Patents

Literature

33results about How to "Improve the efficiency of waste heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

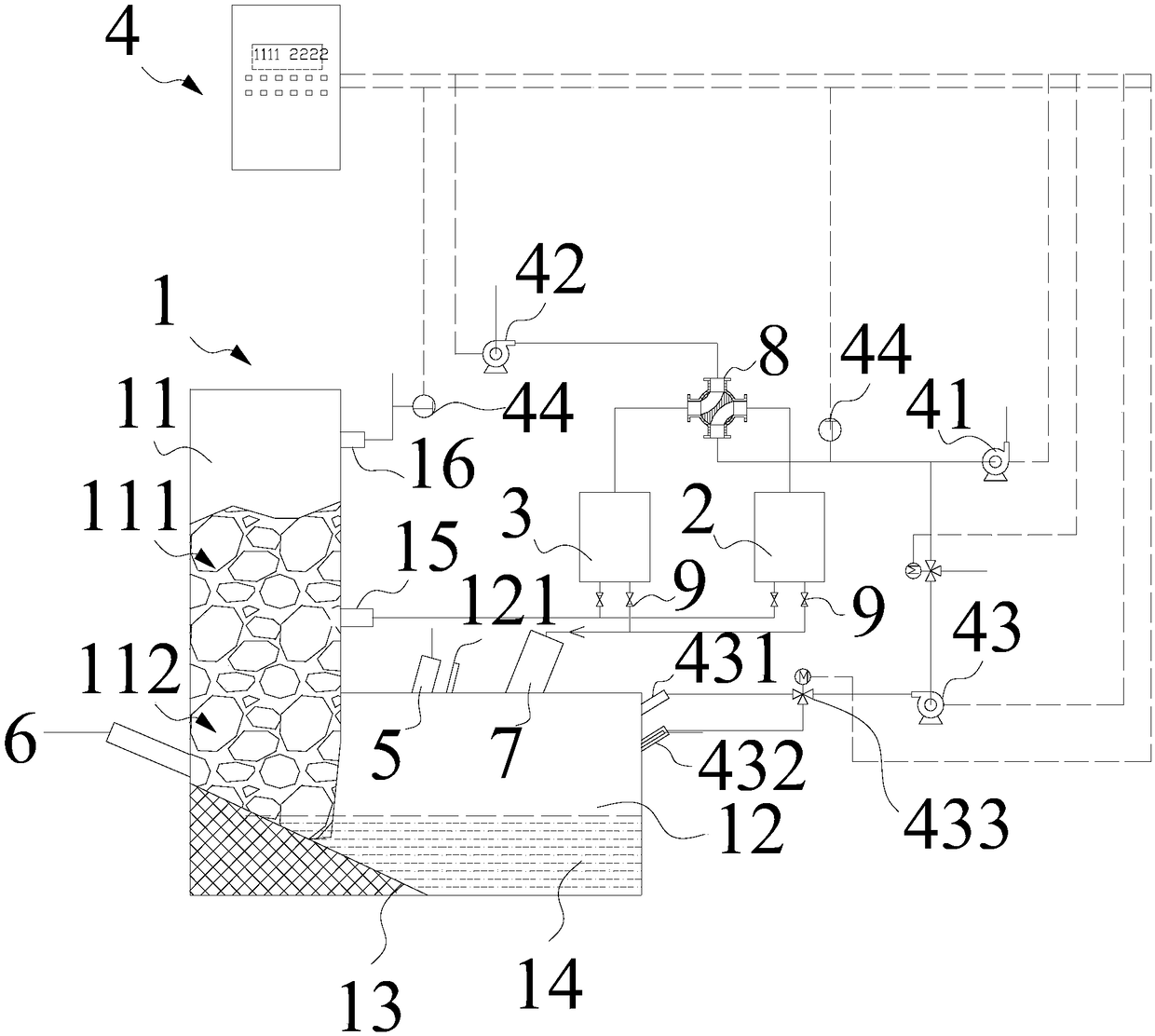

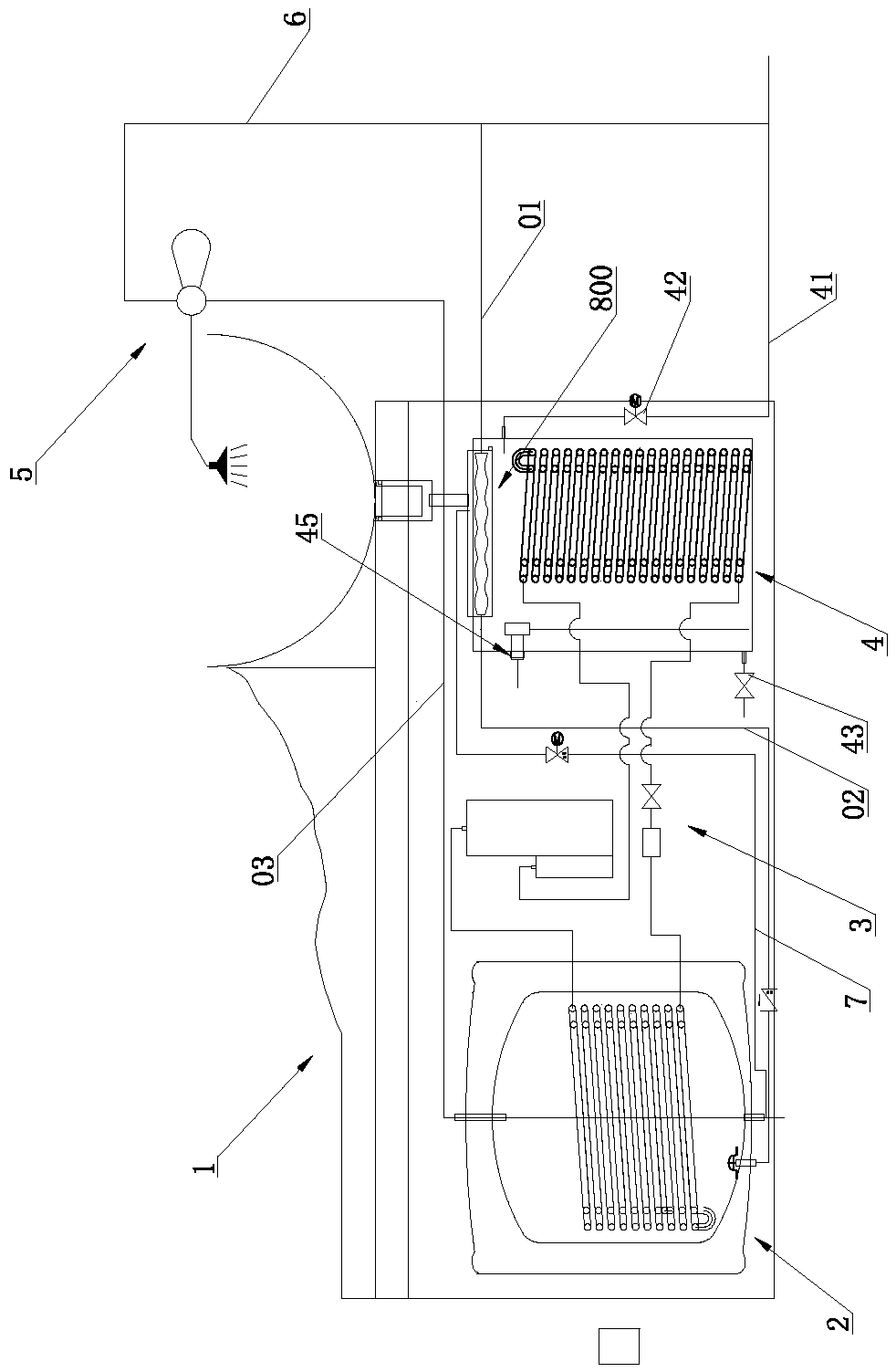

Two-stage expansion jet type waste heat recovery system of internal combustion engine

ActiveCN103670626AImprove the efficiency of waste heat recoveryReduce outlet back pressureInternal combustion piston enginesExhaust apparatusIntercoolerEvaporator

Owner:TIANJIN UNIV

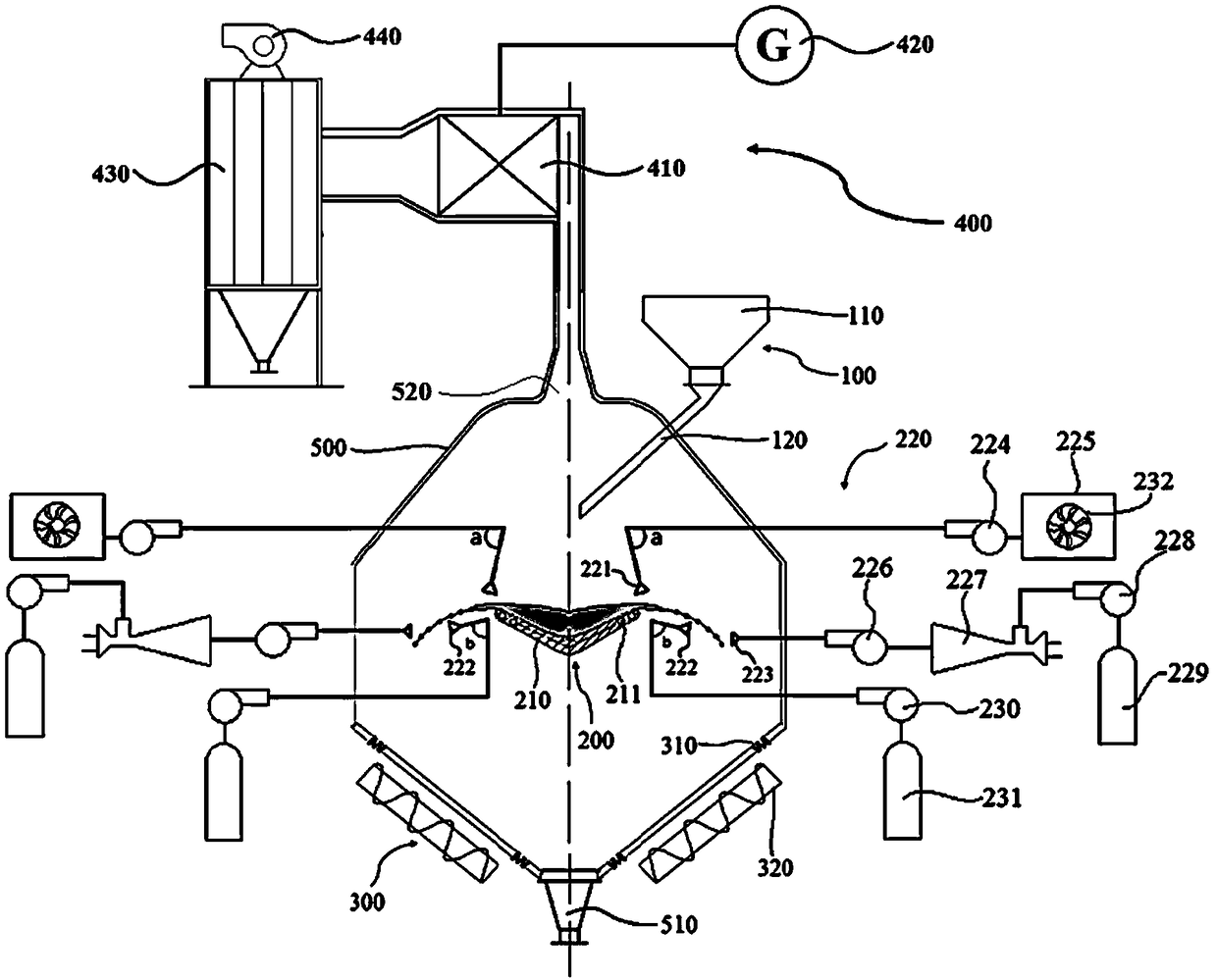

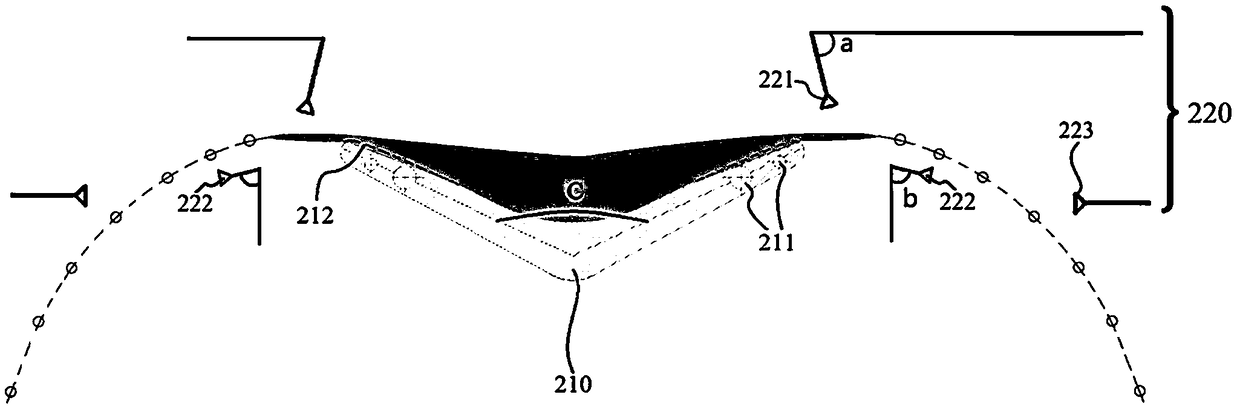

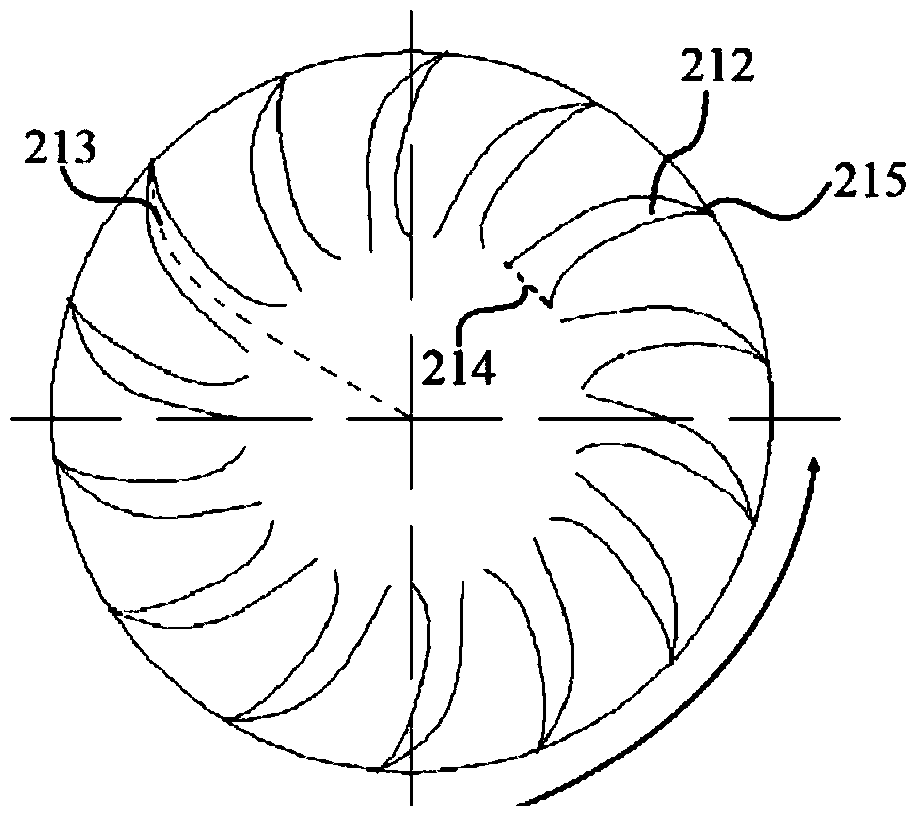

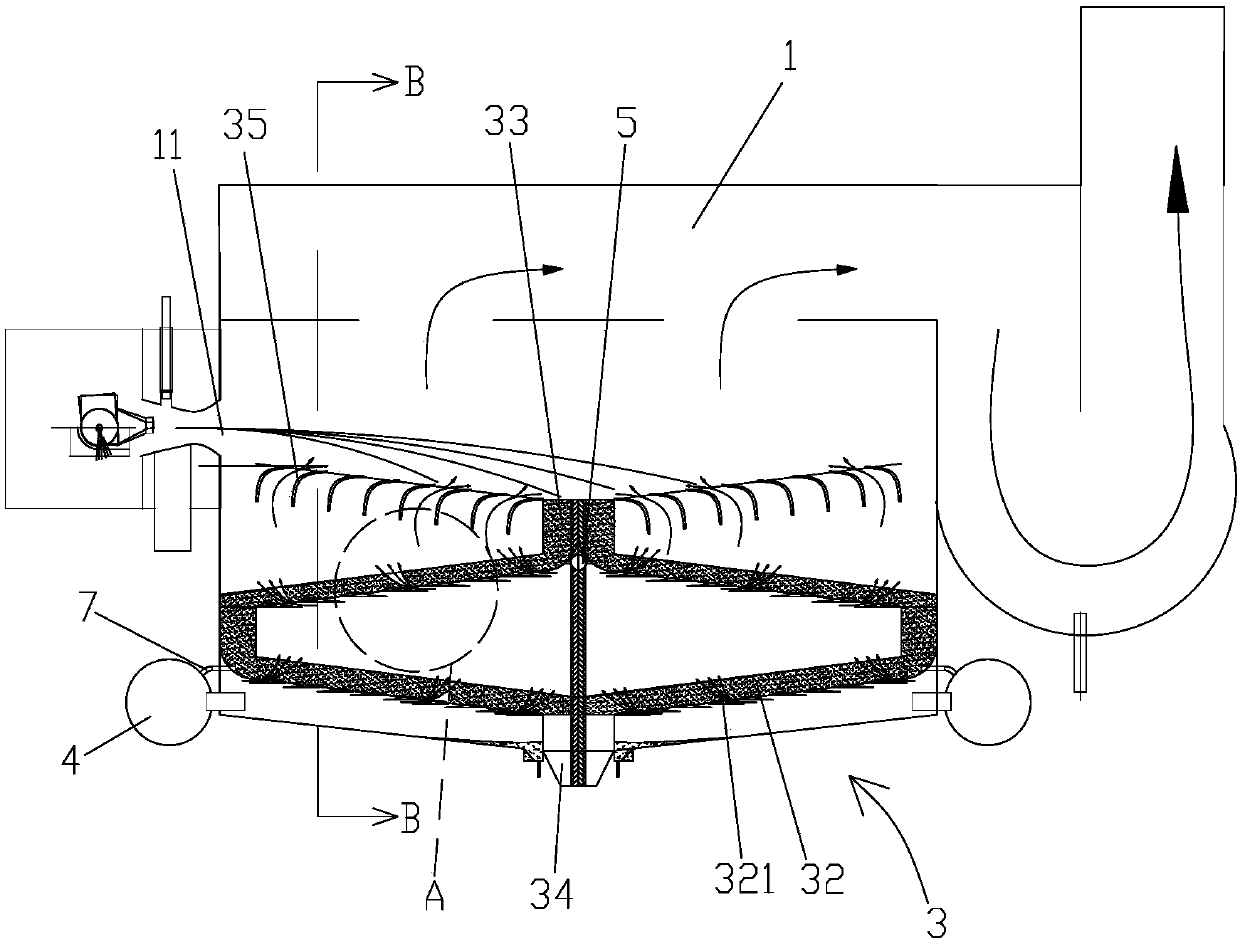

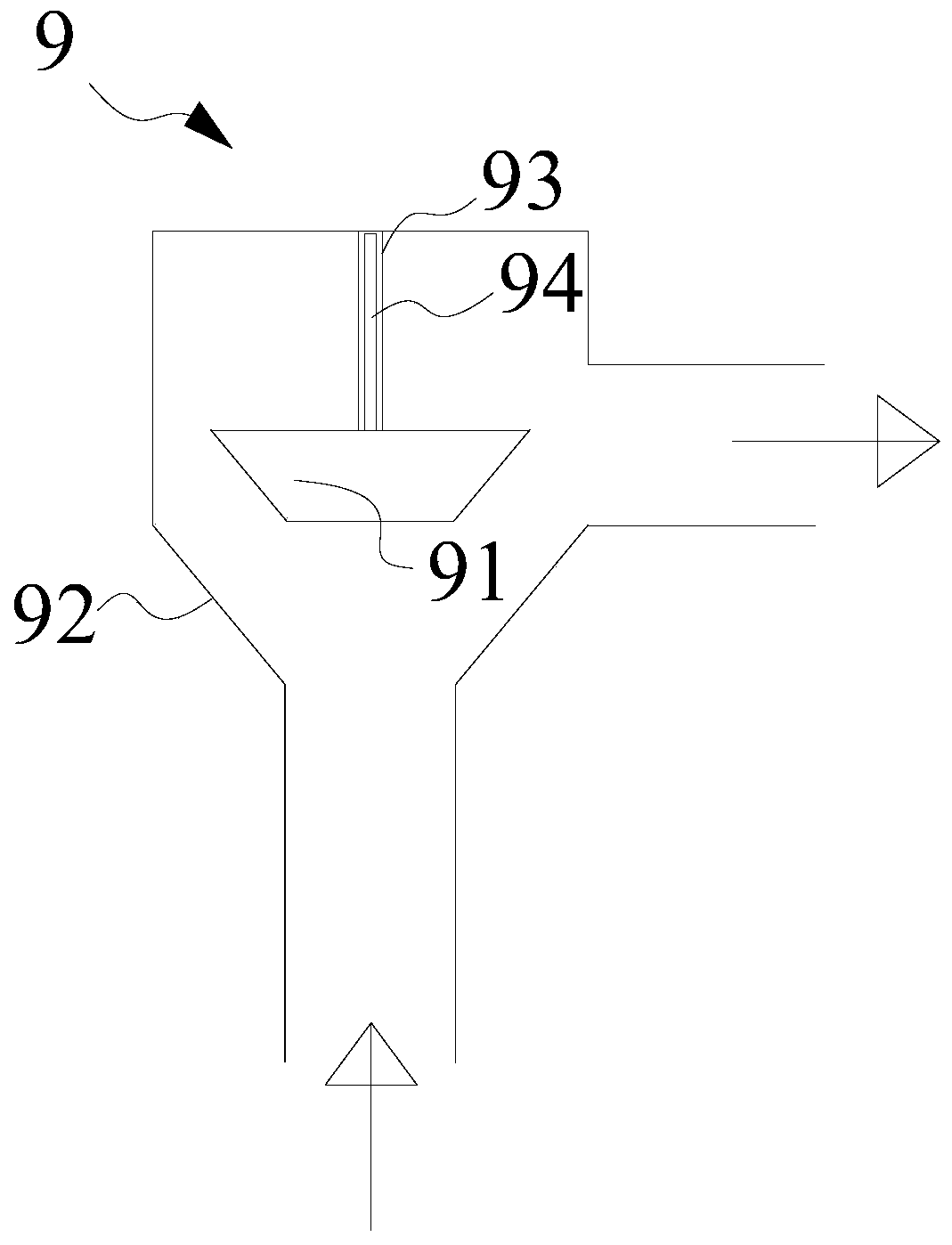

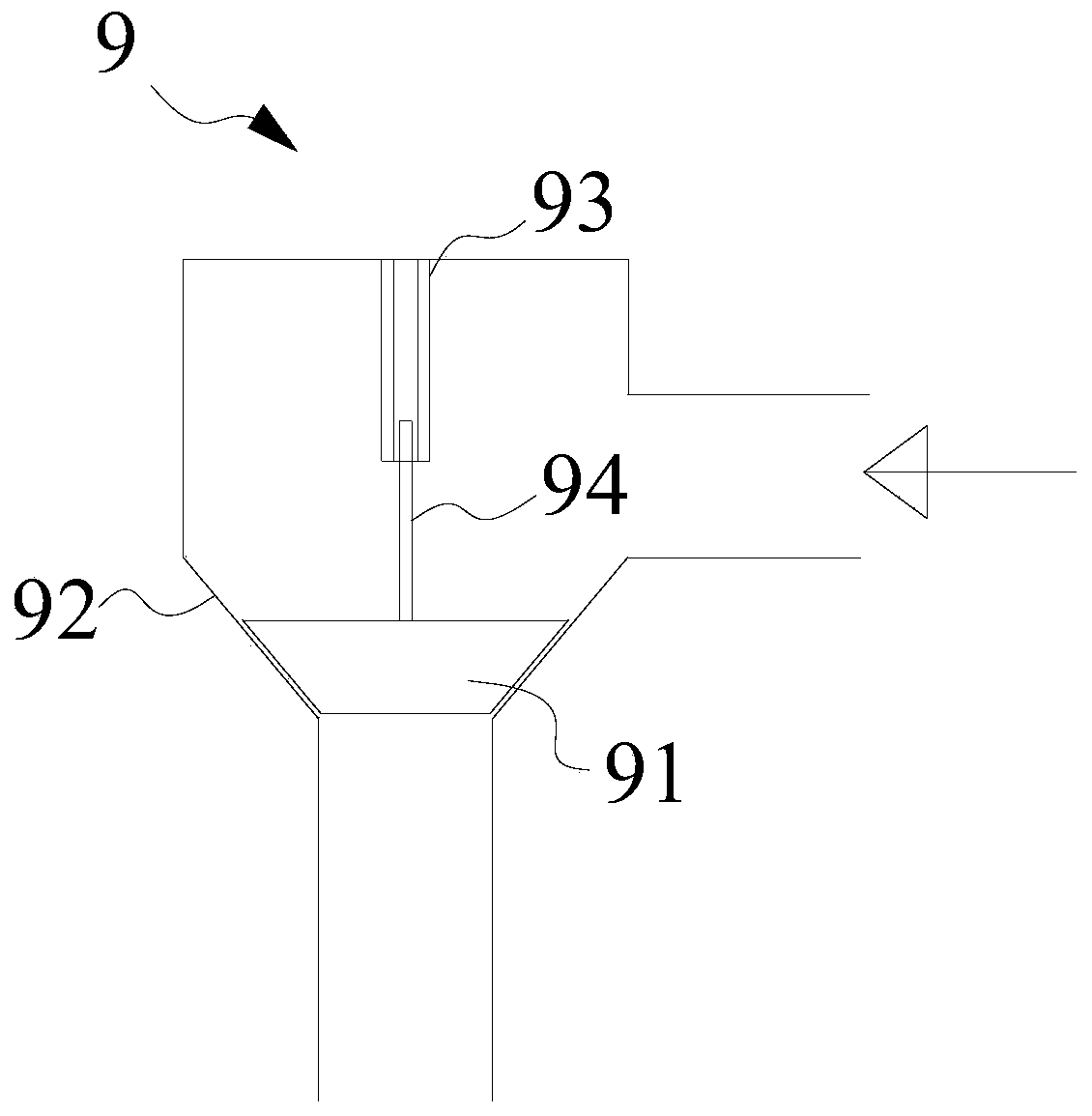

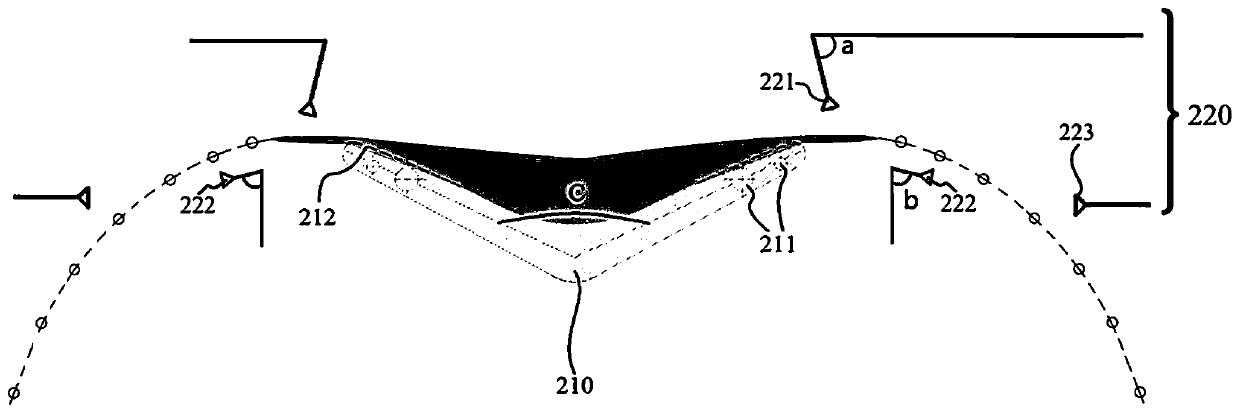

Method of blast furnace slag granulation and waste heat recovery

ActiveCN108796147AInhibition formationImprove liquidityIncreasing energy efficiencyRecycling and recovery technologiesWater vaporSlag

The invention discloses a method of blast furnace slag granulation and waste heat recovery, and belongs to the technical field of blast furnace slag utilization. The method of the blast furnace slag granulation and the waste heat recovery comprises the following steps that blast furnace slag on a rotary slag disk move to the edge position of the rotary slag disk in the process of rotating, heatingelement of the rotary slag disk carries out heating and heat prevention to the blast furnace slag to enable the blast furnace slag to maintain a higher temperature, thus the blast furnace slag has better liquidity, then the forming of a slag film is restrained to facilitate the granularity of granulated slag diminishing; A cooling mechanism cools the blast furnace slag after the blast furnace slag breaking away from the rotary slag disk, the blast furnace slag after cooling forms the granulated slag; meanwhile, cooling water ejected from the cooling mechanism is heated by the blast furnace slag to gasify and generate water vapor, the water vapor enters into a heat transfer unit through an outlet of the granulated slag, the water vapor carries out heat transfer processing and waste-heat utilization in the heat transfer unit, and the use ratio of energy sources is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

