Reactor large cover waste heat recycling device and method

A waste heat recovery and reactor technology, applied in the field of energy conservation and environmental protection, can solve the problems of high investment cost, low heat exchange efficiency, low heat utilization efficiency, etc., and achieve the effects of improving the working environment, reducing the number of emissions, and improving energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

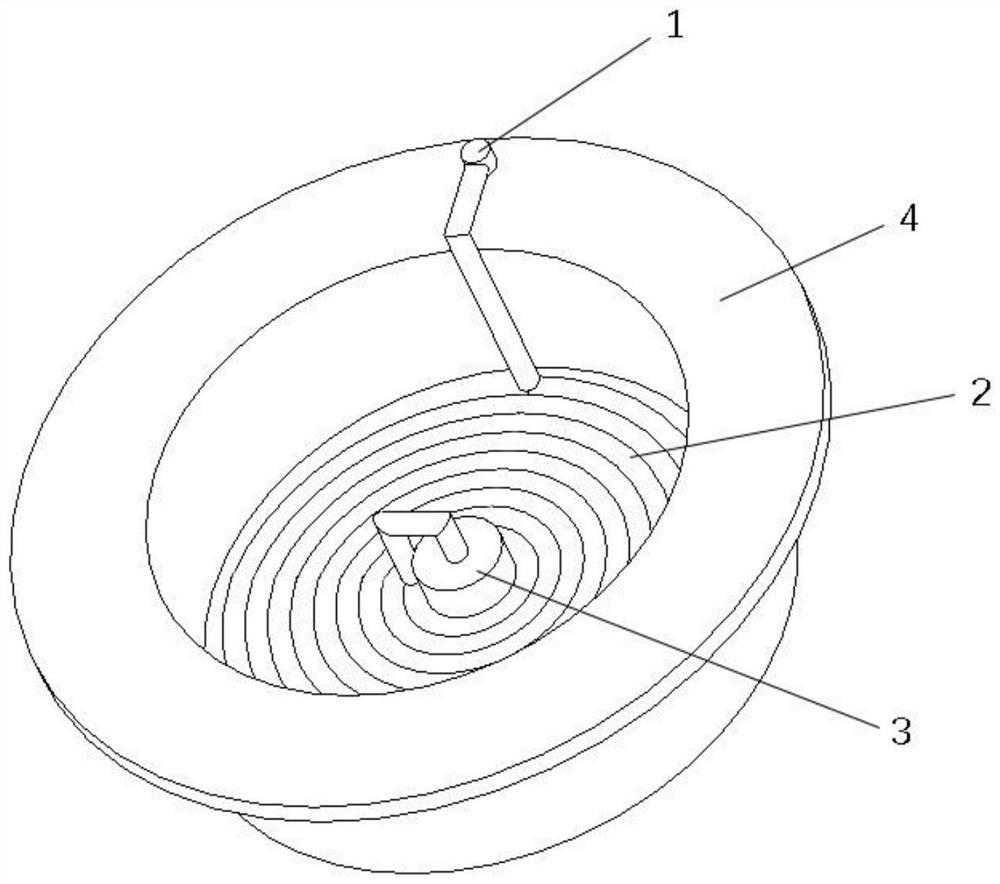

[0049] A device for recovering waste heat from a large reactor cover, comprising a large reactor cover 4 and a preheating coil 2, the preheating coil 2 is located inside the large reactor cover 4 and is in contact with the large reactor cover 4, the The large cover 4 of the reactor is provided with a titanium tetrachloride inlet plug 3, and the inside of the titanium tetrachloride inlet plug 3 is provided with a pipe communicating with the reactor, one end of the preheating coil 2 is connected with the pipe, and the other end A titanium tetrachloride interface 1 is provided.

[0050] The plane where the preheating coil 2 is located is an arc surface, and the arc surface is the same as the arc of the large reactor cover 4 .

[0051] The number of preheating coils 2 in this embodiment is one group.

[0052] The coiling mode of the preheating coil 2 in this embodiment is spiral coiling.

[0053] The preheating coil 2 in this embodiment is a single layer.

[0054] The distribut...

Embodiment 2

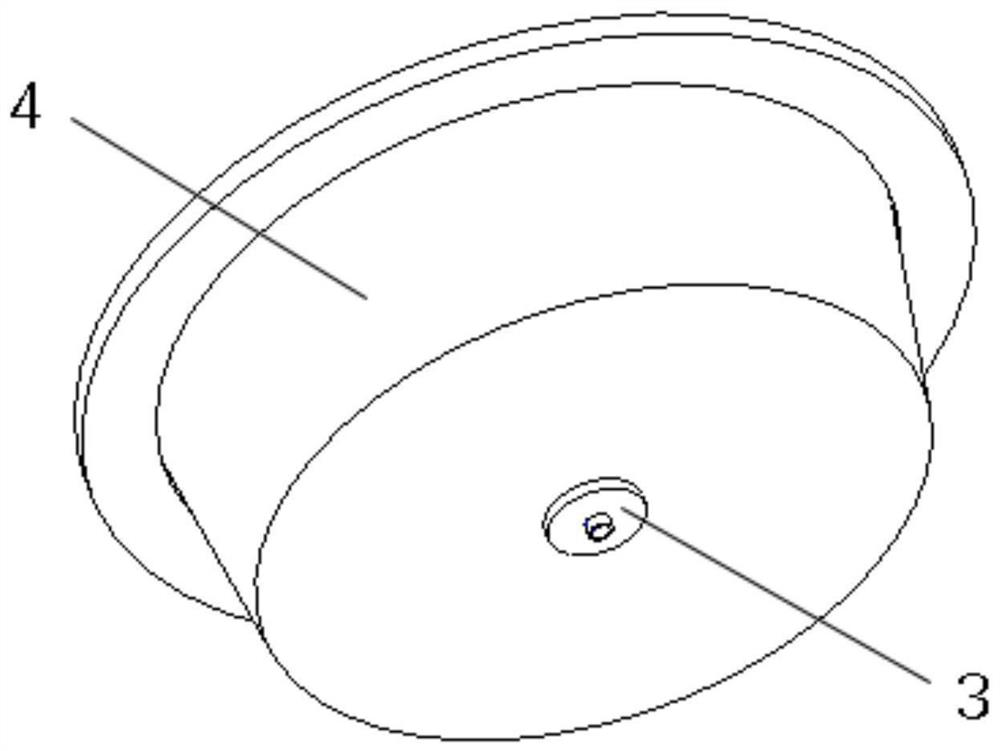

[0063] A device for recovering waste heat from a large reactor cover, comprising a large reactor cover 4 and a preheating coil 2, the preheating coil 2 is located inside the large reactor cover 4 and is in contact with the large reactor cover 4, the The large cover 4 of the reactor is provided with a titanium tetrachloride inlet plug 3, and the inside of the titanium tetrachloride inlet plug 3 is provided with a pipe communicating with the reactor, one end of the preheating coil 2 is connected with the pipe, and the other end A titanium tetrachloride interface 1 is provided.

[0064] In this embodiment, the plane where the preheating coil 2 is located is an arc surface, and the arc surface is the same as the arc of the large reactor cover 4 .

[0065] In this embodiment, the number of preheating coils 2 is multiple groups.

[0066] In this embodiment, the coiling mode of the preheating coil 2 is turn-back coiling.

[0067] In this embodiment, the preheating coil 2 is multi-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com