input voltage. In an on state, the energy storage switch device is an inductor energy storage switch device in the PFC circuit; and in a conducting state,the follow current switch device is a switch device which enables the inductor to release energy to the load of the PFC circuit. According to the embodiment of the invention, a relatively large step voltage change rate caused by zero crossing of the input voltage can be slowed down, so that peak current generated by the PFC circuit during zero crossing of the input voltage is inhibited.

Owner:BEIJING DYNAMIC POWER CO LTD

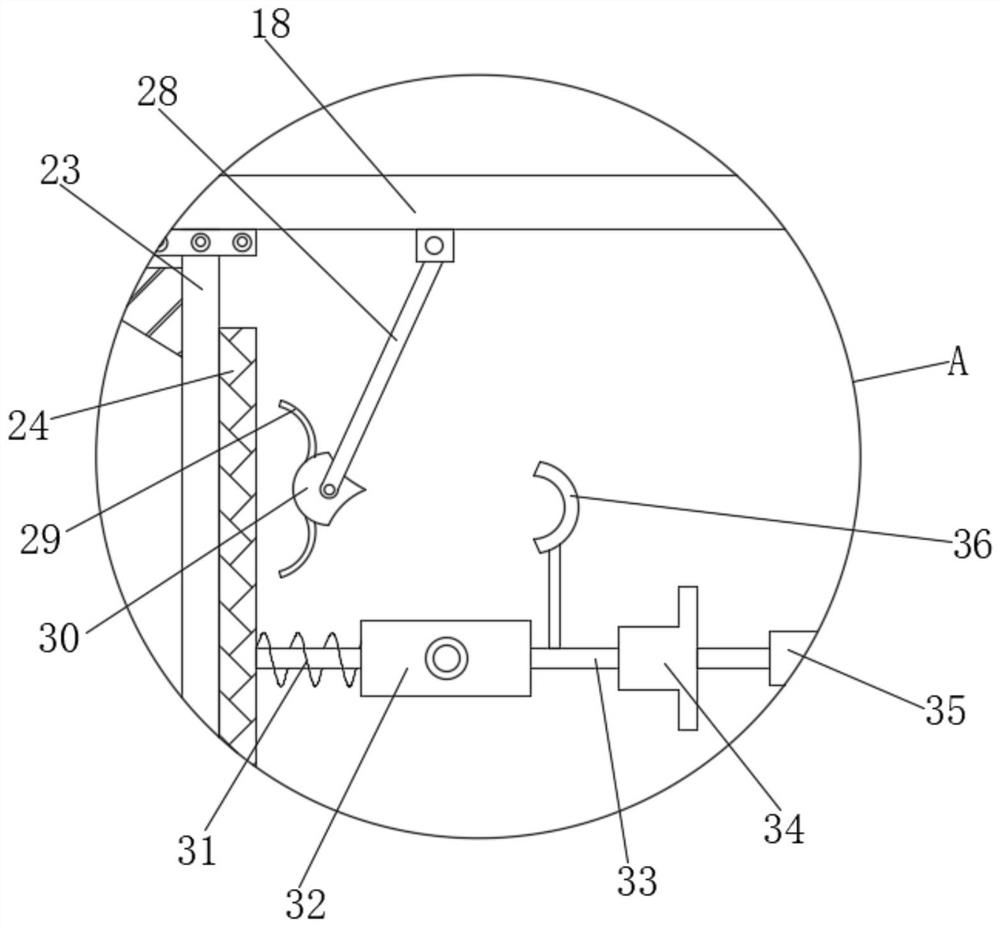

A training aid interference device for basketball shooting

ActiveCN109260679BGuaranteed effectGuaranteed accuracySport apparatusClassical mechanicsSports equipment

The invention provides a training auxiliary interference device for basketball shooting, which relates to the field of sports equipment. In the training auxiliary interference device for basketball shooting, the top of the installation plate is connected to the middle part of the top of the mounting seat through an inclination adjustment mechanism. The top of the lifting rod is fixedly connected with a rubber corrugated hose, and the top of the rubber corrugated hose It is fixedly connected with the top of the inner wall of the cavity, and the middle part of the bottom of the inner wall of the cavity is fixedly bonded with a hand-lifting interference mechanism, the bottom of the movable sleeve B is fixedly connected with a support rod, and the top of the mounting seat is provided with a through groove, so A contraction mechanism is installed in the inner cavity of the mounting base, and the two sides of the top of the contraction mechanism are respectively connected with two support rods. In this way, the amount of air in the airbag C is introduced into the airbag B, and the airbag B is inflated. The inflated airbag B will drive the fixed rod to be compressed, and the compressed fixed rod will be tilted, so that the interference rod that rises and interferes After ascending, there will be a slight forward lean.

Owner:嘉兴市瑞鑫塑业有限公司

Processing method of ethylene tar

ActiveCN103102978BBroaden sources of raw materialsImprove product qualityTreatment with hydrotreatment processesLighter fuelGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of ethylene tar

ActiveCN103102976BBroaden sources of raw materialsImprove product qualityDistillation purification/separationTreatment with hydrotreatment processesGasolineHydrogen treatment