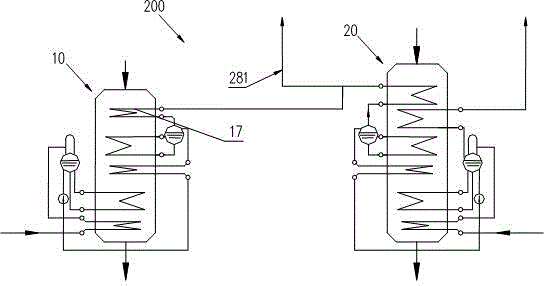

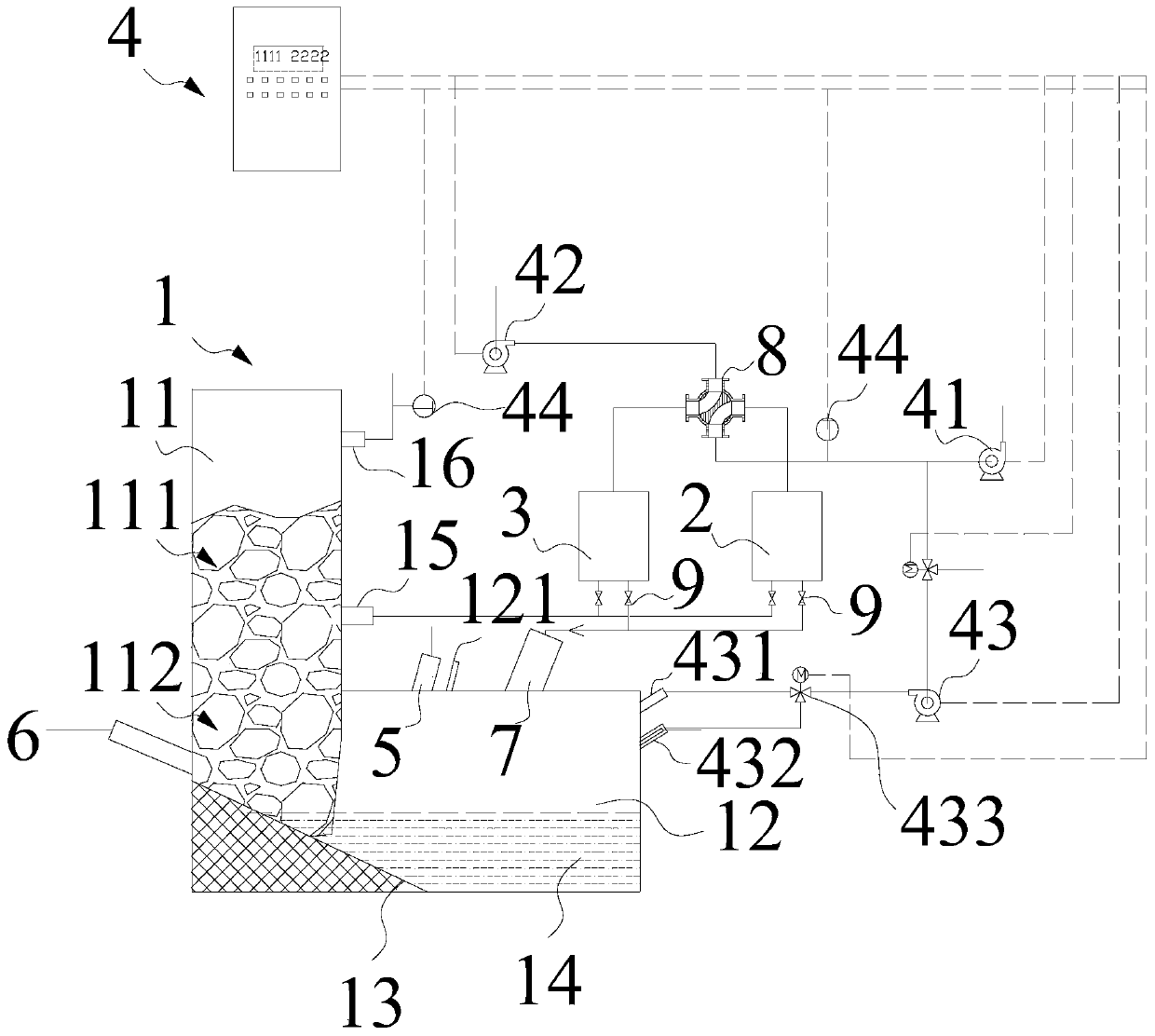

Energy-saving combustion and waste heat recovery system of quick aluminum melting furnace

ActiveCN108800957AImprove recycling efficiencyGuaranteed temperatureIncreasing energy efficiencyWaste heat treatmentCombustion systemWaste heat recovery unit

The invention provides an energy-saving combustion and waste heat recovery system of a quick aluminum melting furnace. The energy-saving combustion and waste heat recovery system of the quick aluminummelting furnace comprises a furnace body, a combustion system and a waste heat recovery system. The furnace body comprises a vertical melting furnace and a transverse holding furnace. The combustionsystem comprises a first fuel spray nozzle, an ignition nozzle and an air spray nozzle, wherein the air spray nozzle is used for guiding the preheated air into the holding furnace in the mode that thepreheated air serves as the combustion-supporting gas. The waste heat recovery system comprises a first heat storage chamber, a second heat storage chamber and a reversing device. The purposes that the heat storage chamber on one side stores the waste heat generated by combustion of the melting furnace, the heat storage chamber on the other side preheats the combustion-supporting gas of the holding furnace, and the operation is alternatively conducted according to the preset time cycle are achieved. The problems that in the prior art, a melting furnace and a holding furnace are low in waste heat recovery efficiency and high in the waste heat recovery difficulty, and due to the fact that the combustion temperature in the melting furnace is high, thermal power type NOX is prone to being generated when the air serves as the combustion-supporting gas are effectively solved, the overall energy consumption of the combustion system is reduced, the flue gas of the system is effectively balanced, and the waste heat recovery efficiency is improved.

Owner:HUATIAN ENG & TECH CORP MCC +1

Method for waste heat recovery and utilization of roasted alumina

InactiveCN102849766AImprove the efficiency of waste heat recoveryReduce heat pollutionEnergy inputAluminium oxide/hydroxide preparationCycloneRed mud

The invention relates to a method for the waste heat recovery and utilization of roasted alumina. The method includes subjecting the high-temperature alumina subjected to the primary cooling by a roasting furnace multistage cyclone cooling system to air fluidized cooling in a double-chamber fluidized cooler, and cooling with a cooling medium. When the cooling medium is the unqualified condensed water from an alumina production system, it is heated in the double-chamber fluidized cooler, and the obtained hot water is used to wash aluminum hydroxide, or wash fine seeds; when the cooling medium is evaporative water cooler drainage water or red mud storage space return water, it is heated in the double-chamber fluidized cooler, and the obtained hot water is used to wash red mud; and the unqualified condensed water, the evaporative water cooler drainage water and the red mud storage space return water are not used as the cooling medium of the double-chamber fluidized cooler simultaneously. The invention improves the waste heat recovery efficiency of the roasting furnace system, reduces the energy consumption of the whole system, reduces the thermal pollution of the roasting system, reduces the construction investment, and reduces the running cost of the system.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Waste heat recovery device for sintering machine and circulating cooling machine

ActiveCN102980412AImprove qualityImprove functional abilityEnergy industryIncreasing energy efficiencyWaste heat recovery unitSuperheater

The invention relates to a waste heat recovery device for a sintering machine and a circulating cooling machine. The waste heat recovery device comprises a waste heat boiler of the sintering machine and a waste heat boiler of the circulating cooling machine. The waste heat boiler of the sintering machine comprises a waste heat boiler drum of the sintering machine, wherein the waste heat boiler drum of the sintering machine is provided with a steam outlet of the waste heat boiler of the sintering machine. The waste heat boiler of the circulating cooling machine comprises a waste heat boiler drum of the circulating cooling machine and a medium-pressure superheater. The waste heat boiler drum of the circulating cooling machine comprises a steam outlet of the waste heat boiler of the circulating cooling machine, wherein the steam outlet of the waste heat boiler of the sintering machine is connected with the steam outlet of the waste heat boiler of the circulating cooling machine, and the steam outlet of the waste heat boiler of the circulating cooling machine is connected with the medium-pressure superheater. According to the waste heat recovery device for the sintering machine and the circulating cooling machine in the structure provided by the invention, the quality of steam is effectively improved and the power capacity of a steam turbine is improved, so that the waste heat recovery rate is improved.

Owner:HARBIN GUANGHAN POWER TECH DEV CO LTD

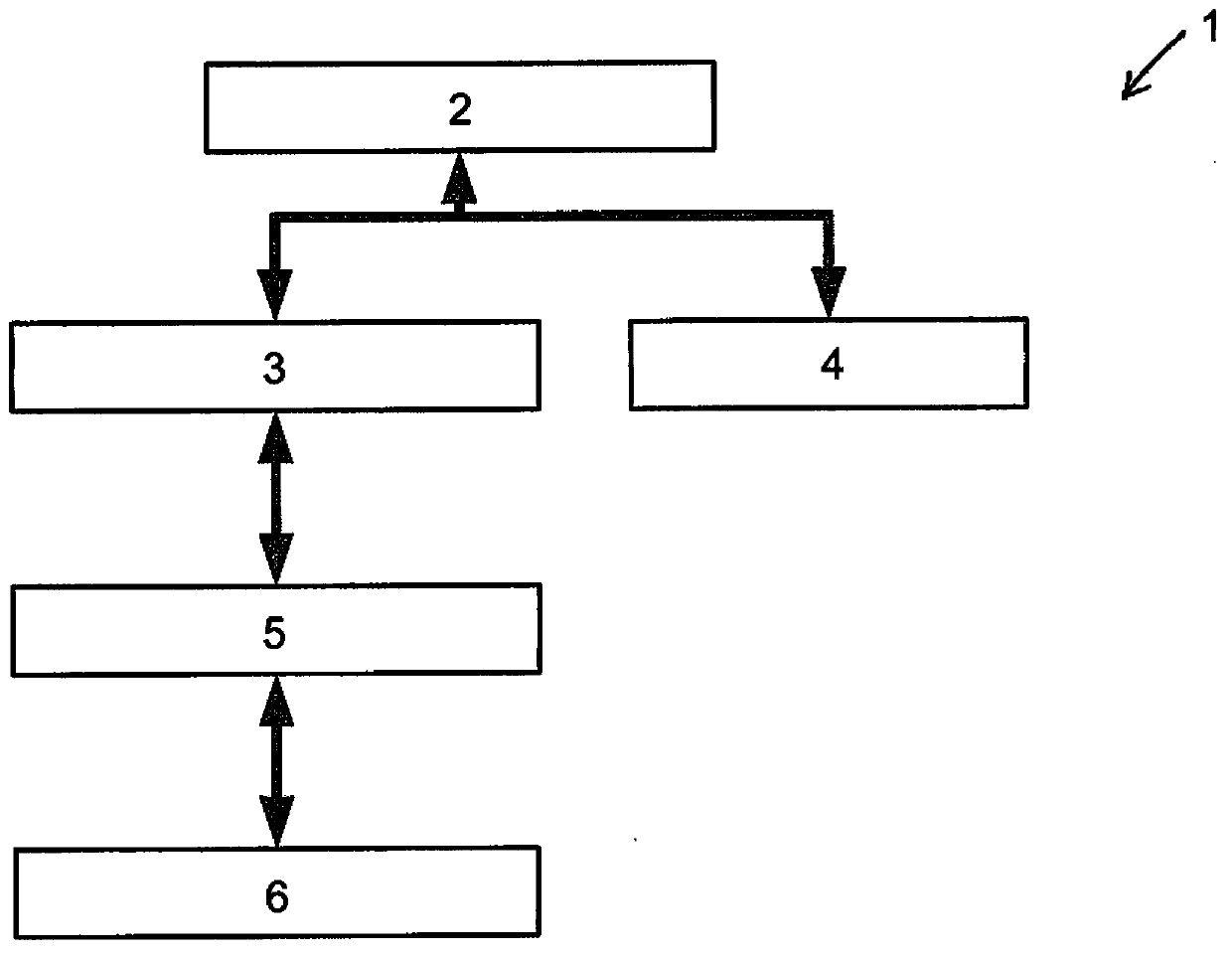

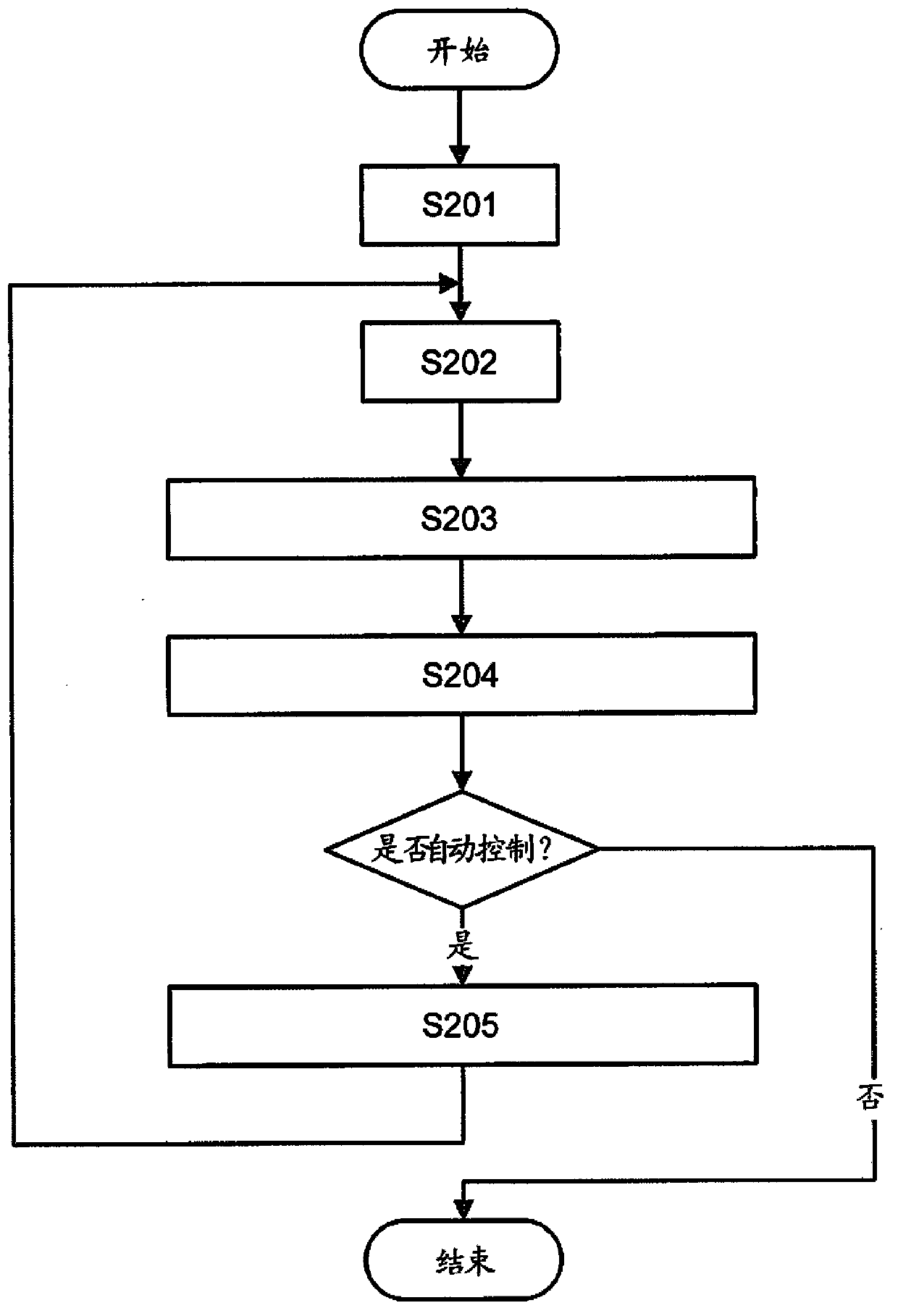

Tail air box control system of sintering machine

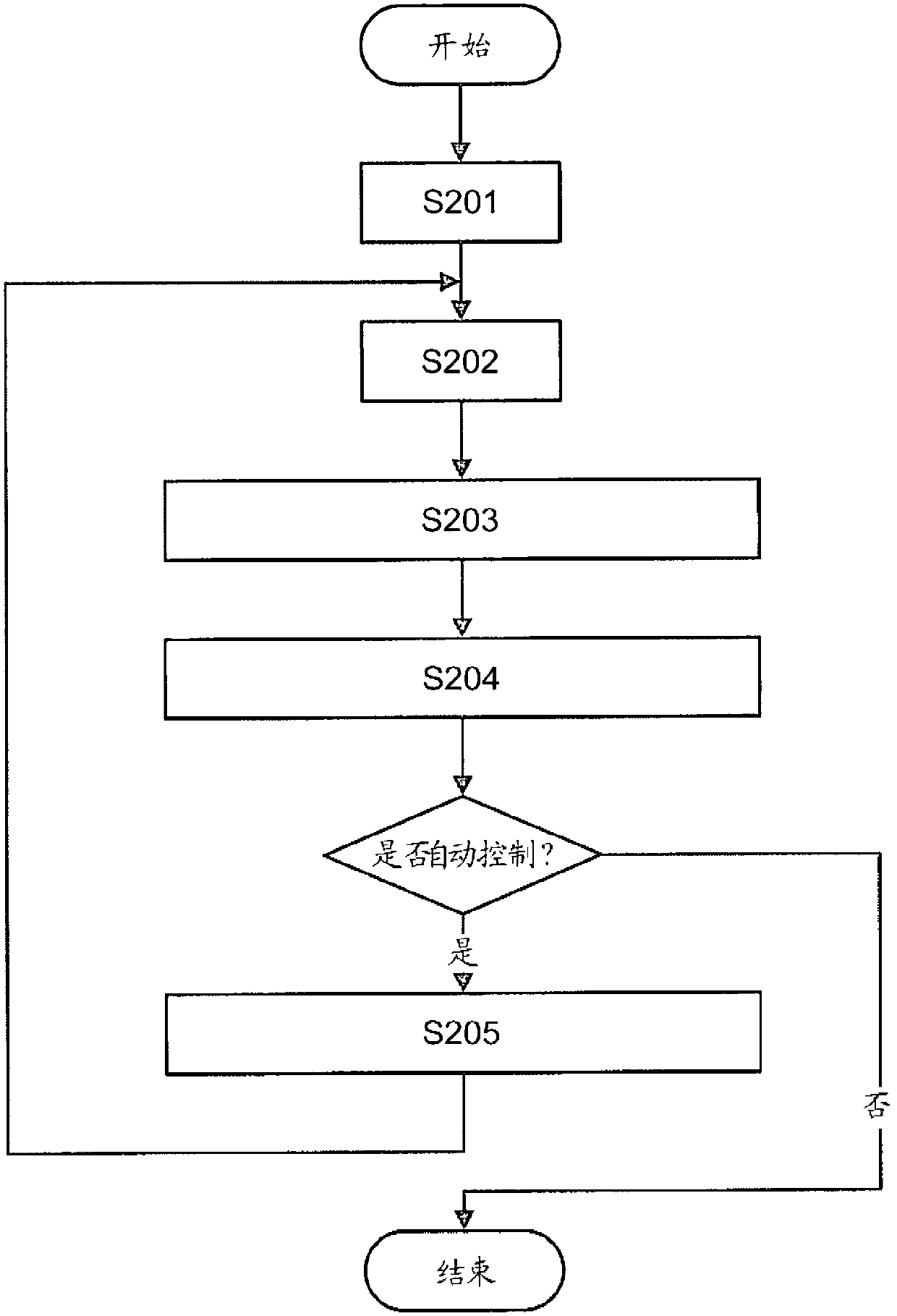

The invention relates to a tail air box control system of a sintering machine, which is characterized by comprising a real-time process data communicator, a tail air box throttle control system of the sintering machine, a control terminal, a sintering machine PLC control system and tail air box throttle control equipment of the sintering machine, wherein the real-time process data communicator, the tail air box throttle control system of the sintering machine and the control terminal realize information share by using a computer network technique; the sintering machine PLC control system and the tail air box throttle control equipment of the sintering machine are communicated with the real-time process data communicator; the sintering machine PLC control system is communicated with the tail air box throttle control equipment of the sintering machine, and the tail air box throttle control equipment of the sintering machine is used for realizing automatic closed-loop control on the air box opening of a sintering machine tail air box on the basis of signals coming from the ail air box throttle control system of the sintering machine.

