A ring-shaped partition wall recovery system and method for waste heat of rotary kiln products calcined with pellets

A recovery system and rotary kiln technology, which is applied in the field of waste heat annular partition wall recovery system for pellet calcined rotary kiln products, can solve the problems of easy corrosion of cooling equipment, low efficiency of waste heat utilization, and waste of cooling water, etc., to improve waste heat Utilization efficiency, improvement of combustion efficiency, and effect of increasing waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

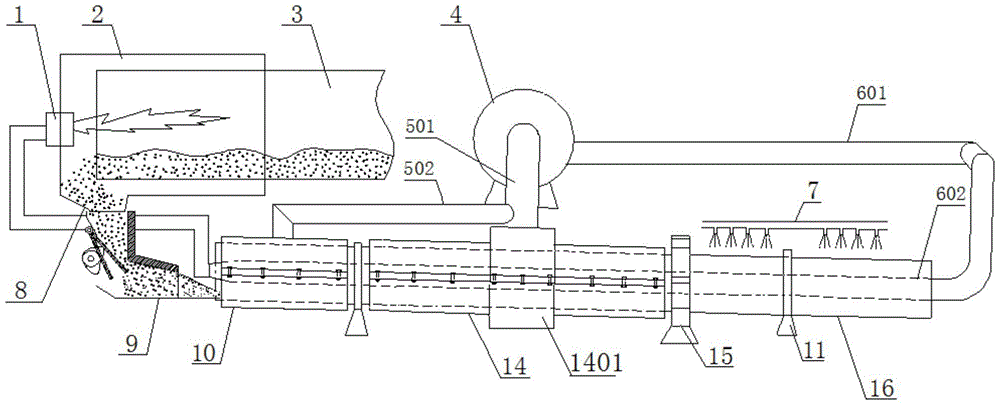

[0053] Such as figure 1 As shown, the pellet calcined rotary kiln product waste heat annular partition wall recovery system in this embodiment includes a burner 1, a combustion chamber 2, a rotary kiln 3, a discharge port 8, a cooling cylinder bearing seat 11, a cooling cylinder driving wheel 15 and Cooling cylinder 16. The burner 1 generates a combustion flame in the combustion chamber 2. The high-temperature flue gas generated by the combustion flame enters the rotary kiln 3 and calcines the pellets in the rotary kiln 3. The calcined pellets flow out from the discharge port 8 to the inlet of the cooling cylinder 16. feed port. There are two cooling cylinder bearing seats 11, and the cooling cylinder 16 is obliquely installed on two cooling cylinder bearing seats 11 of different heights. 16, the cooling cylinder bearing seat 11 at the discharge port, so that the height at the inlet of the cooling cylinder 16 is higher than the height at the discharge port of the cooling cyl...

Embodiment 2

[0103] The pellet calcined rotary kiln product waste heat annular partition wall recovery system in this embodiment is basically the same as that in Embodiment 1, the difference is that in order to ensure that the pellets are fully cooled below the specified temperature, a spray is provided above the low temperature section Device 7, the spraying device 7 is a cooling water spraying device, and the spraying device 7 includes a row of cooling water pipes with uniform round holes on the sides, the cooling water flows down from the round holes on the side of the cooling water pipes, and is sprayed on the surface of the low temperature section , to lower the temperature of the low-temperature section, so that the pellets are further cooled.