Owner:CHINA PETROLEUM & CHEM CORP +1

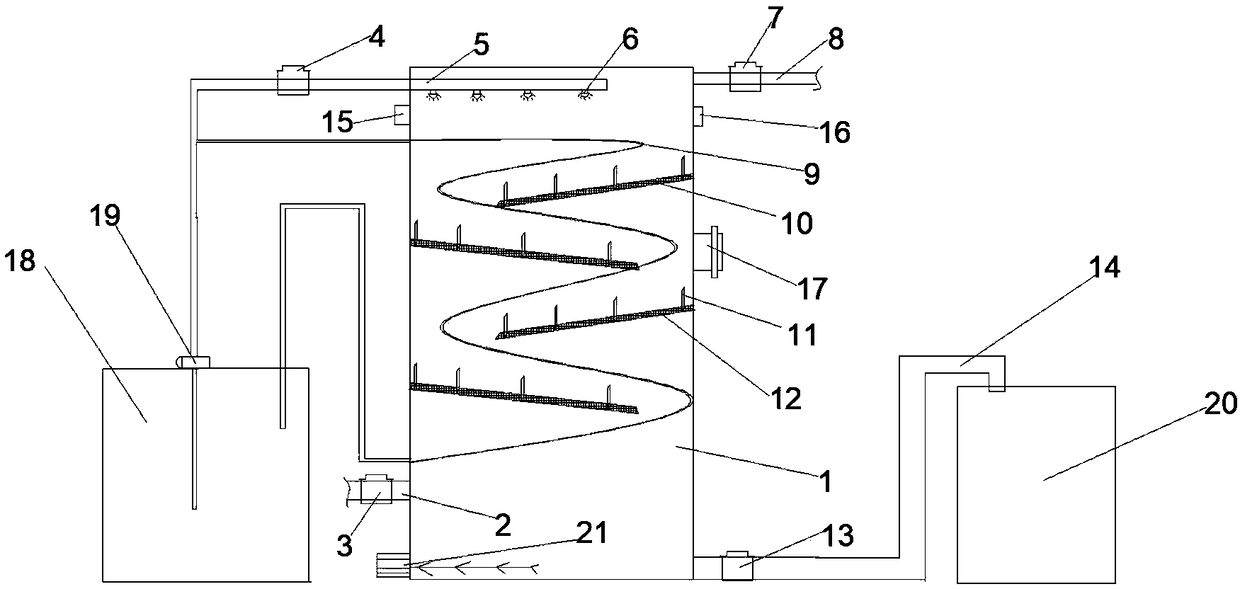

Desulfurization and denitrification integrated desulfurizing tower

PendingCN114100339AExtended stayAdequate responseGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention belongs to the technical field of desulfurization towers, and particularly relates to a desulfurization and denitrification integrated desulfurization tower which comprises a tower body, a first cavity is formed in the tower body, a first smoke inlet pipe, a booster pump and a second smoke inlet pipe are sequentially fixed to the bottom end of the right side of the tower body from right to left, and a smoke outlet pipe is fixed to the top end of the tower body; a fixing column is fixed to the bottom of the first cavity and sleeved with a rotating cylinder, a fixing cylinder is fixedly installed at the top end of the fixing column, a second cavity is formed in the fixing cylinder, a first through hole is formed in the side wall of the fixing cylinder, a rubber sheet is fixedly installed in the first through hole, and a plurality of second through holes are formed in the upper end of the fixing cylinder; a spring is fixedly mounted on the inner wall of the second through hole, a cover plate is fixedly mounted on the spring, a connecting rod is fixedly mounted at the lower end of the cover plate, and the tower body is filled with a desulfurization and denitrification solution; the problems that an existing desulfurizing tower is limited by the height of a tower body, the contact time of flue gas and a medium is too short due to the factor of the flue gas flow speed, and the flue gas is difficult to fully desulfurize and denitrate can be solved.

Owner:徐作元

Water washing device

InactiveCN109385299AIncrease the washing areaImprove washing efficiencyRefining by water treatmentSprayerPerpendicular direction

The invention discloses a water washing device. The water washing device comprises a water washing machine body, a feed pipe is arranged at the lower part of the outer side surface of the water washing machine body, a first valve is arranged on the feed pipe, a water intake pipe is further arranged at the upper part of the feed pipe, a second valve is arranged on the water intake pipe, the water intake pipe penetrates through the machine body to be provided with sprayers, a discharge pipe is arranged at the upper part of the outer side of the water washing machine body, a third valve is arranged on the discharge pipe; a flow guide plate is arranged slantly in the inner part of the water washing machine body, a baffle is arranged on the flow guide plate and is located at the lower part of the flow guide plate, the baffle is arranged in the perpendicular direction, and a filter screen is arranged on the lower surface of the flow guide plate. The water washing device is provided with a sampling opening, so that the water washing process is monitored in real time, and the problem of insufficient water washing caused by the facts that an operation staff cannot judge whether a solution reaches the waster washing standard timely and that the operation staff misjudges is avoided.

Owner:唐林

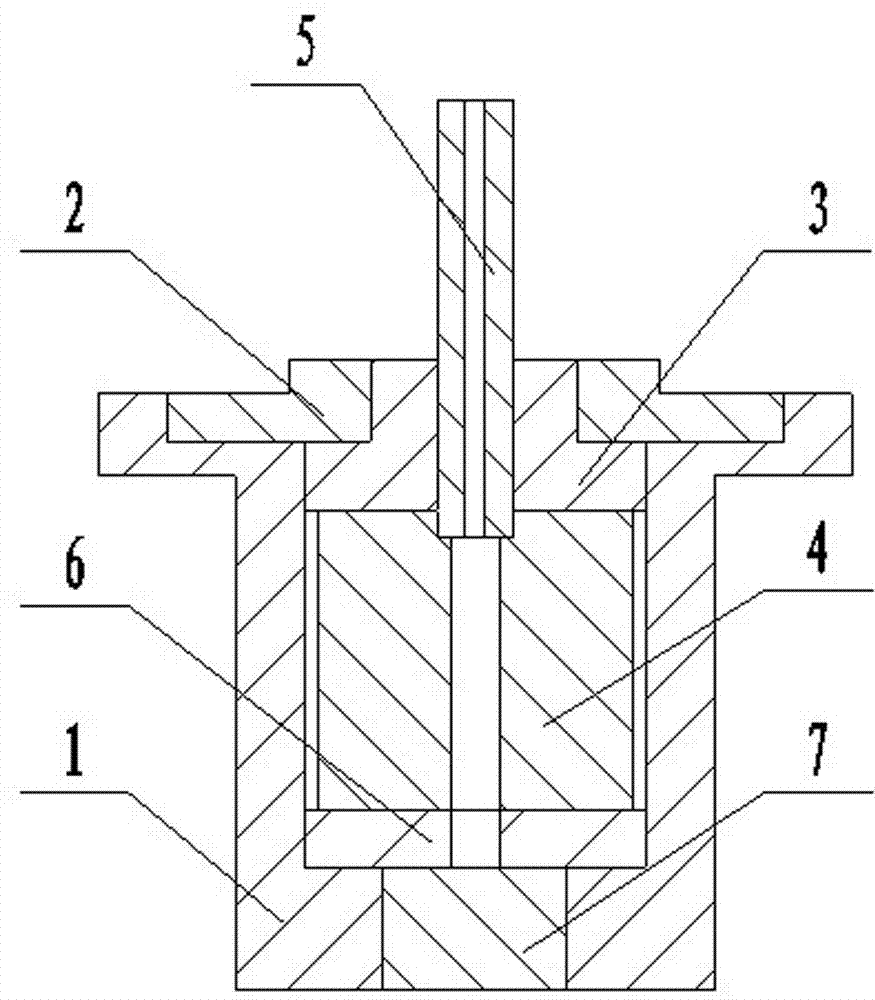

High-temperature pressure sensor

ActiveCN102288355BExtended working hoursReduce deliveryFluid pressure measurement using ohmic-resistance variationEngineeringHeat sink

The invention specifically discloses a high-temperature pressure sensor. The problem that a conventional pressure sensor is invalidly isolated in a high-temperature environment and cannot work normally due to an unreasonable structure is solved. The high-temperature pressure sensor comprises a columnar shell with an open upper end; the upper end of the shell is provided with an upper end cover with a center hole; the lower bottom surface of the upper end cover is provided with a step-shaped upper heat-insulating ring; the upper part of the step-shaped upper heat-insulating ring penetrates into the center hole of the upper end cover; the lower surface of the upper heat-insulating ring is provided with a heat sinking body; a gap is maintained between the heat sinking body and the inner sidewall of the shell; further, the center of the heat sinking body is provided with a through hole; a pressure guiding pipe communicated with the through hole of the heat sinking body and further penetrating through the upper heat-insulating ring is fixed at the upper end of the heat sinking body; a lower heat-insulating ring which is in contact with the heat sinking body and the inner wall of the lower end of the shell is arranged between the heat sinking body and the inner wall of the lower end of the shell; the inner wall of the lower end of the shell is provided with a groove; and a pressuresensor main body communicated with the through hole of the heat sinking body is placed in the groove. The high-temperature pressure sensor has the advantages of reasonable and reliable structure, andalso can work for a long time while the purpose that the pressure sensor can carry out pressure measurement in the high-temperature environment is met.