Owner:吕斌

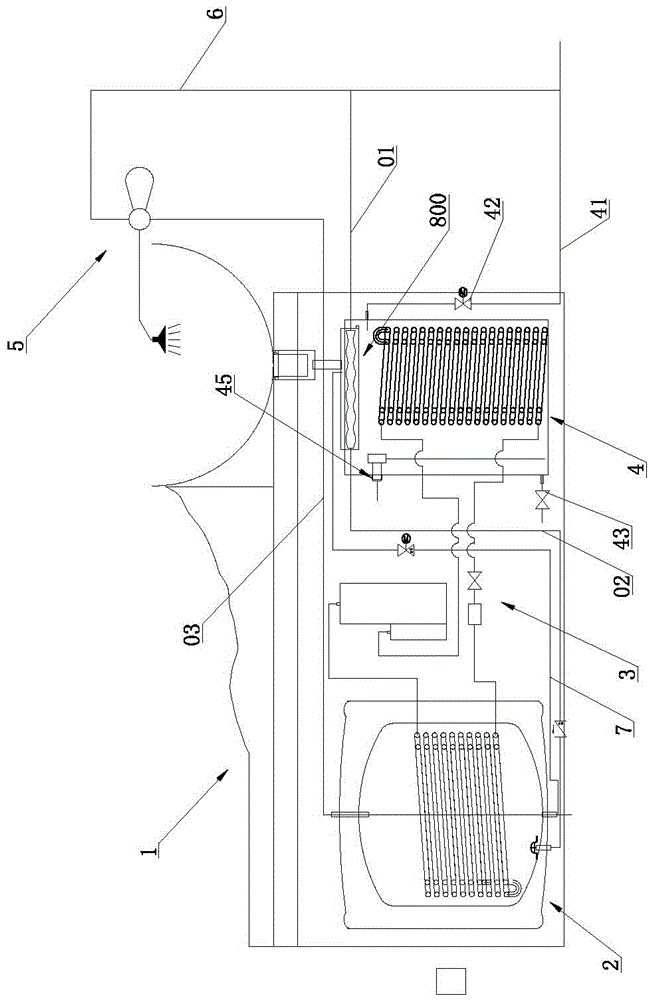

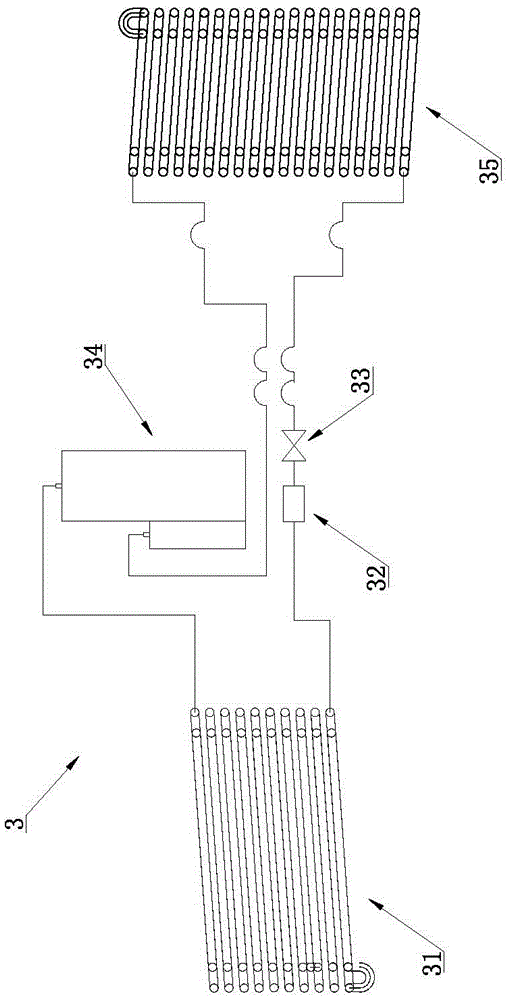

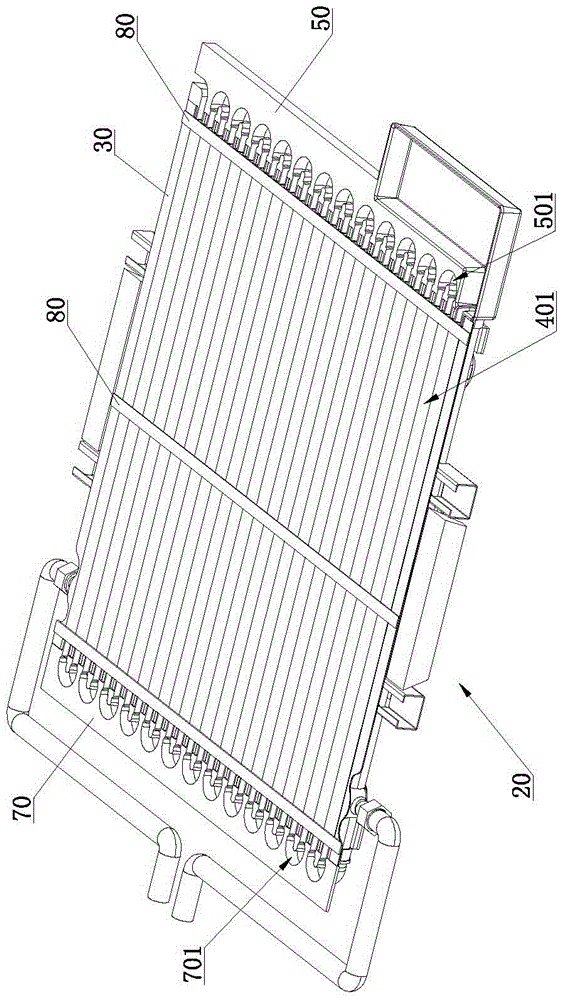

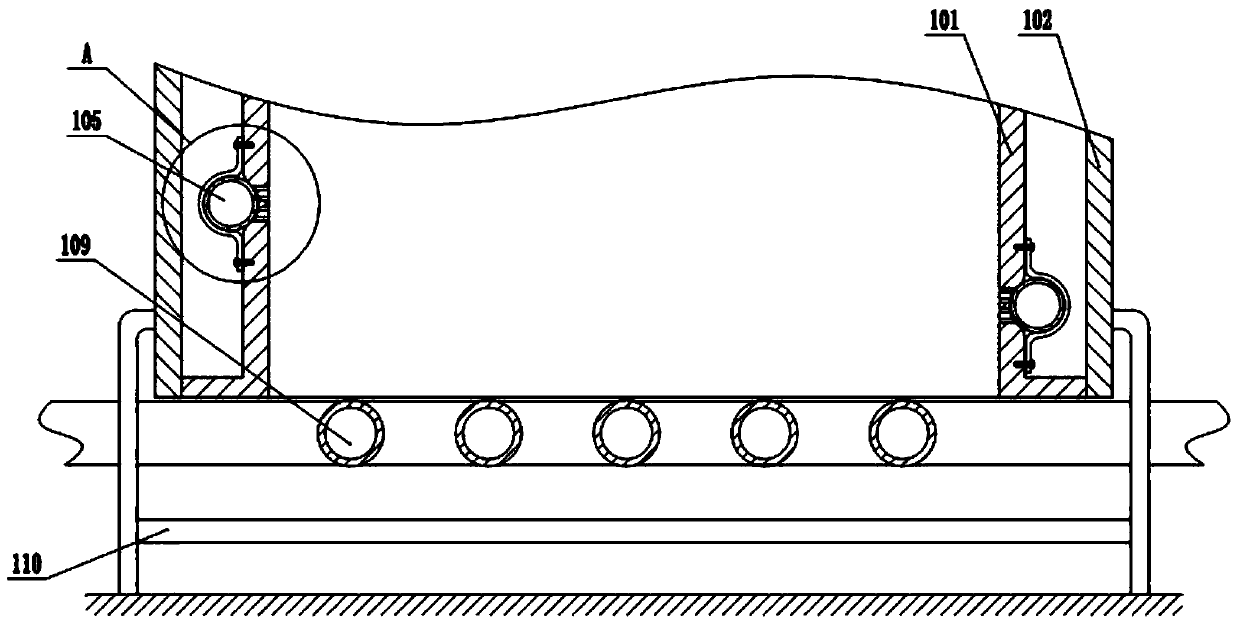

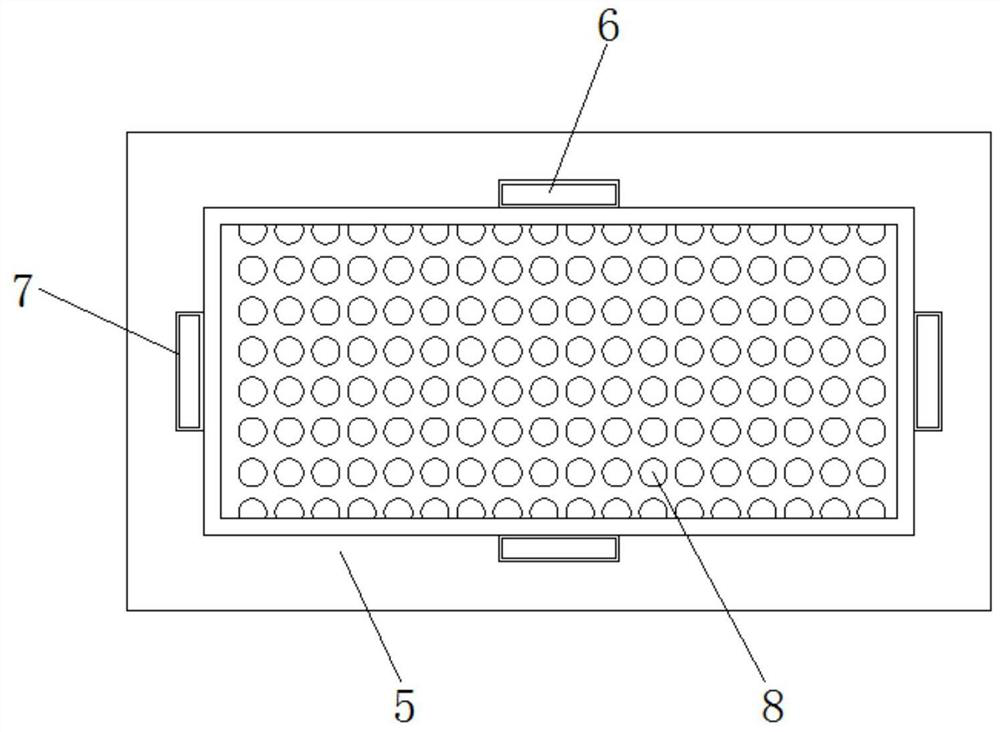

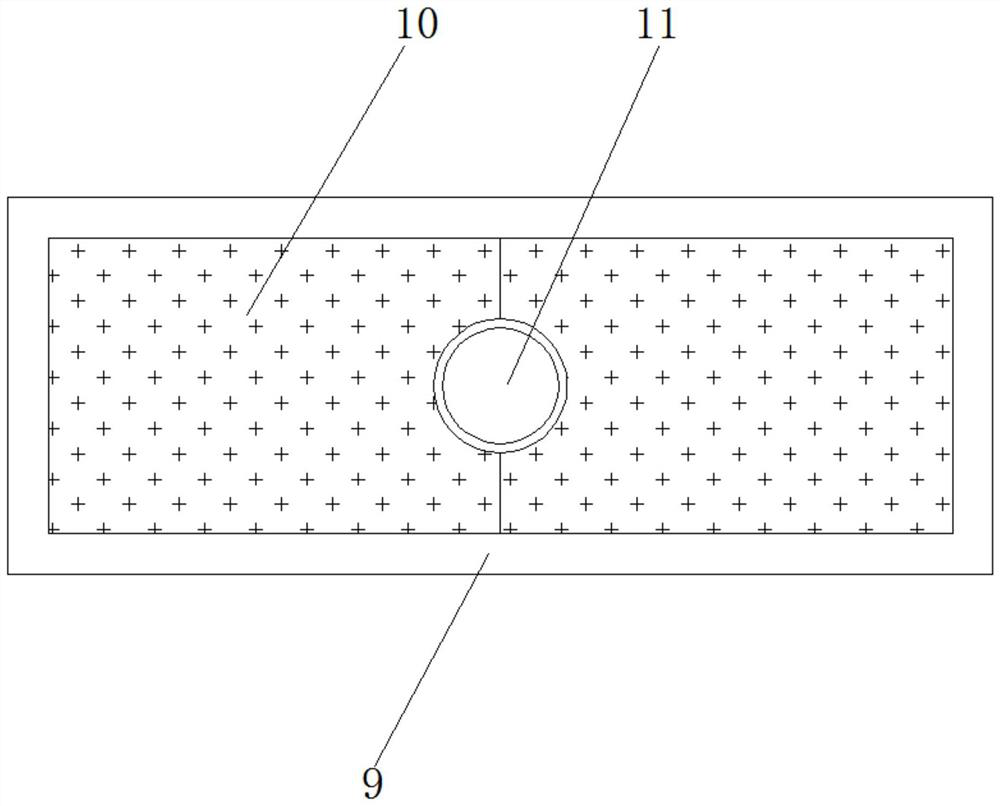

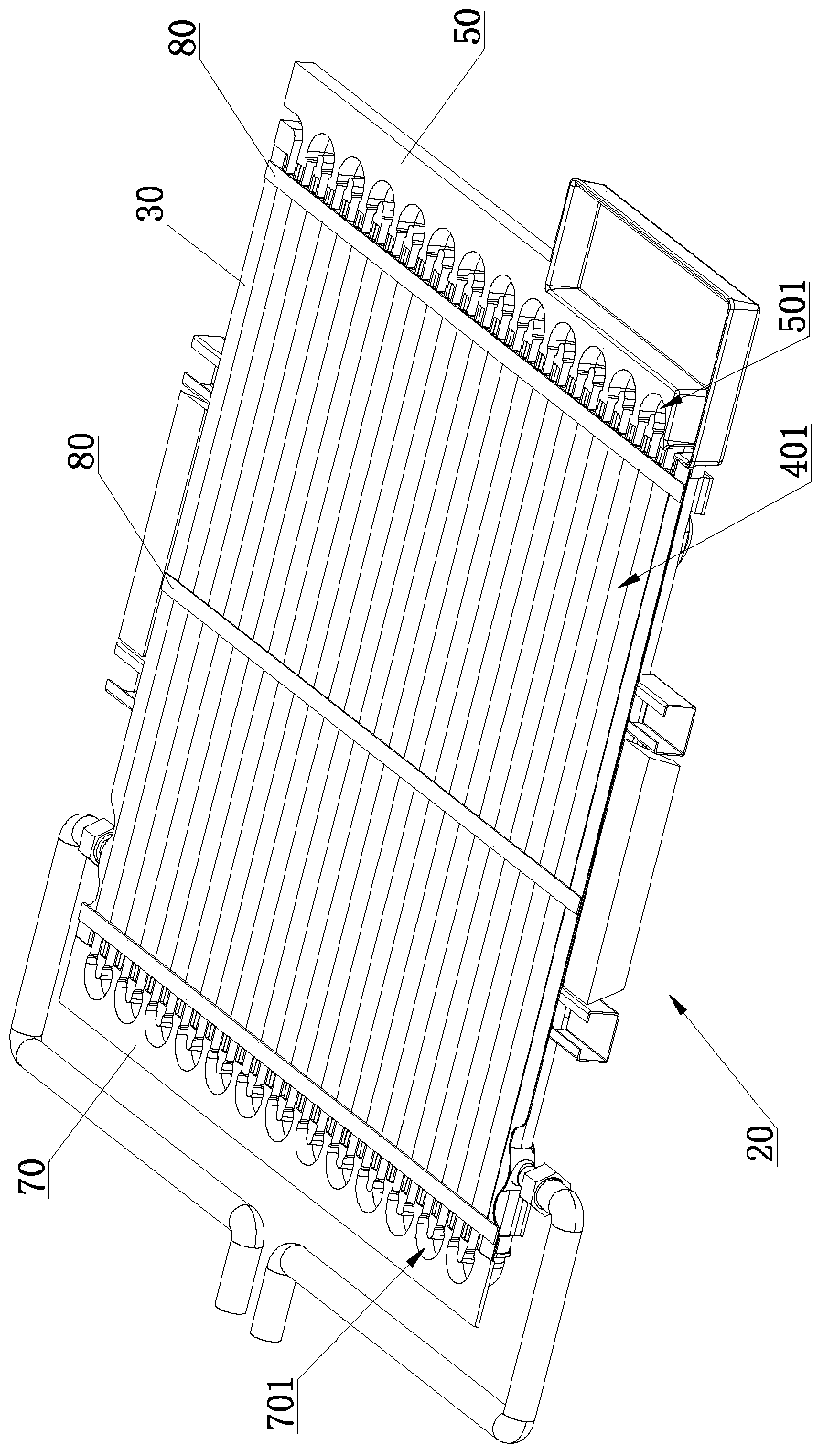

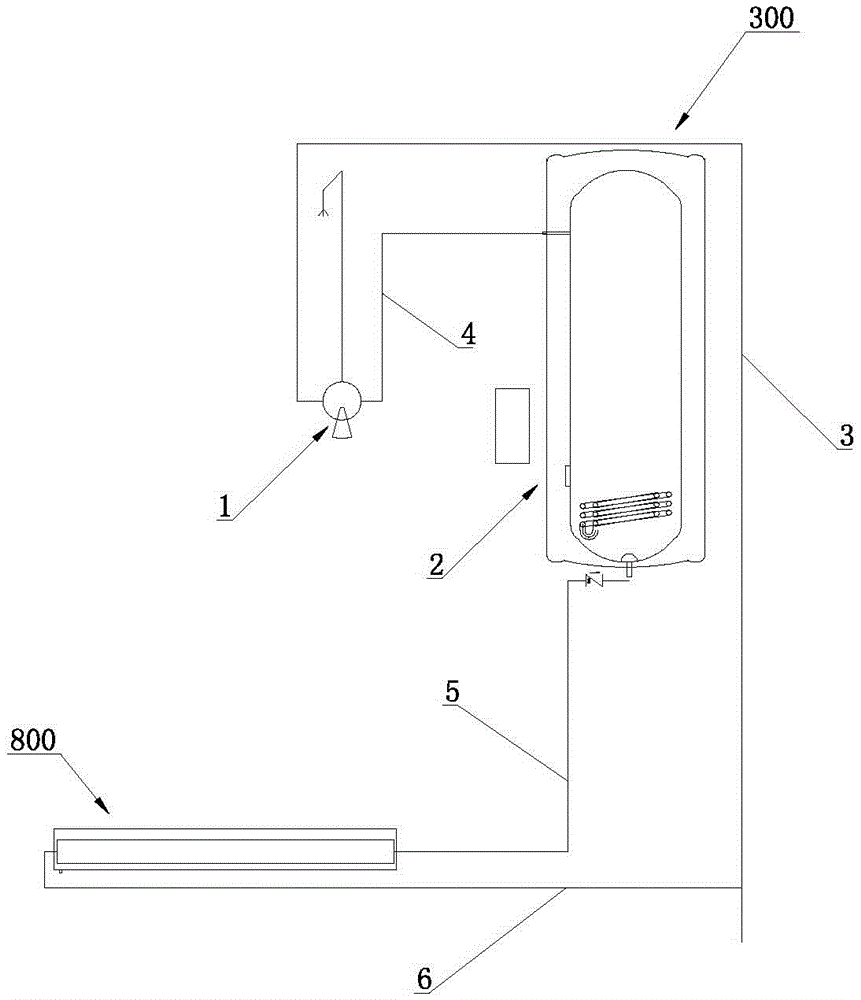

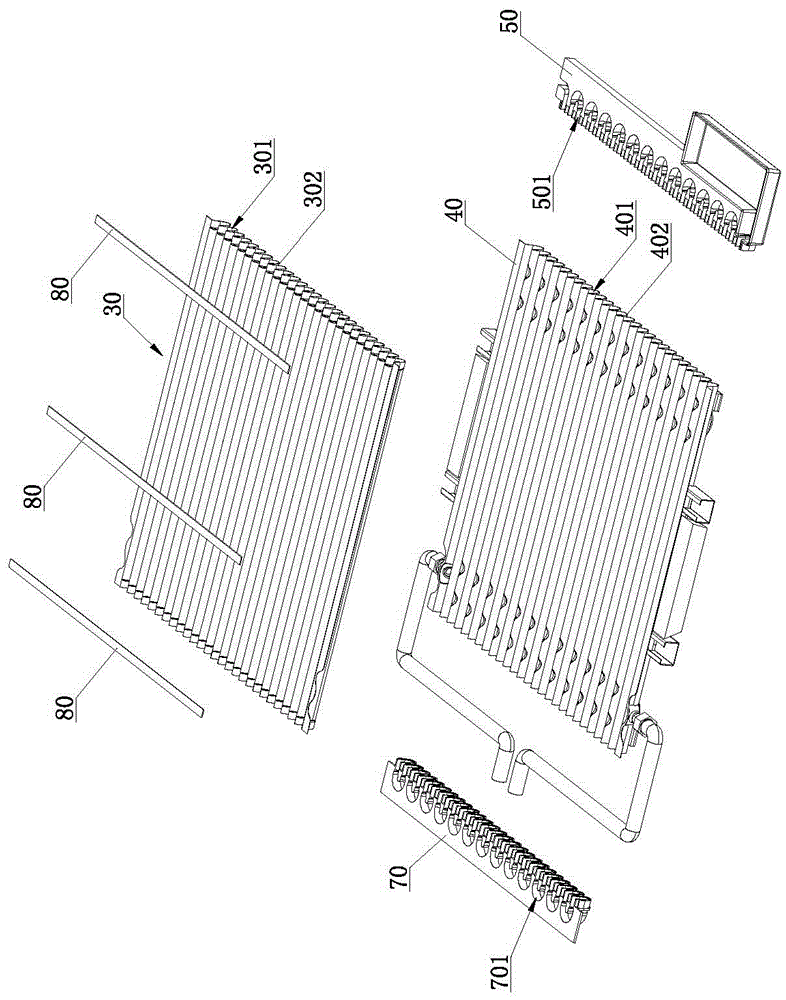

Tube-on-sheet heat exchanger type shampoo bed

ActiveCN106323040ACompact structureEasy to installStationary conduit assembliesHair cleaningLower gradeEngineering

The invention relates to the technical field of shampoo beds, in particular to a tube-on-sheet heat exchanger type shampoo bed. The tube-on-sheet heat exchanger type shampoo bed comprises a shampoo bed body, a hot water tank, a heating device for heating water in the hot water tank, a water mixing valve assembly communicated with the hot water tank and a cold water inlet pipe communicated with the water mixing valve assembly and further comprises a tube-on-sheet heat exchanger and a heat exchange water inlet pipe. The tube-on-sheet heat exchanger type shampoo bed can recover hygienic hot water waste heat immediately and low-grade fluid heat, saves energy and is environmentally friendly, the energy consumption caused by tap water heating is reduced, resources are saved, and the usage cost is reduced. The plate A and the plate B are combined to form the core body by adopting sheet pipe structures, the overall smoothness of a plate A sinking tank is good, sewage is smooth to flow, and the problem of remarkable reduction of the heat transfer coefficient due to dirt blockage and sedimentation is avoided. In addition, tap water is good in heat absorption effect in a medium channel, and the waste water and tap water heat exchange effect is good.

Owner:东莞市康源节能科技有限公司

Waste heat recovery equipment for die heating furnace

PendingCN107449287ATake advantage ofReduce waste of resourcesIncreasing energy efficiencyWaste heat treatmentWaste heat recovery unitFlue gas

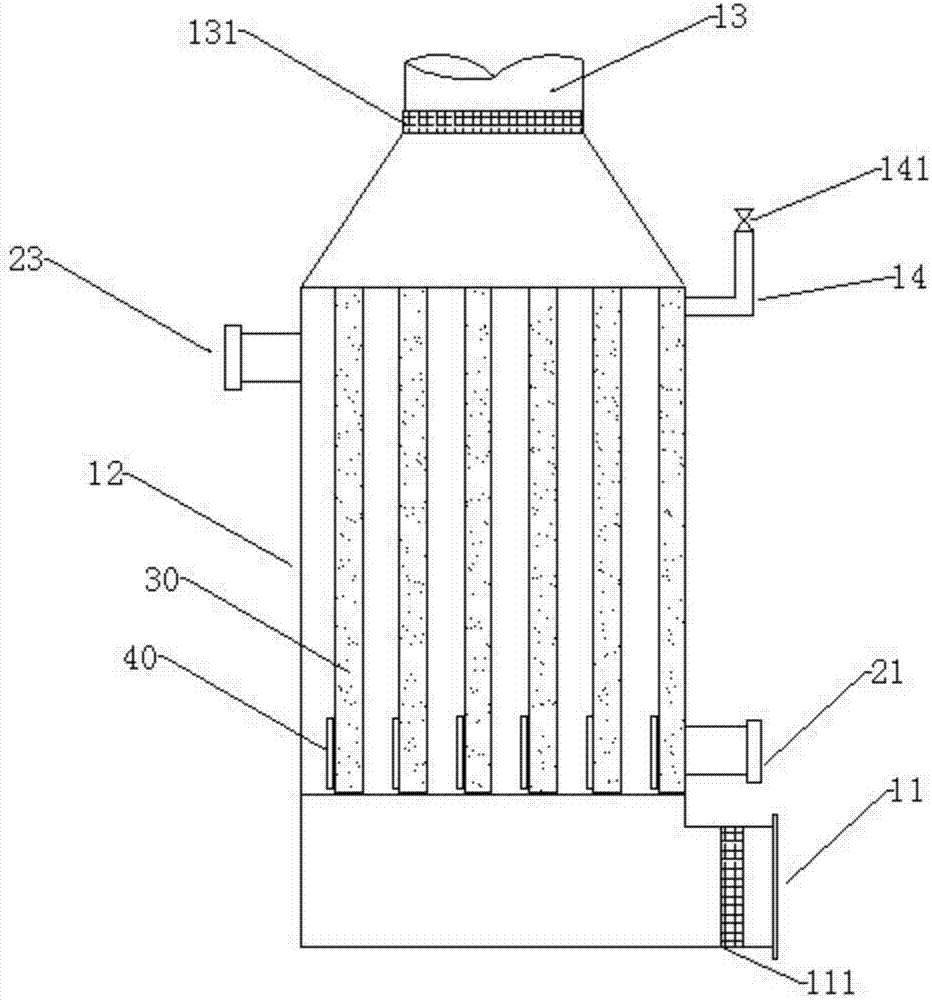

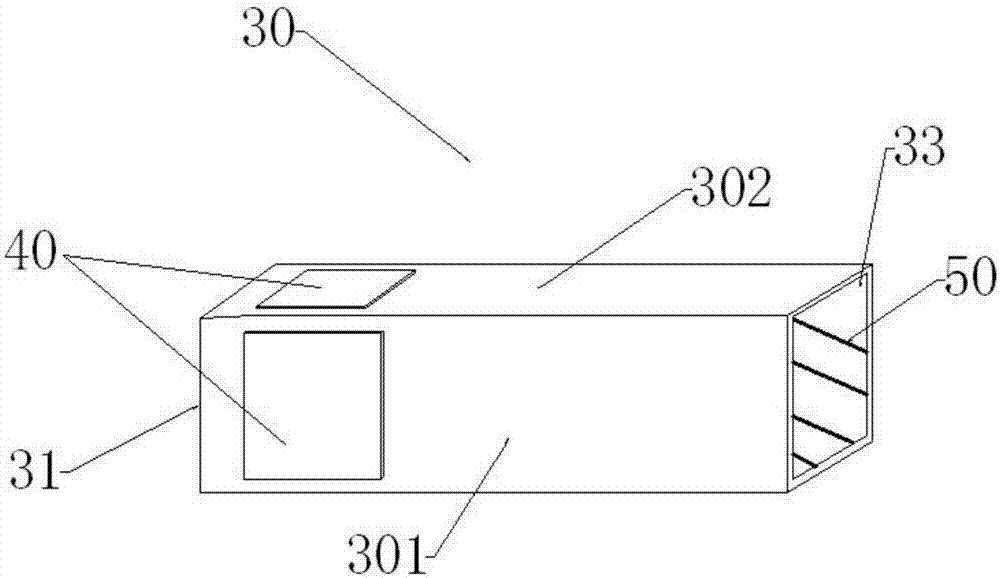

The invention relates to the technical field of aluminium alloy manufacturing and particularly discloses waste heat recovery equipment for a die heating furnace. The waste heat recovery equipment comprises a flue gas inlet, a heat exchange room and a flue gas outlet, wherein the heat exchange room is arranged between the flue gas inlet and the flue gas outlet; a plurality of heat exchange tubes are vertically and parallelly arranged in the heat exchange room; the heat exchange tubes are square tubes; at least one semi-conductor thermoelectric power generation module is fixed on the outer side wall, close to the bottom end, of each heat exchange tube; and spoiler ribs are arranged on the inner wall of each heat exchange tube. On the basis of conventional waste heat recovery equipment for the die heating furnace, the waste heat recovery equipment for the die heating furnace, provided by the invention, utilizes energy in waste heat generated by the die heating furnace more fully, improves the recovery and utilization efficiency of waste heat, saves energy and reduces resource waste.

Owner:TAICANG BEST MECHANICAL EQUIP

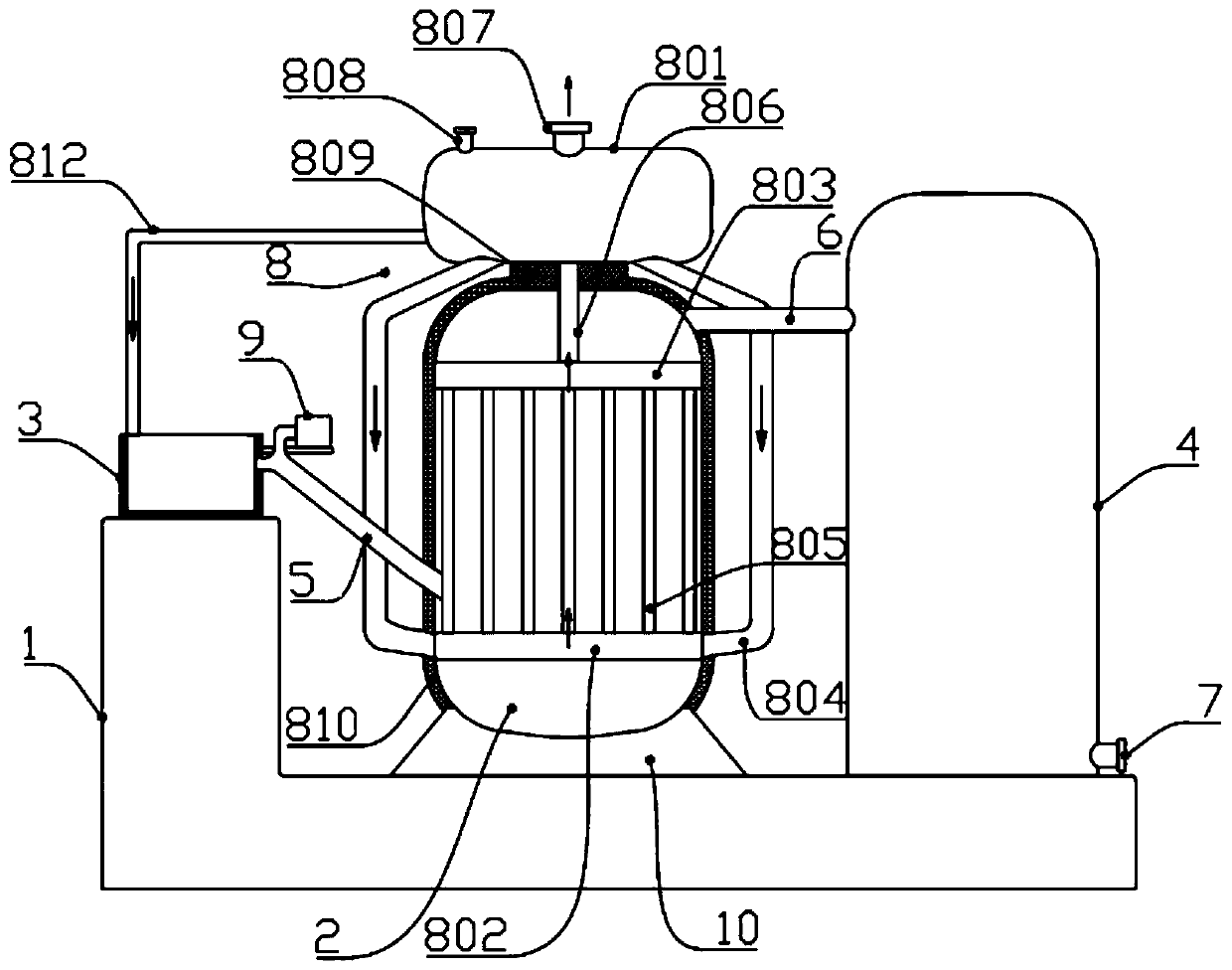

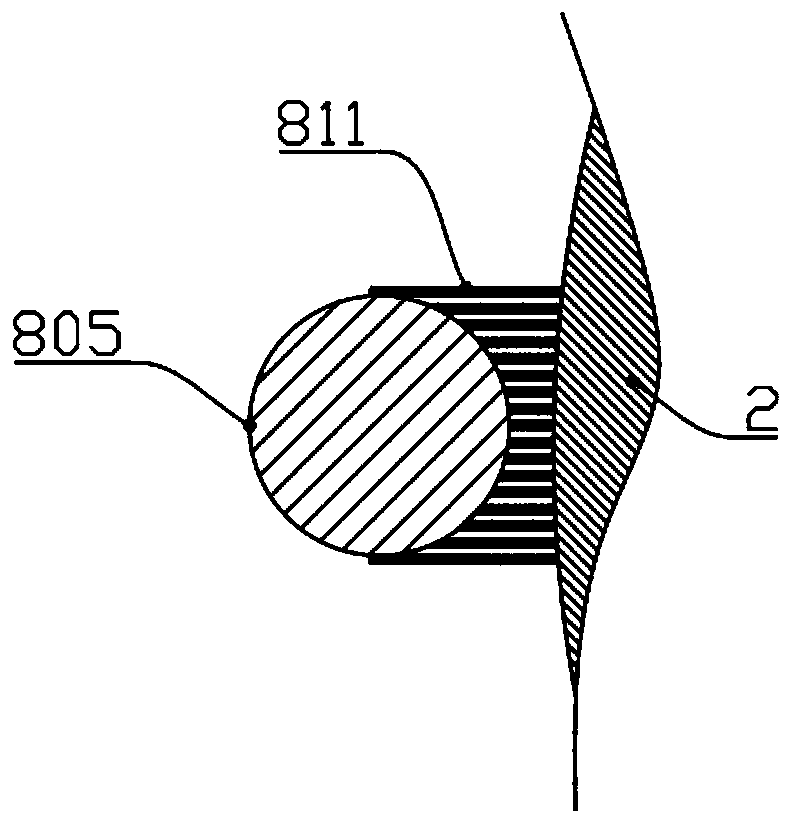

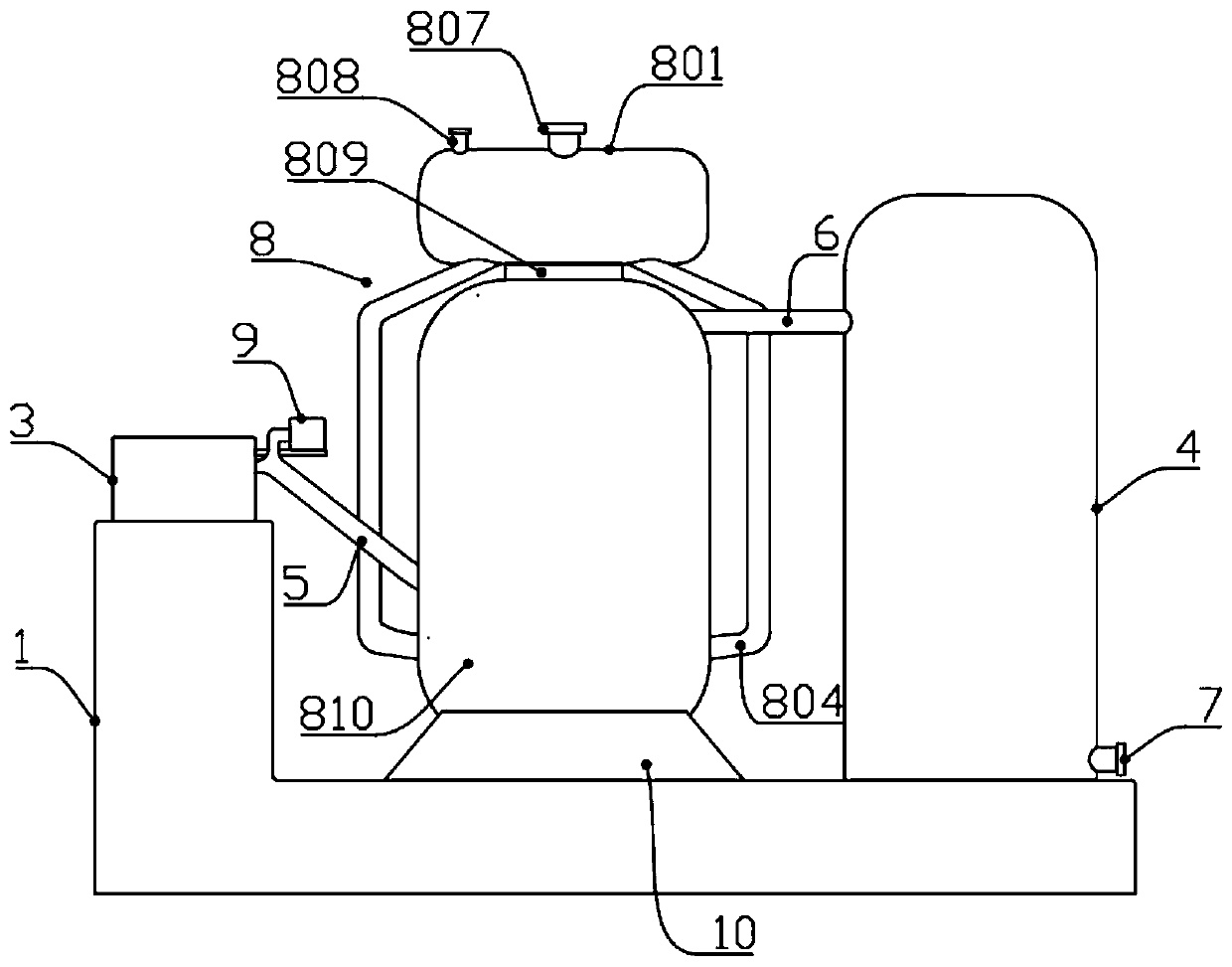

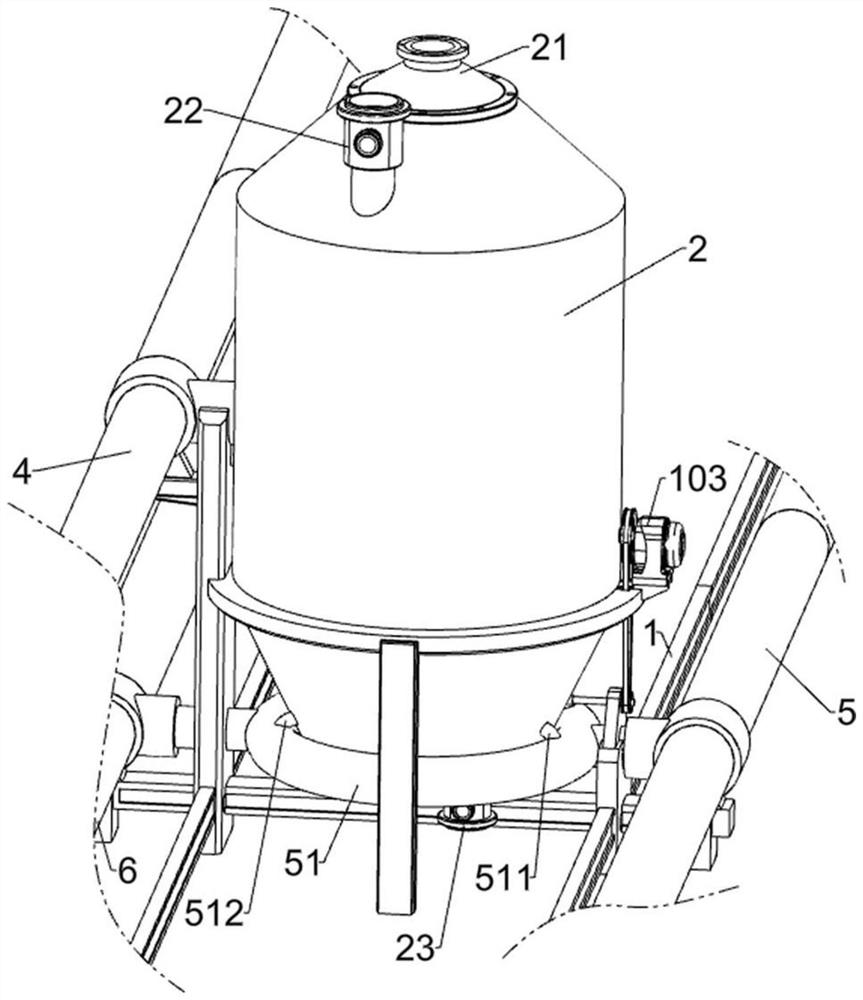

Slag cooler for utilizing and recycling waste heat of slag

InactiveCN114857606AEasy injectionIncrease the heat exchange areaLighting and heating apparatusIncreasing energy efficiencyThermodynamicsSlag

