High-temperature pressure sensor

A pressure sensor and high-temperature technology, applied in the direction of measuring fluid pressure, instruments, fluid pressure measurement by changing ohmic resistance, etc., can solve problems such as unreasonable structure, isolation failure, and failure to work normally, and achieve reliable and reasonable structure and slow down temperature The rate of rise, the effect of extending working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

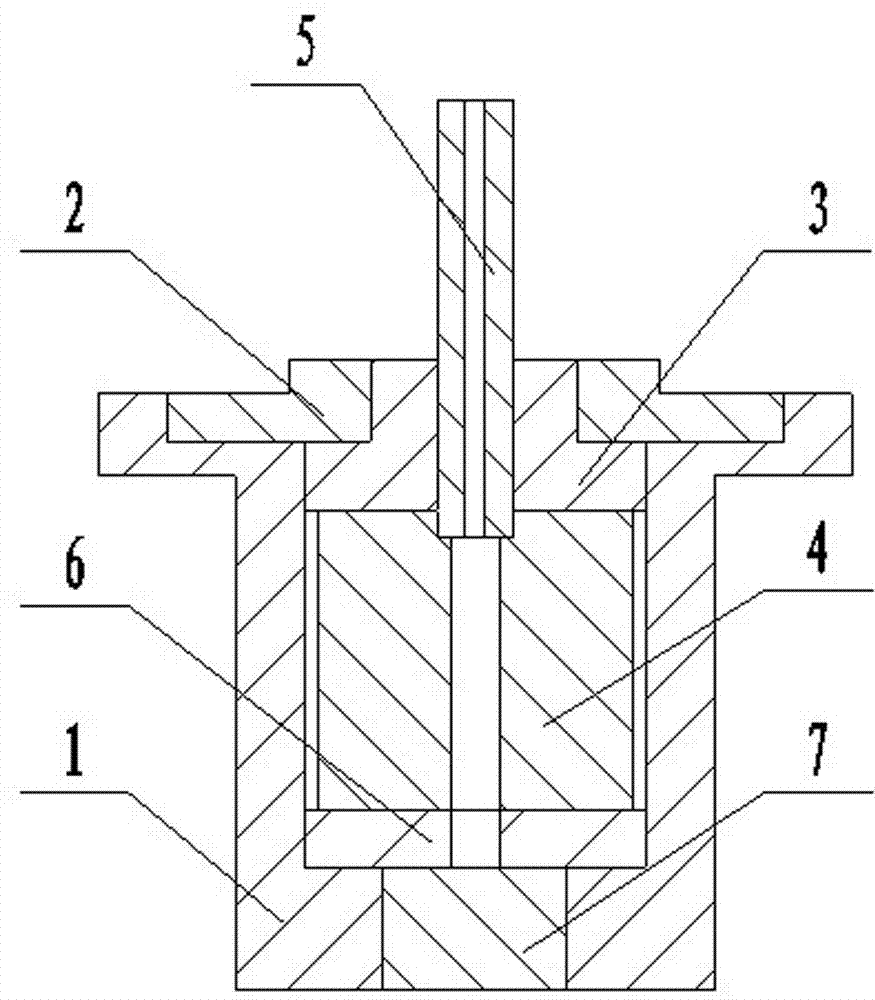

[0010] The high-temperature pressure sensor includes a cylindrical shell 1 with an open upper end. The upper end of the shell 1 is provided with an upper end cover 2 with a central hole. The lower surface of the ring 3 is provided with a heat sink body 4 with a gap with the inner wall of the housing 1 and a through hole in the center, and the upper end of the heat sink body 4 is fixed with a pressure introduction tube 5 communicating with the through hole and passing through the upper heat insulating ring 3 , between the heat sink body 4 and the inner wall of the lower end of the housing 1, there is a lower heat insulating ring 6 in contact with the two, the inner wall of the lower end of the housing 1 is provided with a groove, and the through hole communicating with the heat sink body 4 is placed in the groove Pressure sensor body 7. The shell 1 is made of stainless steel; the upper heat insulating ring 3 is made of microcrystalline mica machinable ceramic material; the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com