Owner:ZHONGBEI UNIV

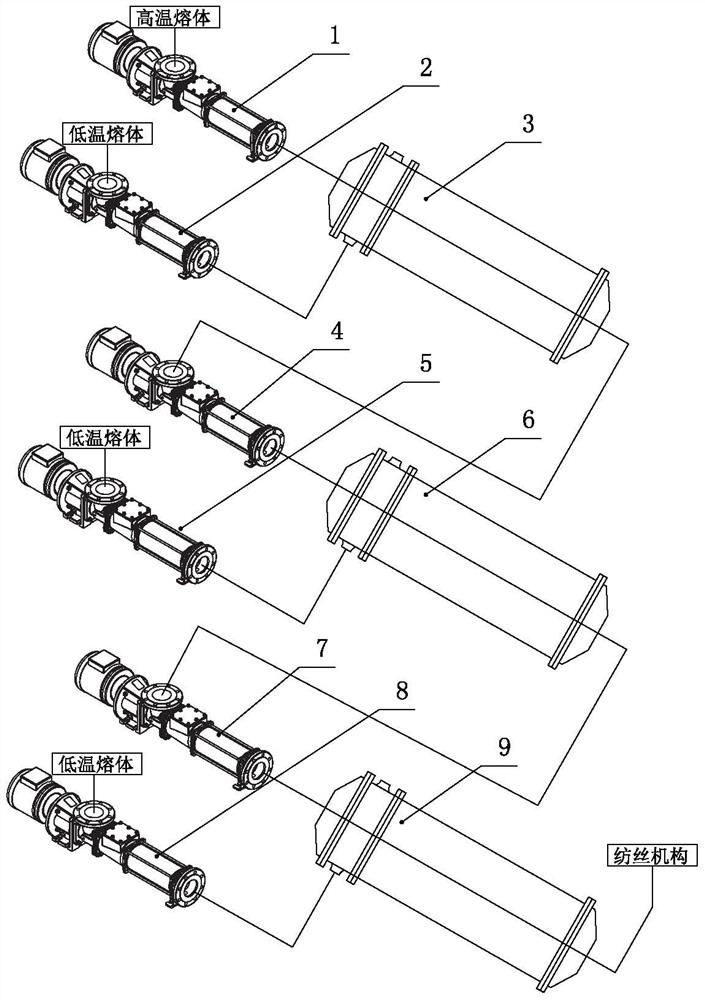

A kind of spinning method of the high-viscosity polyester melt that reduces oligomer

ActiveCN110983453BReduce melt flow rateReduce the probability of generationSpinning head liquid feederPolyesterFiber

Owner:扬州天富龙集团股份有限公司

Fault Current Suppression Method on DC Side of Converter Based on Additional Virtual Inductance Coefficient

ActiveCN109787205BSlow ascent rateReduce overcurrent stressEmergency protective arrangements for limiting excess voltage/currentBreaking capacityAlternate current

The invention relates to a transverter direct current side fault current suppression method based on additional virtual inductance coefficient, belonging to the technical field of flexible direct current power transmission. Firstly, a calculation method of influence of partially cutting a submodule after short circuit fault of a transverter outlet on an alternating current system is put forward, discharge current capacity of an IGBT device and breaking capacity of a direct current breaker are considered comprehensively, a suppression method of transverter direct current side short circuit fault current is put forward, wherein the suppression method can reduce investment proportion of the submodule after fault happens, meanwhile, a fault current suppression method of changing investment proportion of the submodule after fault through mapping the virtual inductance coefficient into a control system is also put forward, and a setting method of the virtual inductance coefficient is also provided. The method, applied to a MMC transverter, can effectively reduce rising rate of the fault current, reduce overcurrent stress of the direct current breaker which cuts off the fault device, andhas good economic efficiency and practicability in comparison with a method of performing fault current suppression through an additional current limiting device.

Owner:NORTHEAST DIANLI UNIVERSITY +1

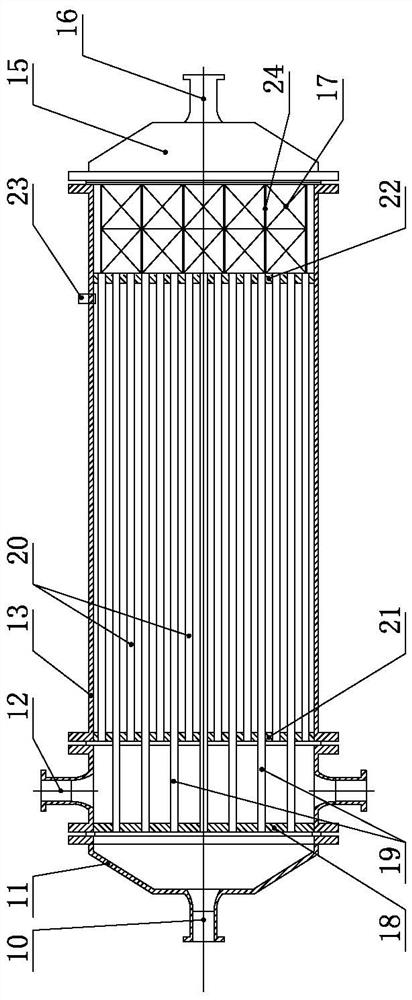

Wastewater treatment device and method for improving ozone utilization rate in wastewater treatment

InactiveCN111634993AReasonable structureImprove practicalitySpecific water treatment objectivesWater/sewage treatment apparatusWater treatmentWastewater disposal

The invention provides a wastewater treatment device and a method for improving the ozone utilization rate in wastewater treatment. The wastewater treatment device comprises a reactor and a reverse circulation system, wherein the reactor comprises a reactor body, a separation net and an aeration device, and the gas inlet and the gas outlet of the reverse circulation system are both in fluid connection with the reaction cavity of the reactor. According to the wastewater treatment device and the method for increasing the ozone utilization rate in wastewater treatment, ozone bubbles are divided into small ozone bubbles, and the rising speed of the ozone bubbles in the reactor is reduced, so that the contact time of the ozone bubbles and the reaction liquid in the reactor can be prolonged so as to increase the ozone utilization rate.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