The invention discloses a slag cooler for slag waste heat utilization and recovery. The slag cooler comprises an outer shell mechanism and an inner shell mechanism installed in the outer shell mechanism. A placing frame is fixed on the outer side of the lower end of the shell mechanism; a water inlet is fixed to the left side of the upper end of the shell mechanism, and a water outlet is formed in the right side of the lower end of the shell mechanism. Connecting plates are installed on the inner wall of the outer shell mechanism at equal intervals, and the other ends of the connecting plates are connected with the outer side face of the inner shell mechanism. Wherein a discharging opening is fixed to the bottom end of the shell mechanism, and a feeding frame is installed at the upper end of the shell mechanism. The slag cooler for slag waste heat utilization and recovery is provided with the hollow outer shell mechanism, the hollow inner shell mechanism and the hollow connecting plate, so that the heat exchange area is increased conveniently, the slag waste heat recovery efficiency of slag cooling can be improved, waste heat recovered in the later period can be used for preheating furnace water, steam for preheating the furnace water can be saved, and the energy consumption is reduced. And the waste heat can be well recycled.

Owner:金钰丹

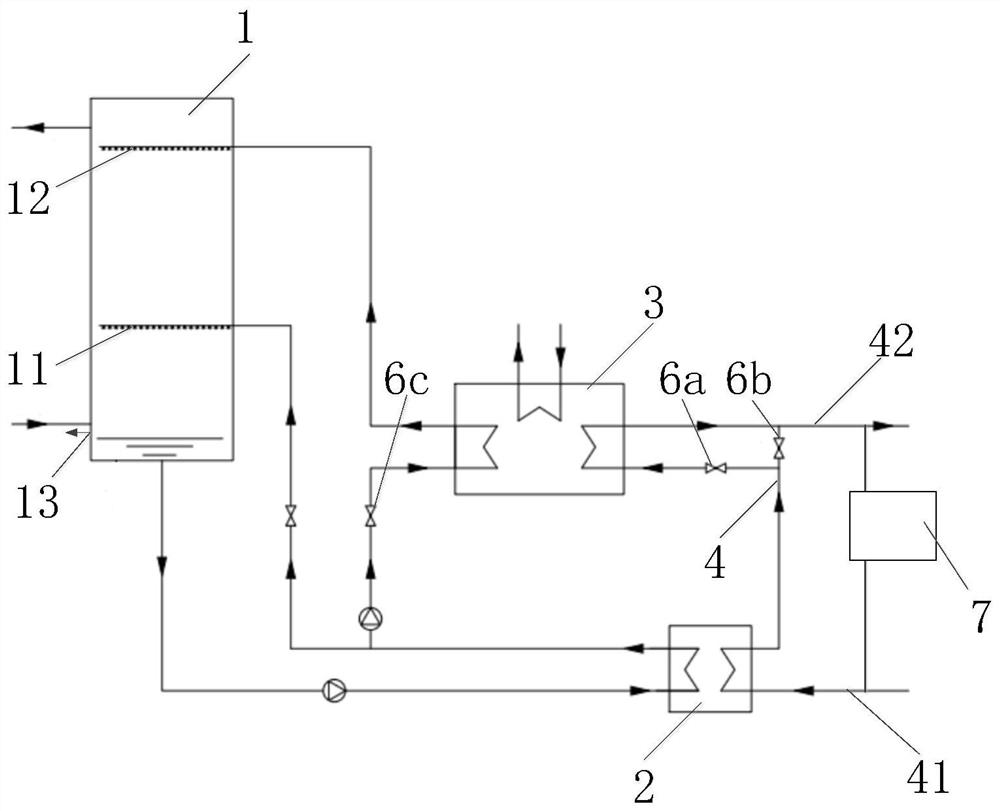

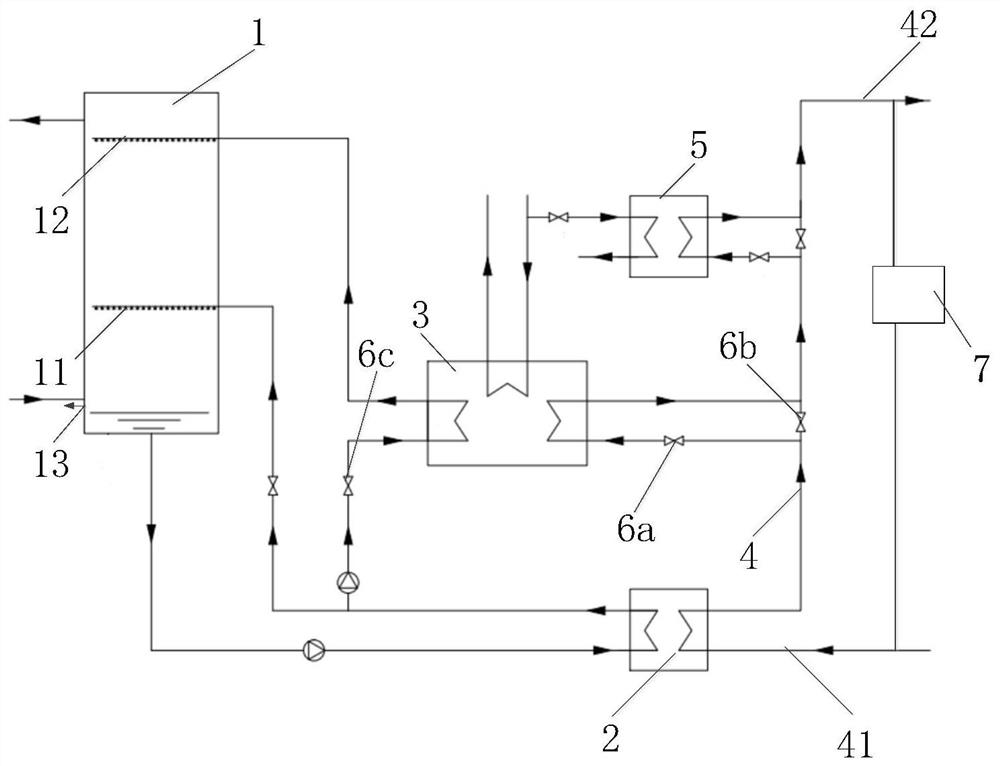

Flue gas waste heat recovery system

ActiveCN111578301ALow powerLess investmentLighting and heating apparatusWaste gas energyFlue gasWater circulation

The invention discloses a flue gas waste heat recovery system. The system comprises a first heat exchanger, a second heat exchanger, a heat pump and a heat supply network pipeline; a first liquid distribution device and a second liquid distribution device are arranged in the first heat exchanger; the bottom of the first heat exchanger communicates with the input end of the heat release side of thesecond heat exchanger; the output end of the heat release side of the second heat exchanger communicates with the first liquid distribution device to form a first fluid circulation loop; the output end of the heat release side of the second heat exchanger further sequentially communicates with the heat pump and the second liquid distribution device to form a second fluid circulation loop; the heat supply network pipeline comprises a heat supply network water return pipeline and a heat supply network water supply pipeline; the heat supply network pipeline communicates with the heat absorptionside of the second heat exchanger to form a heat supply network circulation loop; and / or the heat supply network pipeline sequentially communicates with the heat absorption side of the second heat exchanger and the heat pump to form a heat supply network water circulation loop. Through the arrangement, the flue gas waste heat recovery efficiency can be improved, and the investment of heat pump equipment is reduced.

Owner:北京热科能源技术研究有限公司

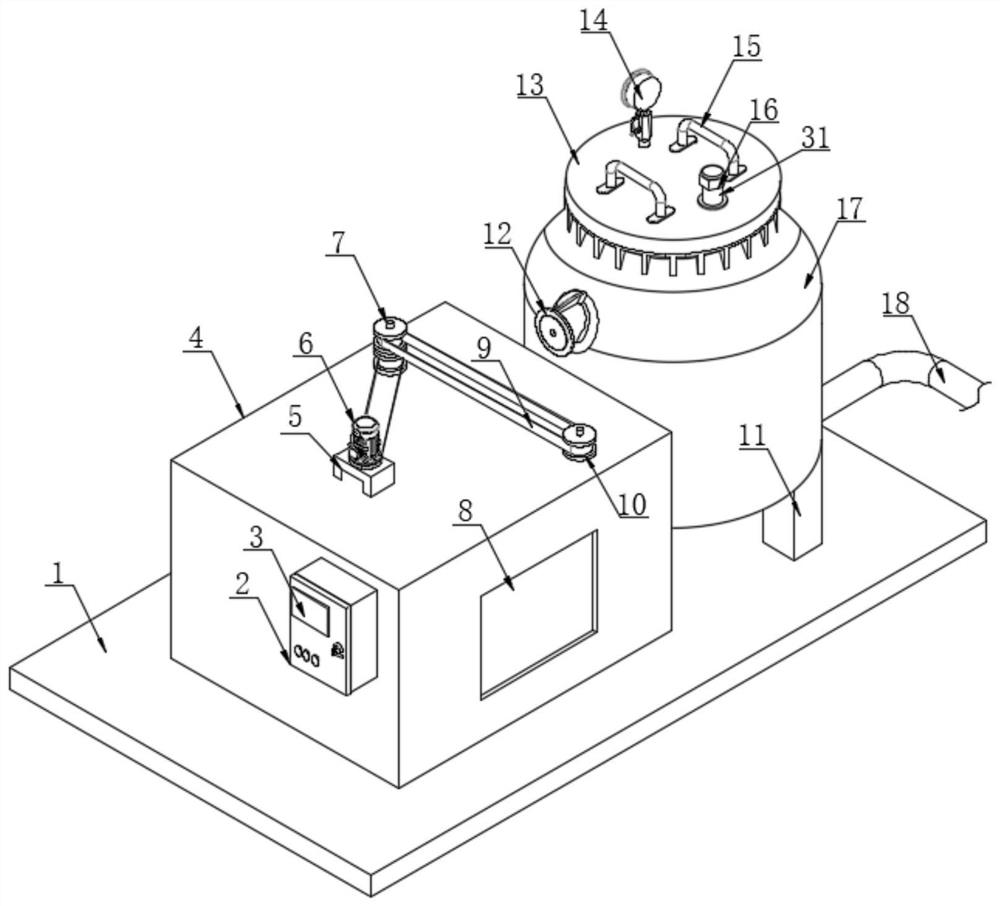

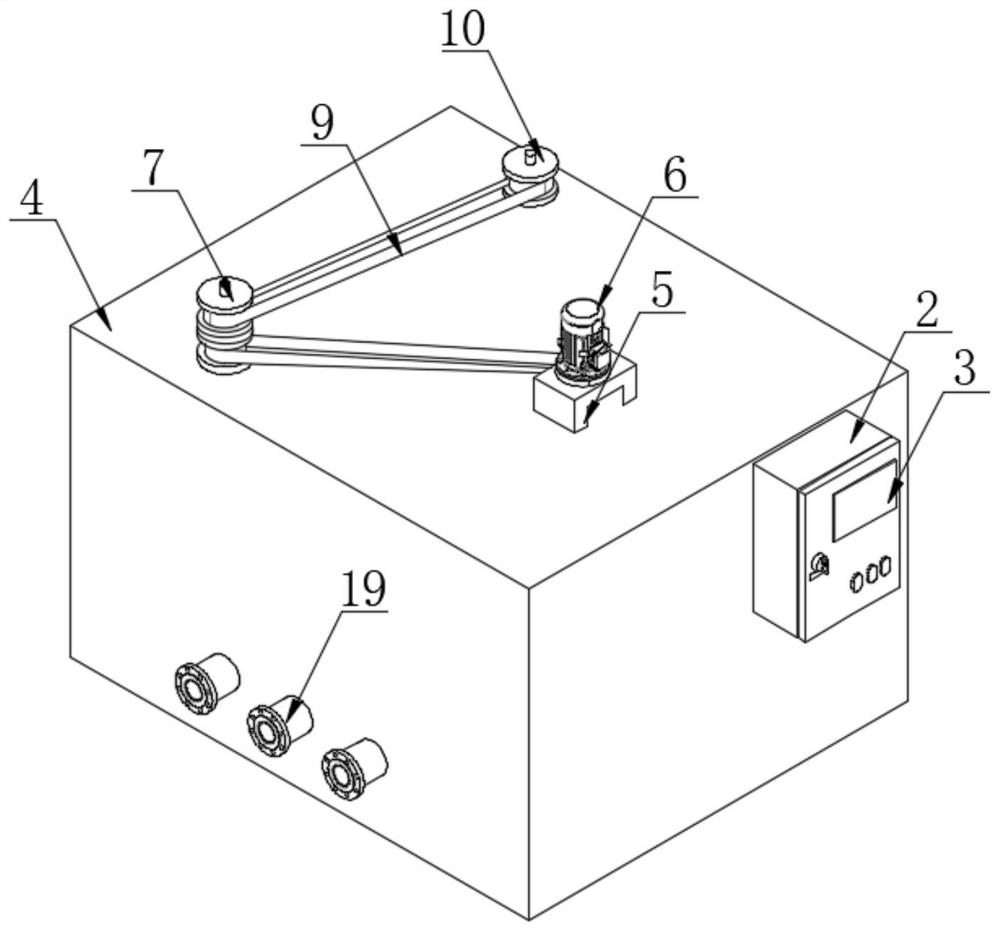

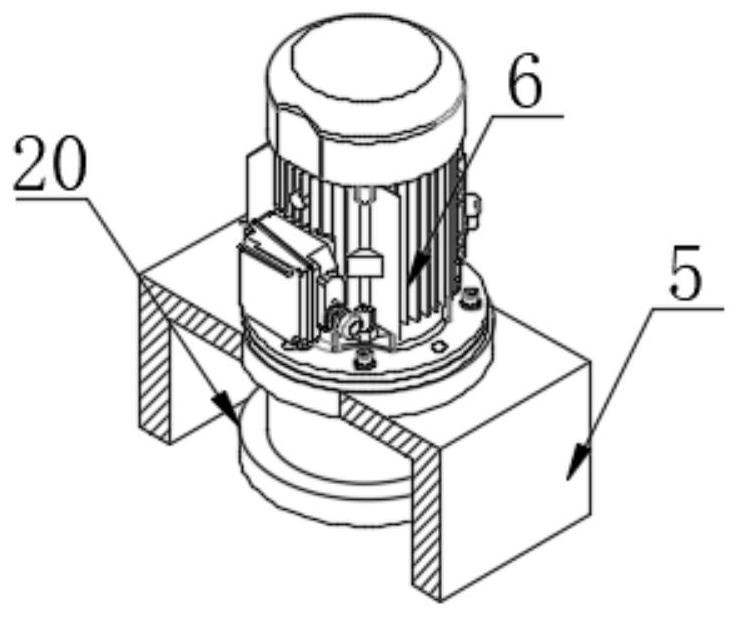

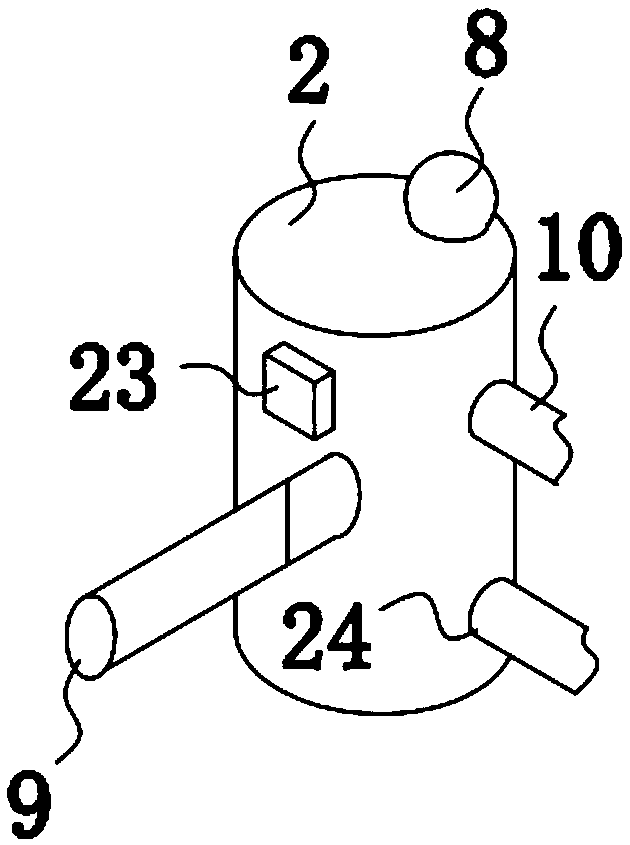

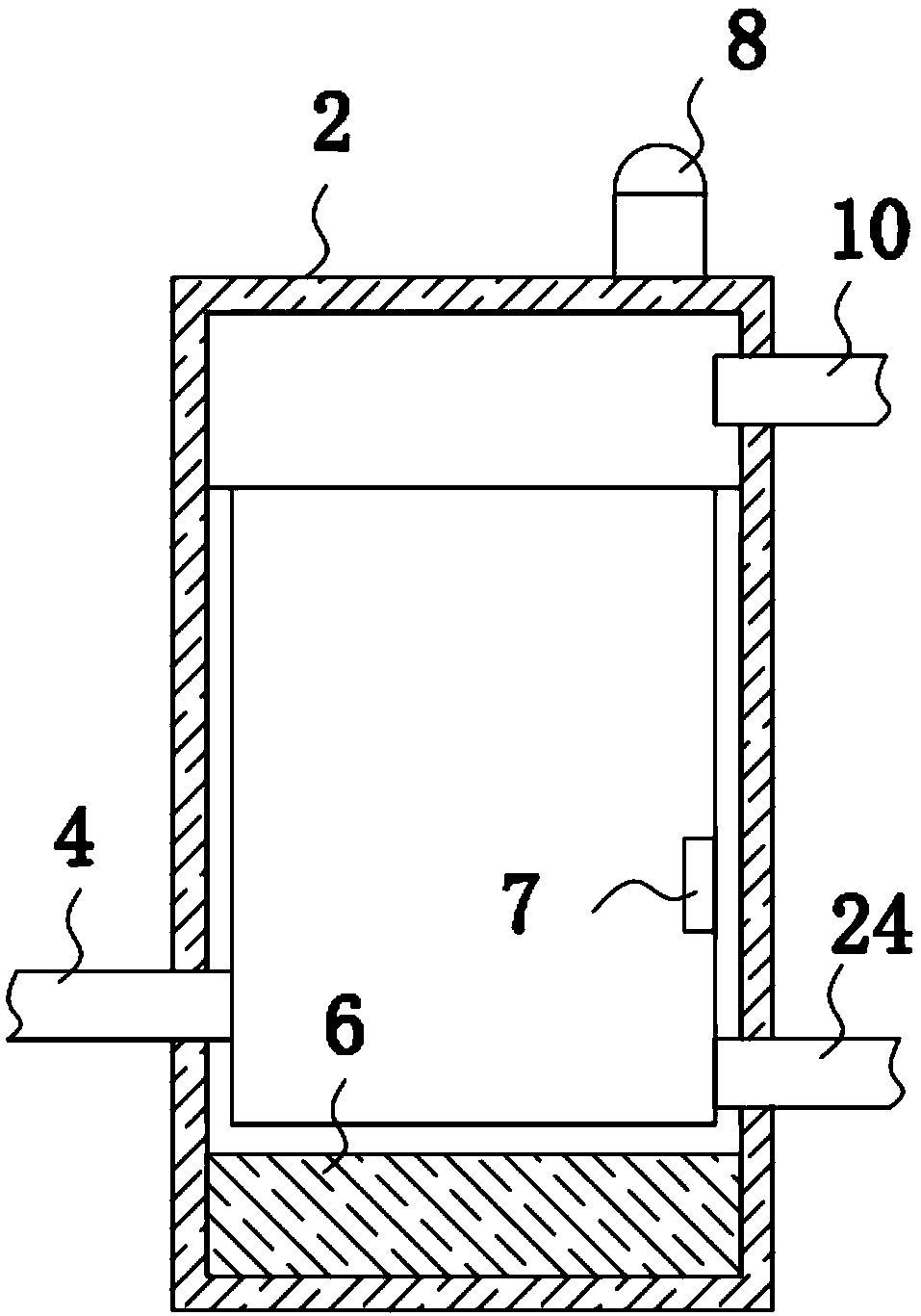

Gas protection type refining furnace with waste heat recovery function

InactiveCN113215362AImprove exchange efficiencyImprove efficiencyMeasurement devicesIncreasing energy efficiencyProcess engineeringGas protection

The invention discloses a gas protection type refining furnace with a waste heat recovery function. The gas protection type refining furnace comprises a bottom plate, a waste heat recovery mechanism, a detection control mechanism and a driving mechanism. The waste heat recovery mechanism is mounted at the top of the bottom plate, and the waste heat recovery mechanism is used for recovering heat generated when the refining furnace is used When the scheme is used, heat generated when the refining furnace is used is recycled through a plurality of heat conduction pipes through the waste heat recycling mechanism, heat dissipation is prevented by installing shells outside the heat conduction pipes, and after the heat reaches the interior of a box body, a motor in a driving mechanism is started to drive a third belt wheel to drive a transmission belt to operate, so that the rotation of a first belt wheel and a second belt wheel is realized; and a rotating rod body is used for driving a plate body to rotate in the box body, so that hot gas circulates in the box body, the exchange efficiency of a heat exchanger is improved, and therefore the waste heat recovery efficiency is improved.

Owner:吕文灶

Boiler waste heat recovery equipment and recovery method thereof

PendingCN108826340AImprove intelligenceHigh degree of humanizationLighting and heating apparatusCombustion technology mitigationRecovery methodFlue gas

The invention discloses boiler waste heat recovery equipment. The boiler waste heat recovery equipment comprises a cold water tank and a boiler body. A water inlet is formed in the middle position ofthe upper end of the cold water tank; the cold water tank is connected to the boiler body through a water delivery pipeline; a first pump body is mounted on the water delivery pipeline; a heater is arranged at the bottom of the boiler body; a temperature sensor is mounted on one side of the inner wall of the boiler body; a buzzer is mounted on one side of the outer top of the boiler body; and a water outlet pipeline communicates to one side of the boiler body. In the heating process, gas-liquid separation is performed on generated flue gas through a cyclone separator, a liquid flows downward and reflows to the boiler body through a water pipe, and gas floats upward and enhances the temperature of the flue gas through the heater and a reheater, so that the boiler waste heat recovery equipment is relatively helpful to improve the flue gas waste heat recovery efficiency subsequently.

Owner:福建省三明长兴机械制造有限公司

Comprehensive utilization device for activated coke regeneration waste heat

PendingCN111495346AAchieve recyclingLow one-time investment costCombustible gas purificationIndirect heat exchangersThermodynamicsCombustion

The utility model discloses a comprehensive utilization device of activated coke regeneration waste heat, belongs to the technical field of activated coke regeneration equipment, and is used for comprehensively utilizing waste heat generated in the activated coke dry desulfurization and denitrification regeneration process. The technical scheme is as follows: the cooling section cooling flue gas outlet pipeline of a regeneration tower is connected with a heating furnace combustion-supporting gas inlet, a heating furnace heating flue gas outlet pipeline and the heat tracing pipeline of the regeneration tower; the heating section hot smoke outlet pipeline of the regeneration tower is connected with the heating furnace hot smoke inlet through a hot smoke fan, a heating furnace hot smoke outlet pipeline is connected with the heating section hot smoke inlet of the regeneration tower, and a heating furnace heating smoke outlet pipeline is connected with a sulfur-rich gas heat tracing pipeline and an ammonia water vaporization smoke inlet pipeline. According to the comprehensive utilization device, the characteristics of the activated coke desulfurization and denitrification process are fully combined, all waste heat generated in the regeneration process can be recycled, the waste heat recycling efficiency is improved, energy consumption is reduced, and the production cost of enterprises is reduced.

