Astringency removing equipment for Carya dabieshanensis processing

A hickory and equipment technology, applied in the field of astringent removal equipment for processing Dabie Mountain hickory, can solve the problems of low steam efficiency, low processing efficiency, waste of resources and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

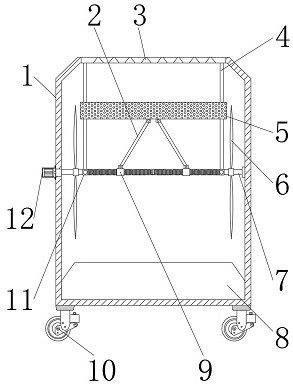

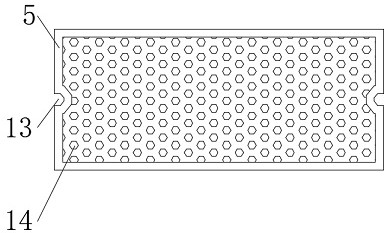

[0024] like Figure 1-2 As shown, the embodiment of the present invention provides a deastringent device for processing Dabie pecans, including a processing box body 1, a steam generating box 8, a universal wheel 10 and a servo motor 12, and the servo motor 12 penetrates the side wall of the processing box body 1. It extends to its interior and is fixedly connected with a transmission threaded rod 7. The end of the transmission threaded rod 7 away from the servo motor 12 is rotatably connected to the inner wall of the work box body 1 through a bearing. The outer surface of the transmission threaded rod 7 is threadedly sleeved with two transmissions. Threaded sleeve 9, the two transmission thread sleeves 9 are symmetrically distributed about the outer surface of the transmission thread rod 7, and the transmission thread on the outer surface of the transmission thread rod 7 is divided into two sections with opposite directions of rotation and equal lengths. The top of the sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com