Comprehensive utilization device for activated coke regeneration waste heat

A technology of active coke regeneration and waste heat, applied in the direction of filter regeneration, indirect heat exchangers, climate sustainability, etc., can solve the problems of hot flue gas discharge, energy waste, etc., to reduce energy consumption and production costs , significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

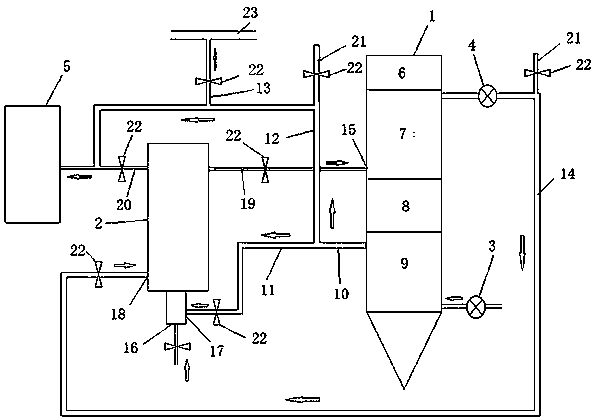

[0020] The present invention consists of regeneration tower 1, heating furnace 2, cooling fan 3, hot smoke fan 4, cooling section cooling flue gas outlet pipe 10, heating section hot smoke flue gas outlet pipe 14, heating furnace hot smoke flue gas outlet pipe 19, heating The furnace heating flue gas outlet pipe 20, the release pipe 21, and the automatic regulating valve 22 are composed.

[0021] As shown in the figure, the cooling flue gas outlet pipe 10 of the cooling section of the regeneration tower is divided into three branch pipes.

[0022] The first branch pipe 11 is connected to the gas inlet 17 of the heating furnace, and the air sent to the heating furnace by the combustion fan in the current design is replaced by cooling flue gas, so that the combustion air is changed from the original normal temperature air to the temperature of 150 ℃ hot air. After calculation, the amount of air used for combustion-supporting accounts for about 28% of the total cooling air volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com