Owner:HANDAN IRON & STEEL GROUP +1

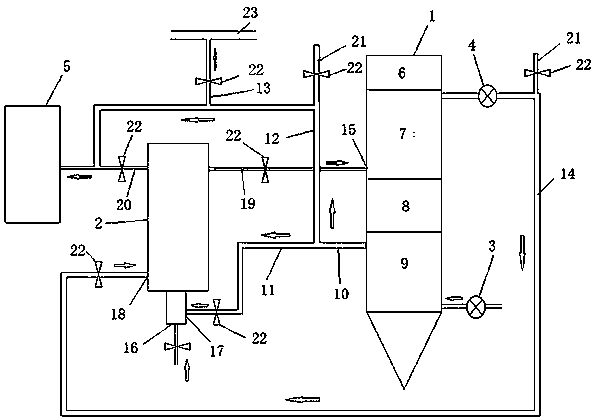

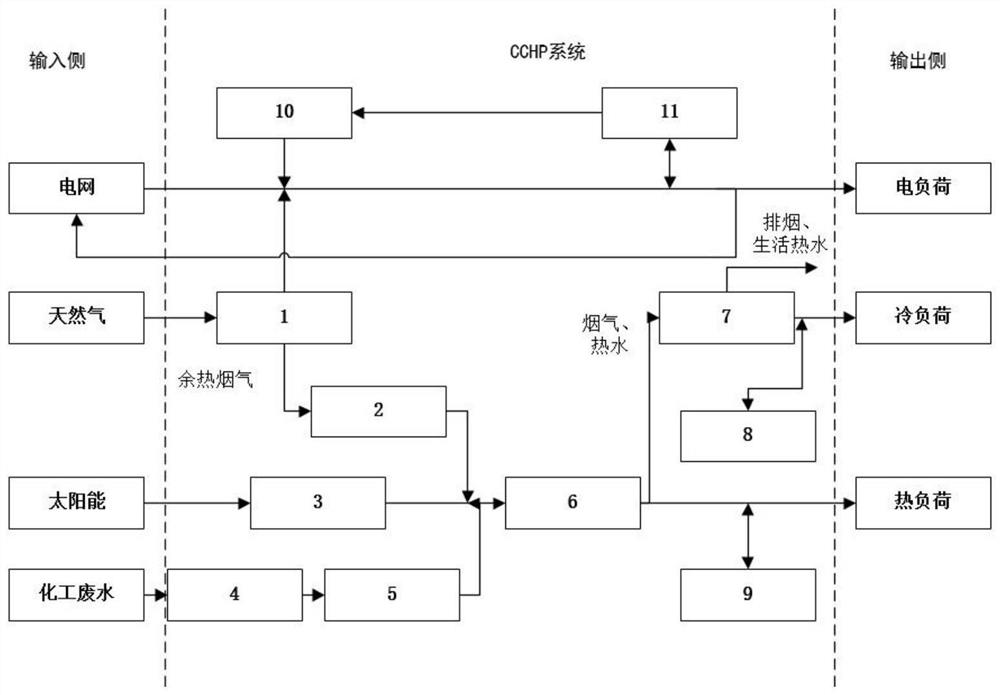

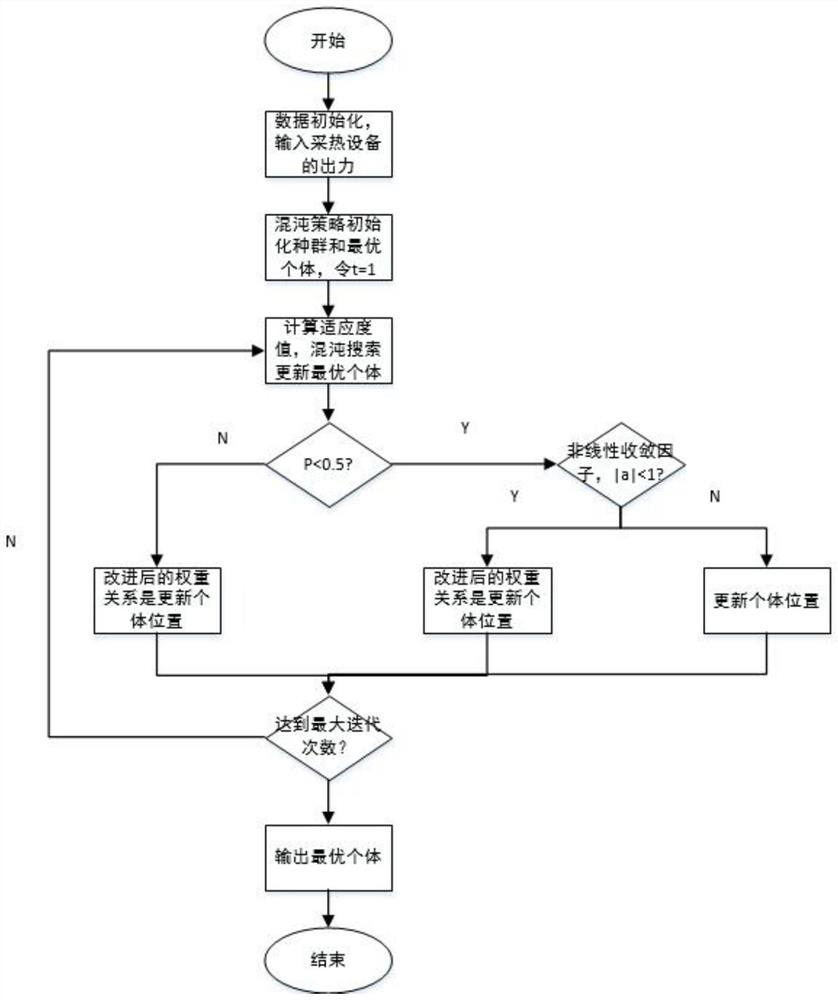

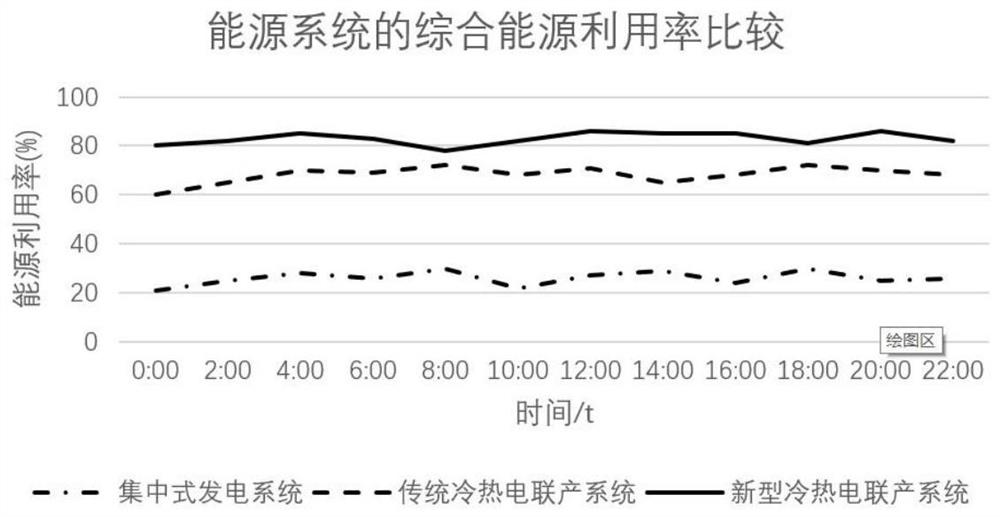

Novel energy system for recycling chemical waste heat and scheduling method thereof

PendingCN114234480AImprove waste heat recovery efficiencySupply heat loadSolar heating energyHeat pumpsMicro gas turbineHeat pump

The novel energy system comprises a waste heat recovery module, the waste heat recovery module comprises a micro gas turbine, a waste heat boiler, an isolation sewage disposal unit, a heat collection water tank, a heat pump and a waste heat conversion device, and the waste heat conversion device comprises a heat exchanger and a refrigerating machine; the micro-gas turbine absorbs natural gas to generate electrical load and flue gas, the waste heat boiler recycles and stores the flue gas generated by the micro-gas turbine and transmits redundant flue gas to the heat exchanger, the heat collection water tank absorbs solar energy, and when the water temperature reaches a preset temperature, water in the heat collection water tank is transmitted to the heat exchanger. The isolation and decontamination unit carries out isolation and decontamination on the chemical wastewater and then sends the chemical wastewater to the heat pump, and the heat pump conveys the treated chemical wastewater to the heat exchanger. The heat exchanger generates a heat load according to the received waste heat, and meanwhile the heat exchanger transmits the redundant waste heat to the refrigerating machine to generate a cold load. The waste heat recovery efficiency of the system is fully improved, and heat loads and cold loads required by chemical plants can be supplied.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

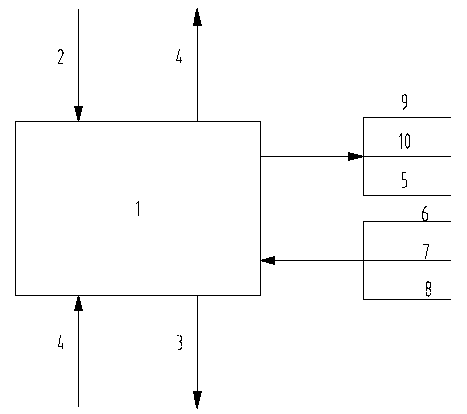

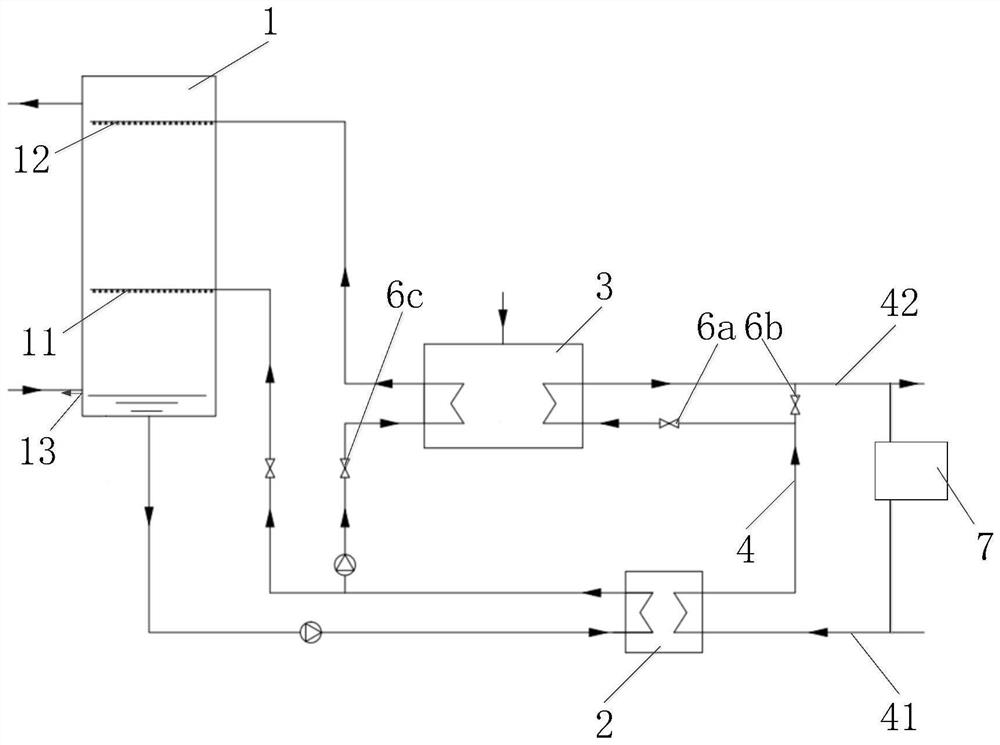

Waste heat recovery system

ActiveCN110081757BReduce CooldownSolve wasteRecuperative heat exchangersHeat exchanger casingsLiquid storage tankIndustrial equipment

Owner:重庆岩昱节能科技有限公司

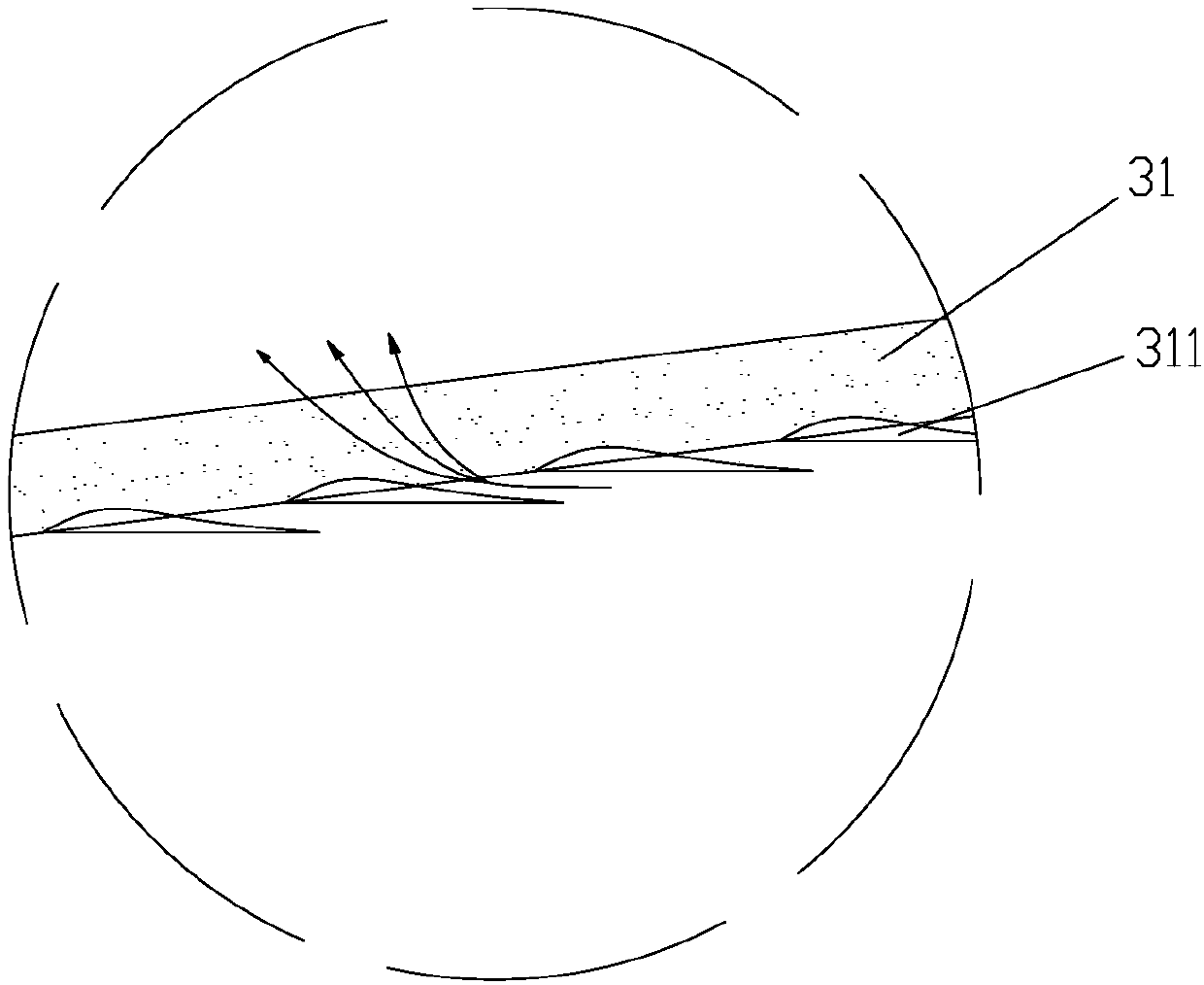

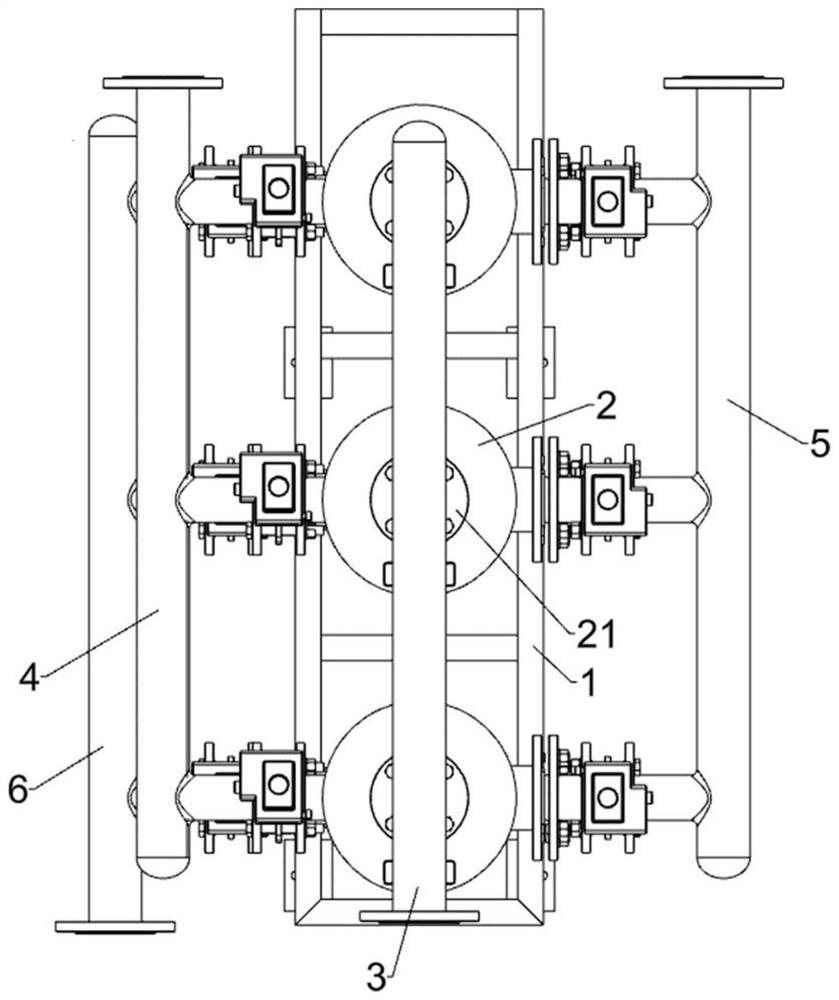

Furnace slag heat exchange device and high-temperature afterheat recycling device containing furnace slag heat exchange device

PendingCN107816898ATo achieve the purpose of waste heat recoveryImprove waste heat utilization efficiencyIncreasing energy efficiencyWaste heat treatmentSlagHot Temperature

The application belongs to the field of energy conservation, and particularly relates to a furnace slag heat exchange device and a high-temperature afterheat recycling device containing the furnace slag heat exchange device. The furnace slag heat exchange device comprises a furnace slag heat exchange mechanism which is used for conveying and distributing furnace slag; the furnace slag heat exchange mechanism comprises a first-stage heat exchange material bed which is arranged in an inclined manner and comprises a high feeding end and a low discharging end; and ventilating holes which can introduce cooling air flow to blow furnace slag to float and move to the discharging end are formed in the bottom of the first-stage heat exchange material bed. According to the furnace slag heat exchangedevice provided by the application, the cooling air flow can blow the furnace slag to float and move to a material bed of the next stage through the ventilating holes in the bottom of the material bed; conveying, heat transferring and heat exchanging of furnace slag particles are realized through collecting, distributing, performing heat exchange and recollecting repeatedly and distributing of thefurnace slag particles; meanwhile, low-pressure cooling air can be subjected to heat exchange stage by stage uniformly to achieve a purpose of recycling afterheat of the furnace slag; and the furnaceslag afterheat utilization efficiency is high.

Owner:中山蓝冰节能环保科技有限公司

Energy-saving combustion and waste heat recovery system for fast melting aluminum furnace

ActiveCN108800957BImprove recycling efficiencyGuaranteed temperatureIncreasing energy efficiencyWaste heat treatmentCombustion systemTime cycles

The invention provides an energy-saving combustion and waste heat recovery system of a quick aluminum melting furnace. The energy-saving combustion and waste heat recovery system of the quick aluminummelting furnace comprises a furnace body, a combustion system and a waste heat recovery system. The furnace body comprises a vertical melting furnace and a transverse holding furnace. The combustionsystem comprises a first fuel spray nozzle, an ignition nozzle and an air spray nozzle, wherein the air spray nozzle is used for guiding the preheated air into the holding furnace in the mode that thepreheated air serves as the combustion-supporting gas. The waste heat recovery system comprises a first heat storage chamber, a second heat storage chamber and a reversing device. The purposes that the heat storage chamber on one side stores the waste heat generated by combustion of the melting furnace, the heat storage chamber on the other side preheats the combustion-supporting gas of the holding furnace, and the operation is alternatively conducted according to the preset time cycle are achieved. The problems that in the prior art, a melting furnace and a holding furnace are low in waste heat recovery efficiency and high in the waste heat recovery difficulty, and due to the fact that the combustion temperature in the melting furnace is high, thermal power type NOX is prone to being generated when the air serves as the combustion-supporting gas are effectively solved, the overall energy consumption of the combustion system is reduced, the flue gas of the system is effectively balanced, and the waste heat recovery efficiency is improved.

Owner:HUATIAN ENG & TECH CORP MCC +1

A method for blast furnace slag granulation and waste heat recovery

ActiveCN108796147BInhibition formationImprove liquidityIncreasing energy efficiencyRecycling and recovery technologiesSlagHeat conservation

The invention discloses a method of blast furnace slag granulation and waste heat recovery, and belongs to the technical field of blast furnace slag utilization. The method of the blast furnace slag granulation and the waste heat recovery comprises the following steps that blast furnace slag on a rotary slag disk move to the edge position of the rotary slag disk in the process of rotating, heatingelement of the rotary slag disk carries out heating and heat prevention to the blast furnace slag to enable the blast furnace slag to maintain a higher temperature, thus the blast furnace slag has better liquidity, then the forming of a slag film is restrained to facilitate the granularity of granulated slag diminishing; A cooling mechanism cools the blast furnace slag after the blast furnace slag breaking away from the rotary slag disk, the blast furnace slag after cooling forms the granulated slag; meanwhile, cooling water ejected from the cooling mechanism is heated by the blast furnace slag to gasify and generate water vapor, the water vapor enters into a heat transfer unit through an outlet of the granulated slag, the water vapor carries out heat transfer processing and waste-heat utilization in the heat transfer unit, and the use ratio of energy sources is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