Astringency removing equipment for Carya dabieshanensis processing

PendingCN114052165AIncrease profitFully contactedFood scienceProcess engineeringMechanical engineering

The invention provides astringency removing equipment for Carya dabieshanensis processing, and belongs to the technical field of processing equipment for walnut production. The astringency removing equipment for Carya dabieshanensis processing comprises a processing box body, a steam generation box, universal wheels and a servo motor, wherein the servo motor penetrates through the side wall of the processing box body, extends into the processing box body and is fixedly connected with a transmission threaded rod. According to the equipment, the contact degree between materials and steam can be improved, the treatment effect is improved, the consistency of the same batch of materials in the treatment process is ensured, meanwhile, the contact degree between the steam and the materials can be further improved in the horizontal direction, the treatment effect of the materials is further improved, meanwhile, the continuous rising speed of the steam is also slowed down, and the utilization rate is improved.

Owner:金寨县富东生态农业开发有限公司

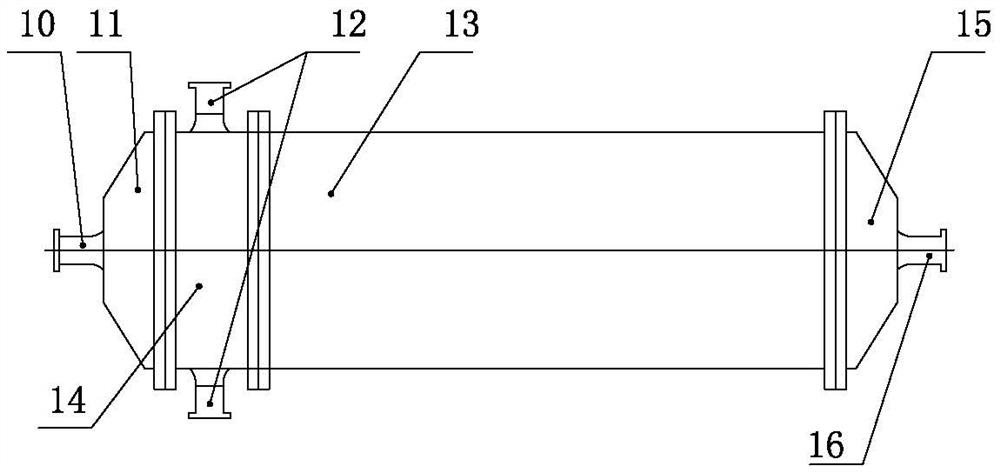

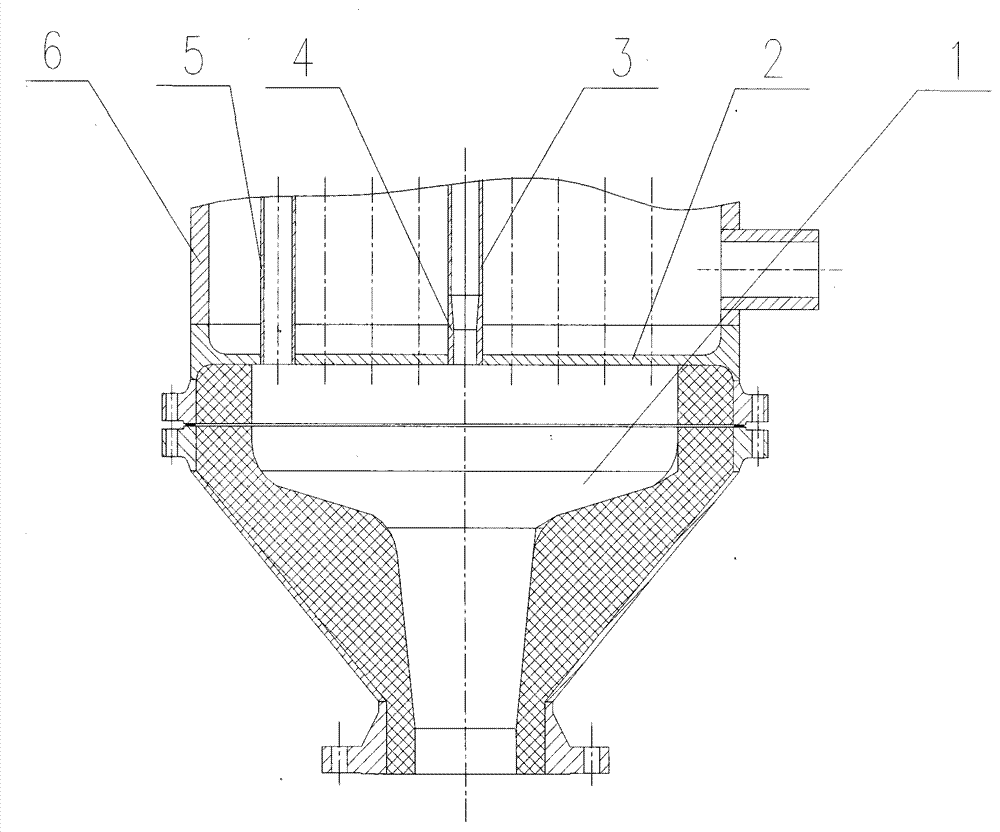

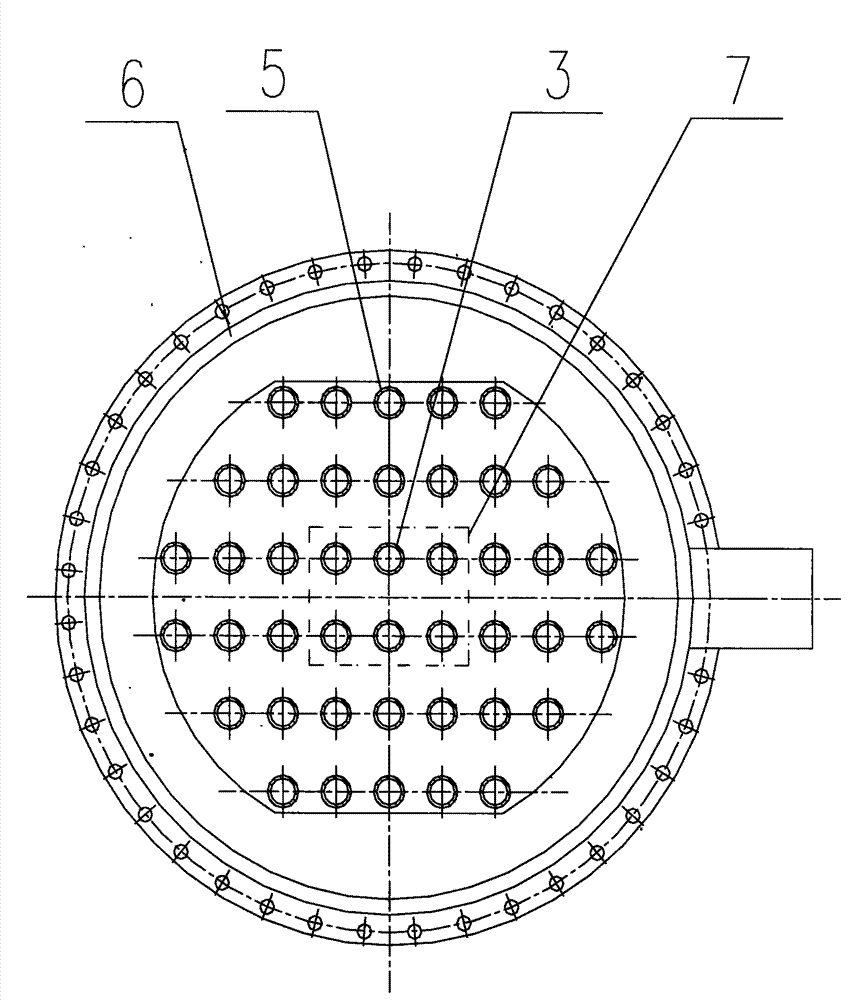

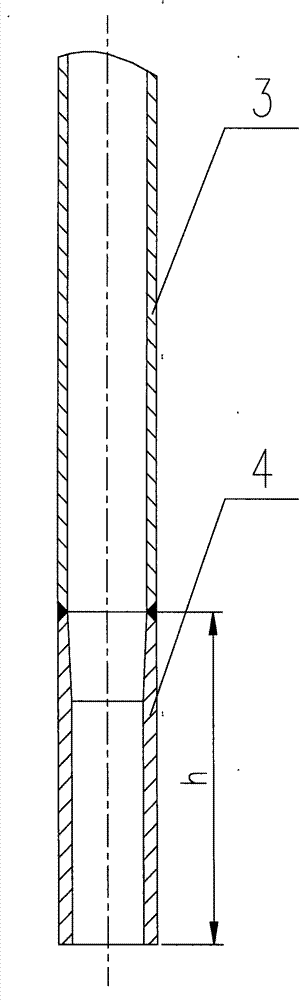

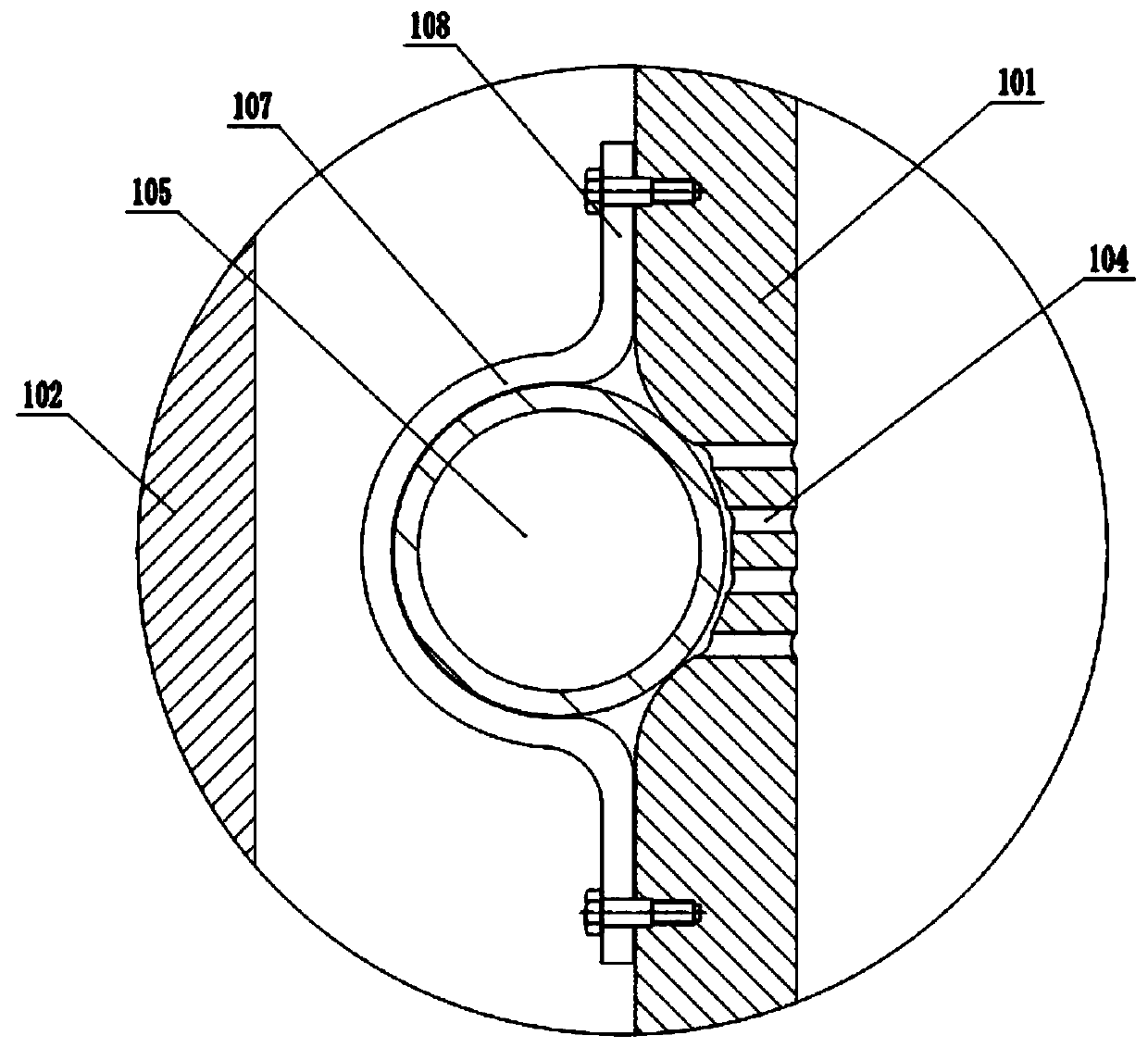

Fluid distribution method for rapid-cooling heat exchanger

ActiveCN101769658BExtended operating cycleIncrease profitThermal non-catalytic crackingFluid circulation arrangementDistribution methodDistribution system

