Method for waste heat recovery and utilization of roasted alumina

A waste heat recovery, alumina technology, applied in alumina/hydroxide preparation, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of heat pollution, heat can not be recycled, etc., to reduce operating costs, reduce heat Pollution, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

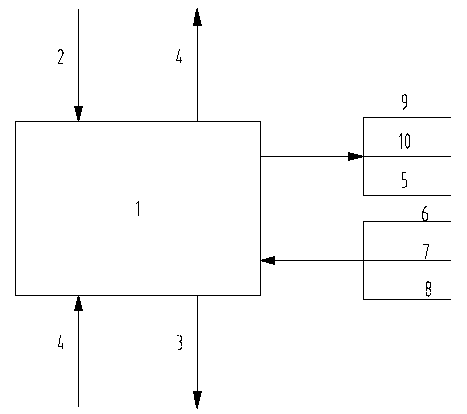

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0023] As shown in the figure, the method for recovering and utilizing the waste heat of roasted alumina of the present invention includes the following steps: completely cancel the original roasting independent circulating water system, and the high-temperature alumina 2 cooled by the multi-stage cyclone cooling system of the roaster in the double-chamber fluid state The inside of the chemical cooler 1 is fluidized and cooled by air 4, and at the same time, it is cooled by a cooling medium. When the cooling medium is unqualified condensed water 6 from the alumina production system (such as evaporation and other processes with self-evaporation and indirect heat exchange devices), its Heated in the double-chamber fluidized cooler 1, the hot water obtained goes to wash the aluminum hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com