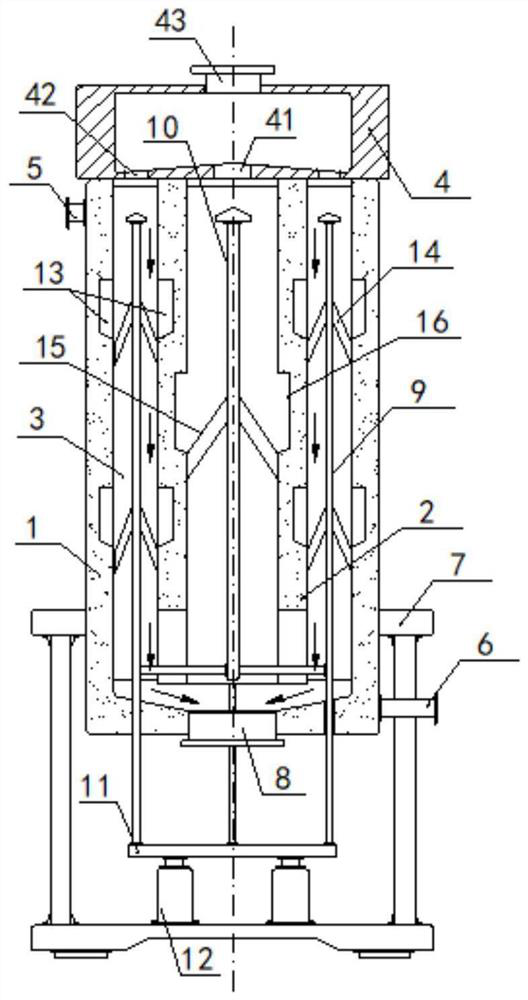

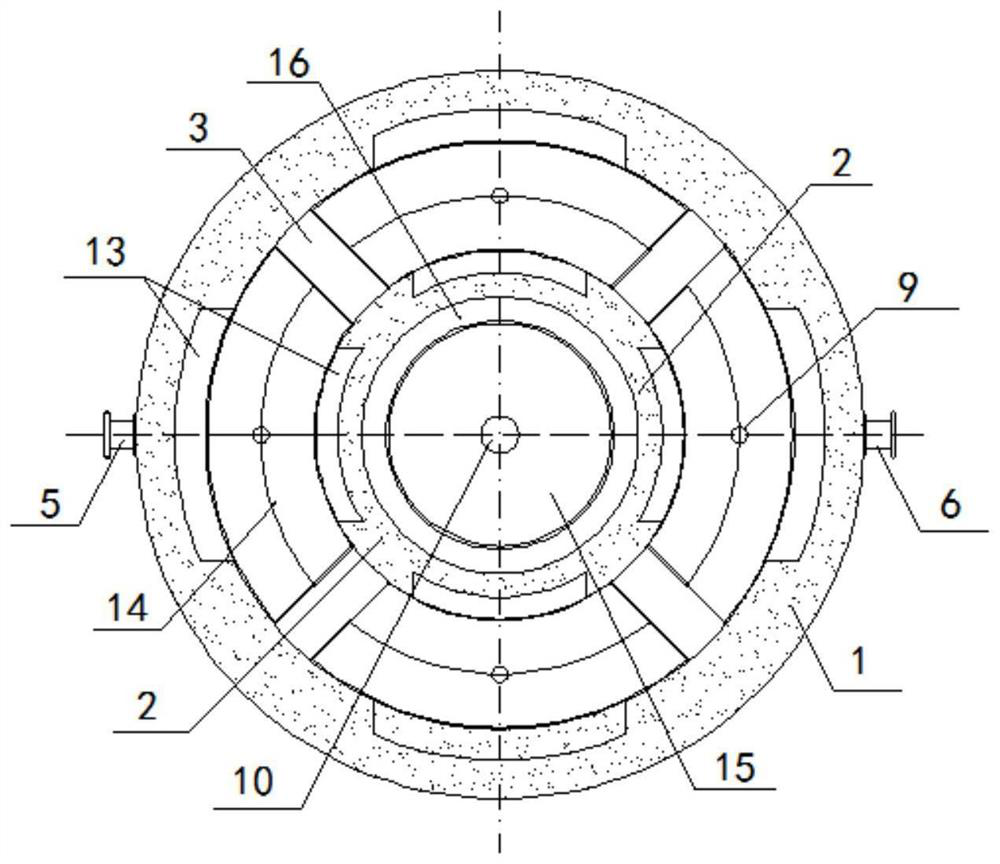

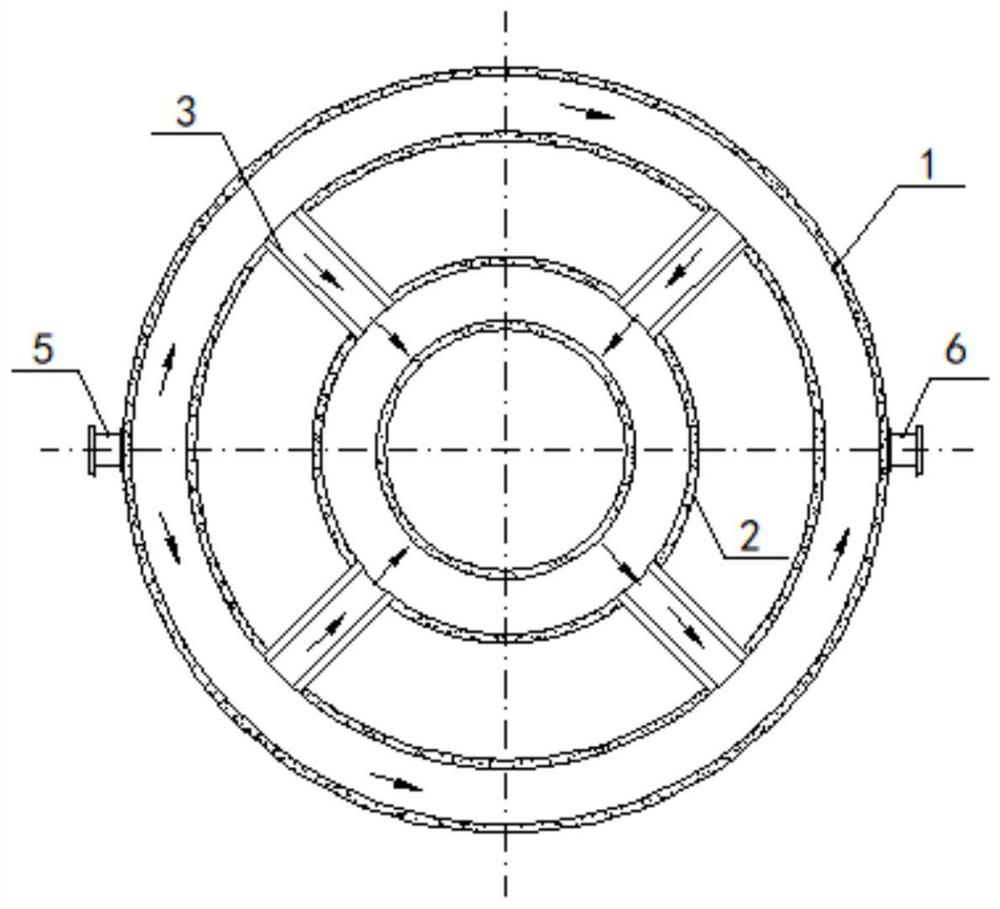

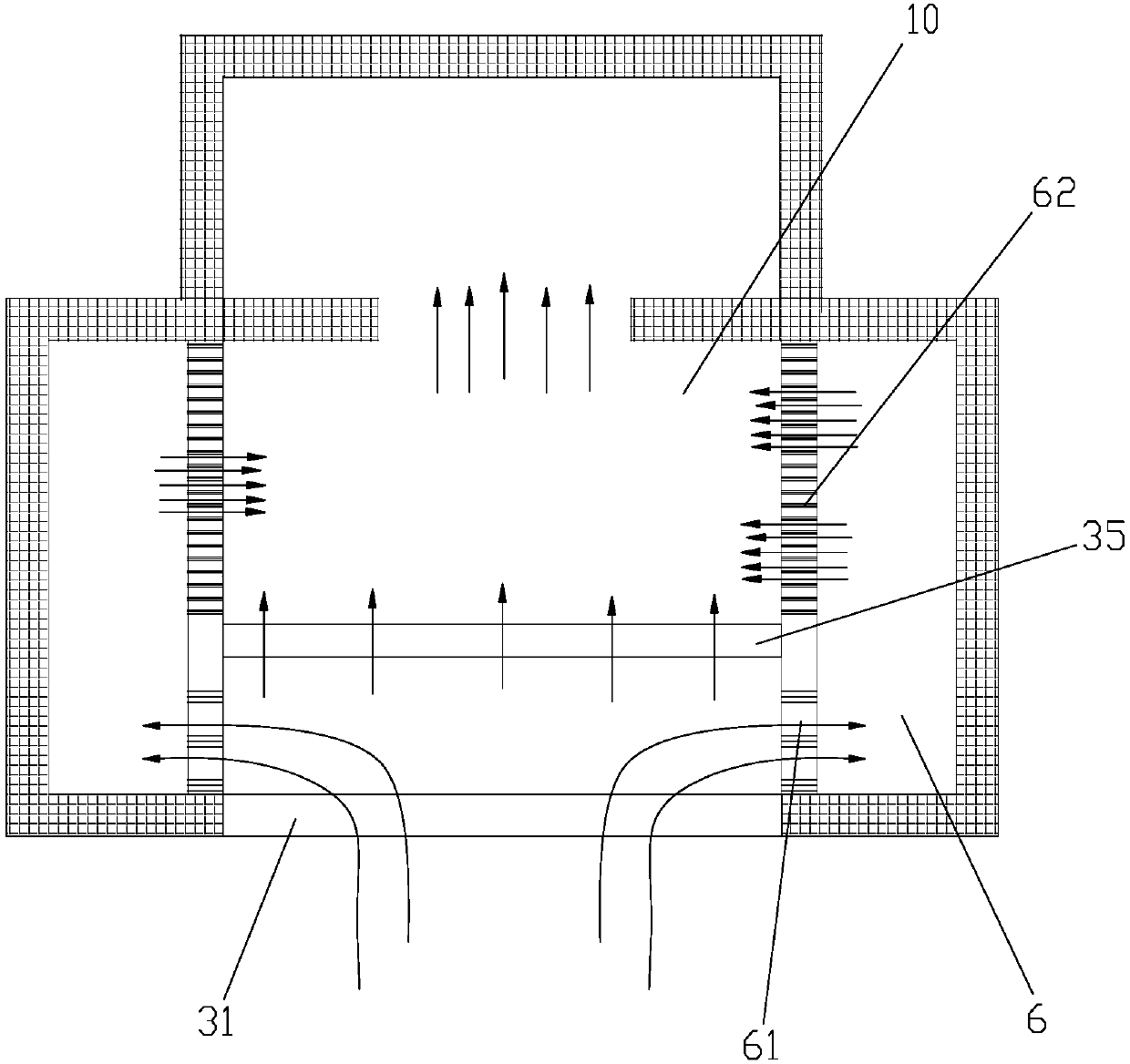

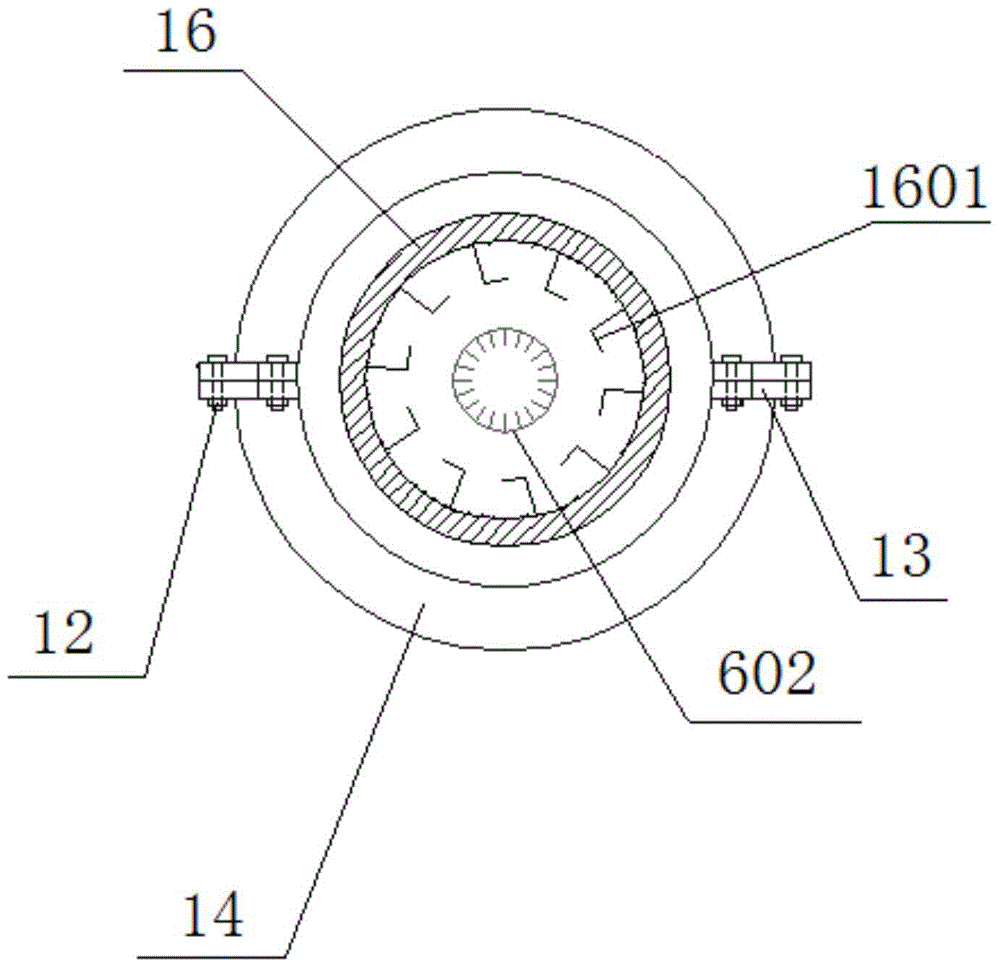

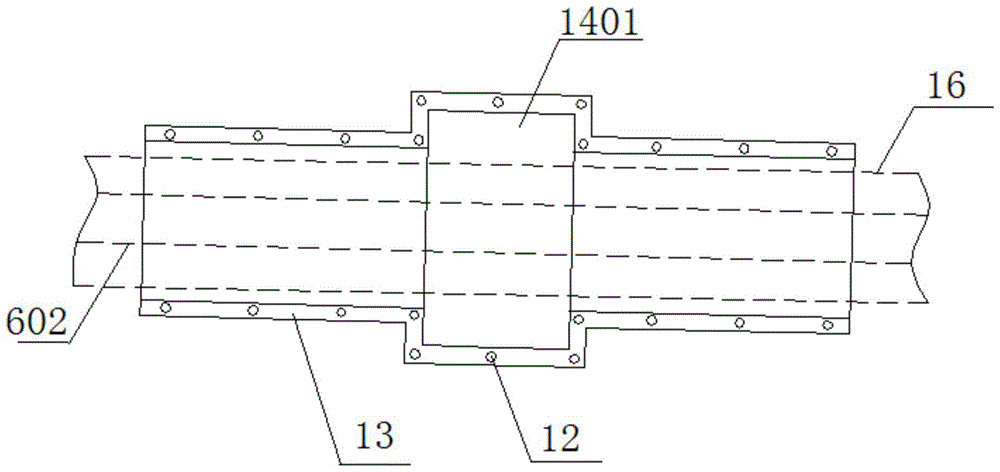

A ring-shaped partition wall recovery system and method for waste heat of rotary kiln products calcined with pellets

ActiveCN104964572BImprove waste heat utilization efficiencyIncrease waste heat recoveryEnergy industryIncreasing energy efficiencyThermodynamicsProcess engineering

The invention discloses a product waste heat ring-shaped partition-type recovery system and method for a pellet calcining rotary kiln, and belongs to the technical field of rotary kiln product waste heat recovery technology. The recovery system comprises a ring-shaped partition heat exchange mechanism and a blast tube heat exchange mechanism. Both a high temperature segment hood body and a middle temperature segment hood body are cylinders with openings at two ends, both internal diameters of high temperature segment hood body and the middle temperature segment hood body are greater than the external diameter of a cooling cylinder, the high temperature segment hood body sleeves on a high temperature segment, and the middle temperature segment hood body sleeves on a middle temperature segment. The blast tube heat exchange mechanism comprises a blast tube, the blast tube comprises a blast tube holding segment and a blast tube heating segment, the blast tube heating segment is disposed in the cooling cylinder, an outlet of the blast tube heating segment comes out of a feed inlet of the cooling cylinder, and the outlet of the blast tube heating segment communicates with an air inlet of a burner through a pipe. According to the product waste heat ring-shaped partition-type recovery system and method for the pellet calcining rotary kiln, the efficiency of waste heat utilization of a rotary kiln is raised, the consumption of cooling water is reduced, the probability that a cooling device is corroded is reduced, and the operation environment can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Fluidized bed roaster outer wall waste heat recovery system

PendingCN114322583ALower pressure limitNo high voltage problemsSteam useIncreasing energy efficiencyOrganic Rankine cycleFluidized bed

The invention discloses a fluidized bed roaster outer wall waste heat recovery system. The fluidized bed roaster outer wall waste heat recovery system comprises a liquid metal circulating system and an organic Rankine circulating system. The liquid metal circulating system is composed of a pipeline exchanging heat with the outer wall of the fluidized bed roaster and an electromagnetic pump. And the pipeline is wound on the outer wall of the fluidized bed roaster for heat exchange. The organic Rankine cycle system is composed of an evaporator, a steam turbine, a generator, a condenser and a circulating pump. A working medium in the evaporator is organic matter. And the circulating pump is a power device for organic matter circulation. According to the waste heat recovery system, liquid metal obtained after waste heat absorption from the outer wall of the fluidized bed roaster is fed into an evaporator through an electromagnetic pump and exchanges heat with an organic matter working medium, the liquid metal obtained after heat exchange flows into the electromagnetic pump, next circulation is started, organic matter absorbs heat and evaporates, and generated steam is used for power generation; therefore, the waste heat of the outer wall of the fluidized bed roaster is recycled, and the gas after heat exchange enters the condenser to be cooled to start the next cycle.

Owner:CENT SOUTH UNIV +1

A flue gas waste heat recovery system

ActiveCN111578301BLow powerLess investmentLighting and heating apparatusWaste gas energyFlue gasWater circulation

The invention discloses a flue gas waste heat recovery system, comprising: a first heat exchanger, a second heat exchanger, a heat pump and a heat network pipeline; the first heat exchanger is provided with a first liquid distribution device and a second liquid distribution device device; the bottom of the first heat exchanger is communicated with the input end of the heat release side of the second heat exchanger; the output end of the heat release side of the second heat exchanger is communicated with the first liquid distribution device to form a first fluid circulation loop; The output end of the heat release side of the second heat exchanger is also communicated with the heat pump and the second liquid distribution device in sequence to form a second fluid circulation loop; the heat network pipeline includes a heat network return water pipeline and a heat network water supply pipeline; the heat network pipeline is connected with The heat absorption side of the second heat exchanger is connected to form a heat network circulation loop; and / or the heat network pipeline is sequentially connected with the heat absorption side of the second heat exchanger and the heat pump to form a heat network water circulation loop. This setting can improve the recovery efficiency of waste heat from flue gas and reduce investment in heat pump equipment.