The invention relates to a fluid distribution system for a rapid-cooling heat exchanger. Heat exchange tubes of the rapid-cooling heat exchanger comprise a center heat exchange tube (3) and a periphery heat exchange tube (5), the entrance end of the center heat exchange tube (3) is a short uniform-flow tube (4), the exit end of the center heat exchange tube (3) is an equal-diameter tube, the short uniform-flow tube (4) and the equal-diameter tube are butt-welded, so as to form the whole center heat exchange tube (3), and the periphery heat exchange tube (5) is an equal-diameter tube, the inner diameter of the inner tube of which is invariable in the full-length range. By adopting the method, the flow resistance property of the center heat exchange tube (3) is adjusted to lead the flow resistance of the center heat exchange tube (3) to increase properly, thus reducing the cracking gas flow in the center heat exchange tube (3) and increasing the cracking gas flow in the periphery heat exchange tube (5), so as to lead the fluid to distribute uniformly. The rapid-cooling heat exchanger which is provided with a fluid distribution system can distribute the cracking gas into each heat exchange tube uniformly, thus improving the utilization ratio of the heat exchange tubes and prolonging the running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dynamic Biofunctional Leg Guards

ActiveCN106267784BAvoid damageReduce movement hindranceSport apparatusProtective garmentTibiaCruciate ligament

A dynamic biofunctional leg protector, including a biomechanical protective belt set based on the structural position and direction of the tendons, ligaments and muscles of the knee, and the biomechanical characteristics of the human body during exercise. The biomechanical protective belt includes a cruciate ligament protective belt , patellar tendon protection belt, thigh muscle group protection belt, calf muscle group protection belt; the elastic modulus of the cruciate ligament protection belt and patellar tendon protection belt changes in stages based on the stretch ratio of the fabric caused by knee bending, and changes in stages It includes the initial stretch low modulus stage, stretch abrupt change stage, and stretch high modulus stage that gradually transition as the knee angle decreases. The present invention provides comfortable elastic protection for athletes to perform knee-bending movements, automatically adjusts the elastic modulus of the knee material according to the size of the knee angle caused by different knee-bending ranges, and can provide health and comfort under small knee angles and high exercise volumes Stretch protection with a thermal comfort zone to wick away perspiration, and a reinforced cleat to keep the suit from slipping.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

