Fluidized bed roaster outer wall waste heat recovery system

A waste heat recovery system, a technology of boiling roasting furnace, applied in furnaces, furnace components, waste heat treatment and other directions, can solve the problems of waste, waste heat is not well utilized, and reduce the utilization rate of energy, so as to improve the service life and improve the Efficiency and the effect of reducing overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

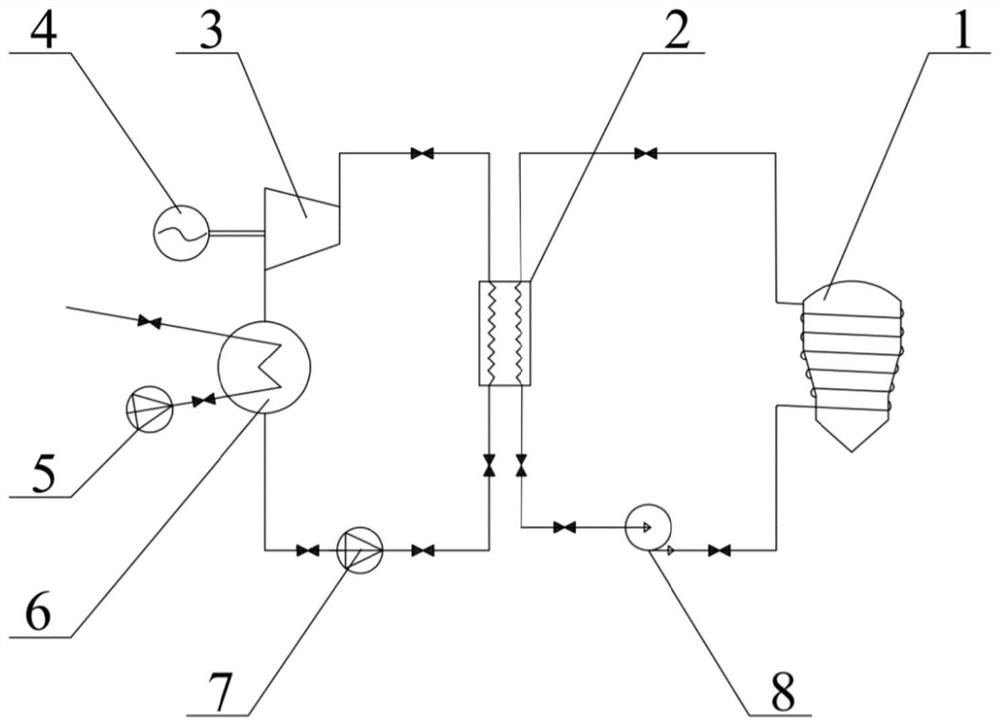

[0021] see figure 1 , the present invention includes a liquid metal heat exchange system and an organic Rankine cycle system;

[0022] The liquid metal heat exchange system consists of a heat exchange pipe wound on the outer wall of the fluidized roaster 1 for heat exchange and an electromagnetic pump 8 installed on the heat exchange pipe to form a closed cycle. Insulation cotton is laid on the heat exchange pipe of the exchange. The medium used in the liquid metal heat exchange system is liquid metal gallium indium tin alloy or a mixed alloy of gallium indium alloy. Its thermal conductivity is much higher than that of water and heat transfer oil, and it has good heat transfer Ability, electromagnetic pump 8 is the power unit of liquid metal circulation.

[0023] The organic Rankine cycle system is composed of an evaporator 2, a steam turbine 3, a generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com