Owner:北京热科能源技术研究有限公司

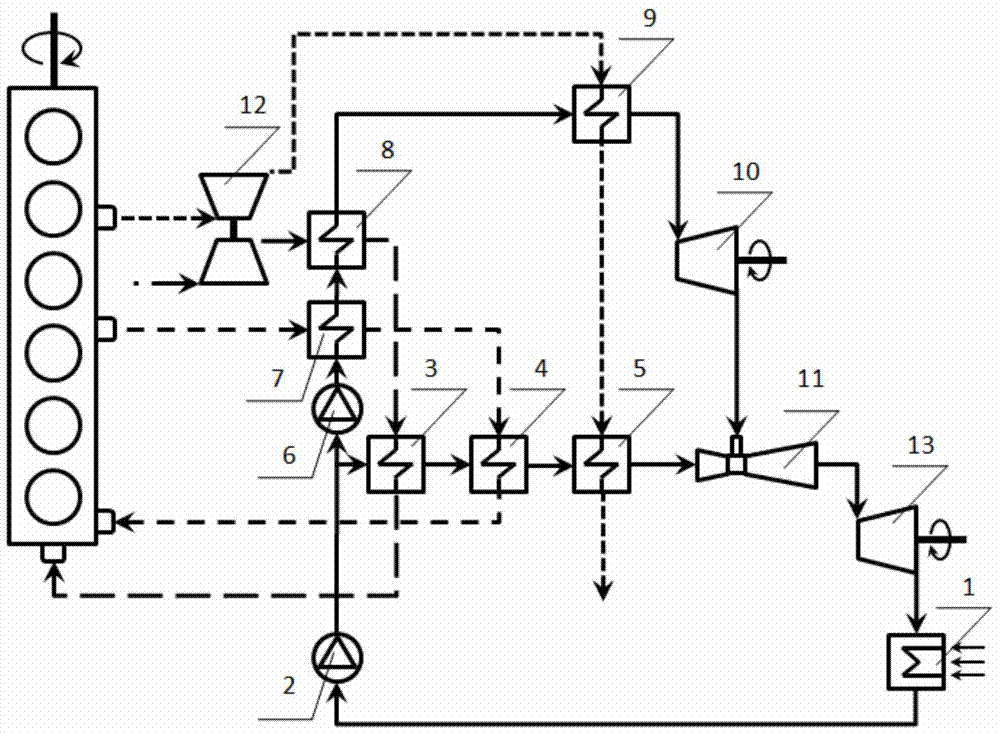

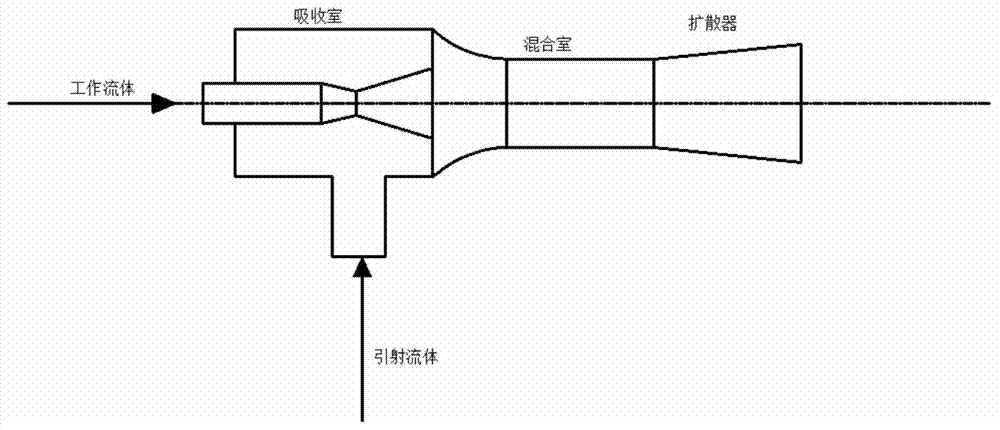

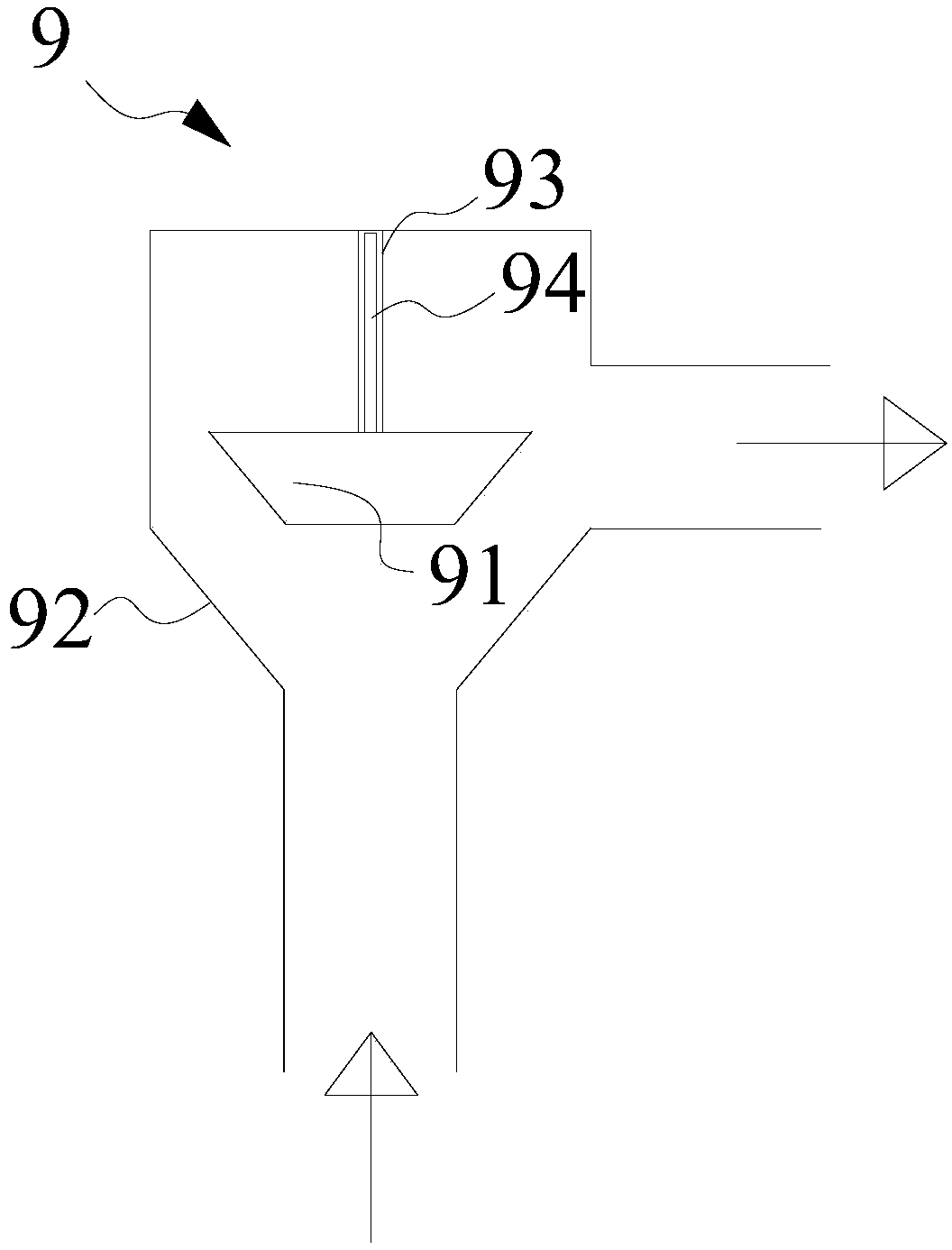

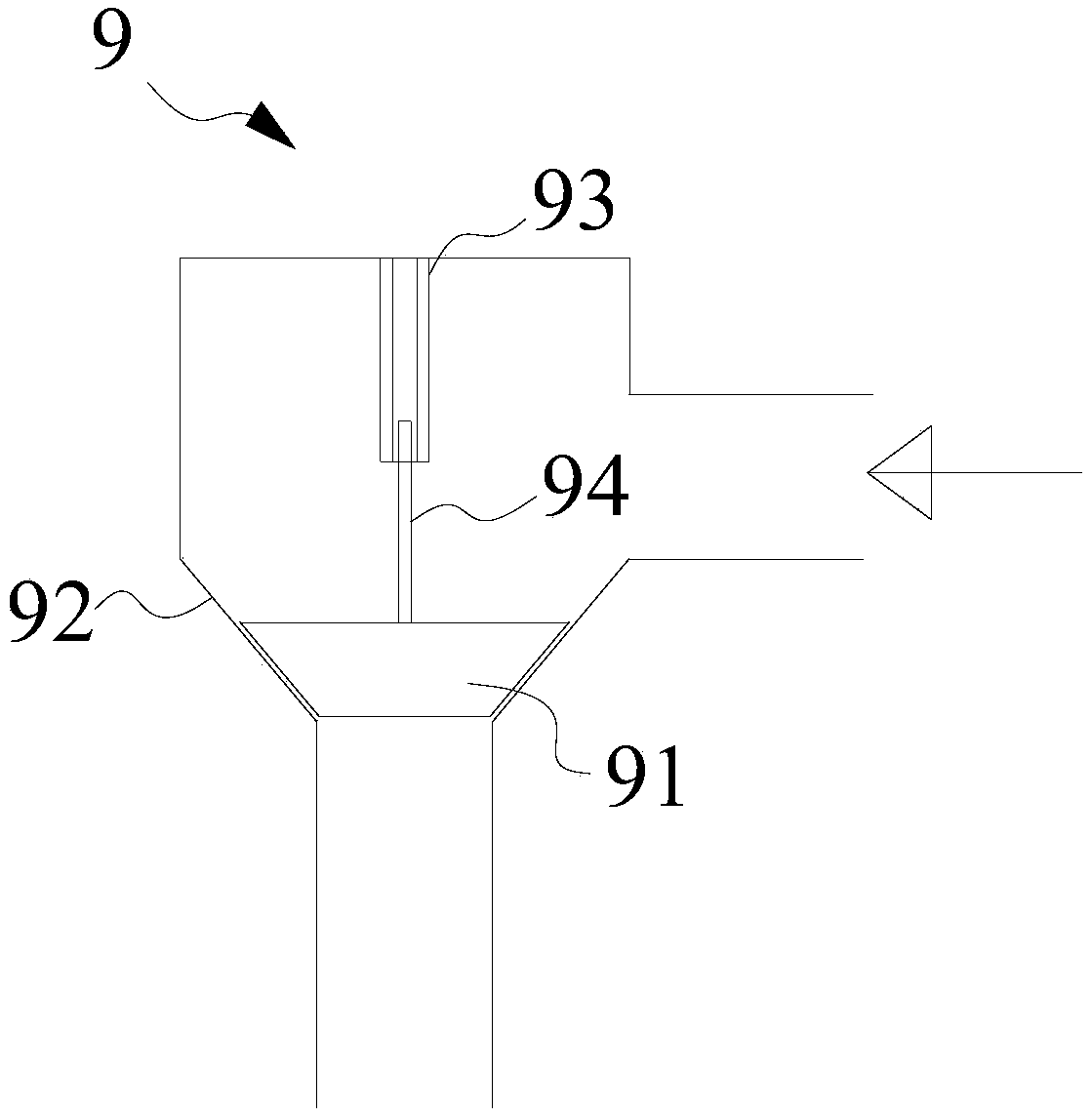

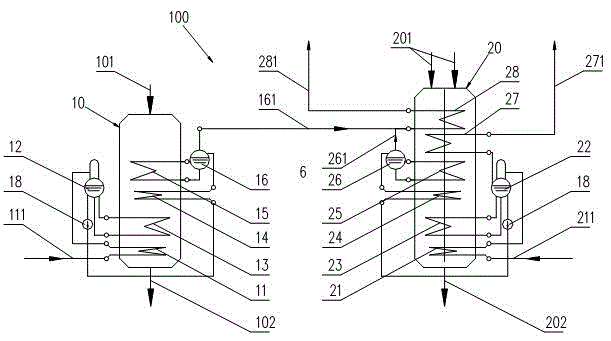

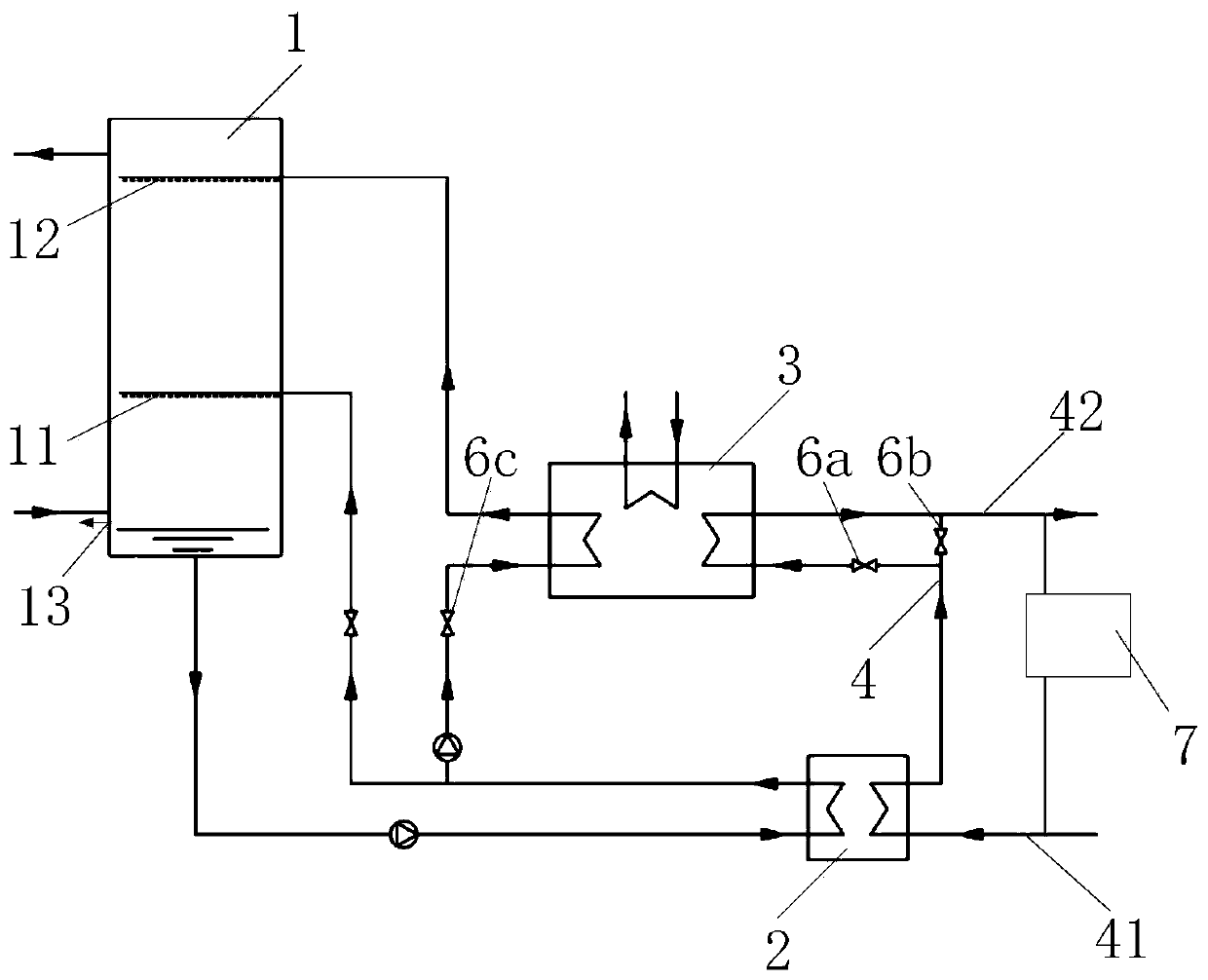

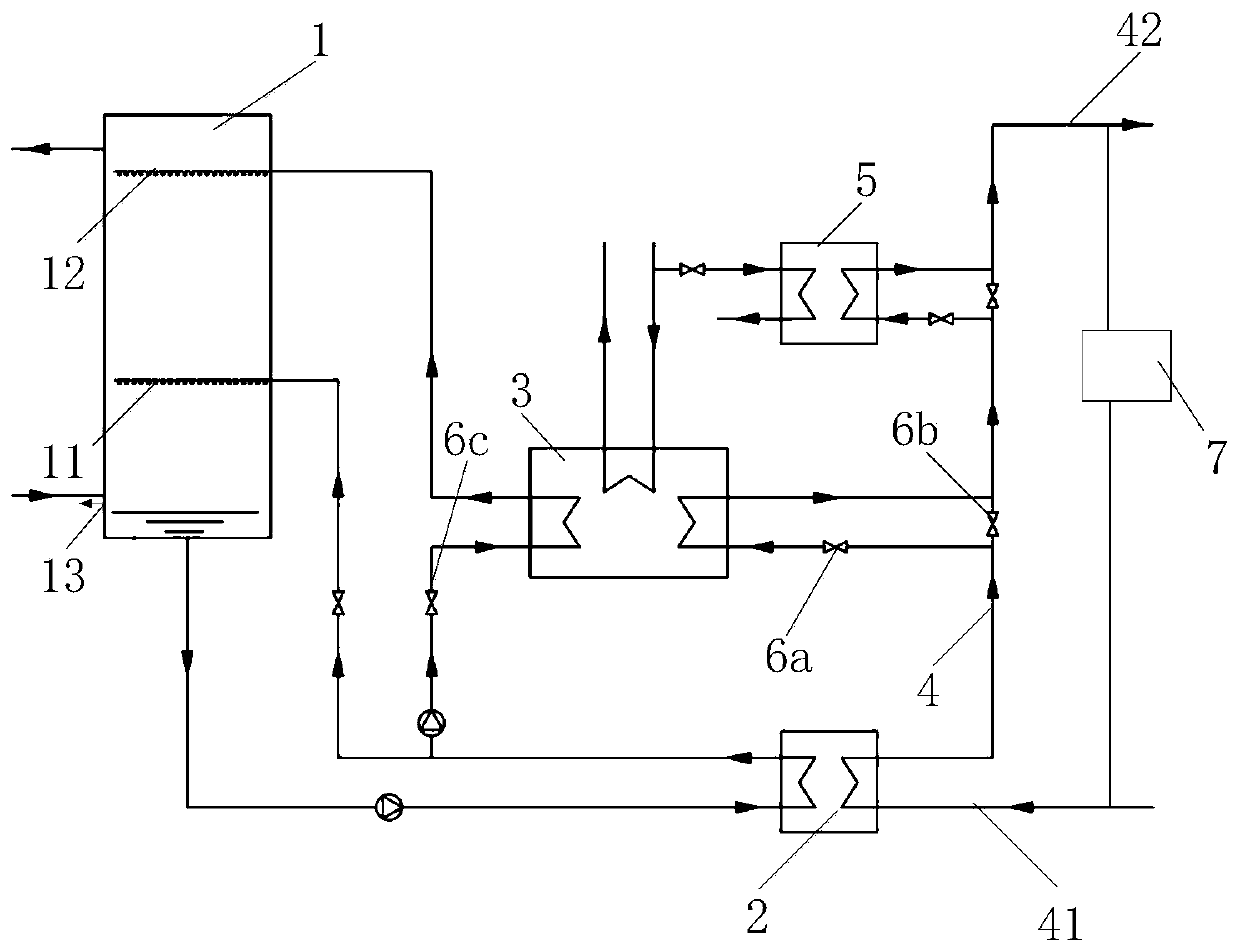

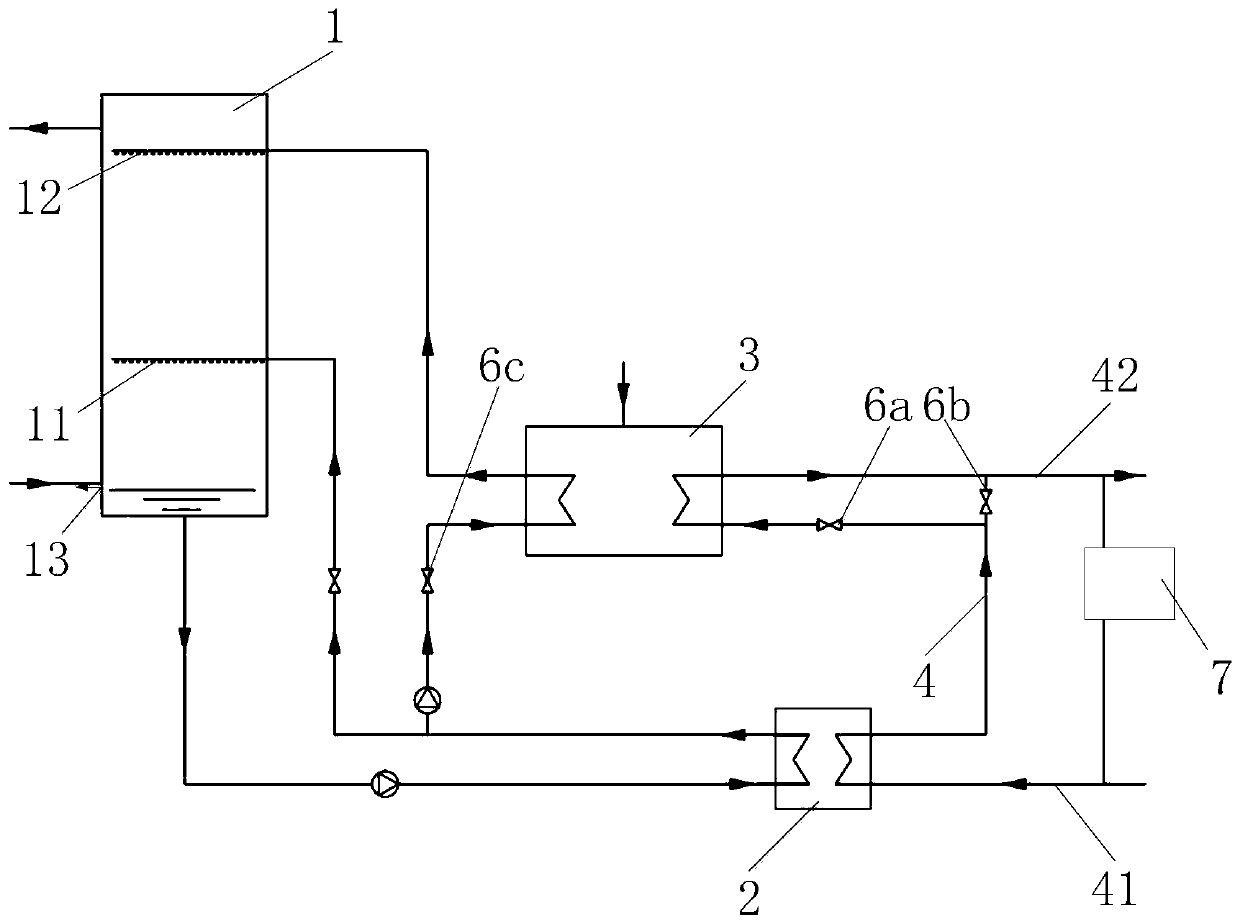

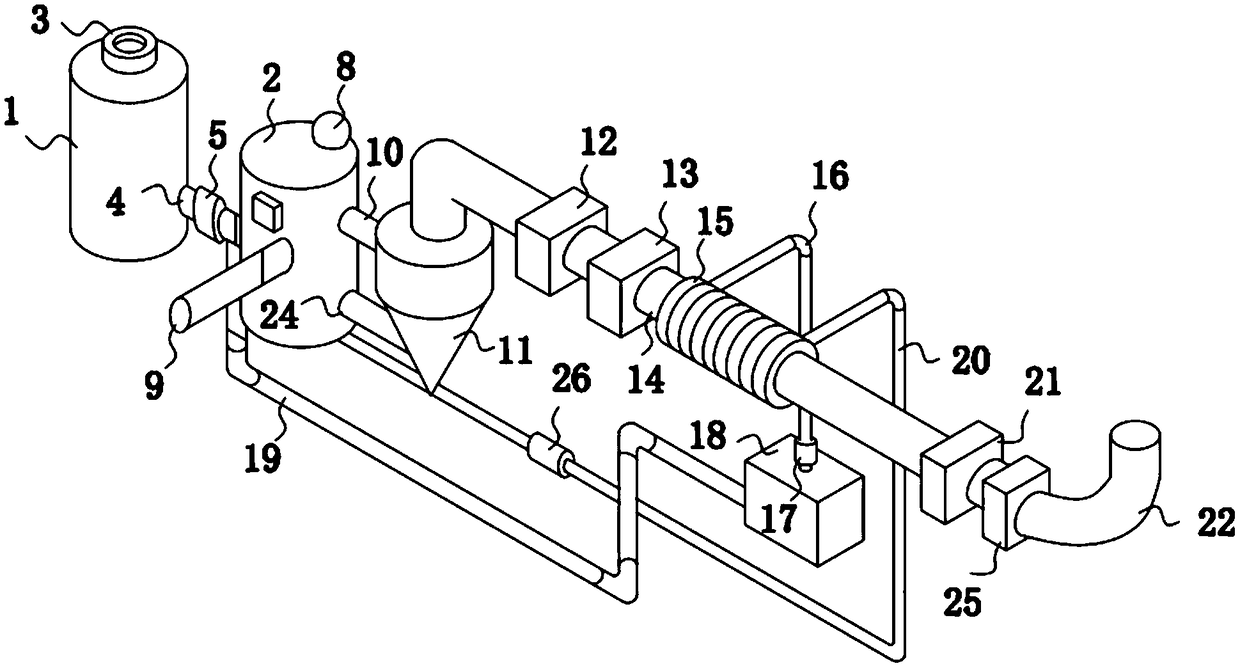

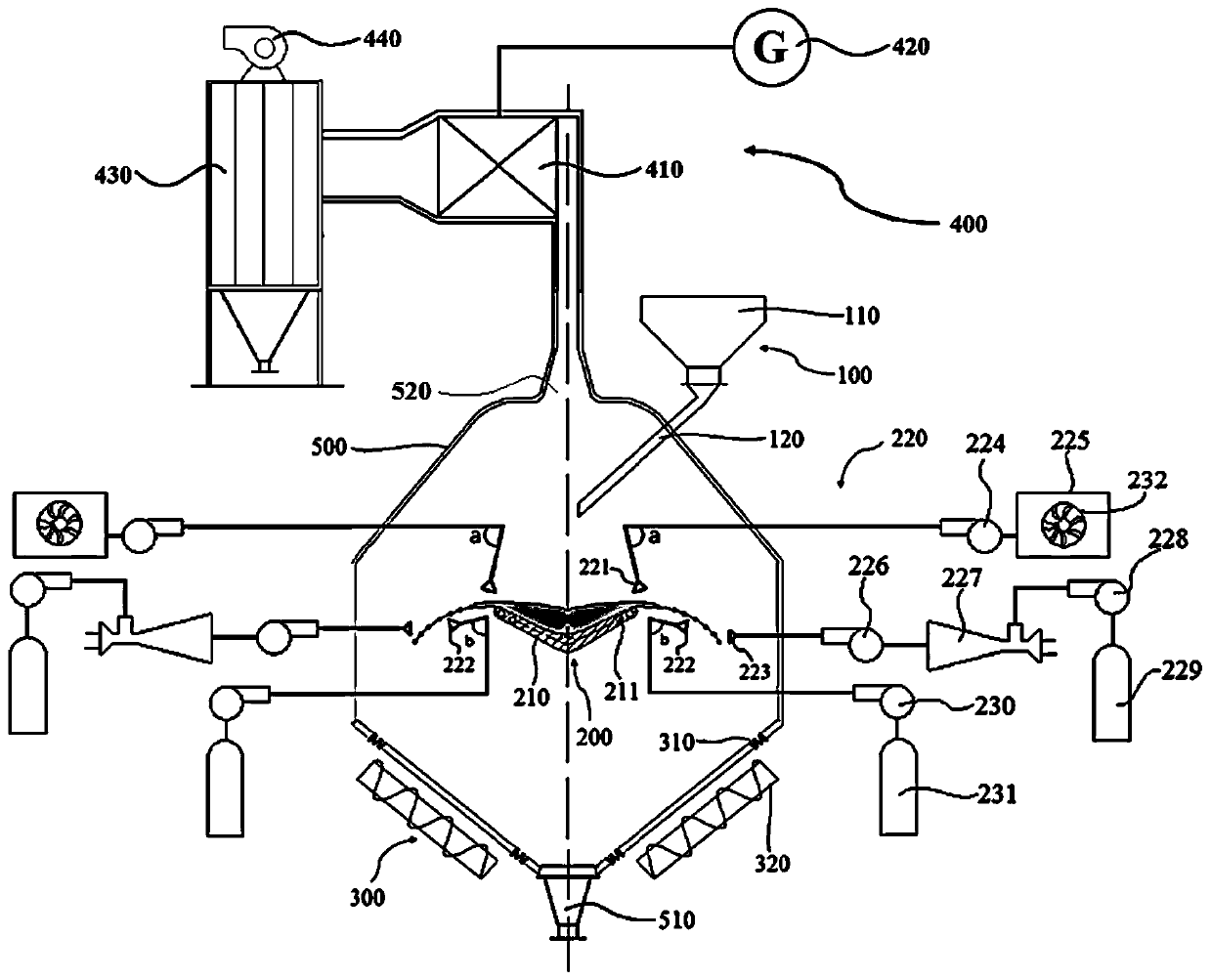

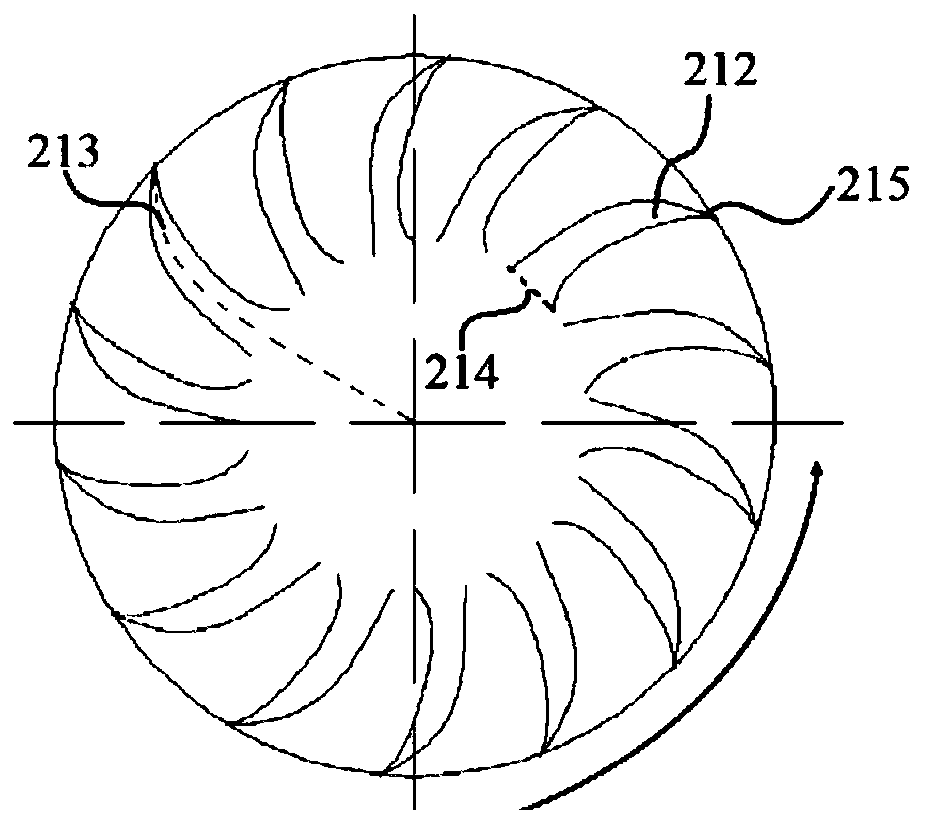

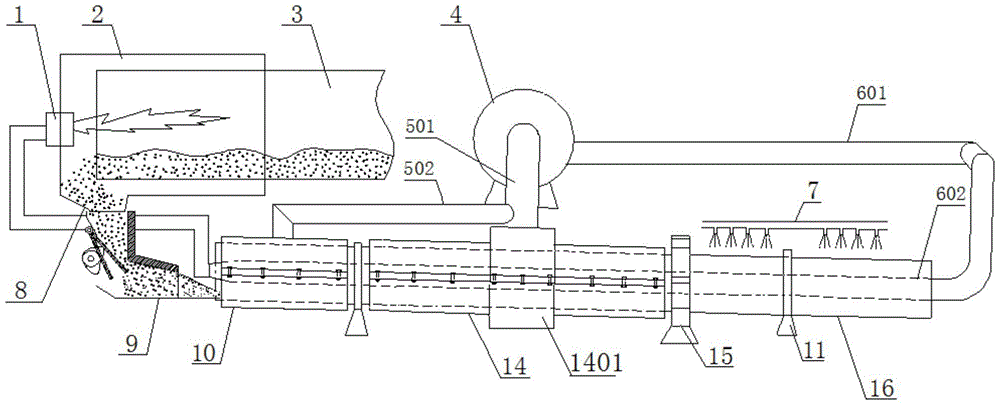

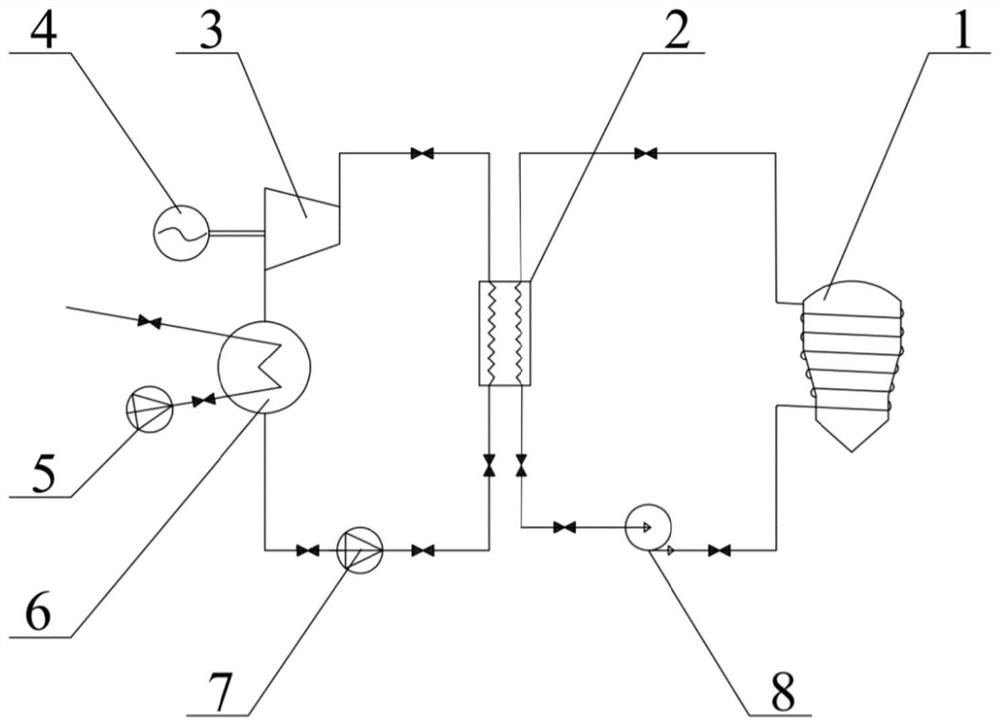

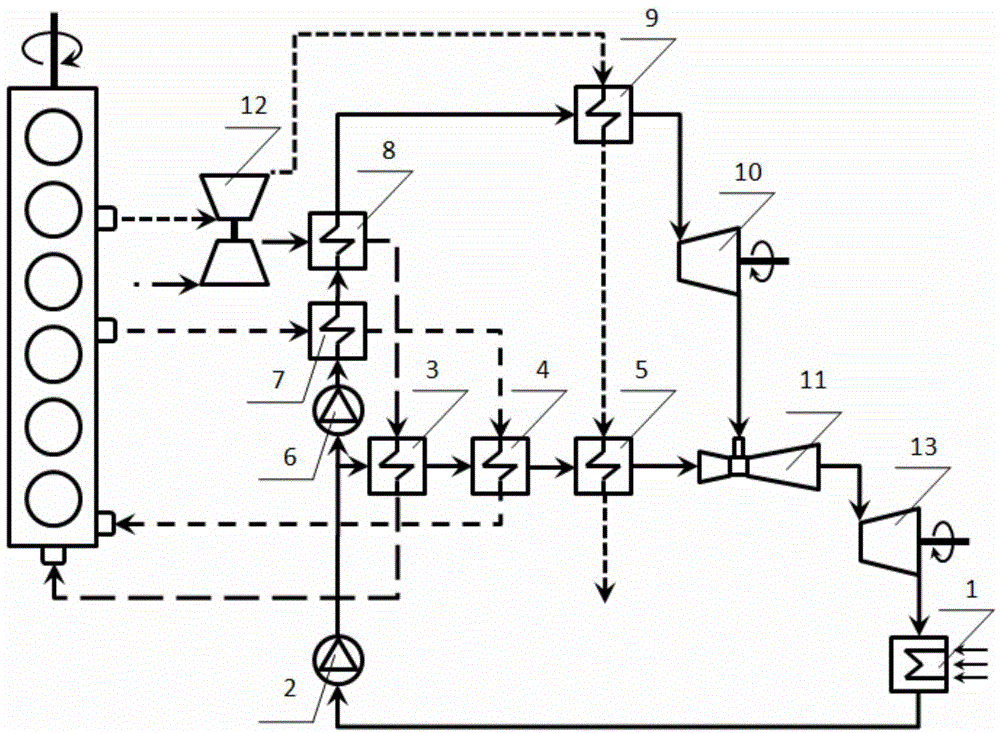

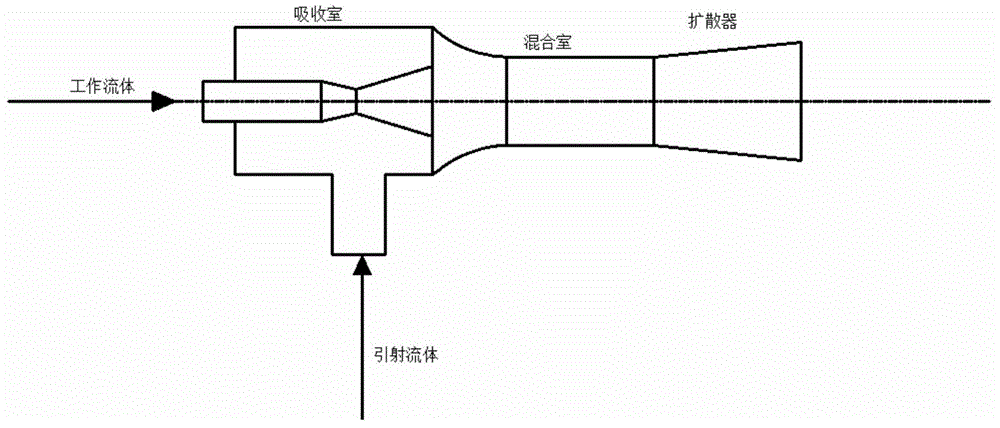

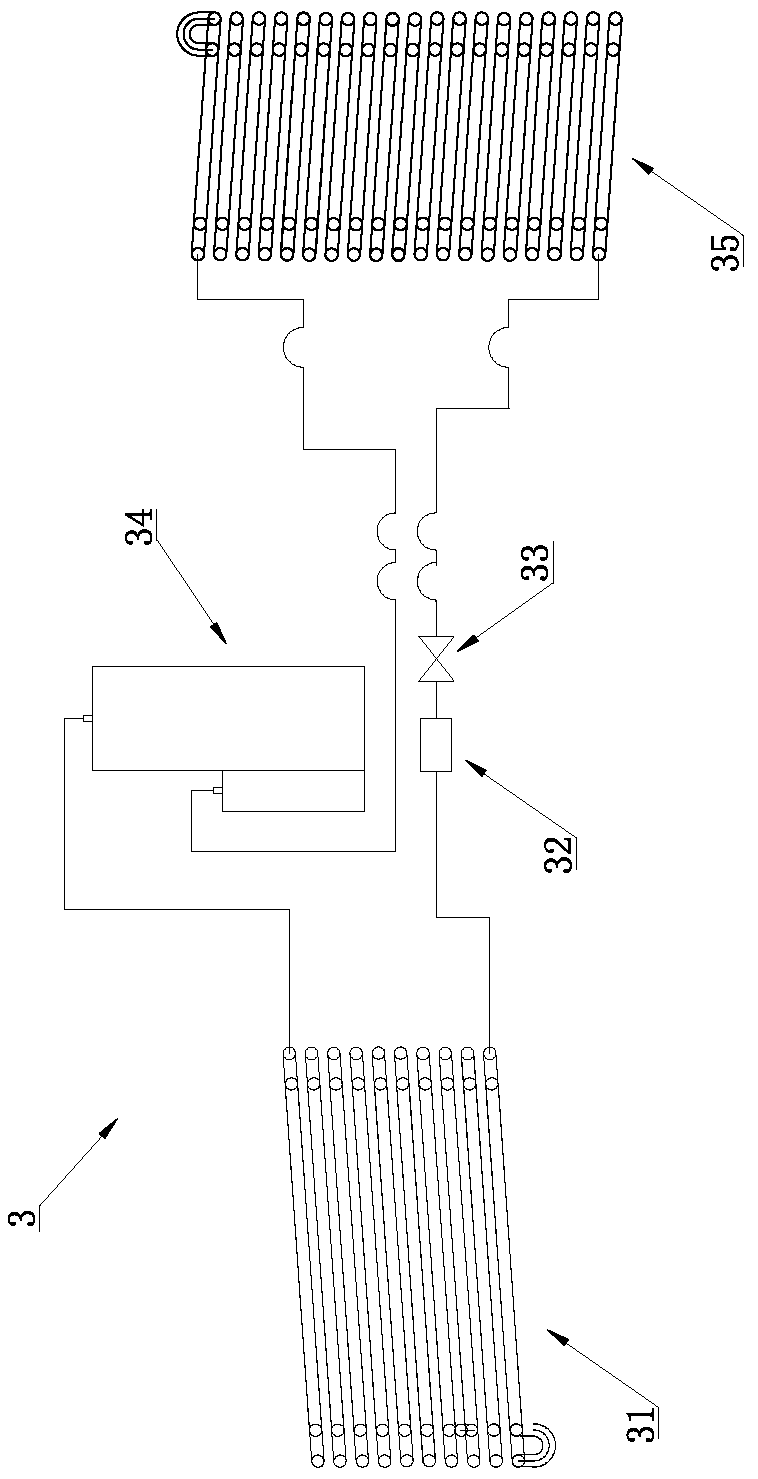

Two-stage expansion injection waste heat recovery system of internal combustion engine

ActiveCN103670626BImprove the efficiency of waste heat recoveryReduce outlet back pressureInternal combustion piston enginesExhaust apparatusExternal combustion engineTurbocharger

The invention discloses a two-stage expansion jet type waste heat recovery system of an internal combustion engine. According to the scheme, an ORC main circulating system is formed by sequentially connecting a condenser, a lower-pressure working medium pump, a high-pressure working medium pump, a high-temperature preheater, a high-temperature intercooler, a high-temperature flue gas heat exchanger, a first expansion machine, a jet pipe and a second expansion machine in series. A low-temperature intercooler, a low-temperature evaporator and a low-temperature flue gas heat exchanger are sequentially connected between the high-pressure working medium pump and the jet pipe and between the low-pressure working medium pump and the jet pipe, so that the ORC main circulating system is divided into a high-temperature stage branch and a low-temperature stage branch. Cooling water of a cylinder sleeve of the internal combustion engine is connected to the water side of the high-temperature preheater and the water side of the low-temperature evaporator and then returns to the cylinder sleeve. Intake air of the internal combustion engine enters the internal combustion engine by sequentially passing the air side of a gas compressor in a turbocharger, the air side of the high-temperature intercooler and the air side of the low-temperature intercooler. Exhaust gas of the internal combustion engine is connected to a turbine of the turbocharger, the high-temperature flue gas heat exchanger and a reheater in sequence. Waste heat of each part of the internal combustion engine waste heat recovery system can be utilized according to the quality ladder of the waste heat so that efficiency of the internal combustion engine waste heat recovery system can be improved obviously.

Owner:TIANJIN UNIV

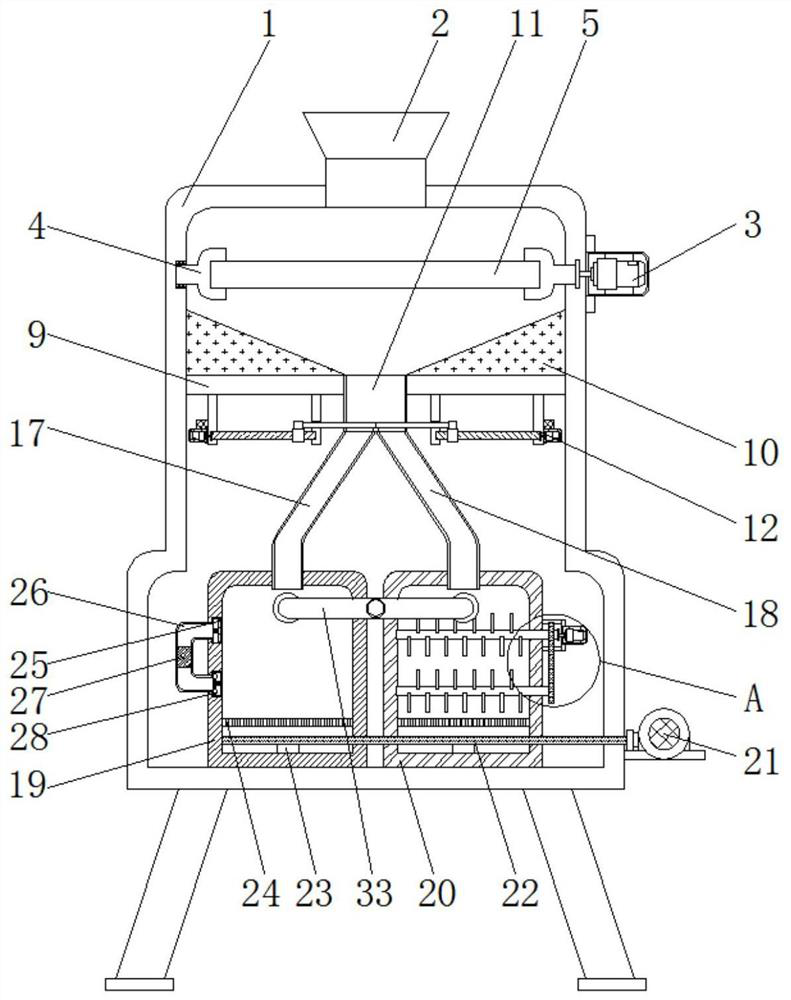

Multi-stage waste heat recovery device convenient for coal cinder processing

ActiveCN113048828AInfluence of waste heat recovery efficiencyImprove stabilitySievingRecuperative heat exchangersProcess engineeringAir blower

The invention discloses a multi-stage waste heat recovery device convenient for coal cinder processing. The multi-stage waste heat recovery device comprises a protective shell, wherein a feeding pipe is fixed above the protective shell, and a placing plate is arranged on the inner wall of a clamping device; a hanging ring is arranged on the inner wall of a clamping block, and a fixing plate is fixed on the inner wall of the protective shell; a fixing frame is fixed under an inclined plate; and a clamping ring is arranged on the outer wall of a threaded rod. According to the multi-stage waste heat recovery device convenient for coal cinder processing, an unloading plate, an air blower, a circulating pipeline and a transmission device are arranged; when a user needs to improve the waste heat recovery efficiency of coal cinder, through the unloading plate, the air blower, the circulating pipeline and the transmission device, the user can conveniently carry out segmented treatment on coal cinder of different sizes, so that the waste heat of the coal cinder of different sizes can be played to the maximum extent, the time spent by the user for recycling the coal cinder of different sizes is shortened, and the working efficiency of the user is improved.