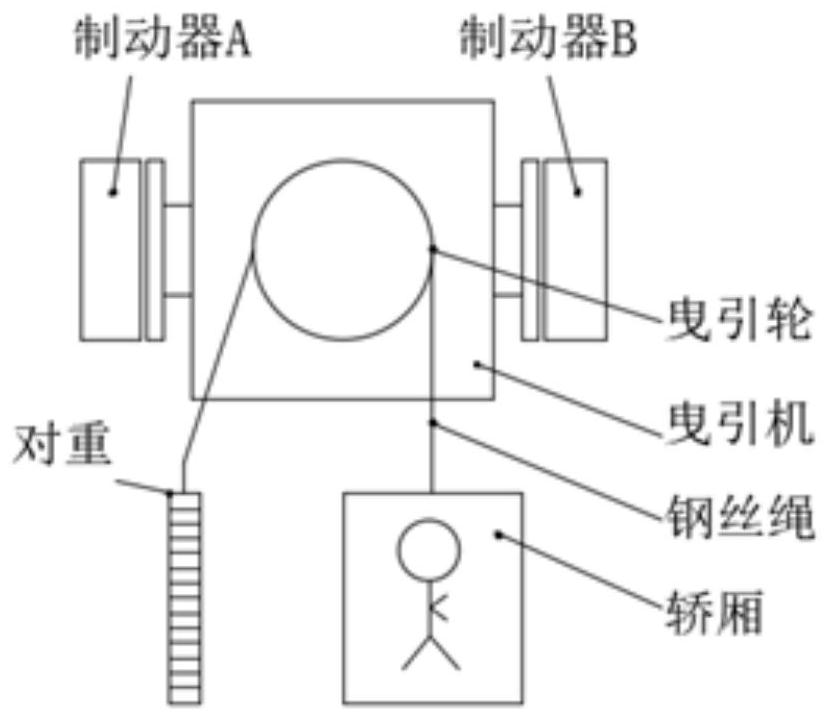

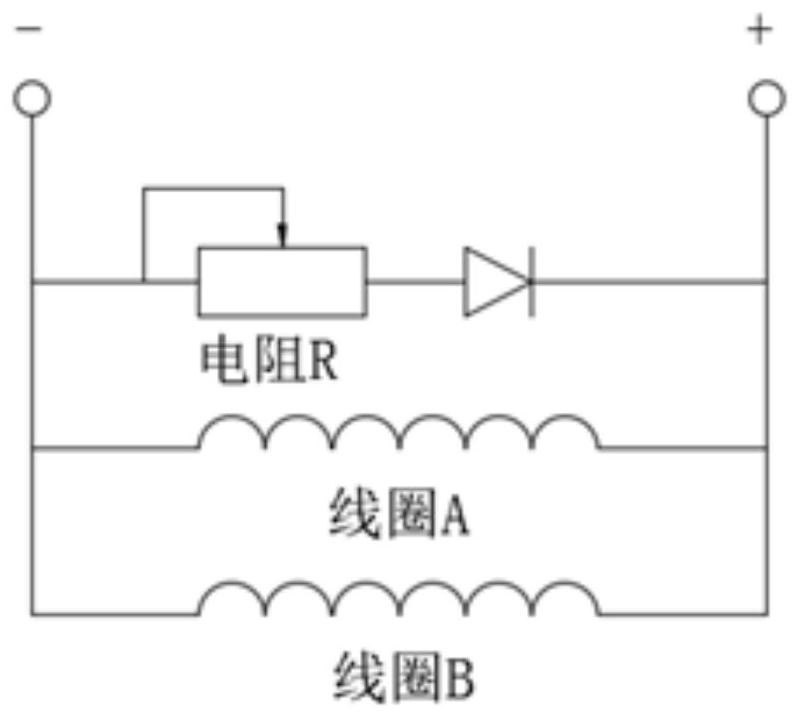

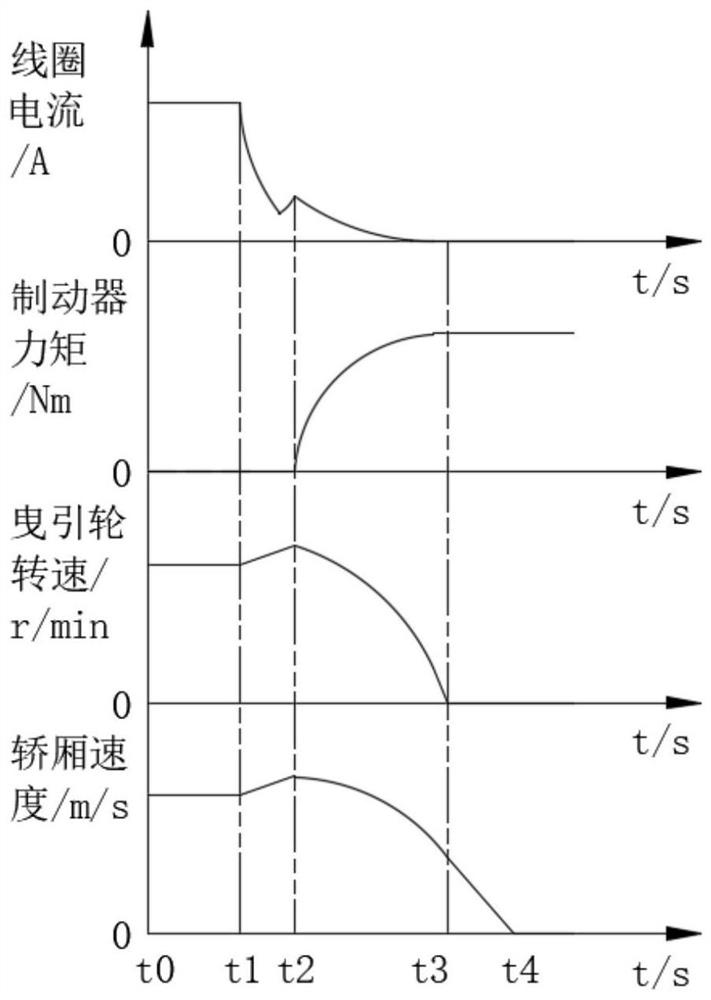

Elevator braking equipment, braking control method and device and storage medium

PendingCN112174009ASlow ascent rateReduce decelerationElevatorsHoisting equipmentsBrake torquePower grid

The invention relates to elevator braking equipment, a braking control method and device and a storage medium. The elevator braking equipment comprises a driving module and a plurality of brakes, thedriving module is connected with each brake, under the condition that a power grid power supply loses power, the driving module drives any brake to perform braking action, the driving module drives the other brake to perform a braking action after a preset duration to complete the driving, driving times are updated, and the driving module accumulates the driving times until each brake completes the braking action. According to the elevator braking equipment, all the brakes can conduct braking respectively, the braking torque is generated in advance in the mode that the braking torque is reduced by multiple times, and after preset time is delayed, the other group of brakes generates the braking torque again to conduct superimposed braking; therefore, the rising speed of the braking torque is reduced, the deceleration of a lift car under the condition of power loss is effectively reduced, and the impact degree on passengers is reduced; and meanwhile, abrasion of a steel wire rope and traction wheel parts is weakened, and the service life is prolonged.

