Preparation device and method of medicinal-grade nutritional phosphate

A preparation device and phosphate technology, applied in the direction of phosphate, phosphorus oxyacids, chemical instruments and methods, etc., can solve the problems of high equipment cost, lack of waste heat recovery and utilization, loss of thermal energy resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

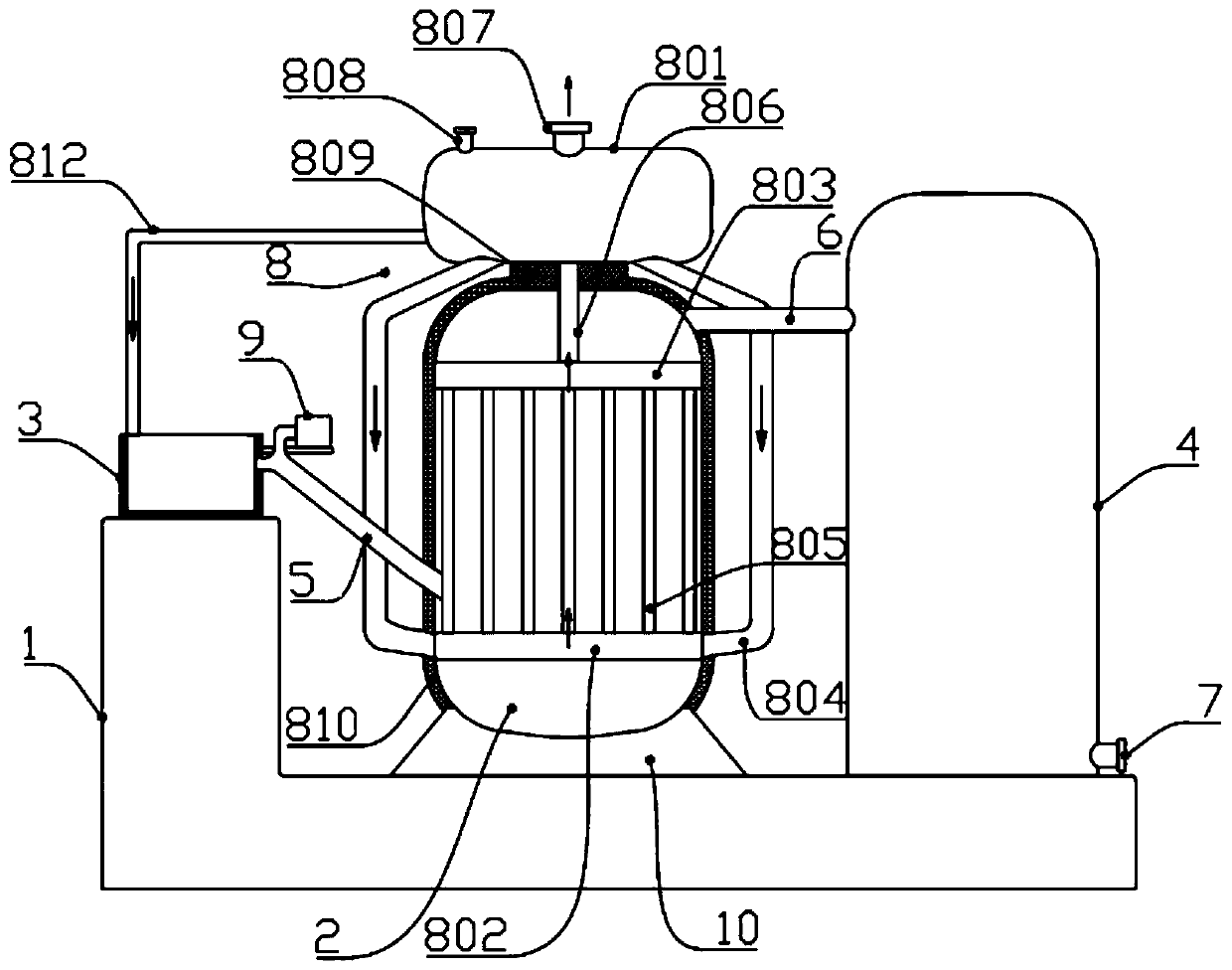

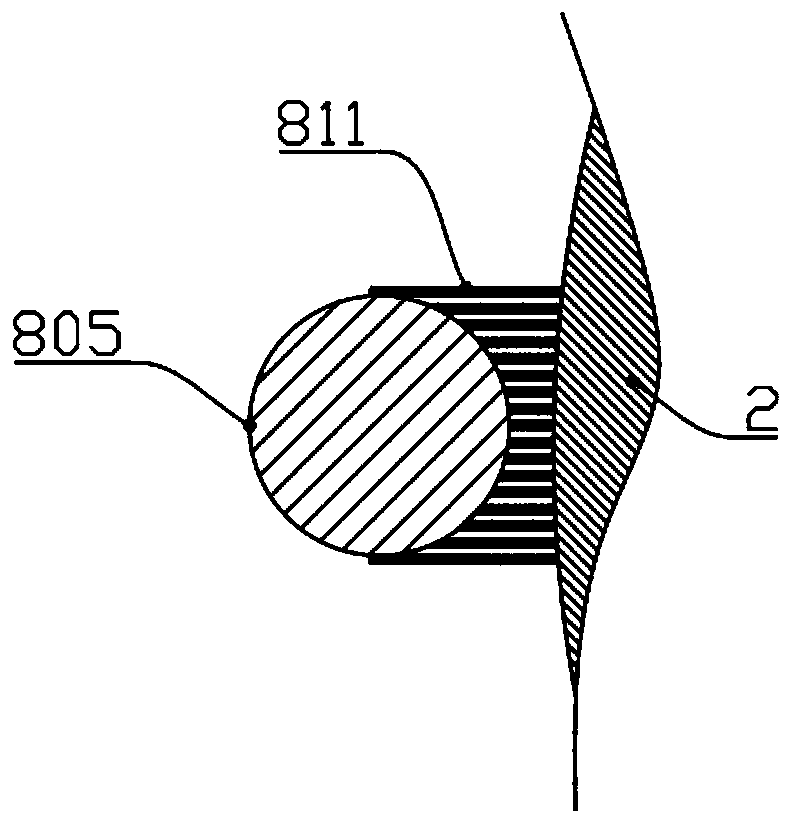

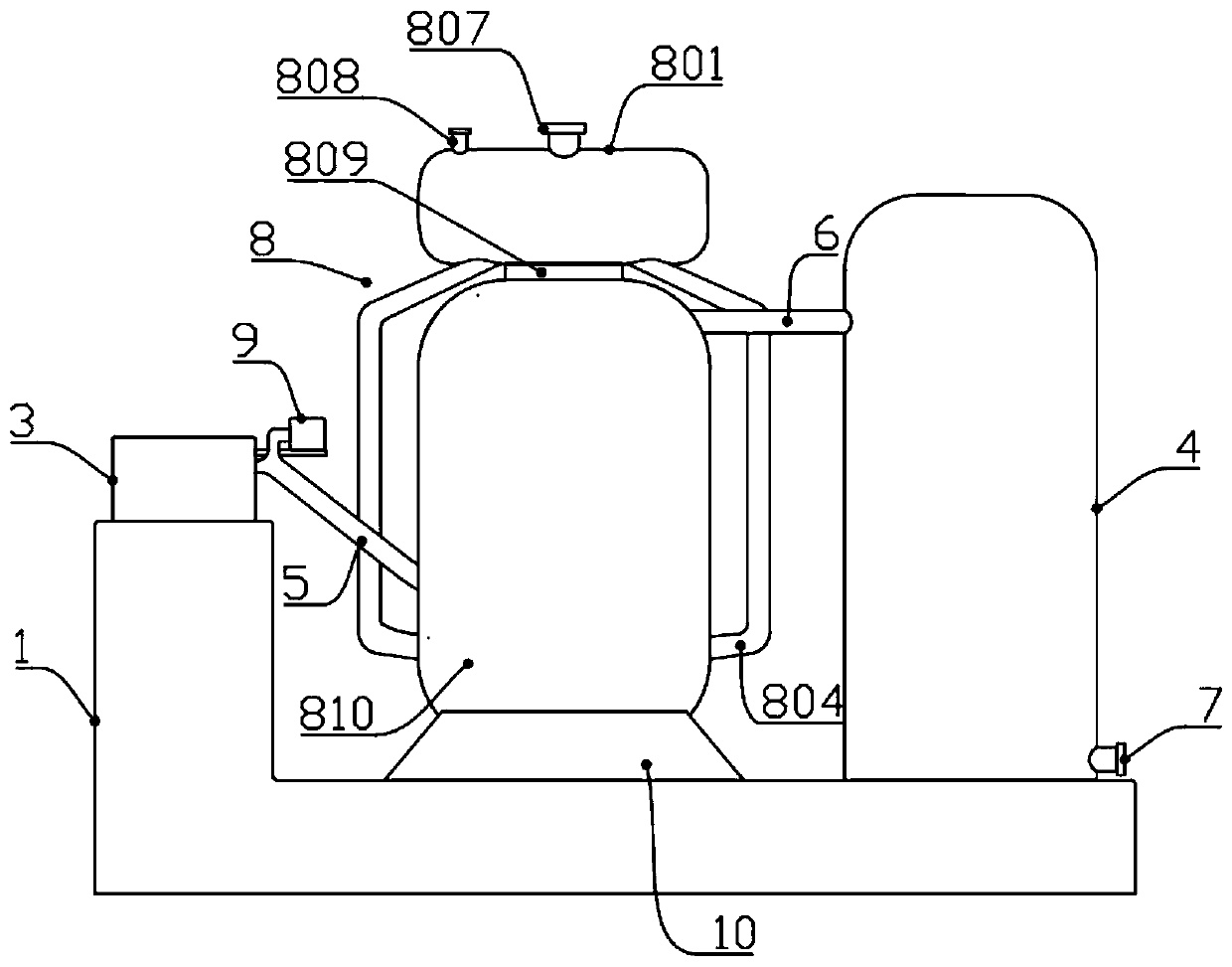

[0034] refer to Figure 1-4 , a preparation device for pharmaceutical-grade nutritional phosphate, including a special combustion tower 2, a phosphorus melting tank 3 and a hydration tower 4 arranged on the upper side wall of the base 1, and a gap between the phosphorus melting tank 3 and the special combustion tower 2 A phosphorus spray gun 5 is connected to it, and the two ends of the phosphorus spray gun 5 respectively penetrate the side wall of the phosphorus melting tank 3 and the side wall of the special combustion tower 2 and are respectively fixedly connected to them, and the special combustion tower 2 and the hydration tower 4 are connected An outlet conveying pipeline 6 is provided, and the two ends of the outlet conveying pipeline 6 run through the side wall of the special combustion tower 2 and the side wall of the hydration tower 4 respectively and are respectively fixedly connected thereto. A phosphoric acid outlet 7 runs through and is fixedly connected to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com