Embodiment 3

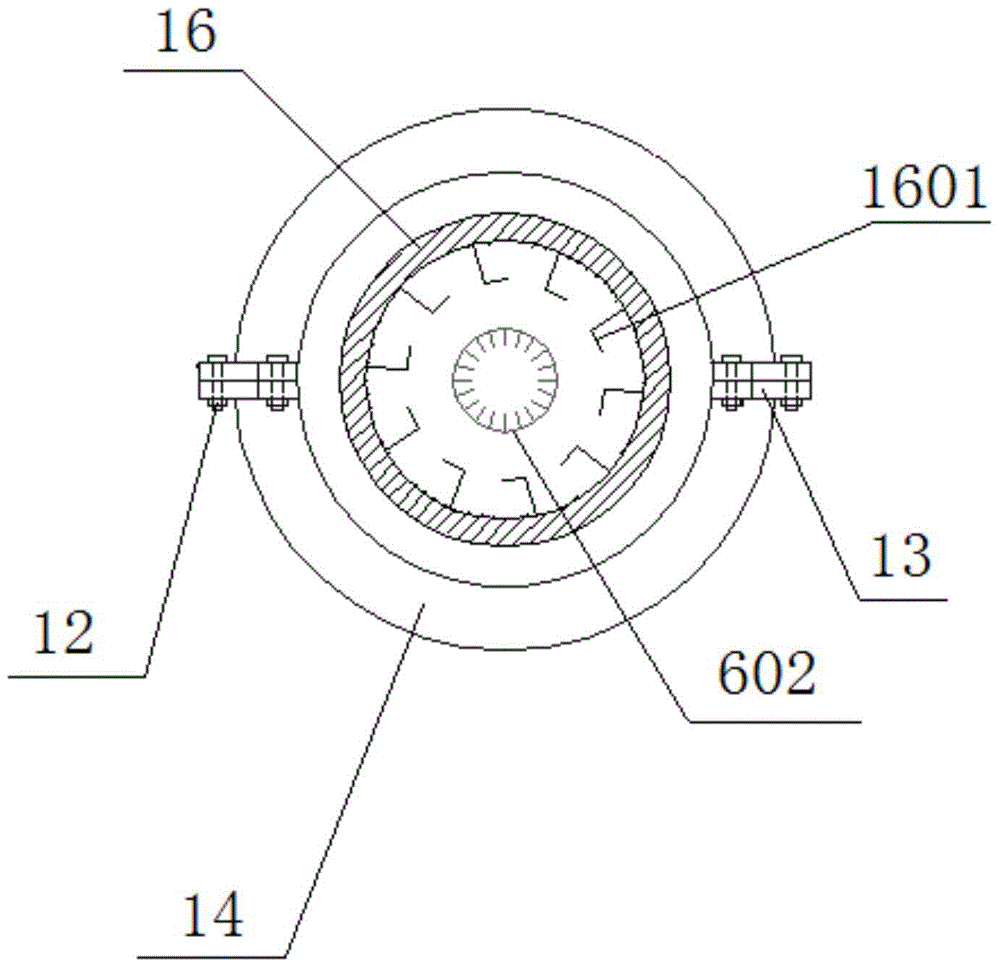

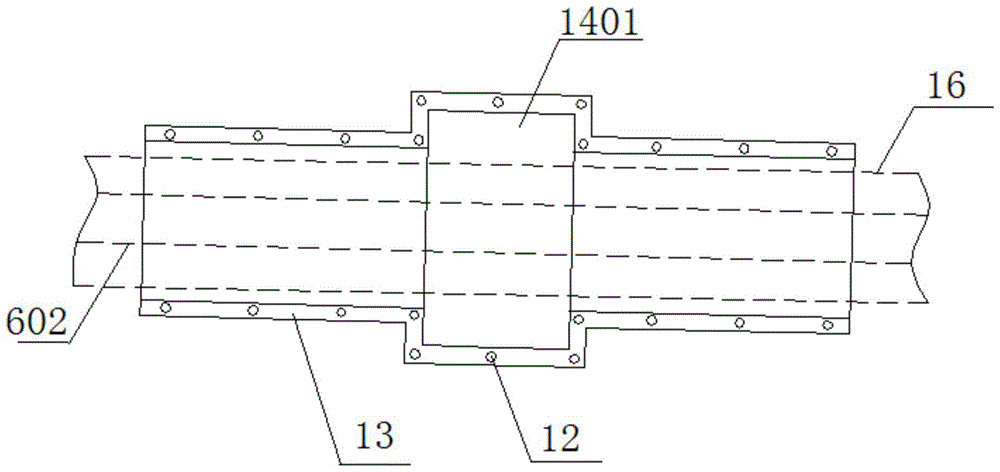

[0105] The waste heat annular partition wall recovery system for pellet calcined rotary kiln products in this embodiment is basically the same as that in Embodiment 1, the difference is that the inner surface of the heating section 602 of the air supply pipe is welded with ribs 6021 at equal intervals along the circumference, Specifically, the number of ribs 6021 in this embodiment is 15, and the height of each rib 6021 is 55 mm; the swing frequency of the movable jaw 903 in this embodiment is 3 times / second, and the movable jaw 903 and the fixed jaw 903 are in the swing process. The distance between the jaws 902 is controlled at 35mm; the length of the high-temperature section cover 10 is 1500mm, and the length of the middle-temperature section cover 14 is 3000mm; The outer diameter of 16 is 60 mm, and the inner diameter at both sides of the upper cover body expansion section 1401 of the middle temperature section cover body 14 is larger than the outer diameter of the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com