Owner:HITACHI ELEVATOR GUANGZHOU

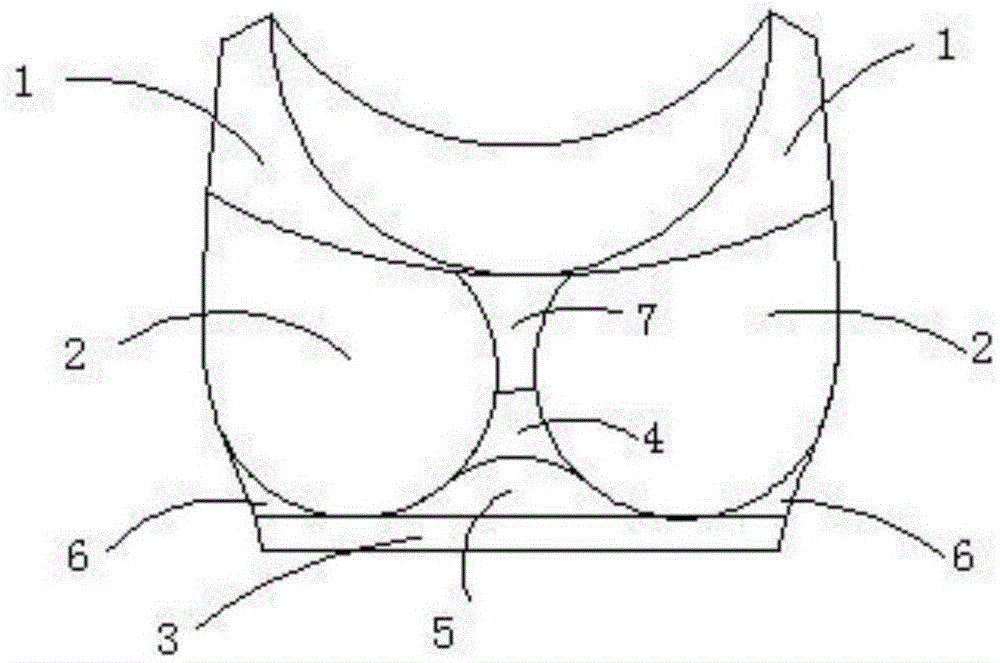

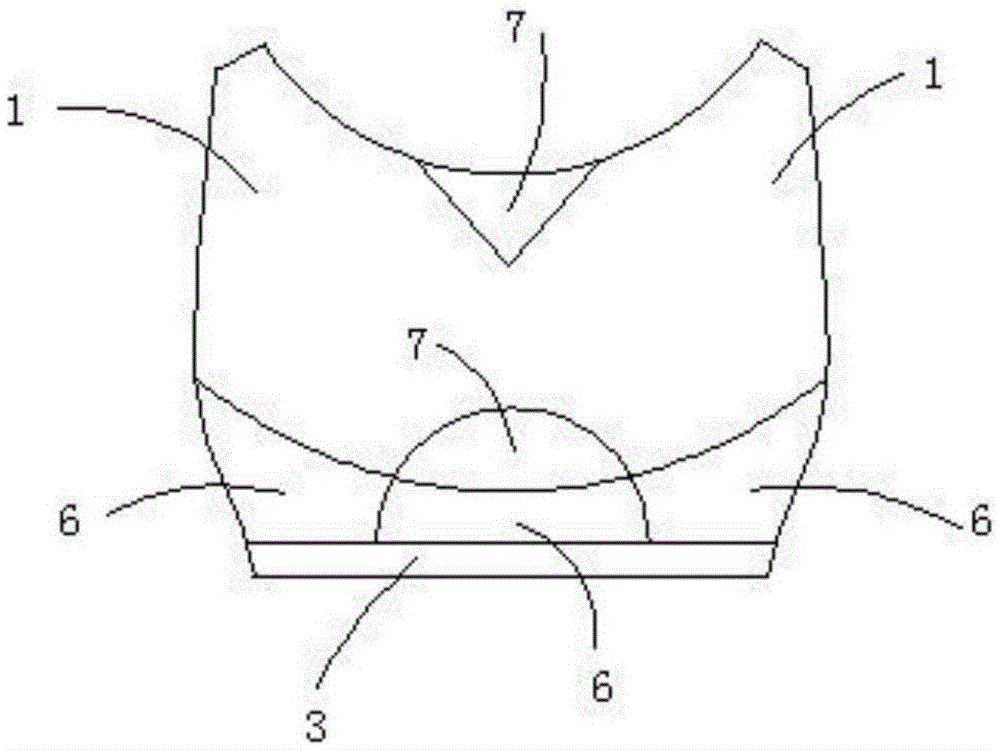

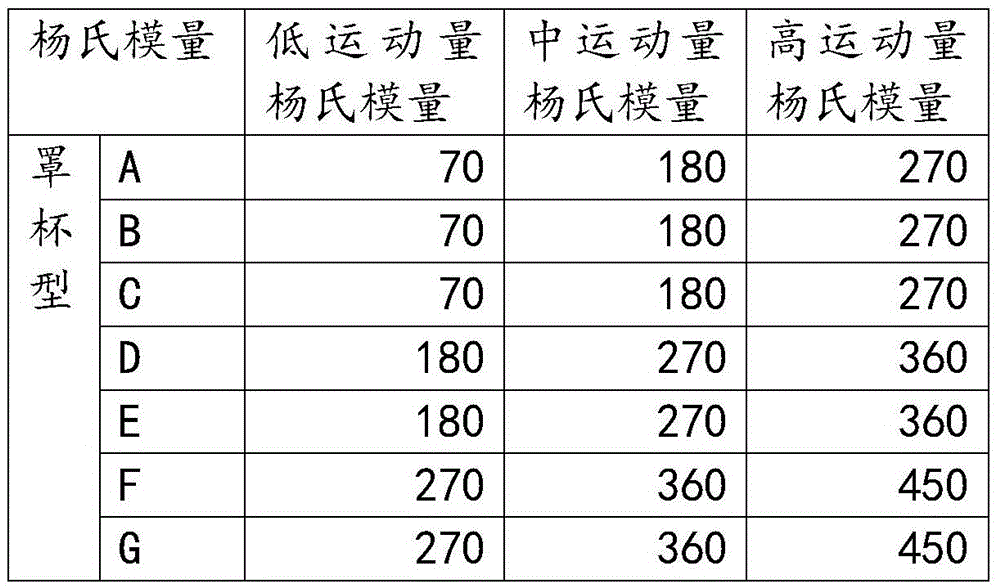

a sports bra

ActiveCN104770903BSolve the low heat dissipation efficiencyReduce displacementBrassieresHandkerchiefsLiquid waterEvaporation

A sports bra comprises two cups (2), shoulder straps (1), a bottom (3), a heart-shaped portion (4), a cloth joint (5), sides (6), and an auxiliary portion (7). The cups (2), the shoulder straps (1), the bottom (3), the heart-shaped portion (4), the cloth joint (5), the sides (6) and the auxiliary portion (7) are separately made of seven types of cloth with functions of dynamically absorbing or transferring sweat, composite indexes of dynamically transferring liquid water are greater than or equal to 3, and the seven types of cloth have different Young's moduli in different deformation quantities. Compared with a traditional bra that reduces displacement quantities of breasts in sports by means of a pressure or a modulus, the sports bra can automatically regulate the Young's modulus of a bra material according to breast displacement caused by different exercise intensities on the premise of keeping comfort or reducing sports injury as far as possible, can prevent or reduce damage to breasts due to high-intensity exercises, can improve the heat dissipation efficiency on the surface of skin of the breasts by effectively improving the transfer and evaporation efficiency of sweat in the bra, and delay the increase rate of the core temperature of a human body.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

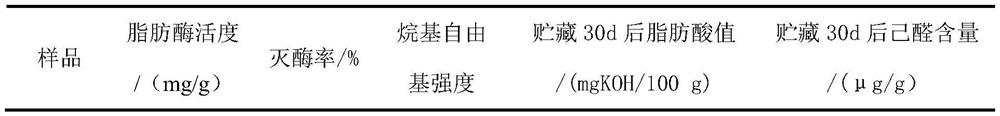

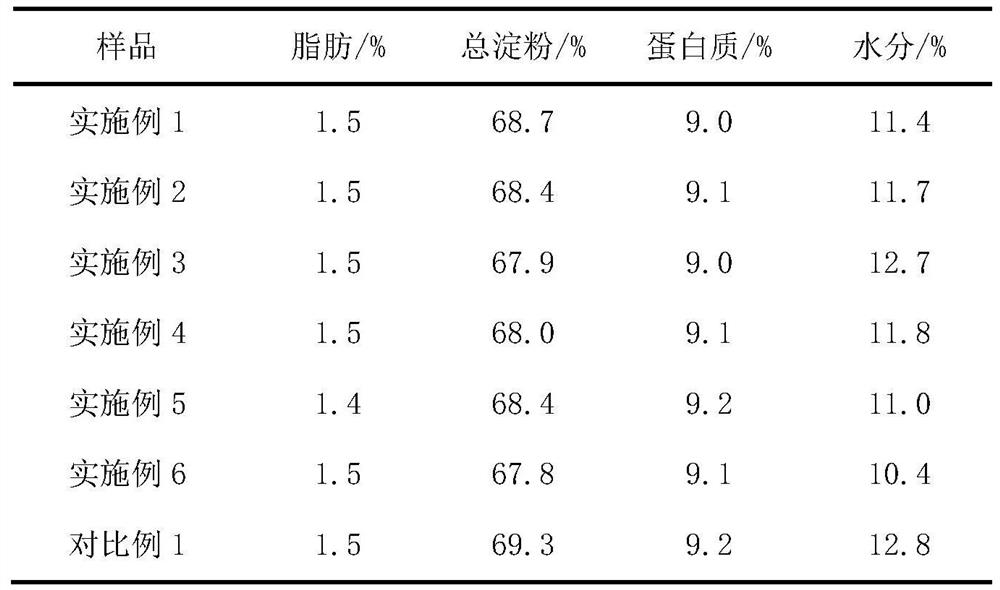

Processing method for improving storage stability of highland barley

ActiveCN113180104AReduce lipase activityGood storage stabilitySeed preservation by irradiation/electric treatmentAnimal scienceRadiofrequency heating

The invention relates to a processing method for improving the storage stability of highland barley, and belongs to the technical field of grain processing. The highland barley is treated by combining water replenishing and radio frequency heating, the treated highland barley sample is stored, the highland barley product which is moderately inactivated by lipase and relatively low in free radical strength is obtained by optimizing the target moisture content of water replenishing treatment and the temperature parameter of radio frequency treatment, and the highland barley product is good in quality and stable in storage. According to the highland barley processing method provided by the invention, the processing and storage cost of the highland barley is greatly reduced, and the nutrition and commercial value of the highland barley are improved.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com