Owner:SHANXI WENLONG COAL MINE ENG DESIGN

A plate and tube heat exchanger type shampoo bed

ActiveCN106323040BReduce energy consumptionLow costStationary conduit assembliesHair cleaningEngineeringAbsorption effect

Owner:东莞市康源节能科技有限公司

Preparation device and method of medicinal-grade nutritional phosphate

The invention discloses a preparation device of medicinal-grade nutritional phosphate. The preparation device comprises a special combustion tower, a phosphorus melting tank and a hydration tower which are arranged on the side wall of the upper end of a base; a phosphorus spraying gun is arranged between the phosphorus melting tank and the special combustion tower in a communicating mode; and an outlet conveying pipeline is arranged between the special combustion tower and the hydration tower in a communicating mode. Phosphate is prepared by adopting a hot-method phosphate process; the qualityrequirement can be met without being matched with various purification processes; moreover, the preparation device is reasonable in structure, the equipment cost is low, the operation is simple, theefficiency is improved, meanwhile, a waste heat recovery mechanism is arranged on the preparation device, heat energy generated in the preparation process is utilized while preparation is conducted, the recovered heat energy is utilized in the process of producing phosphoric acid through the hot method, steam can be externally supplied to other chemical processes for use, the waste heat recovery efficiency is effectively improved, and loss of a large number of heat energy resources is avoided.

Owner:天富(连云港)食品配料有限公司

Tail air box control system of sintering machine

A sintering machine tail bellows control system, which is characterized in that the sintering machine tail bellows control system includes a real-time process data communication machine, a sintering machine tail bellows damper control system, and a control terminal, and information is realized between them through computer network technology Sharing also includes a sintering machine PLC control system and a sintering machine tail bellows damper control device that are communicated with the real-time process data communication machine. The sintering machine PLC control system communicates with the sintering machine tail bellows damper control device. Communication connection, the sintering machine tail bellows damper control device realizes closed-loop automatic control of the damper opening of the sintering machine tail bellows based on signals from the sintering machine tail bellows damper control system.

Owner:吕斌

Reactor large cover waste heat recycling device and method

InactiveCN111945020AImprove heat transfer performanceShorten distillation timeIncreasing energy efficiencyWaste heat treatmentTitanium chlorideTetrachloride

The invention discloses a reactor large cover waste heat recycling device and method, and belongs to the technical field of energy conservation and environmental protection. The problems that in the prior art, a waste heat recovery device in the titanium sponge preparation process is low in heat exchange efficiency, high in investment cost and low in heat utilization efficiency are solved. According to the technical scheme, the reactor large cover waste heat recycling device comprises a reactor large cover and a preheating coil, wherein the preheating coil is located on the inner side of the reactor large cover and in contact with the reactor large cover, a titanium tetrachloride inlet plug is arranged on the reactor large cover, a pipeline communicating with the reactor is arranged in thetitanium tetrachloride inlet plug, one end of the preheating coil is connected with the pipeline, and the other end of the preheating coil is provided with a titanium tetrachloride interface. According to the reactor large cover waste heat recycling device and method, reaction waste heat recycling is achieved, the temperature of a reaction area can also be reduced, heat exchange with other mediais not needed, pipelines do not need to be laid, the heat exchange efficiency and the heat utilization efficiency can be improved, the investment cost is reduced, and the reactor large cover waste heat recycling device and method are suitable for recycling the reaction waste heat in the titanium sponge preparation process.

Owner:云南国钛金属股份有限公司

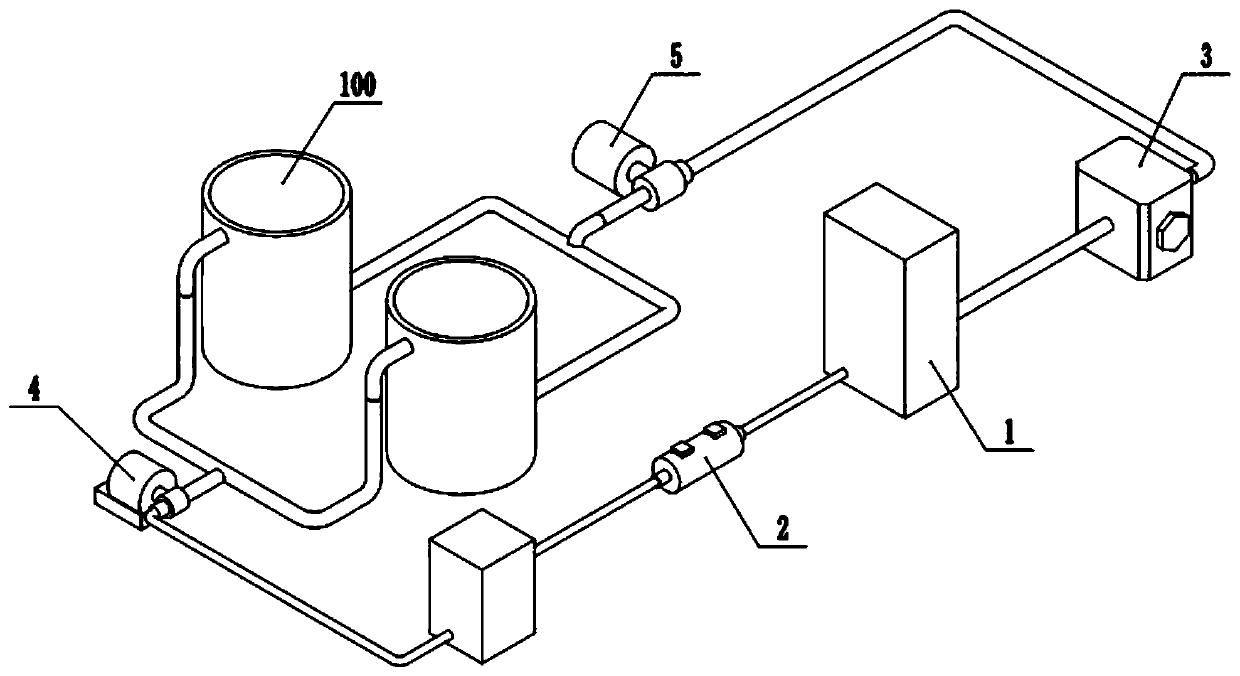

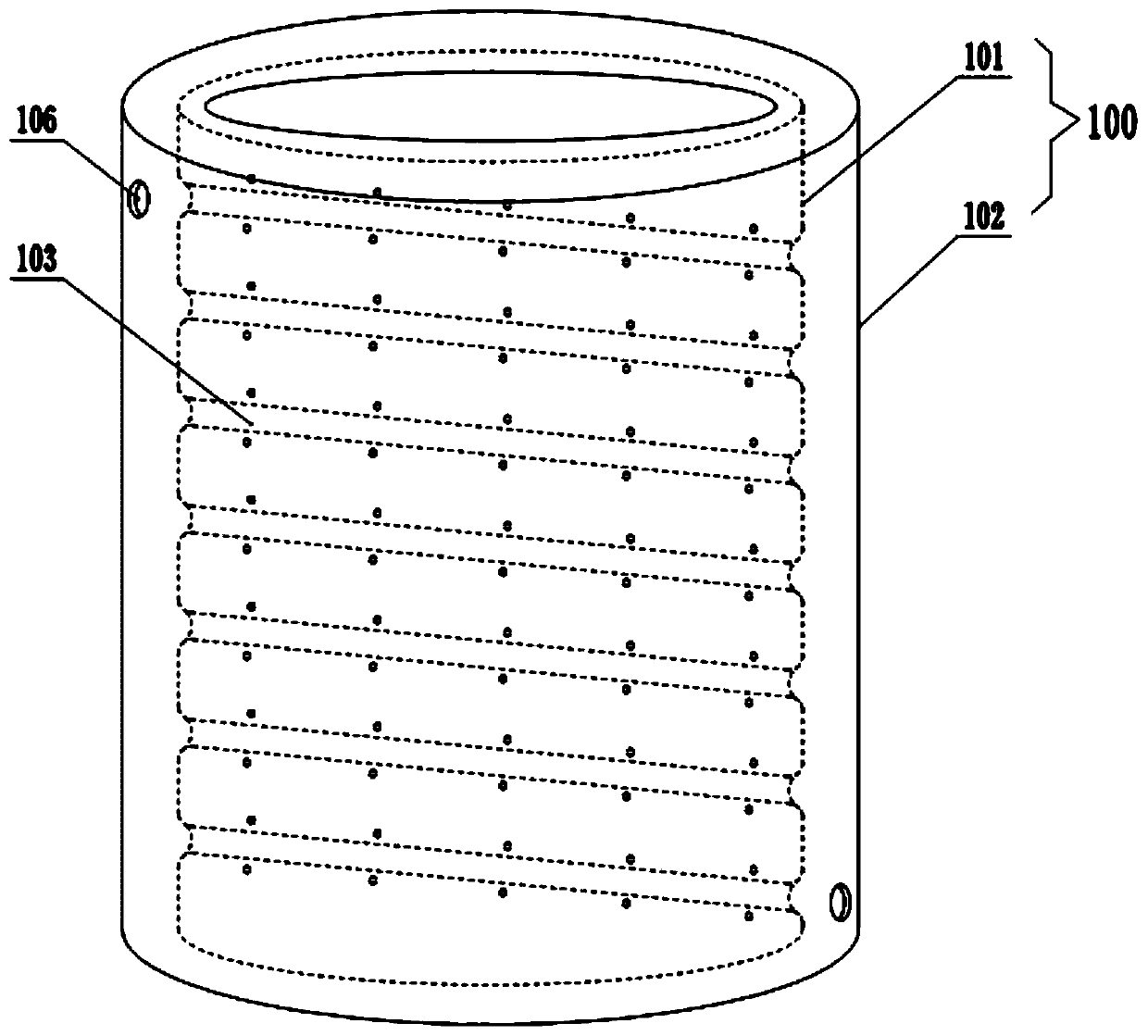

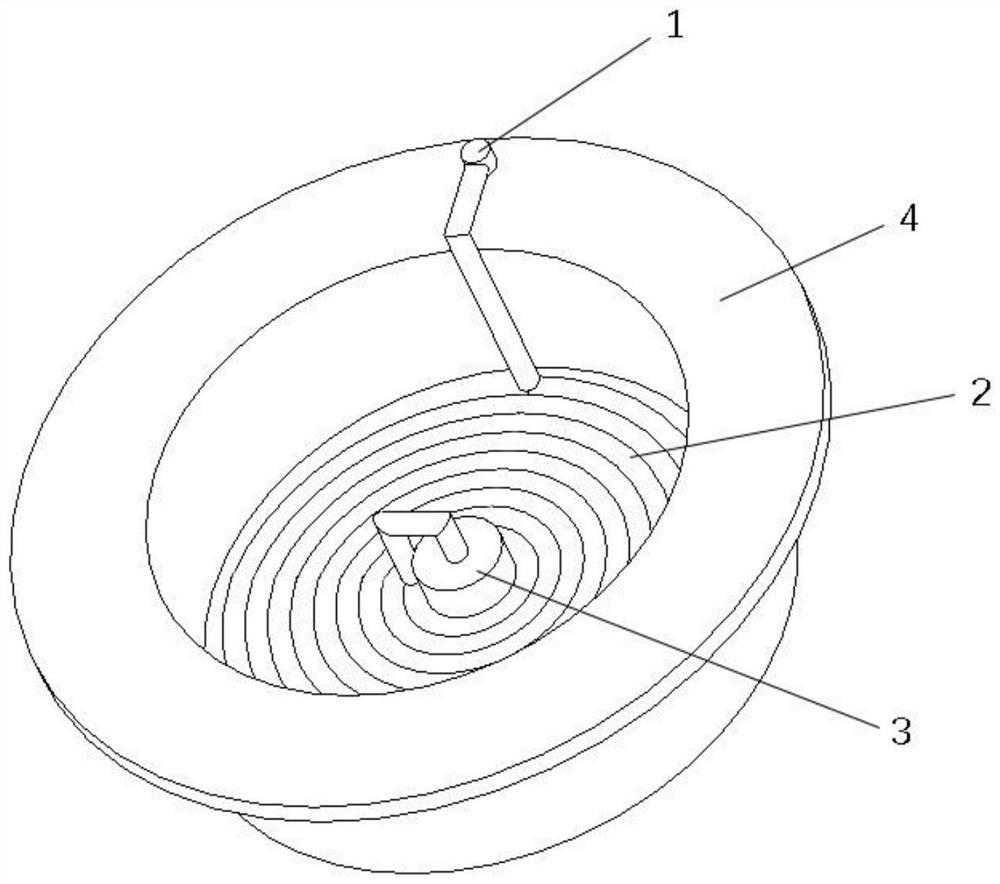

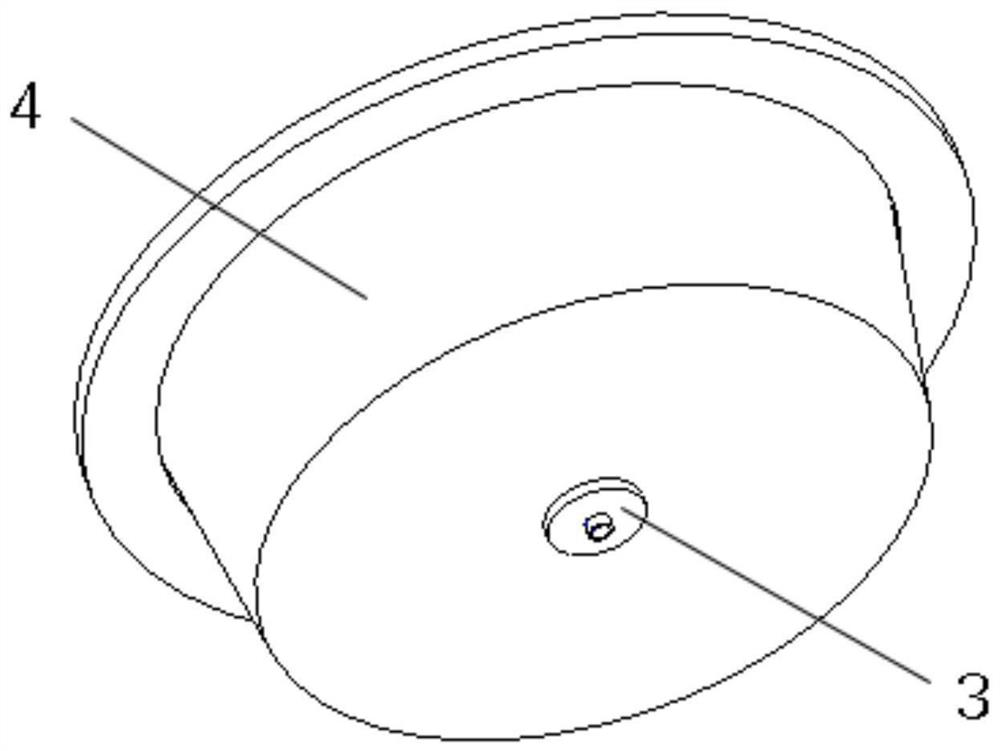

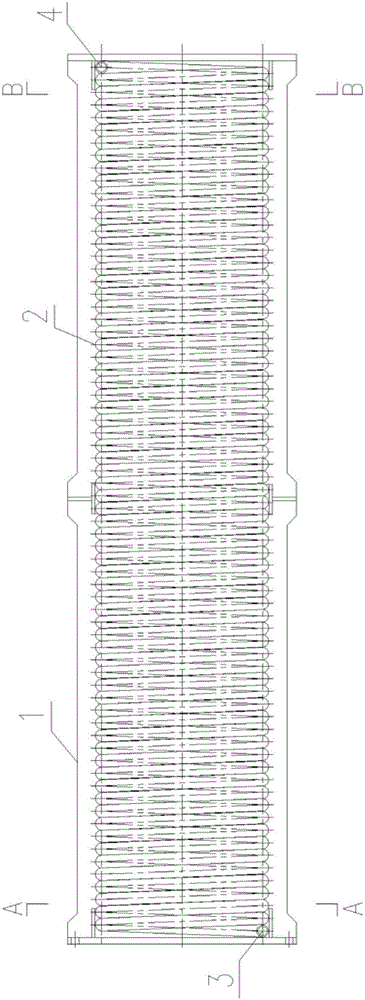

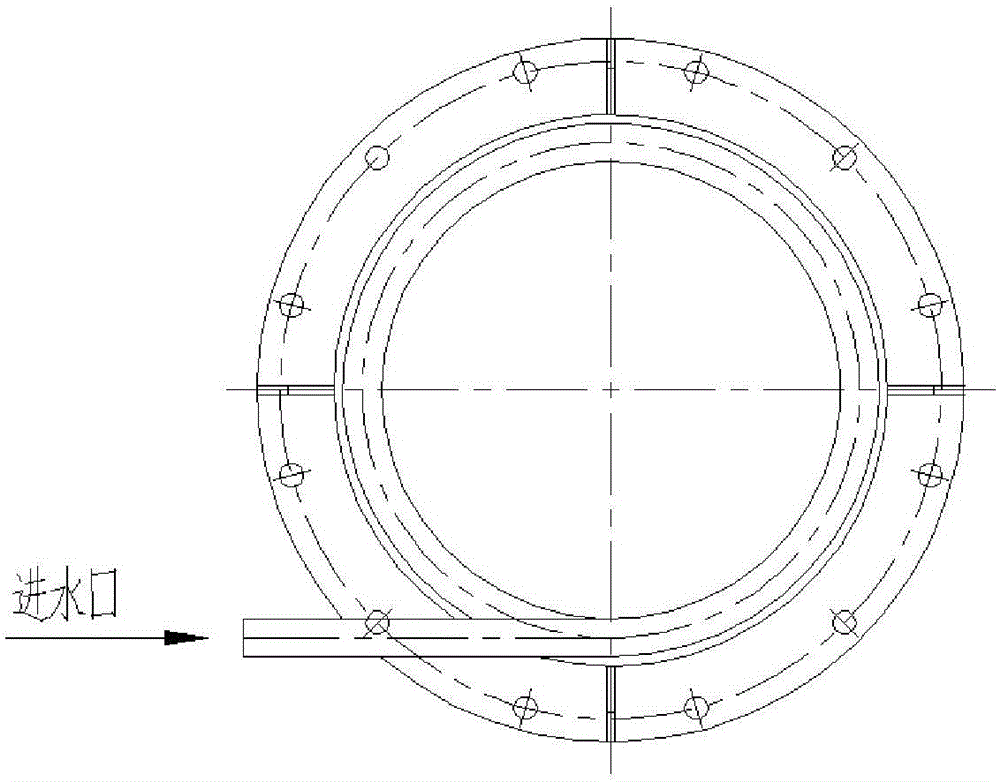

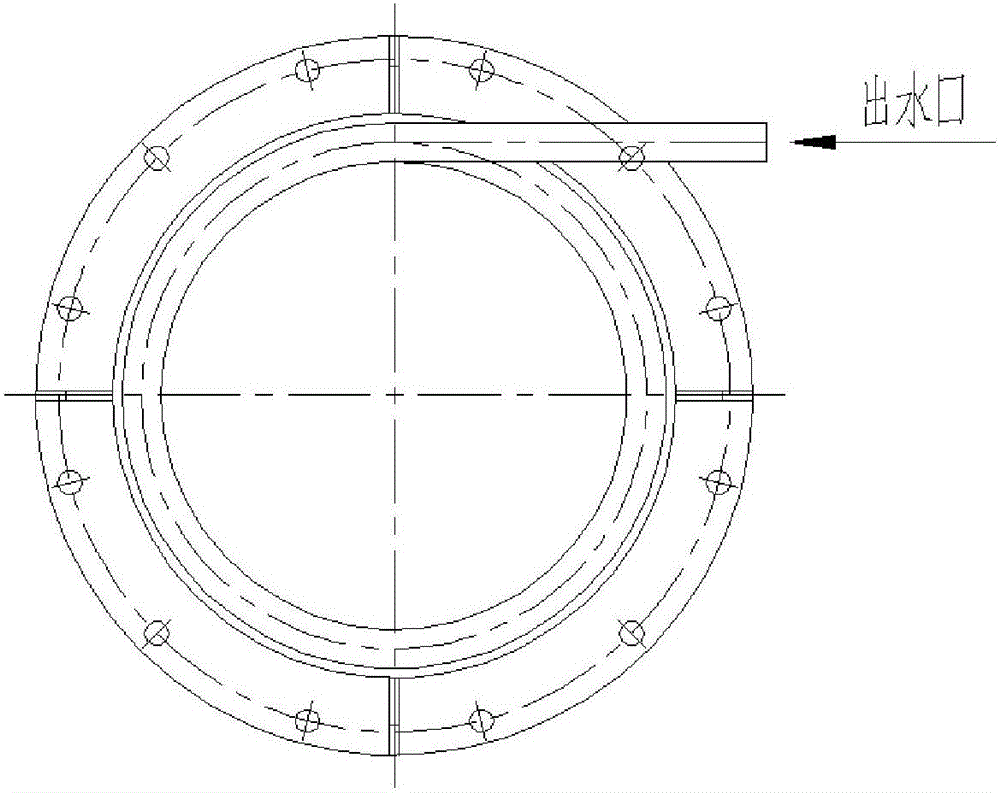

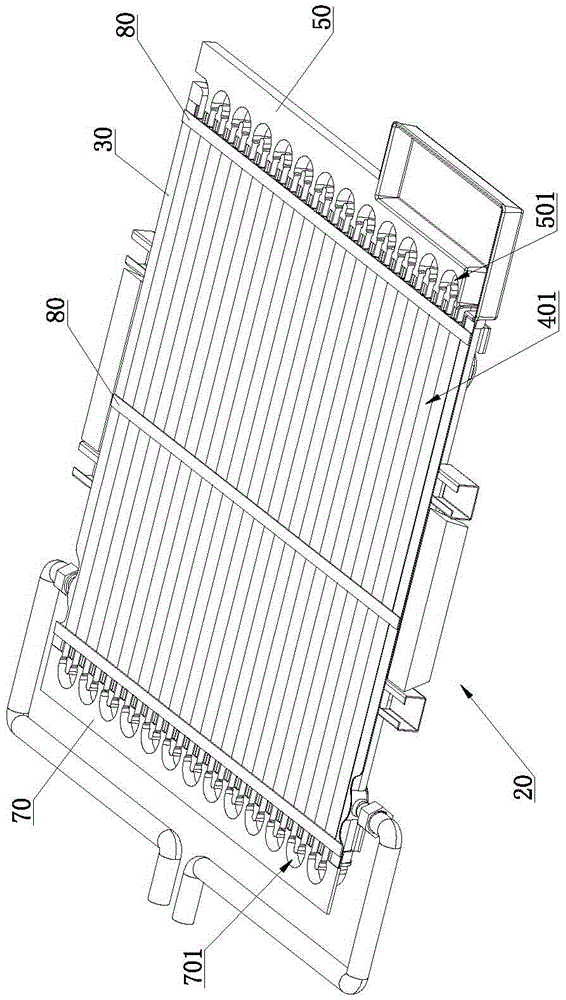

Coke oven ascending pipe waste-heat utilization equipment

InactiveCN106524783AImprove heat transfer effectImprove efficiencyIncreasing energy efficiencyStationary conduit assembliesEngineeringCarbonization

The invention discloses coke oven ascending pipe waste-heat utilization equipment. The coke oven ascending pipe waste-heat utilization equipment comprises an ascending pipe heat exchange device and a steam-water separator. The ascending pipe heat exchange device comprises an outer shell, a heat insulation layer, a flame retardant coating and a heat exchange channel which are sequentially arranged from outside to inside. The heat exchange channel comprises heat exchange pipes which are spirally arranged, and every two circles of adjacent heat exchange pipes are tightly attached to each other. The outer wall of the side, facing the circle center of the heat exchange channel, of each heat exchange pipe is provided with a nano non-stick coating. The outer shell is connected with a carbonization chamber and a bridge duct in a sealing mode. The upper ends of the heat exchange pipes are provided with steam-water mixture outlets, and the steam-water mixture outlets stretch out of the outer shell and are connected with the outer shell in a sealing mode. The lower ends of the heat exchange pipes are provided with water inlets, and the water inlets stretch out of the outer shell and are connected with the outer shell in a sealing mode. The steam-water mixture outlets of the heat exchange pipes communicate with the upper portion of the steam-water separator, and the water inlets communicate with the lower portion of the steam-water separator. The lower portion of the steam-water separator is further provided with a water replenishing opening, and the water replenishing opening communicates with an industrial water pipeline. The coke oven ascending pipe waste-heat utilization equipment is high in heat exchange efficiency and capable of preventing coking.

Owner:HUATIAN ENG & TECH CORP MCC

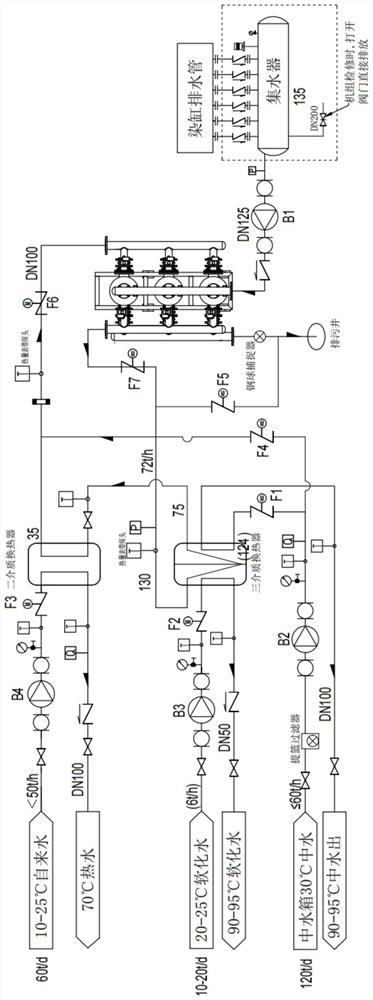

High-temperature sewage closed cooling and white smoke eliminating equipment with waste heat recovery function

PendingCN114849294AFast coolingImprove efficiencyHeat recovery systemsRecuperative heat exchangersSewage treatmentSewage

The invention relates to the field of sewage treatment, in particular to high-temperature sewage closed cooling and white-eliminating equipment with a waste heat recovery function. The technical problems that waste gas pollution is caused when high-temperature process sewage is discharged in an unorganized mode, and no clear cooling target and no corresponding adjusting program exist in waste heat recycling are solved. The high-temperature sewage closed-type cooling and white-eliminating equipment with the waste heat recovery function comprises a process high-temperature sewage closed-type discharge water collector, a steel ball filter unit, a heat exchange unit and the like. The multi-stage cooling system is arranged, each stage of cooling system is provided with a specified cooling target and a corresponding adjusting program, the high-temperature sewage waste heat recovery efficiency is improved while the high-temperature sewage cooling speed is increased, it is guaranteed that the whole process from a source to discharge is closed and does not make contact with the atmosphere, white pollution is eliminated, and the environment protection effect is achieved. When the heat exchange temperature is detected to be excessive or insufficient, the water pump adjusts the flow speed of the cooling liquid in a variable-frequency mode, and the heat exchange efficiency is improved.

Owner:山东双合节能环保技术股份有限公司

Tube-on-sheet heat exchanger type water heater

The invention relates to the technical field of water heaters, in particular to a tube-on-sheet heat exchanger type water heater. The tube-on-sheet heat exchanger type water heater comprises a water heater body and further comprises a tube-on-sheet heat exchanger, a heat exchange water outlet pipe and a heat exchange water inlet pipe. The tube-on-sheet heat exchanger comprises a core body, wherein the core body comprises a plate A, a plate B, a front sealing plate and a rear sealing plate. The tube-on-sheet heat exchanger type water heater recovers the heat of waste water, the energy consumption caused by tap water heating is reduced, resources are saved, and the usage cost is reduced. The tube-on-sheet heat exchanger adopts a plate A sinking tank formed in the plate A and a plate B sinking tank formed in the plate B, and the heat exchange coefficient is higher after heat exchange of the plate A and the plate B is strengthened by adopting sheets and corrugations. The plate A and the plate B are combined to form the core body by adopting sheet pipe structures, the overall smoothness of the plate A sinking tank is good, waste water is smooth to flow, and the problem of remarkable reduction of the heat transfer coefficient due to dirt blockage and sedimentation is effectively avoided. In addition, tap water is good in heat absorption effect in a medium channel, and the waste water and tap water heat exchange effect is good.

Owner:东莞市康源节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com